Beruflich Dokumente

Kultur Dokumente

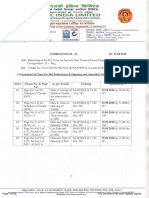

Form For Disclosure of Particulars With Respect To Conservation of Energy

Hochgeladen von

Heerok KumarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Form For Disclosure of Particulars With Respect To Conservation of Energy

Hochgeladen von

Heerok KumarCopyright:

Verfügbare Formate

Measures referred in (a) are expected to result in energy saving of Rs. Lacs.

Measures referred in (b) are expected to result in energy savings of Rs. 211.86 Lacs

per annum.

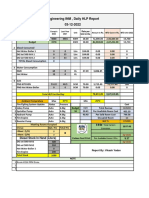

Form for Disclosure of particulars with respect to conservation of energy:

Particulars 2012-13 2011-12

A

Power and Fuel Consumption

1

Electricity

A

Purchased

Units (Lacs Kwh) 719.17

Total Amount (Rs. In Lacs) 3,686.00

Rate/Unit (Rs.) 5.13

B

Own Generation

Through Diesel Generator

Units (Lacs Kwh) NIL

Units / Ltr. of HSD NIL

Total Amount (Rs. In Lacs) NIL

HSD const / Unit Generated (Rs./unit) NIL

2 Coal (C&D Grade used as fuel in Kiln)

Quantity (MT) 121,538

Total Cost (Rs. In Lacs) 4,277.35

Average Rate (Rs./MT) 3,519.35

3

High Speed Oil for Kiln

Quantity (K. Ltr) 35,933

Total Cost (Rs. In Lacs) 12.72

Average Rate (Rs./K.Ltr) 35,389.00

B

Consumption per unit of

Production

Electricity (Kwh/T of Cement) 91.47

HSD (Ltr/T of Clinker ) 0.02

Coal (K.Cal/Kg of Clinker) 785

Coal % per MT of Clinker 17.00

B. TECHNOLOGICAL ABSORPTION

Research & Development (R&D)

The Company has developed a Research & Development cell for carrying out R&D Projects in

the plant with a specified objective of performance optimization of the mills & Kiln optimization,

use of alternate fuel for kiln and cement quality improvement.

Specific area in which R&D was carried out by the Company:

1. Study of sustainability of Grinding Aid and Performance improvers in Cement Mill. We

have obtained the permission from BIS for addition of performance Improver in OPC.

2. Optimization of cost of Raw Materials: Use of alternative raw material like iron ore,

Laterite etc.

3. Study of suitability of fly ash from different sources.

4. Trial production of PPC Part-II and slag cement & its commercial production.

5. Study of calcined clay suitability from different sources & Laboratory trials.

6. Proportionate use of Low Grade Lime Stone & designing suitable raw mix.

7. Launching of new design of PP Bags after extensive trial.

Benefit derived as a result of R&D

1. Usage of different types of grinding aid resulted into higher output of Cement Mill &

lower energy consumption.

2. Use of low cost raw material like laterite & iron ore fines resulted to reduced input

cost.

3. Sourcing of Fly Ash from different sources has resulted into optimization of PPC cost

and has also helped in selecting the right quality of fly ash.

4. Launch of new product PPC Part-II & PSC for exploring new market.

5. Calcined clay suitability study will reduce the manufacturing cost if product is

established in the market.

6. Using proportionate low grade lime stone leading to conservation of natural sources

and improved mines life.

7. New PP bags will reduce the rate of bag bursting leading to customer satisfaction.

Future Plan of Action

1. Setting up of Separate Laboratory for study on Raw Material Mix, Fuel Mix, Alternative

Fuel, Refractory Application and Bag Size Optimization.

Das könnte Ihnen auch gefallen

- Name: Ramchandra V NesariDokument10 SeitenName: Ramchandra V NesarirvnesariNoch keine Bewertungen

- Investment Analysis DG WHRDokument19 SeitenInvestment Analysis DG WHRFeroz Baig0% (1)

- Energy Conservation FrameworkDokument8 SeitenEnergy Conservation FrameworkdiebymyswordNoch keine Bewertungen

- NECA - Fuel ConsumptionDokument6 SeitenNECA - Fuel ConsumptionAmarsen ShrivastavaNoch keine Bewertungen

- Energy Consumption Survey Chapter Analyzes Data CollectionDokument32 SeitenEnergy Consumption Survey Chapter Analyzes Data CollectionAllanNoch keine Bewertungen

- Cs Distr Steam Methane ReformDokument5 SeitenCs Distr Steam Methane ReformJuan Antonio SánchezNoch keine Bewertungen

- 04 Day #2 - WorkShop 02 Energy Intensity SheetDokument2 Seiten04 Day #2 - WorkShop 02 Energy Intensity SheetzakalyNoch keine Bewertungen

- Energy Savings MeasuresDokument6 SeitenEnergy Savings MeasuresRakesh KumarNoch keine Bewertungen

- Biomass gasification in India: key opportunities and challengesDokument30 SeitenBiomass gasification in India: key opportunities and challengesShivi TripathiNoch keine Bewertungen

- Energy Supply and Demand: Calculating A Building's Operational Carbon FootprintDokument2 SeitenEnergy Supply and Demand: Calculating A Building's Operational Carbon FootprintNati DaveNoch keine Bewertungen

- Annual Report 2006 07Dokument191 SeitenAnnual Report 2006 07Ritu AgarawalNoch keine Bewertungen

- Walk Through Energy Audit of Purbani TextilesDokument57 SeitenWalk Through Energy Audit of Purbani Textilesm_immaculateNoch keine Bewertungen

- Cost Calculation TCG 2020 V16K With CNGDokument2 SeitenCost Calculation TCG 2020 V16K With CNGR_afflyNoch keine Bewertungen

- Pragati GTCC EIADokument23 SeitenPragati GTCC EIAProbodh1Noch keine Bewertungen

- Daily HLP Report 01 Dec 2022Dokument1 SeiteDaily HLP Report 01 Dec 2022Vicky YadavNoch keine Bewertungen

- Bangladesh Electricity Tariff AnalysisDokument10 SeitenBangladesh Electricity Tariff AnalysisAsif KhanNoch keine Bewertungen

- Power Sector - 72 - UltraTech - Sewagram - 0Dokument70 SeitenPower Sector - 72 - UltraTech - Sewagram - 0BHUVANESH MNoch keine Bewertungen

- Media Charge - Wear - Ball MillsDokument4 SeitenMedia Charge - Wear - Ball MillsPedro RodriguezNoch keine Bewertungen

- Daily INM Engineering HLP Report 03-12-2022Dokument1 SeiteDaily INM Engineering HLP Report 03-12-2022Vicky YadavNoch keine Bewertungen

- Mid Exam MM507Saseful AzharDokument3 SeitenMid Exam MM507Saseful AzharSaeful AzharNoch keine Bewertungen

- Walk-Through Energy Audit Report ABONI COMPOSITE TEXTILES LTDDokument53 SeitenWalk-Through Energy Audit Report ABONI COMPOSITE TEXTILES LTDm_immaculateNoch keine Bewertungen

- Total Raw Material CostDokument2 SeitenTotal Raw Material Costpriska jesikaNoch keine Bewertungen

- Natural Gas Vs Furnace OilDokument2 SeitenNatural Gas Vs Furnace OilvdNoch keine Bewertungen

- H&M EnergyDokument14 SeitenH&M EnergyMd. Fayez RefaetNoch keine Bewertungen

- Daily HLP 02 Report Dec 2022Dokument1 SeiteDaily HLP 02 Report Dec 2022Vicky YadavNoch keine Bewertungen

- Algae Farm Cost Model: Considerations For Photobioreactors: Y Zhu DB Anderson SB JonesDokument29 SeitenAlgae Farm Cost Model: Considerations For Photobioreactors: Y Zhu DB Anderson SB JonesWrongNoch keine Bewertungen

- Steam Cost Calculations 2020Dokument3 SeitenSteam Cost Calculations 2020Malwadkar P.B.0% (1)

- Steam Cost Calculations 2020Dokument3 SeitenSteam Cost Calculations 2020Malwadkar P.B.Noch keine Bewertungen

- Toaz - Info Steam Cost Calculations 2020xls PRDokument3 SeitenToaz - Info Steam Cost Calculations 2020xls PRMizanur RahmanNoch keine Bewertungen

- Gacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site ConditionDokument6 SeitenGacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site ConditionDurga PrasadNoch keine Bewertungen

- Chartered Institution of Building Services Engineers Head Quarters Renewable Energy Integration FeasibilityDokument14 SeitenChartered Institution of Building Services Engineers Head Quarters Renewable Energy Integration Feasibilitybombay__badboyNoch keine Bewertungen

- Indian Oil Corporation Limited: Certificate of Merit RefineryDokument5 SeitenIndian Oil Corporation Limited: Certificate of Merit RefineryBadiuzzama AzmiNoch keine Bewertungen

- These Questions Are Intended To Guide Your Studying. All Lecture, Problem Set, and Section Handout Materials Could Be Included On The ExamDokument8 SeitenThese Questions Are Intended To Guide Your Studying. All Lecture, Problem Set, and Section Handout Materials Could Be Included On The ExamLynn ShiyayoNoch keine Bewertungen

- 1100V PVC Cable Machine Production Cost AnalysisDokument5 Seiten1100V PVC Cable Machine Production Cost AnalysisRizwanSaifiNoch keine Bewertungen

- GR/KWH, KG/HR or Tons/Month.: ScopeDokument5 SeitenGR/KWH, KG/HR or Tons/Month.: ScopeThaigroup CementNoch keine Bewertungen

- LNG Demande in PakistanDokument21 SeitenLNG Demande in PakistanAnonymous icnhaNsFNoch keine Bewertungen

- CAPEX & OPEX On FuelDokument2 SeitenCAPEX & OPEX On FuelVivek MoreNoch keine Bewertungen

- Carbon Dioxide Emissions From Fired Heaters: Matthew Martin XRG TechnologiesDokument7 SeitenCarbon Dioxide Emissions From Fired Heaters: Matthew Martin XRG TechnologiesDeepika UmlaniNoch keine Bewertungen

- Effect of Primary Reformer Steam To Carbon Ratio On Ammonia Plant EfficiencyDokument2 SeitenEffect of Primary Reformer Steam To Carbon Ratio On Ammonia Plant EfficiencyManish GautamNoch keine Bewertungen

- Section - Iii: Long Descriptive Questions: Marks: 6 X 10 60Dokument31 SeitenSection - Iii: Long Descriptive Questions: Marks: 6 X 10 60YogaAnandNoch keine Bewertungen

- Conversion FactorDokument3 SeitenConversion FactorAniket AngreNoch keine Bewertungen

- G2E - Executive Report - 3Dokument4 SeitenG2E - Executive Report - 3RUANGLADDA LIMPONGSAWATNoch keine Bewertungen

- Material Flow and Cost Estimation for a 20t/h Py450 Biomass-to-Methanol PlantDokument11 SeitenMaterial Flow and Cost Estimation for a 20t/h Py450 Biomass-to-Methanol PlantAnonymous sVheFhq9PNoch keine Bewertungen

- SSRN Id4005089Dokument31 SeitenSSRN Id4005089dinilNoch keine Bewertungen

- SREDA Walk-Through Energy Audit Report (KNIT ASIA LTD)Dokument51 SeitenSREDA Walk-Through Energy Audit Report (KNIT ASIA LTD)m_immaculateNoch keine Bewertungen

- FOPS C-III Progress Report, Q-2Dokument19 SeitenFOPS C-III Progress Report, Q-2Muhammad KamranNoch keine Bewertungen

- Feasibility Study For Tank FarmDokument3 SeitenFeasibility Study For Tank FarmFahmy ArdhiansyahNoch keine Bewertungen

- CCL Gujarat-2Dokument13 SeitenCCL Gujarat-2Ajit ParwaniNoch keine Bewertungen

- NeyveliDokument50 SeitenNeyvelioranekNoch keine Bewertungen

- PYROLYSISDokument10 SeitenPYROLYSISNITIN P SHAHNoch keine Bewertungen

- Mungal EcuacionDokument12 SeitenMungal EcuacionPAOLA ALEXANDRA FORTUNATO ALVAREZNoch keine Bewertungen

- 20% Coal 80% MSW Prefersibility StudyDokument3 Seiten20% Coal 80% MSW Prefersibility StudyAamirMalikNoch keine Bewertungen

- Hydrogen BookletDokument250 SeitenHydrogen Bookletjiji1183Noch keine Bewertungen

- CPG Annual Report 2018Dokument72 SeitenCPG Annual Report 2018Anonymous 2vtxh4Noch keine Bewertungen

- Conversion FactorDokument4 SeitenConversion Factorpks_2410Noch keine Bewertungen

- Comments of Ministry of PowerDokument2 SeitenComments of Ministry of PowerRahul MathurNoch keine Bewertungen

- A Fair Share: Doing the Math on Individual Consumption and Global WarmingVon EverandA Fair Share: Doing the Math on Individual Consumption and Global WarmingNoch keine Bewertungen

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasVon EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNoch keine Bewertungen

- Hydrogen Production TechnologiesVon EverandHydrogen Production TechnologiesMehmet SankirNoch keine Bewertungen

- Hydraulic Control SystemDokument16 SeitenHydraulic Control SystemHeerok Kumar100% (1)

- Hydraulic For ConstructionDokument1 SeiteHydraulic For ConstructionHeerok KumarNoch keine Bewertungen

- Table 2 Shows The Principal Specifications of HPD71+71Dokument1 SeiteTable 2 Shows The Principal Specifications of HPD71+71Heerok KumarNoch keine Bewertungen

- TechnicalDokument2 SeitenTechnicalHeerok KumarNoch keine Bewertungen

- MethodologyDokument1 SeiteMethodologyHeerok KumarNoch keine Bewertungen

- DriveDokument1 SeiteDriveHeerok KumarNoch keine Bewertungen

- Models: Mini ExcavatorsDokument11 SeitenModels: Mini ExcavatorsHeerok KumarNoch keine Bewertungen

- Excavators: ModelsDokument12 SeitenExcavators: ModelsAnonymous m4e8KwH7Noch keine Bewertungen

- Big PlantDokument1 SeiteBig PlantHeerok KumarNoch keine Bewertungen

- 2.1 Product Series and Specifications: Table 1 Duplex Pump SeriesDokument1 Seite2.1 Product Series and Specifications: Table 1 Duplex Pump SeriesHeerok KumarNoch keine Bewertungen

- CementDokument1 SeiteCementHeerok KumarNoch keine Bewertungen

- Preventive Maintenance Strategies and Techniques for Improving Equipment UptimeDokument2 SeitenPreventive Maintenance Strategies and Techniques for Improving Equipment UptimeHeerok KumarNoch keine Bewertungen

- CementDokument1 SeiteCementHeerok KumarNoch keine Bewertungen

- Introduction of Duplex Pump HPD71+71 and Short-Stroke Pump HPV112+112Dokument1 SeiteIntroduction of Duplex Pump HPD71+71 and Short-Stroke Pump HPV112+112Heerok KumarNoch keine Bewertungen

- Introduction of Duplex Pump HPD71+71 and Short-Stroke Pump HPV112+112Dokument1 SeiteIntroduction of Duplex Pump HPD71+71 and Short-Stroke Pump HPV112+112Heerok KumarNoch keine Bewertungen

- Fig. 1 Appearance of HPD71+71 (3D-CAD)Dokument1 SeiteFig. 1 Appearance of HPD71+71 (3D-CAD)Heerok KumarNoch keine Bewertungen

- UploadDokument1 SeiteUploadHeerok KumarNoch keine Bewertungen

- Excavator NoteDokument1 SeiteExcavator NoteHeerok KumarNoch keine Bewertungen

- Hydraulic 1Dokument1 SeiteHydraulic 1Heerok KumarNoch keine Bewertungen

- 2.1 Product Series and Specifications: Table 1 Duplex Pump SeriesDokument1 Seite2.1 Product Series and Specifications: Table 1 Duplex Pump SeriesHeerok KumarNoch keine Bewertungen

- Table 1 Duplex Pump SeriesDokument1 SeiteTable 1 Duplex Pump SeriesHeerok KumarNoch keine Bewertungen

- This Is A PenDokument1 SeiteThis Is A PenHeerok KumarNoch keine Bewertungen

- UploadDokument1 SeiteUploadHeerok KumarNoch keine Bewertungen

- HydrauDokument1 SeiteHydrauHeerok KumarNoch keine Bewertungen

- HydrauDokument1 SeiteHydrauHeerok KumarNoch keine Bewertungen

- Amar-Windmill Products List With ProfileDokument23 SeitenAmar-Windmill Products List With ProfilebalaNoch keine Bewertungen

- Innovative Sustainable Construction Projects: Pearl River TowerDokument12 SeitenInnovative Sustainable Construction Projects: Pearl River Towercontactshanz100% (2)

- Systems: Lubrication & Filtration, Turbine FoundationsDokument52 SeitenSystems: Lubrication & Filtration, Turbine FoundationsSuriya KJNoch keine Bewertungen

- The Water CycleDokument34 SeitenThe Water Cycleapi-192449107Noch keine Bewertungen

- Grid Connected Ground Mounted Solar Power Plant PDFDokument35 SeitenGrid Connected Ground Mounted Solar Power Plant PDFkannan1987sNoch keine Bewertungen

- APEC 2011 Seminar ACDC ACAC Final Inclusive Swiss Rectifier As Sent 010211Dokument268 SeitenAPEC 2011 Seminar ACDC ACAC Final Inclusive Swiss Rectifier As Sent 010211Cristian BandilaNoch keine Bewertungen

- Increase power plant efficiency with an air preheaterDokument8 SeitenIncrease power plant efficiency with an air preheaterabhishek01raiNoch keine Bewertungen

- Teri Group 04Dokument27 SeitenTeri Group 04kumar SpkNoch keine Bewertungen

- Silo - Tips - Ground Source Heat Pump Association MembersDokument15 SeitenSilo - Tips - Ground Source Heat Pump Association MembersYip DavidNoch keine Bewertungen

- 2.3 Revision - 3Dokument14 Seiten2.3 Revision - 3sureshthevanNoch keine Bewertungen

- Notes - PSV by MukharjeeDokument3 SeitenNotes - PSV by MukharjeeWade ColemanNoch keine Bewertungen

- 3 Introduction To Technical Loss of Power SystemDokument23 Seiten3 Introduction To Technical Loss of Power SystemاحمدعليNoch keine Bewertungen

- Glycol Dehydration Instrumentation and ControlsDokument3 SeitenGlycol Dehydration Instrumentation and ControlsdndudcNoch keine Bewertungen

- Risk Based Inspection Planning Optimisation of Offshore Wind TurbinesDokument10 SeitenRisk Based Inspection Planning Optimisation of Offshore Wind TurbineseankiboNoch keine Bewertungen

- Dragsted History Booklet 2013Dokument98 SeitenDragsted History Booklet 2013ozakyusNoch keine Bewertungen

- Biofuel Pitch FinalDokument2 SeitenBiofuel Pitch Finalapi-232630455Noch keine Bewertungen

- 03 HAL-2011 Steering Tools FDokument10 Seiten03 HAL-2011 Steering Tools FMiftahul Riski NasutionNoch keine Bewertungen

- Solution: Renewable EnergyDokument6 SeitenSolution: Renewable EnergyAhsan PervaizNoch keine Bewertungen

- Sources of EnergyDokument22 SeitenSources of EnergyVishisht KhilariwalNoch keine Bewertungen

- General Chemistry I Chapter 1 -16 Practice Questions SolvedDokument6 SeitenGeneral Chemistry I Chapter 1 -16 Practice Questions SolvedHajime Hikari100% (1)

- Materi Future PerfectDokument3 SeitenMateri Future Perfectlouis kucingNoch keine Bewertungen

- VGF BrochureDokument6 SeitenVGF BrochureGeorgiy ChachshinNoch keine Bewertungen

- Dwa 125RDokument35 SeitenDwa 125RGuillermo HernandezNoch keine Bewertungen

- Switch Mode InvertersDokument22 SeitenSwitch Mode InvertersVivek SinghNoch keine Bewertungen

- Jet 1Dokument20 SeitenJet 1Karim El ShamashergyNoch keine Bewertungen

- Residential PV System Design for Daily Load of 17360WhDokument4 SeitenResidential PV System Design for Daily Load of 17360WhAjala Oladimeji DurotoluwaNoch keine Bewertungen

- Presentation Sharing of ISTS Charges Regulations 2020Dokument28 SeitenPresentation Sharing of ISTS Charges Regulations 2020koinsuriNoch keine Bewertungen

- Understanding Fuel Cells and Their DiagramDokument4 SeitenUnderstanding Fuel Cells and Their Diagrambashar68Noch keine Bewertungen

- DC-Link Voltage Control of A Single-Phase Photovoltaic InverterDokument6 SeitenDC-Link Voltage Control of A Single-Phase Photovoltaic Invertertinhmaixatoi2006Noch keine Bewertungen

- 2 Paivi Rousu PDFDokument34 Seiten2 Paivi Rousu PDFMahendra Pratap SinghNoch keine Bewertungen