Beruflich Dokumente

Kultur Dokumente

Z Bracket - Calc - 7-2-2017 PDF

Hochgeladen von

vtalexOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Z Bracket - Calc - 7-2-2017 PDF

Hochgeladen von

vtalexCopyright:

Verfügbare Formate

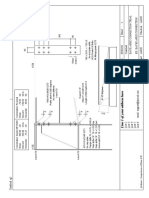

Designed by: Engineer :M.

S date 4/11/2015

Checked by : YSQ

PROJECT:

Client:

stone types:

STONE SIZE=800mm x400mm x30mm

Cavity =30mm

bracket type: Z with pin

no. of brackets used = 2 per edge of stone Width 25

Z bracket used: h1 34

h2 25

Y3 25

d1 14

t 3

pin used: 4mmx40mm

Flat head bolt 6mmx62mm

Anchor Bolt used: 8mm70mm

Slot size 9mm15mm

Note: contractor to be ensure that all the brackets are aligned in away to make sure distribution of the load equally

Type material for the angle

stainless steel type 316 for brackets

ultimate stress u1 490 N/mm2

yield stress y1 190 N/mm2

allowable shear stress=qall 1=0.6*y1 114

Loading calculations

A. Vertival loads

stone width =PW 800 mm

stone height =Ph 400 mm

stone thickness=Pt (stone) 30 mm

number of brackets 2

specific gravity of stone 26.1 kN/m3

total load of stone 0.25056

load for each bracket (Fv) 0.12528 kN

B.Wind load

if the stones are external use wind 1 calculation

if the stones are internal use minimum horizontal load calculation

Wind load 1

number of brackets 2

wind velocity V and wind load are designed according to BS6399-2:1997

Vb=basic wind speed 33 m/s

K1=altitude factor 1

K2= directional factor 1

K3= seasonal building factor 1

K4= terrain &building factor 1.7

design wind speed Vz Vz=K1*K2*K3*K4*Vb 56.1 m/s

design wind pressure q q=0.613*Vz^2 1929.2 n/mm2

wind force om each stone panel q*W*h 0.6174 kN

pressure on each bracket Hp 0.3087 kN

suction on each bracket Hs 0.3087 kN

Minimum horizontal load

minimum horizontal force 0.5 kn/m2 (internal) 0.5*W*L//no.of brackets 0.08 kN

minimum horizontal force 0.5 kn (internal) 0.5/no.of brackets 0.25 kN

C. Seismic Load.

Seismic loading as per Specifications of UBC 1997.

Ca= Seismic Coefficient 0.19 (For Zone Ao=0.1g)

Ip = Importance Factor 1

Ws = Total weight of stone 0.2506 kN

Fp=Seismic Force / panel Fp=4.Ca.Ip.Ws 0.1904 kN

Seismic force on each bracket=Fp 0.0952 kN

Design horizontal force(FH) max of Fp&Hp& min 0.31 kN

Thermal Movement of Stone.

Temperature Difference,T T=T1-T2 50 C

Coeff.of Thermal Expansion, f 7.2 x10 ^-6mm/mmC

Length of Stone 800 mm

Thermal Movement of Stone (= f*T*h) 0.288 mm

IF (f*T*h)<1 ..ok ok

Design of Elements.

cavity 30 mm

bracket size

W=width of the bracket 25 mm

t= thickness of the angle 3 mm

SL=slot length 15 mm

slot width 9

=angle of bend in plate 20

Dn= nominal diameter for extension arm (flat head bolt) 6

M=1.0mm+Dn 7 mm

N= 9 mm

d1 14 mm offset=d1+t

d2=cavity+pt/2-t 42 mm

d3=cavity-d1-N-t+pt/2 19 mm

d4=pt/2+5 20 mm

=anchor bolt diameter 8 mm

d5=d3-pt/2-5 -1 mm

y1=0.5xSL+t 10.5 mm

y2= 8 mm

Y3=d1 tan 5.092777799 mm

h1=2*+SL+t 34 mm

h2 25 mm

Z=W*(t^2)/6 37.5 mm3

y4=y1+y3+h2/2+SL-M/2 39.5927778 mm

y5=Y3+h2/2 17.5927778 mm

y6=y4+y5 57.1855556 mm

x1=d2+t 45 mm

L=y1+y2+2*y3+h2+SL 68.6855556 mm

x=d1-N 5

cavity adjustability (inward) 5

check(d1) ..x>d3-pt/2 not ok

Reaction

Df1=dead load factor (first case) 1.4

Df2=dead load factor (second case) 1.2

Wf= wind load factor 1.2

R1=Df1*Fv*X1/y6 138.0180697 N

R2=Df1*Fv 175.392 N

R3=((Df2*Fv*X1)-(Wf*FH*y5))/y6 3.857733939 N

R4=Wf*FH+R3 375.8577339 N

R5=Df2*Fv 150.336 N

Checking moments for plate design

moment @1(moment transfered to external wall)=R1*(y1+SL-(/2)) 2967.388499 N.mm

moment @2=R1(y1+SL+y3-(/2))-R2*d1 1214.795861 N.mm

moment @3=R1(y1+SL+y3-/2+h2/2)-R2*d1 2940.021732 N.mm

moment @4=R1(y1+SL+y3-/2+h2/2)-R2*d1-Fv*Df1*(d3+N) -1970.954268 N.mm

moment @5=R1*y3 702.8953614 N.mm

moment@8 = R3*(y1+SL-/2) 82.9412797 N.mm

moment@9=(R3*(y1+SL+y3-/2))-R5*d1 -2002.116139 N.mm

moment@10=R3*y4-R5*(d1+t) -2402.973597 N.mm

moment@11= R4(y3+h2/2-M/2) 5296.879529 N.mm

moment@12=R4*y3 1914.159923 N.mm

min- -2402.973597

Abs 2402.973597

max+ 5296.879529

(Md) design moment= greatest value 5296.879529 N.mm

Mcp for plate= moment capacity= y*Z 7125 N.mm

moment capacity check ok

Md/Mcp 0.743421688 <1

Extension arm design:

stainless steel type 316 for bracketsfor extension arm

ultimate stress for extension arm u2 700 N/mm2

yield stress for extension arm y2 450 N/mm2

allowable shear stress=qall 2=0.6*y2 270

th= Thickness of flat part 3.5 mm

Dn= nominal diameter 6 mm

De= effective diameter 5 mm

Ae= effevtive cross section area 19.625 mm2

Z4=modulus of elasticity of flatted part=Dn*th^2/6 12.25 mm3

Z3=modulus of elasticity of round part = 3.14/4*(De/2)^3 12.265625 mm3

N= clamping height. 9 mm

e=edge distance from pin center 8 mm

Min extension arm length required=d3+t+2N+e=L(extension) 48 mm

M(6-6)=Df1*Fv*d3 3332.448 N.m

M(13-13)=Df2*Fv(d3+N) 4209.408

Maximum of M6 & M13 4209.408

M(7-7)=Df1*Fv*d4 3507.84 N.m

M(14-14)=Df2*Fv*d4 3006.72

Maximum of M7 & M14 3507.84

Mcp(6-6)(13-13)=moment capacity at section (6-6)= y2*Z3 5519.53125 N.m

Mcp(7-7)(14-14)=moment capacity at section (7-7)= y2*Z4 5512.5 N.m

M(6-6)/Mcp(6-6) 0.762638675 ok ok ,if <1

M(7-7)/Mcp(7-7) 0.636342857 ok ok ,if <1

Deflection check

b=width of the flatted part 12 mm

L=deflection=L(extension)-2N-t 27 mm

E =Mod.of Elasticity 210000 N/mm2

I1 = Moment of Inertia of section (round part)= 1/4*3.14*(D/2)^4 30.6640625

I2 = Moment of Inertia of section (flatted part)= b*th^3/12 42.875

minimum I 30.6640625

max= FV*L^3/(3*E*Imin) 0.127644703 mm 0.063822351

all=allowable deflection for cantilever=2xL/180 0.3 mm

IF all> maxok ok

Anchor bolt design

Bolt code TM8 70A4

=anchor bolt diameter( Nominal) 8

eff=anchor bolt diameter (effective) 7 mm

Bolt length(Lb) 70 mm

Nrec=tension safty load 3800 N

V rec=shear safety load 4400 N

effictive embedment depth 46 mm

installtion required torque 13

Nb= number of bolts 1

N(app)= bolt tension( pull out force)=(M1-1/(y1+/2))/Nb+Wf*FH/Nb 583.9563214 N

moment ok

V(app)=bolt shear=Df2*Fv/Nb 150.336 N

shear ok

resultant force due to combined pull_out and shear=(Napp/Nrec)+(Vapp/Vrec) 0.187839989

combined ok

Bolt must tested with failure more than 3xPout 1751.868964 Kn

pin dowel design:

stainless steel type 316 for brackets

ultimate stress for pin u3 700 N/mm2

yield stress for pin y3 450 N/mm2

allowable shear stress=qall 2=0.6*y2 270 N/mm2

(Nd)= no. of dowels 1

Dl=Dowel length 40 mm

Dd= dowel diameter 4 mm

Ad=dowel area=*Dd^2/4 12.56 N.mm

bending arm = L/8 5 mm

Mu=Wf*FH * bending arm/4 465 N.mm 93

Z5=(*Dd^3/32)/Nd 6.28 mm3

Mu (app) =applied moment stress =Mu1/Z 74.04458599 N/mm2

ok

Mu/ y3 0.164543524

Shear stress,T=4/3*Wf*FH/Ad/Nd 39.49044586

ok

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Punctuation WorksheetsDokument10 SeitenPunctuation WorksheetsRehan Sadiq100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Pinned Base Plate DesignDokument12 SeitenPinned Base Plate DesignvtalexNoch keine Bewertungen

- Augusta Issue 1145 - The Jail ReportDokument24 SeitenAugusta Issue 1145 - The Jail ReportGreg RickabaughNoch keine Bewertungen

- Aluminum CurtainwallDokument8 SeitenAluminum CurtainwallvtalexNoch keine Bewertungen

- Banana Stem Patty Pre Finale 1Dokument16 SeitenBanana Stem Patty Pre Finale 1Armel Barayuga86% (7)

- Writing Capstone Research Project For Senior High School A Modified Guide ManualDokument9 SeitenWriting Capstone Research Project For Senior High School A Modified Guide ManualIOER International Multidisciplinary Research Journal ( IIMRJ)Noch keine Bewertungen

- Performance Management Systems and Strategies by Dipak Kumar BhattacharyyaDokument385 SeitenPerformance Management Systems and Strategies by Dipak Kumar Bhattacharyyasayal96amrit100% (3)

- Heat TreatmentDokument14 SeitenHeat TreatmentAkhilesh KumarNoch keine Bewertungen

- Quikjoint - Eaves Haunch Calculations PDFDokument9 SeitenQuikjoint - Eaves Haunch Calculations PDFvtalexNoch keine Bewertungen

- Quick Dashboard in Excel: Service Level Quality ScoreDokument3 SeitenQuick Dashboard in Excel: Service Level Quality ScorevtalexNoch keine Bewertungen

- Fixed Base Plate ExampleDokument5 SeitenFixed Base Plate ExamplevtalexNoch keine Bewertungen

- Mitsubishi IC Pneumatic Forklift PDFDokument5 SeitenMitsubishi IC Pneumatic Forklift PDFfdpc1987Noch keine Bewertungen

- Prelims Reviewer Biochem LabDokument4 SeitenPrelims Reviewer Biochem LabRiah Mae MertoNoch keine Bewertungen

- Finkster-Python CheatsheetDokument11 SeitenFinkster-Python CheatsheetvtalexNoch keine Bewertungen

- DM04 04 PDFDokument16 SeitenDM04 04 PDFvtalexNoch keine Bewertungen

- Kec Metro ReactionsDokument157 SeitenKec Metro ReactionsvtalexNoch keine Bewertungen

- Interpolation - MathDokument1 SeiteInterpolation - MathvtalexNoch keine Bewertungen

- Scia Engineer - Load Generators en 2Dokument3 SeitenScia Engineer - Load Generators en 2vtalexNoch keine Bewertungen

- Commentary: Standards Secondary and Structural Girts Practices DesignDokument2 SeitenCommentary: Standards Secondary and Structural Girts Practices DesignvtalexNoch keine Bewertungen

- Pinned Base PlateDokument7 SeitenPinned Base PlatevtalexNoch keine Bewertungen

- Purlin Bracing CriteriaDokument19 SeitenPurlin Bracing CriteriavtalexNoch keine Bewertungen

- Calculation Headline: Roof GeometryDokument2 SeitenCalculation Headline: Roof GeometryvtalexNoch keine Bewertungen

- Purlin Bracing CriteriaDokument19 SeitenPurlin Bracing CriteriavtalexNoch keine Bewertungen

- TNEB Online Payment ReceiptDokument1 SeiteTNEB Online Payment Receiptvtalex0% (1)

- Quikjoint - ResultsDokument15 SeitenQuikjoint - ResultsvtalexNoch keine Bewertungen

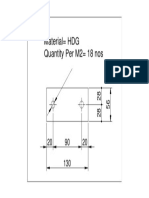

- Material HDG Quantity Per M2 18 NosDokument1 SeiteMaterial HDG Quantity Per M2 18 NosvtalexNoch keine Bewertungen

- Doha Festival CIty Aug 16 Rev. 1Dokument6 SeitenDoha Festival CIty Aug 16 Rev. 1vtalexNoch keine Bewertungen

- A1 60 Stone CladdingDokument1 SeiteA1 60 Stone CladdingvtalexNoch keine Bewertungen

- Hilti - Pull Out Test Report-SampleDokument3 SeitenHilti - Pull Out Test Report-SamplevtalexNoch keine Bewertungen

- Nonlinear Robust Control of High-Speed Supercavitating Vehicle in The Vertical PlaneDokument10 SeitenNonlinear Robust Control of High-Speed Supercavitating Vehicle in The Vertical Planesamsaptak ghoshNoch keine Bewertungen

- Chen Probable Cause Affidavit 050714Dokument7 SeitenChen Probable Cause Affidavit 050714USA TODAYNoch keine Bewertungen

- Case For Overhead and DistributionDokument2 SeitenCase For Overhead and DistributionBhargav D.S.Noch keine Bewertungen

- Foundstone Hacme Bank User and Solution Guide v2.0Dokument60 SeitenFoundstone Hacme Bank User and Solution Guide v2.0Yeison MorenoNoch keine Bewertungen

- Samsung WF8500NMW8Dokument180 SeitenSamsung WF8500NMW8Florin RusitoruNoch keine Bewertungen

- AAR Safety Fact SheetDokument2 SeitenAAR Safety Fact Sheetrogelio mezaNoch keine Bewertungen

- Docker Tutorial: Anthony BaireDokument99 SeitenDocker Tutorial: Anthony BairesuderNoch keine Bewertungen

- Transcendental Meditaton ProgramDokument3 SeitenTranscendental Meditaton Programacharyaprakash0% (3)

- 4148-Article Text-14752-1-10-20211029Dokument7 Seiten4148-Article Text-14752-1-10-20211029Daffa AzkaNoch keine Bewertungen

- MSDS Potassium DichromateDokument8 SeitenMSDS Potassium DichromateAyu Lakshemini OkaNoch keine Bewertungen

- SR Cheat Sheets PDFDokument4 SeitenSR Cheat Sheets PDFDevin ZhangNoch keine Bewertungen

- CV (Martin A Johnson)Dokument7 SeitenCV (Martin A Johnson)kganesanNoch keine Bewertungen

- FTP Booster Training Plan OverviewDokument1 SeiteFTP Booster Training Plan Overviewwiligton oswaldo uribe rodriguezNoch keine Bewertungen

- Learning Spoken English in Half The TimeDokument86 SeitenLearning Spoken English in Half The TimeΔέσποινα ΤζουτNoch keine Bewertungen

- Serie10 ElecDokument75 SeitenSerie10 Elecmealier severineNoch keine Bewertungen

- Fundamentals of Heat and Mass Transfer 7Th Edition Incropera Solutions Manual Full Chapter PDFDokument68 SeitenFundamentals of Heat and Mass Transfer 7Th Edition Incropera Solutions Manual Full Chapter PDFbrainykabassoullw100% (10)

- Curriculum Vitae: Mobile No: +917019900128 E-MailDokument5 SeitenCurriculum Vitae: Mobile No: +917019900128 E-MailJay MNoch keine Bewertungen

- Social and Professional Issues Pf2Dokument4 SeitenSocial and Professional Issues Pf2DominicOrtegaNoch keine Bewertungen

- RHEL 9.0 - Configuring Device Mapper MultipathDokument59 SeitenRHEL 9.0 - Configuring Device Mapper MultipathITTeamNoch keine Bewertungen

- Prishusingh Blogspot Com 2024 03 Digital-Marketing-Course HTMLDokument12 SeitenPrishusingh Blogspot Com 2024 03 Digital-Marketing-Course HTMLsudharaj86038Noch keine Bewertungen

- EVC AC Charger CatalogDokument2 SeitenEVC AC Charger CatalogRaison AutomationNoch keine Bewertungen

- PapernathazDokument26 SeitenPapernathazAbelardo LapathaNoch keine Bewertungen