Beruflich Dokumente

Kultur Dokumente

Sop of Plasma/Arc Cutting

Hochgeladen von

abhishek kumar0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten1 Seitestandard operating procedure

Originaltitel

Sop Cutting

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenstandard operating procedure

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten1 SeiteSop of Plasma/Arc Cutting

Hochgeladen von

abhishek kumarstandard operating procedure

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

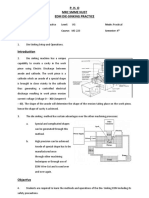

SOP OF PLASMA/ARC CUTTING:

i. The job is loaded on the Platform.

ii. Alignment is done by taking two points on either edge of the job.

iii. As per the thickness of job, Nozzle and gas ratio are selected.

iv. The profile to be cut is selected from CNC machine.

v. A trial run is performed.

vi. Ignition time is set.

vii. Piercing time is set.

viii. Kerf time is set.

ix. Speed is set (in mm per minute).

x. High preheating and Post preheating is performed.

xi. Cutting is started.

xii. Nozzle stops and gas is off as soon as cutting is completed.

Das könnte Ihnen auch gefallen

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Construction Methodology For TG Pedestal Column - R2Dokument11 SeitenConstruction Methodology For TG Pedestal Column - R2Hariom Gupta100% (1)

- Typ. Construction MethodologyDokument29 SeitenTyp. Construction MethodologyvijayshelkeNoch keine Bewertungen

- Sop For Fabrication of Fuel TankDokument3 SeitenSop For Fabrication of Fuel TankVinod Kumar Verma75% (8)

- Construction of Segmental Concrete BridgeDokument72 SeitenConstruction of Segmental Concrete Bridgejaffna100% (1)

- SOP Shot Blasting MachineDokument4 SeitenSOP Shot Blasting Machineabhishek kumar100% (3)

- 1) JOB PROCEDURE For Tank Fabrication and Erection of HPCLDokument15 Seiten1) JOB PROCEDURE For Tank Fabrication and Erection of HPCLsenthilkumarsk88% (8)

- Preassemble and Erection of Ceiling GirderDokument25 SeitenPreassemble and Erection of Ceiling GirderArvind Shukla100% (1)

- Method Statement Sheet PilingDokument9 SeitenMethod Statement Sheet PilingAMA MUTTAHIZI AHADAN AUHAN100% (1)

- Tankage Erection - Procedure - CPCL SiteDokument10 SeitenTankage Erection - Procedure - CPCL SiteAnantha Narayanan100% (1)

- Method Statement For Construction of PilesDokument27 SeitenMethod Statement For Construction of PilesShakti SharmaNoch keine Bewertungen

- Industrial Piping and Equipment Estimating ManualVon EverandIndustrial Piping and Equipment Estimating ManualBewertung: 5 von 5 Sternen5/5 (7)

- SSD4702 Steel Project ReportDokument80 SeitenSSD4702 Steel Project Reportluckyways100% (1)

- Fabrication and Optimization of Cooling Tower: Abhishek KumarDokument15 SeitenFabrication and Optimization of Cooling Tower: Abhishek Kumarabhishek kumarNoch keine Bewertungen

- Job Procedure For Pipe Line Field Joint Coating-IoclDokument3 SeitenJob Procedure For Pipe Line Field Joint Coating-IoclVineet Khanduri0% (1)

- Repair WeldingDokument33 SeitenRepair WeldingAkhilesh Kumar100% (1)

- Lab Report On CNC MachineDokument5 SeitenLab Report On CNC MachineAhmad Syamil100% (1)

- Dokumen - Tips - Method Statement Sheet PilingDokument8 SeitenDokumen - Tips - Method Statement Sheet PilingSyed ZamanNoch keine Bewertungen

- Technology Multi Choice Exam Package 4 QDokument5 SeitenTechnology Multi Choice Exam Package 4 QraofrhanNoch keine Bewertungen

- Installation - Gocht 2015Dokument208 SeitenInstallation - Gocht 2015vũ minh tâm100% (1)

- Welding Inspection of Hmu Existing Flare Line Shutdown Tie-In Jobs PDFDokument5 SeitenWelding Inspection of Hmu Existing Flare Line Shutdown Tie-In Jobs PDFRakesh RanjanNoch keine Bewertungen

- 1.. Installation of RefractoriesDokument207 Seiten1.. Installation of RefractoriesYhane100% (1)

- Dismantling, Fabrication & Installation of Sam Washery Ground Reversible HopperDokument4 SeitenDismantling, Fabrication & Installation of Sam Washery Ground Reversible HopperMccurtis AkpojaroNoch keine Bewertungen

- Computer Numerical Control (CNC) : Maitha and Alyazia Mohammed A12-51Dokument12 SeitenComputer Numerical Control (CNC) : Maitha and Alyazia Mohammed A12-51Maitha AlhosaniNoch keine Bewertungen

- Safety Method Statement BP IOG Terminal WELDMEC / SMS 17459-028 Rev 02Dokument22 SeitenSafety Method Statement BP IOG Terminal WELDMEC / SMS 17459-028 Rev 02Cobbinah MarkNoch keine Bewertungen

- Edm Wire Cut Pho 16082019Dokument3 SeitenEdm Wire Cut Pho 16082019talha umarNoch keine Bewertungen

- Method Statement 20 Bridges PDF FreeDokument109 SeitenMethod Statement 20 Bridges PDF FreeThabiso MotalingoaneNoch keine Bewertungen

- Project Report KPTLDokument11 SeitenProject Report KPTLNirmit GandhiNoch keine Bewertungen

- Edm Die Sinking Pho 16082019Dokument3 SeitenEdm Die Sinking Pho 16082019talha umarNoch keine Bewertungen

- Work Procedure For Ducting Assembly & ErectionDokument23 SeitenWork Procedure For Ducting Assembly & ErectionSadhasivam VeluNoch keine Bewertungen

- STD-InSP-0003 (Coded Marking Procedures LATEST)Dokument3 SeitenSTD-InSP-0003 (Coded Marking Procedures LATEST)airbroomNoch keine Bewertungen

- Annexure 16 - Structural SteelDokument12 SeitenAnnexure 16 - Structural SteelmasoodNoch keine Bewertungen

- Solid State Physics LaboratoryDokument41 SeitenSolid State Physics LaboratoryMOHIT PARASHARNoch keine Bewertungen

- Indian Railways Presented by Y.K.Jha Sse/Nc/AiiwDokument9 SeitenIndian Railways Presented by Y.K.Jha Sse/Nc/Aiiwdhanalakshmi k sNoch keine Bewertungen

- Indian Railways Presented by Y.K.Jha Sse/Nc/AiiwDokument9 SeitenIndian Railways Presented by Y.K.Jha Sse/Nc/Aiiwdhanalakshmi k sNoch keine Bewertungen

- Paper Bridge Construction MethodDokument16 SeitenPaper Bridge Construction MethodAsep ArdiantoNoch keine Bewertungen

- SolidStatePhysicsLaboratory - DRDO Demo Report.Dokument41 SeitenSolidStatePhysicsLaboratory - DRDO Demo Report.Drive filesNoch keine Bewertungen

- IC348 Yuen Wai Ying Individual ReportDokument12 SeitenIC348 Yuen Wai Ying Individual ReportEunice YuenNoch keine Bewertungen

- Method of Statement - Welding JointingDokument4 SeitenMethod of Statement - Welding JointingAmirul Asyhraf ArsadNoch keine Bewertungen

- Overview of BHELDokument8 SeitenOverview of BHELRahul KashyapNoch keine Bewertungen

- Construction Methodology TemplateDokument4 SeitenConstruction Methodology TemplateIan Dela CruzNoch keine Bewertungen

- Technics Offshore Engineering Pte. LTD.: 1.0 PurposeDokument2 SeitenTechnics Offshore Engineering Pte. LTD.: 1.0 PurposeHanuman RaoNoch keine Bewertungen

- T/L TowersDokument72 SeitenT/L TowersEngr Imtiaz Hussain Gilani100% (1)

- Mma - Welding Procedure For Clip Bases.: ScopeDokument2 SeitenMma - Welding Procedure For Clip Bases.: ScopePaul RuckNoch keine Bewertungen

- Work Scope - Francis Turbine Refurbishment WorkDokument6 SeitenWork Scope - Francis Turbine Refurbishment WorkmanikanthNoch keine Bewertungen

- TS-1326 (21581) MS For Dismantling Temporary Steel Platform at Grid P-7 To P-8 & P-AC To PTI-ADokument21 SeitenTS-1326 (21581) MS For Dismantling Temporary Steel Platform at Grid P-7 To P-8 & P-AC To PTI-AJiabing ZouNoch keine Bewertungen

- Study On Transformers: A Project Report Submitted in Partial Fulfillment of TheDokument32 SeitenStudy On Transformers: A Project Report Submitted in Partial Fulfillment of TheSourabhSinhaNoch keine Bewertungen

- Application Methodology - PrimerDokument2 SeitenApplication Methodology - PrimerVikash SinghNoch keine Bewertungen

- Specification Sheet of ConveyorDokument6 SeitenSpecification Sheet of ConveyorLinh HoNoch keine Bewertungen

- Technology 3Dokument9 SeitenTechnology 3Prabhu KalpakkamNoch keine Bewertungen

- Vertical Milling Machine: Meteorology and Machining LabDokument4 SeitenVertical Milling Machine: Meteorology and Machining LabSumit JadhavNoch keine Bewertungen

- A1 Poster - Adjustable WrenchDokument1 SeiteA1 Poster - Adjustable WrenchKah KiatNoch keine Bewertungen

- Galvanizing EnglishDokument7 SeitenGalvanizing Englishsilverware1Noch keine Bewertungen

- Mid-Term Test: Material and Metal ProcessingDokument8 SeitenMid-Term Test: Material and Metal ProcessingekanandaardiansyahNoch keine Bewertungen

- Test Report PVC Cassette (SYG) : ObjectiveDokument5 SeitenTest Report PVC Cassette (SYG) : Objectiveikmal rashidNoch keine Bewertungen

- Sheet 2Q Manufacturing Processes 1Dokument1 SeiteSheet 2Q Manufacturing Processes 1Mohamed MoawedNoch keine Bewertungen

- Processes Involved in Production of Aluminium Sheets: Department of Mechanical EngineeringDokument29 SeitenProcesses Involved in Production of Aluminium Sheets: Department of Mechanical EngineeringSudeepHandikherkarNoch keine Bewertungen

- Report of The Inspection Carried Out On Construction of byDokument4 SeitenReport of The Inspection Carried Out On Construction of byaloysius akpanNoch keine Bewertungen

- Crane Tech Spec 2019Dokument23 SeitenCrane Tech Spec 2019Brajesh JhaNoch keine Bewertungen

- How to prepare Welding Procedures for Oil & Gas PipelinesVon EverandHow to prepare Welding Procedures for Oil & Gas PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- Apply For PassportDokument1 SeiteApply For Passportabhishek kumarNoch keine Bewertungen

- Apply For PassportDokument1 SeiteApply For Passportabhishek kumarNoch keine Bewertungen

- How To ImportDokument1 SeiteHow To Importabhishek kumarNoch keine Bewertungen

- Import From Catia To AnsysDokument3 SeitenImport From Catia To Ansysabhishek kumarNoch keine Bewertungen

- Sop of SR Process:: XviiDokument1 SeiteSop of SR Process:: Xviiabhishek kumarNoch keine Bewertungen

- CHPPDFDokument33 SeitenCHPPDFpanjumuttaiNoch keine Bewertungen

- Study of Adulterants in FoodstuffDokument18 SeitenStudy of Adulterants in Foodstuffabhishek kumarNoch keine Bewertungen

- Algorithm For Decimal To Hex ConversionDokument1 SeiteAlgorithm For Decimal To Hex Conversionabhishek kumarNoch keine Bewertungen

- Fabrication of Cooling Tower: Binay Augustin Kachhap Bhushan Tirkey Nitish Kumar Mahto Rituraj Singh Abhishek KumarDokument13 SeitenFabrication of Cooling Tower: Binay Augustin Kachhap Bhushan Tirkey Nitish Kumar Mahto Rituraj Singh Abhishek Kumarabhishek kumarNoch keine Bewertungen