Beruflich Dokumente

Kultur Dokumente

XLI Gas Lift Valve: Applications High-Pressure Completions

Hochgeladen von

nciri0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

27 Ansichten2 SeitenXli Gas Lift Valve

Originaltitel

Xli Gas Lift Valve

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenXli Gas Lift Valve

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

27 Ansichten2 SeitenXLI Gas Lift Valve: Applications High-Pressure Completions

Hochgeladen von

nciriXli Gas Lift Valve

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

XLI Gas Lift Valve

The XLI gas lift valve.

High-pressure completions Applications

The Schlumberger XLift* high-pressure gas Subsea gas lift installations

lift system extends the capability of present

High-performance installations

gas lift systems by increasing the range of

operating pressures from 2,000 psi to 5,000 High-pressure

psi. Improving on field-proven Camco* gas deepwater installations

lift technology, this new system enables

operators to complete high-pressure gas lift Benefits

wells and operate with higher injection pres- Better well efficiency because

sures and deeper injection points to increase a single valve offers flexible

well performance. With higher operating operating ranges over a series

pressures, wells can be completed with of injection pressures

fewer mandrels and valves.

No learning curve required,

To accommodate higher operating pres-

because it employs familiar

sure, the 134-in XLI gas lift valve incorporates

injection-pressure-operated

an innovative edge-welded bellows system

techniques with simplified

developed by Flexial (US Patent 5,662,335).

hardware

Manufactured using state-of-the-art tech-

nology and corrosion-resistant materials, Reliable performance in

the new bellows reduces internal gas deepwater, high-pressure

charge while increasing the operating environments

injection pressure. During offshore Cost savings because no

operation, this allows the operator to modifications are required to

inject high-pressure gas below the mudline existing completion practices

and significantly improves the depth of or surface facilities

injection required to maximize drawdown Cost savings and improved

and increase production. In deepwater off- safety by permitting first valve

shore applications, the first unloading valve placement below the mudline

can be placed below the mudline. In addi-

tion, the XLift system uses a positive Features

sealing check system to replace the

velocity check valve systems used in A larger 134-in OD

todays traditional gas lift valves. Reliable, retrievable gas lift

valve design using field-proven

High-pressure performance technology

The XLI gas lift valve is subsurface- Subsurface-actuated assembly

controlled, having no physical link to the (no linkage to the surface)

surface. It features a venturi flow config- Increased operating

uration for more efficient and stable gas pressure envelope for

flow throughout and a positive check valve deeper gas injection

that eliminates potential leak paths to the

Improved and robust check

casing/tubing annulus. A larger 134-in outside

valve system provides a positive

diameter (OD) improves the valves geometry

seal between the tubing and

and results in improved performance.

the casing annulus

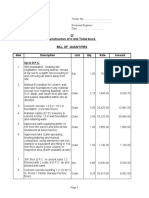

XLI High-Pressure Gas Lift Valve Specifications

OD (not including latch) 1.725 in [43.382 mm]

Length with latch 34.063 in [865.200 mm]

Operating pressure (max. unloading differential) 7,500 psi [51,710 kPa]

Max. gas injection pressure 5,000 psi [34,474 kPa]

Max. temperature 350 degF [177 degC]

Min. temperature 32 degF [0 degC]

Venturi orifice size range 8

64 to 2064 in

Materials

Body parts Inconel 925

O-rings and seals Viton with PEEK backups

Bellows Hastelloy C-276 and C-22

Seat Tungsten carbide

Packing Modified Campac Carbon and Moly Filled Teflon

with PEEK/Teflon backup and stainless steel retainer ring

Secondary accessories

Pulling tool 2.000-in JDC type

Mandrel series XLG

Intensifier arrangement to reduce internal gas charge pressure (maximum dome charge 3,000 psi [20,684 kPa]

www.slb.com/xlift

06-AL-076 August 2006

*Mark of Schlumberger

Other company, product, and service names are the

properties of their respective owners.

Copyright 2006 Schlumberger. All rights reserved.

Produced by Schlumberger Marketing Communications

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- HW4 Fa17Dokument4 SeitenHW4 Fa17mikeiscool133Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Effective Communication LeaderDokument4 SeitenEffective Communication LeaderAnggun PraditaNoch keine Bewertungen

- NYLJtuesday BDokument28 SeitenNYLJtuesday BPhilip Scofield50% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- WPGPipingIndex Form 167 PDFDokument201 SeitenWPGPipingIndex Form 167 PDFRaj AryanNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- DTMF Controlled Robot Without Microcontroller (Aranju Peter)Dokument10 SeitenDTMF Controlled Robot Without Microcontroller (Aranju Peter)adebayo gabrielNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Dokument6 SeitenType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Design of Open Channels US Department of Agriculture SCSDokument293 SeitenDesign of Open Channels US Department of Agriculture SCSMiguelGuavitaRojasNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Bench VortexDokument3 SeitenBench VortexRio FebriantoNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Cinnamon Peelers in Sri Lanka: Shifting Labour Process and Reformation of Identity Post-1977Dokument8 SeitenCinnamon Peelers in Sri Lanka: Shifting Labour Process and Reformation of Identity Post-1977Social Scientists' AssociationNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Chapter03 - How To Retrieve Data From A Single TableDokument35 SeitenChapter03 - How To Retrieve Data From A Single TableGML KillNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- ACC403 Week 10 Assignment Rebecca MillerDokument7 SeitenACC403 Week 10 Assignment Rebecca MillerRebecca Miller HorneNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Surge Arrester: Technical DataDokument5 SeitenSurge Arrester: Technical Datamaruf048Noch keine Bewertungen

- Marketing Management - Pgpmi - Class 12Dokument44 SeitenMarketing Management - Pgpmi - Class 12Sivapriya KrishnanNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- BS en Iso 11666-2010Dokument26 SeitenBS en Iso 11666-2010Ali Frat SeyranNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Mix Cases UploadDokument4 SeitenMix Cases UploadLu CasNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Spare Parts ManagementDokument21 SeitenSpare Parts Managementdajit1100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Attachment BinaryDokument5 SeitenAttachment BinaryMonali PawarNoch keine Bewertungen

- Catalog enDokument292 SeitenCatalog enSella KumarNoch keine Bewertungen

- Catalogue of The Herbert Allen Collection of English PorcelainDokument298 SeitenCatalogue of The Herbert Allen Collection of English PorcelainPuiu Vasile ChiojdoiuNoch keine Bewertungen

- Comparative Analysis of Mutual Fund SchemesDokument29 SeitenComparative Analysis of Mutual Fund SchemesAvinash JamiNoch keine Bewertungen

- Dbms UPDATED MANUAL EWITDokument75 SeitenDbms UPDATED MANUAL EWITMadhukesh .kNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- SKF LGMT-2 Data SheetDokument2 SeitenSKF LGMT-2 Data SheetRahul SharmaNoch keine Bewertungen

- Fast Binary Counters and Compressors Generated by Sorting NetworkDokument11 SeitenFast Binary Counters and Compressors Generated by Sorting Networkpsathishkumar1232544Noch keine Bewertungen

- 19-2 Clericis LaicosDokument3 Seiten19-2 Clericis LaicosC C Bờm BờmNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- 3.1 Radiation in Class Exercises IIDokument2 Seiten3.1 Radiation in Class Exercises IIPabloNoch keine Bewertungen

- Change Language DynamicallyDokument3 SeitenChange Language DynamicallySinan YıldızNoch keine Bewertungen

- Common Base AmplifierDokument6 SeitenCommon Base AmplifierMuhammad SohailNoch keine Bewertungen

- Manulife Health Flex Cancer Plus Benefit IllustrationDokument2 SeitenManulife Health Flex Cancer Plus Benefit Illustrationroschi dayritNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Sec2 8 PDFDokument3 SeitenSec2 8 PDFpolistaNoch keine Bewertungen

- Bode PlotsDokument6 SeitenBode PlotshasanozdNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)