Beruflich Dokumente

Kultur Dokumente

145PM40-B - 2GNM110071 New PDF

Hochgeladen von

vanessa quispeOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

145PM40-B - 2GNM110071 New PDF

Hochgeladen von

vanessa quispeCopyright:

Verfügbare Formate

Type PM40-B, 123-170 kV, up to 40 kA

Power Circuit Breaker

Standard features

- Dead tank, with one 3-cycle self-blast interrupter per phase

- Continuous current ratings through 3150 A

- Performance certified per IEC 62271-100 and ANSI C37.04,

C37.06, and C37.09

- Galvanized steel frame, tested per ASTMB-117

- NEMA-3R steel control cabinet with TGIC polyester

powdercoat finish

- BLK-222 rated IEC class M1 for mechanical endurance

- National Board certification of interrupter tanks per the ASME

Pressure Vessel and Boiler Code

- All tanks factory leak tested in a hard-vacuum chamber with a

helium mass spectrometer

- Single tank-mounted gas density monitor and pressure gauge

- Porcelain bushings

- Ships fully assembled and factory tested with positive SF6 gas

pressure and standard bushings

Options and accessories

- Condition monitoring with the Circuit Breaker Sentinel (CBS)

- Density monitor and temperature compensated pressure

gauge mounted on each tank for independent gas monitoring

- Extra creep and/or extra strike bushings

The 123 - 170 PM40-B breaker is designed with interrupter, - Silicone rubber composite bushings

mechanism, and bushing technology that have been field - Tank heaters for ambient temperatures below -30 C

proven through extensive application on a variety of ABB type - High seismic designs

PM SF6 power circuit breaker configurations. - Customized control designs

- IP55 or NEMA 4X control cabinet construction

ABB advantages

- High performance interrupter complies with IEC/ANSI C2 BLK-222 mechanism

capacitive current switching, which allows greater flexibility in BLK-222 spring-spring minimum-

utility applications maintenance operating mechanism,

- Single-piece interrupter assembly simplifies field change-out located within a dedicated housing,

whenever end of life is reached, by eliminating need for internal provides the driving force to gang-

tank mounting of separate parts and alignment operate the breakers high performance

- Simple, motor-charged spring-spring operating mechanism interrupters. Mechanical energy,

has fewer impacted components and low mechanical stresses, stored in the flat spiral tension closing

resulting in lower maintenance demands spring, is mechanically translated to the

- Externally accessible current transformers enable simple field operating shaft to simultaneously close

change-out without degassing breaker and bushing removal the breaker and charge the trip spring. Close spring charge is

- Standard side location of control cabinet with respect to automatically maintained by the operation of a universal motor.

bushings ideally suits application as direct replacement for oil The unit stores an Open-Close-Open operating sequence, and it

circuit breakers is recharged within 15 seconds. There are over 28,000 of these

- Extensive range of available field services, from technical popular mechanisms installed world wide in various breaker

assistance to turn-key installation, can dramatically reduce configurations operating in a variety of environmental conditions.

construction costs and time to commercial operation

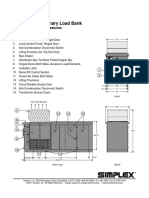

149" (3789.14)

SHIPPING AND INSTALLED WIDTH

86"

85" (2148.52) 75" (1894.57) (2175.53)

MAX DIMENSION FOR BUSHING REMOVAL PHASE SPACING

71" (1800.65)

20" METAL TO METAL

(507.5)

ADDITIONAL

HEIGHT

61" (1549.27) REQUIRED

METAL TO METAL

FOR BUSHING

REMOVAL

Document Number - 2GNM110071 / July 2009

173"

(4396.61)

INSTALLED

HEIGHT

121"

(3074.85)

163"

(4129.76)

TOP OF

TERMINAL

PAD

168"

(4272.86)

152"

(3862.91)

HEIGHT

TO LIVE

PARTS

93"

(2357.33)

HEIGHT TO CL

OF BREAKER

113"

(2870.07)

MINIMUM

BUSHING

HEIGHT

47"

(1198.01)

48"

(1223.8)

30"

(764.68) 23"

(585.3)

Typical outline

Rated capabilities @ 50/60 Hz

Short Circuit Maximum Power Frequency 2 -sec Chopped

Rated Maximum and Short Time Continuous Rated Interrupting Full Wave Insulation Wave Impulse Closing and

Circuit Breaker Voltage Current Current Time Withstand Voltage Withstand Voltage Voltage Latching Current

Type (kV, rms) (kA, rms) (A, rms) (Cycles) (kV, Peak) (kV, rms) (kV, Peak) (kA, Peak)

123PM40-20B 123 40 2000 3 550 260 710 104

123PM40-30B 123 40 3150 3 550 260 710 104

145PM40-20B 145 40 2000 3 650 310 838 104

145PM40-30B 145 40 3150 3 650 310 838 104

170PM40-20B 170 40 2000 3 750 365 968 104

170PM40-30B 170 40 3150 3 750 365 968 104

For more information please contact:

ABB Inc.

High Voltage Products

Westmoreland Distribution Park East

100 Distribution Circle

Mount Pleasant, Pennsylvania, USA

Phone: +1 (724) 696-1500

Fax: +1 (724) 696-1502

www.abb.com/highvoltage

Das könnte Ihnen auch gefallen

- Case Study On "Unilever in Brazil-Marketing Strategies For Low Income Consumers "Dokument15 SeitenCase Study On "Unilever in Brazil-Marketing Strategies For Low Income Consumers "Deepak BajpaiNoch keine Bewertungen

- GL 107 MV Outdoor Cicuit Breaker BrucherDokument6 SeitenGL 107 MV Outdoor Cicuit Breaker BrucherNguyễn Tiến Dũng100% (2)

- Bulletin DTB145PM63BDokument2 SeitenBulletin DTB145PM63BDanielAlejandroRamosQueroNoch keine Bewertungen

- Saft+Uptimax+TM en 0918 Rev3Dokument15 SeitenSaft+Uptimax+TM en 0918 Rev3vanessa quispeNoch keine Bewertungen

- Hydraulics Sheet 5 Energy ADokument19 SeitenHydraulics Sheet 5 Energy AMohamed H AliNoch keine Bewertungen

- Catalogo Interuptor 220 KVDokument2 SeitenCatalogo Interuptor 220 KVRommel Augusto Arnica AguedoNoch keine Bewertungen

- 72PMI 2GNM110053 NewDokument2 Seiten72PMI 2GNM110053 NewJules LopezNoch keine Bewertungen

- 123-145 PM-B - 2GNM110004Dokument2 Seiten123-145 PM-B - 2GNM110004Prashant gaurNoch keine Bewertungen

- 72PM 33-200B PDFDokument2 Seiten72PM 33-200B PDFDanielAlejandroRamosQueroNoch keine Bewertungen

- Disjuntor 123-160 KV - ABBDokument2 SeitenDisjuntor 123-160 KV - ABBdmezzavillaNoch keine Bewertungen

- E30C - Globe Valves NewDokument20 SeitenE30C - Globe Valves NewTaha FaNoch keine Bewertungen

- 72PM 2GNM110001 NewDokument2 Seiten72PM 2GNM110001 NewmorrissubhashNoch keine Bewertungen

- American Meter.: HoneywellDokument4 SeitenAmerican Meter.: HoneywellRolando PradaNoch keine Bewertungen

- 72PM 2GNM110001 NewDokument2 Seiten72PM 2GNM110001 NewMahyar MashayekhiNoch keine Bewertungen

- Champion Screw Compressors 30-45Dokument6 SeitenChampion Screw Compressors 30-45Uroš VučkovićNoch keine Bewertungen

- Power Circuit Breaker 242 KV Type PMRI: The ABB Advantage - . .Dokument2 SeitenPower Circuit Breaker 242 KV Type PMRI: The ABB Advantage - . .Victor GuzmanNoch keine Bewertungen

- Viking Q4195 1Dokument14 SeitenViking Q4195 1arbiNoch keine Bewertungen

- GC Compressor Brochure 10-02-20Dokument6 SeitenGC Compressor Brochure 10-02-20arnoldbusaNoch keine Bewertungen

- Hoja Técnica Asco 2905 - 700 KW2905Dokument2 SeitenHoja Técnica Asco 2905 - 700 KW2905Hernán Peñafiel ReaNoch keine Bewertungen

- Ficha Técnica Conectores de TornilloDokument6 SeitenFicha Técnica Conectores de TornilloFernando Castillo HerreraNoch keine Bewertungen

- 154 Bettis Cba-Series CatalogDokument16 Seiten154 Bettis Cba-Series CatalogsebastianNoch keine Bewertungen

- Manejadora AhrDokument12 SeitenManejadora AhrIsrael ArceoNoch keine Bewertungen

- Technical Brochure: Submersible 4" Non-Clog Sewage PumpDokument4 SeitenTechnical Brochure: Submersible 4" Non-Clog Sewage PumpLisandro Torrealba MedranoNoch keine Bewertungen

- Aoscg10210series300 PDFDokument6 SeitenAoscg10210series300 PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- GG4195 MarkedDokument8 SeitenGG4195 MarkedRoshan ShanmughanNoch keine Bewertungen

- Power Circuit Breaker 121 KV Through 169 KV Type PM: Standard FeaturesDokument2 SeitenPower Circuit Breaker 121 KV Through 169 KV Type PM: Standard FeaturesVictor GuzmanNoch keine Bewertungen

- 121-169PM - 33-300BDokument2 Seiten121-169PM - 33-300BDanielAlejandroRamosQueroNoch keine Bewertungen

- Technical Data Manual: Vitodens 100-WDokument32 SeitenTechnical Data Manual: Vitodens 100-WRed SquerrelNoch keine Bewertungen

- RC 25 BrochureDokument4 SeitenRC 25 BrochureJuan Adres VelazquezNoch keine Bewertungen

- Viking Oil Pump 495 SeriesDokument2 SeitenViking Oil Pump 495 SeriesIkhwanEfendiNoch keine Bewertungen

- Tamco GV3NDokument15 SeitenTamco GV3NAnonymous j5apk2AumNoch keine Bewertungen

- BOMAFA Steam Conditioning ValvesDokument8 SeitenBOMAFA Steam Conditioning ValvesbagastcNoch keine Bewertungen

- Siemens Circuit Switcher BrochureDokument16 SeitenSiemens Circuit Switcher BrochureCarlos FernandezNoch keine Bewertungen

- KKI Series 1200 and 7200Dokument18 SeitenKKI Series 1200 and 7200Tabiquera Guadalupe Victoria Texcoco De Mora100% (1)

- 9617 Pressure SwitchDokument4 Seiten9617 Pressure SwitchargaNoch keine Bewertungen

- Catalogo Visa PDFDokument36 SeitenCatalogo Visa PDFDANE80Noch keine Bewertungen

- Lehw0067 01Dokument6 SeitenLehw0067 01majed al.madhajiNoch keine Bewertungen

- Manual Book Pompa 104G5Dokument7 SeitenManual Book Pompa 104G5Ardi 4791Noch keine Bewertungen

- Datasheet - GEGA - Slab - Torch Cutting - MAIL - enDokument12 SeitenDatasheet - GEGA - Slab - Torch Cutting - MAIL - en킹쿡Noch keine Bewertungen

- Brushless Servo Motors B SeriesDokument17 SeitenBrushless Servo Motors B SeriesAnonymous LJTck8PNoch keine Bewertungen

- West Europe Sourcing Priorities With SpecificationsDokument14 SeitenWest Europe Sourcing Priorities With SpecificationsAlaa AjajNoch keine Bewertungen

- PG Spec 18V2000DS1250 1130kVA 3B FC 50HzDokument4 SeitenPG Spec 18V2000DS1250 1130kVA 3B FC 50HzGerman E.Noch keine Bewertungen

- 11 BuyLog2013 PanelboardsDokument54 Seiten11 BuyLog2013 PanelboardsJuan Gervacio OrtegaNoch keine Bewertungen

- Triple Duty 1Dokument6 SeitenTriple Duty 1Diana Andreina Linarez ContrerasNoch keine Bewertungen

- MCS-SERI-G-J-K-L Spec SheetsDokument1 SeiteMCS-SERI-G-J-K-L Spec SheetsSyed Ali KhanNoch keine Bewertungen

- Jspl-Refilling StationDokument21 SeitenJspl-Refilling StationNaveen Kumar ChauhanNoch keine Bewertungen

- Ensemble Clapet Et VanneDokument4 SeitenEnsemble Clapet Et VannegwinnruNoch keine Bewertungen

- AOS Cyclone Mxi BTH English CANCG10210 - 0920 - CompressedDokument6 SeitenAOS Cyclone Mxi BTH English CANCG10210 - 0920 - CompressedMatteo TorresNoch keine Bewertungen

- PM 1360 Data SheetDokument8 SeitenPM 1360 Data SheetEzequiel Juarez BenítezNoch keine Bewertungen

- TFP1586 11 2023Dokument12 SeitenTFP1586 11 2023fassart.jNoch keine Bewertungen

- MANUAL (38 YCD) Condensing Unit Carrier.Dokument18 SeitenMANUAL (38 YCD) Condensing Unit Carrier.Carlos Manuel de la Hoz SerranoNoch keine Bewertungen

- GX and Baumann ValvesDokument25 SeitenGX and Baumann ValvesSATHISHKUMAR RNoch keine Bewertungen

- DM 300Dokument40 SeitenDM 300RicardoNoch keine Bewertungen

- Manejadora AHR Guia TecnicaDokument10 SeitenManejadora AHR Guia TecnicaJulio JumboNoch keine Bewertungen

- Gis PDFDokument27 SeitenGis PDFZaheer AhamedNoch keine Bewertungen

- PG Spec 12V2000DS890 820kVA 3B FC 50HzDokument4 SeitenPG Spec 12V2000DS890 820kVA 3B FC 50HzSilver SilverNoch keine Bewertungen

- Literature IND UD-SeriesDokument2 SeitenLiterature IND UD-SeriesSanjay OhriNoch keine Bewertungen

- Page 57Dokument1 SeitePage 57Abhishek ShatagopachariNoch keine Bewertungen

- Goulds 4ns Tech BrochureDokument4 SeitenGoulds 4ns Tech BrochureJaime FalconNoch keine Bewertungen

- K575a AvtronDokument2 SeitenK575a AvtronjithukshajiNoch keine Bewertungen

- Grid Code Compliance Monitoring Pfm300-Gcc: FeaturesDokument2 SeitenGrid Code Compliance Monitoring Pfm300-Gcc: Featuresvanessa quispeNoch keine Bewertungen

- IEEE STD 3004.8 - 2016: Protection & CoordinationDokument17 SeitenIEEE STD 3004.8 - 2016: Protection & Coordinationvanessa quispeNoch keine Bewertungen

- Catalog SIPROTEC 5 Protection PDFDokument330 SeitenCatalog SIPROTEC 5 Protection PDFcarlosNoch keine Bewertungen

- Iec61000-4-7 Vista PreviaDokument7 SeitenIec61000-4-7 Vista Previavanessa quispeNoch keine Bewertungen

- Subst A T Ion de Sign ManualDokument127 SeitenSubst A T Ion de Sign ManualVinothNoch keine Bewertungen

- Products For Modern Energy Grids: Integrated Advanced Cyber SecurityDokument8 SeitenProducts For Modern Energy Grids: Integrated Advanced Cyber Securityvanessa quispeNoch keine Bewertungen

- Abb Acs 600Dokument104 SeitenAbb Acs 600alexNoch keine Bewertungen

- A Comparative Study of IEC 76 and ANSI C57.12 On TransformersDokument9 SeitenA Comparative Study of IEC 76 and ANSI C57.12 On TransformersprasannamohandasNoch keine Bewertungen

- TP SeriesDokument3 SeitenTP SeriesPrasad KadamNoch keine Bewertungen

- Abb Acs 600Dokument104 SeitenAbb Acs 600alexNoch keine Bewertungen

- CG Industrial Product OverviewDokument12 SeitenCG Industrial Product Overviewvanessa quispeNoch keine Bewertungen

- Short Circuit Current RatingsDokument1 SeiteShort Circuit Current Ratingsvanessa quispeNoch keine Bewertungen

- Sural Bare AAACDokument8 SeitenSural Bare AAACAlejandro Ramirez BenitesNoch keine Bewertungen

- T26 Current Ratings GeneralDokument1 SeiteT26 Current Ratings Generalvanessa quispeNoch keine Bewertungen

- Aac SuralDokument8 SeitenAac Suralvanessa quispeNoch keine Bewertungen

- FP - A.1 - EGAT - Experience On Off-Line Partial Discharge Measurement For Hydrogenerator With Capacity of 280 MVADokument7 SeitenFP - A.1 - EGAT - Experience On Off-Line Partial Discharge Measurement For Hydrogenerator With Capacity of 280 MVAvanessa quispeNoch keine Bewertungen

- Saturn-HV Stationary Load Bank: Dimensions and Key FeaturesDokument1 SeiteSaturn-HV Stationary Load Bank: Dimensions and Key Featuresvanessa quispeNoch keine Bewertungen

- 01-G130 Chassis UnitsDokument12 Seiten01-G130 Chassis Unitsvanessa quispeNoch keine Bewertungen

- Core Influence On The Frequency Response Analysis (FRA) of Power Transformers Through The Finite Element MethodDokument14 SeitenCore Influence On The Frequency Response Analysis (FRA) of Power Transformers Through The Finite Element Methodvanessa quispeNoch keine Bewertungen

- InstallationSheetURLDokument6 SeitenInstallationSheetURLvanessa quispeNoch keine Bewertungen

- 2750 515-12en - 20160930Dokument44 Seiten2750 515-12en - 20160930vanessa quispeNoch keine Bewertungen

- Cadworx® Questions and AnswersDokument15 SeitenCadworx® Questions and AnswersAbbas RizviNoch keine Bewertungen

- 15 BlissDokument7 Seiten15 Blissvanessa quispeNoch keine Bewertungen

- Changes To Nfpa 70e 2015 11 19 14Dokument58 SeitenChanges To Nfpa 70e 2015 11 19 14vanessa quispeNoch keine Bewertungen

- Coordinacion Aislacion 60071 2 PDFDokument8 SeitenCoordinacion Aislacion 60071 2 PDFbelarminodionelNoch keine Bewertungen

- Tiastar Motor Control Center Integrated Drives Technical BrochureDokument4 SeitenTiastar Motor Control Center Integrated Drives Technical Brochurevanessa quispeNoch keine Bewertungen

- 18 Pulse MCC FlyerDokument2 Seiten18 Pulse MCC Flyervanessa quispeNoch keine Bewertungen

- App JDokument3 SeitenApp Jvanessa quispeNoch keine Bewertungen

- Industrial Automation Using PLCDokument29 SeitenIndustrial Automation Using PLCAditya JagannathanNoch keine Bewertungen

- Math 10 Week 3-4Dokument2 SeitenMath 10 Week 3-4Rustom Torio QuilloyNoch keine Bewertungen

- ICSE Class 10 Chemistry Sample Mock Paper Term 2 Exam 2021 22Dokument5 SeitenICSE Class 10 Chemistry Sample Mock Paper Term 2 Exam 2021 22dhruv sharmaNoch keine Bewertungen

- Emulsion LectureDokument30 SeitenEmulsion LectureRay YangNoch keine Bewertungen

- Contemporary Architecture Is The Architecture of The 21st Century. No Single Style Is DominantDokument2 SeitenContemporary Architecture Is The Architecture of The 21st Century. No Single Style Is DominantShubham DuaNoch keine Bewertungen

- ZEROPAY WhitepaperDokument15 SeitenZEROPAY WhitepaperIlham NurrohimNoch keine Bewertungen

- Summer Internship Project Report ANALYSIDokument60 SeitenSummer Internship Project Report ANALYSIKshitija KudacheNoch keine Bewertungen

- Temperature Measurement: Temperature Assemblies and Transmitters For The Process IndustryDokument32 SeitenTemperature Measurement: Temperature Assemblies and Transmitters For The Process IndustryfotopredicNoch keine Bewertungen

- LUNG ARTIFACTSreviewDokument13 SeitenLUNG ARTIFACTSreviewMayra ValderramaNoch keine Bewertungen

- P&CDokument18 SeitenP&Cmailrgn2176Noch keine Bewertungen

- Unwrapping The StandardsDokument2 SeitenUnwrapping The Standardsapi-254299227100% (1)

- Army Public School No.1 Jabalpur Practical List - Computer Science Class - XIIDokument4 SeitenArmy Public School No.1 Jabalpur Practical List - Computer Science Class - XIIAdityaNoch keine Bewertungen

- Trox Quick Selection GuideDokument47 SeitenTrox Quick Selection GuideErwin LouisNoch keine Bewertungen

- Rizal Noli Me TangereDokument35 SeitenRizal Noli Me TangereKristine Cantilero100% (2)

- Assignment OSDokument11 SeitenAssignment OSJunaidArshadNoch keine Bewertungen

- Dial 1298 For Ambulance - HSBCDokument22 SeitenDial 1298 For Ambulance - HSBCDial1298forAmbulanceNoch keine Bewertungen

- Bethelhem Alemayehu LTE Data ServiceDokument104 SeitenBethelhem Alemayehu LTE Data Servicemola argawNoch keine Bewertungen

- System Administration ch01Dokument15 SeitenSystem Administration ch01api-247871582Noch keine Bewertungen

- GDCR - Second RevisedDokument290 SeitenGDCR - Second RevisedbhaveshbhoiNoch keine Bewertungen

- The Life Cycle of Brent FieldDokument21 SeitenThe Life Cycle of Brent FieldMalayan AjumovicNoch keine Bewertungen

- PTD30600301 4202 PDFDokument3 SeitenPTD30600301 4202 PDFwoulkanNoch keine Bewertungen

- Project - Dreambox Remote Video StreamingDokument5 SeitenProject - Dreambox Remote Video StreamingIonut CristianNoch keine Bewertungen

- Artificial Intelligence and Expert Systems: Management Information Systems, 4 EditionDokument27 SeitenArtificial Intelligence and Expert Systems: Management Information Systems, 4 Editionabhi7219Noch keine Bewertungen

- Luxi User's GuideDokument14 SeitenLuxi User's GuidephilsouthNoch keine Bewertungen

- Kübra Şendoğan CVDokument5 SeitenKübra Şendoğan CVKübra ŞendoğanNoch keine Bewertungen

- Encephalopathies: Zerlyn T. Leonardo, M.D., FPCP, FPNADokument50 SeitenEncephalopathies: Zerlyn T. Leonardo, M.D., FPCP, FPNAJanellee DarucaNoch keine Bewertungen

- A Database For Handwritten Text Recognition ResearchDokument5 SeitenA Database For Handwritten Text Recognition Researchtweety492Noch keine Bewertungen

- 11 - Chapter 3Dokument27 Seiten11 - Chapter 3sam000678Noch keine Bewertungen