Beruflich Dokumente

Kultur Dokumente

Astm G 41 1990 R 2006 PDF

Hochgeladen von

JORGE ARTURO TORIBIO HUERTAOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Astm G 41 1990 R 2006 PDF

Hochgeladen von

JORGE ARTURO TORIBIO HUERTACopyright:

Verfügbare Formate

Designation: G 41 90 (Reapproved 2006)

Standard Practice for

Determining Cracking Susceptibility of Metals Exposed

Under Stress to a Hot Salt Environment1

This standard is issued under the fixed designation G 41; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1141 Practice for the Preparation of Substitute Ocean

1.1 This practice covers procedures for testing metals for Water

embrittlement and cracking susceptibility when exposed under D 1193 Specification for Reagent Water

stress to a hot salt environment. This practice can be used for G 1 Practice for Preparing, Cleaning, and Evaluating Cor-

testing all metals for which service conditions dictate the need rosion Test Specimens

for such information. The test procedures described herein are G 30 Practice for Making and Using U-Bend Stress-

generally applicable to all metal alloys; required adjustments in Corrosion Test Specimens

environmental variables (temperature, stress) to characterize a G 38 Practice for Making and Using C-Ring Stress-

given materials system should be made. This practice describes Corrosion Test Specimens

the environmental conditions and degree of control required, G 39 Practice for Preparation and Use of Bent-Beam Stress-

and suggests means for obtaining this desired control. Corrosion Test Specimens

1.2 This practice can be used both for alloy screening for G 49 Practice for Preparation and Use of Direct Tension

determination of relative susceptibility to embrittlement and Stress-Corrosion Test Specimens

cracking, and for the determination of time-temperature-stress 3. Summary of Practice

threshold levels for onset of embrittlement and cracking.

However, certain specimen types are more suitable for each of 3.1 The hot salt test consists of exposing a stressed, salt-

these two types of characterizations. coated test specimen to elevated temperature for various

predetermined lengths of time, depending on the alloy, stress

NOTE 1This practice relates solely to the performance of the exposure level, temperature, and selected damage criterion (that is,

test. No detailed description concerning preparation and analysis of

embrittlement, cracking, or rupture, or a combination thereof).

specimen types is offered. However, the optimum sample design may be

one that uses the same type of stress encountered in service loading Exposures are normally carried out in laboratory ovens or

situations. Standards describing principal types of stress corrosion speci- furnaces with associated loading equipment for stressing of

mens, their preparation, and analysis, include Practices G 30, G 38, and specimens.

G 39. 3.2 The ovens are provided with facilities to circulate air at

1.3 This standard does not purport to address all of the various flow rates and ambient pressure. However, for certain

safety concerns, if any, associated with its use. It is the specific applications, airflow and pressure may be adjusted to

responsibility of the user of this standard to establish appro- obtain information on material behavior in simulated service

priate safety and health practices and determine the applica- environments. Exposure temperatures and stress levels are

bility of regulatory limitations prior to use. (For more specific generally selected on the basis of mechanical property data for

safety hazard statements see Section 8.) a given alloy, or of expected service conditions, or both.

--````,``,,,`,````,,`,`,,,`,``,-`-`,,`,,`,`,,`---

2. Referenced Documents 4. Significance and Use

2.1 ASTM Standards: 2 4.1 The hot salt test as applied to metals is utilized as a

secondary design consideration indicator, as cracking has been

shown to occur in laboratory tests simulating possible service

1

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion conditions. Although limited evidence exists linking this phe-

of Metals and is the direct responsibility of Subcommittee G01.06 on Environmen- nomenon to actual service failures, cracking under stress in a

tally Assisted Cracking.

Current edition approved Nov. 1, 2006. Published December 2006. Originally hot salt environment should be recognized as a potential design

approved in 1974. Last previous edition approved in 2000 as G 41 90 (2000). controlling factor.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standards Document Summary page on

the ASTM website.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Provided by IHS under license with ASTM Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Mendez, Fernan

No reproduction or networking permitted without license from IHS Not for Resale, 12/21/2006 16:18:05 MST

G 41 90 (2006)

4.2 The hot salt test is not to be misconstrued as being If an as-received surface condition is to be investigated, efforts

related to the stress corrosion cracking of materials in other should be made to ascertain the state of residual stress as

environments. It is considered solely as a test in an environ- regards the material surface. Both magnitude and algebraic

ment that might be encountered in service. sign (tension or compression) of residual stress should be

4.3 Because hot salt cracking under stress is considered a determined and reported if possible. Chemical milling can be

secondary design consideration and service failures have not employed in final surface preparation in order to avoid extra-

been attributed solely to this phenomenon, manufacturing neous surface effects. However, care should be taken to ensure

processes will be optimized or alloying changes will be made that proper chemical milling techniques are employed, and that

only after consideration is given to primary design factors such hydrogen uptake does not occur during the surface preparation.

as creep resistance of a given high temperature alloy. The

usefulness of the test lies rather in limiting maximum operating 6. Apparatus

temperatures and stress levels or categorizing different alloys 6.1 Apparatus for Salt CoatingA conventional air brush

as to susceptibility, or both, if it is found that hot salt damage should be used for spraying the specimens to accomplish the

may accelerate failure by creep, fatigue, or rupture. salt-coating procedure. This will generally provide a thin

4.4 Finally, the test does not lend itself to the utilization of uniform salt deposition of the desired density.

pre-cracked specimens because cracking reinitiates at any 6.2 Apparatus for Conducting Exposure Test:

salt-metal-air interface, resulting generally in many small 6.2.1 Apparatus required for conducting the exposure test

cracks which extend independently. For this reason, specimens depends on the selection of the specimen type to be used. If a

that are recommended for utilization in routine testing are of constant-deflection type specimen is utilized for which no

the smooth specimen category. external loading requirement exists, conventional laboratory

ovens are suitable for conducting the exposure test. Provision

5. Interferences for controlling or monitoring inlet air humidity is recom-

5.1 Hot salt cracking under stress is often considered a mended.

hydrogen-related phenomenon, and the source of hydrogen is a 6.2.1.1 Specimen Holders, suitable for applying stress to

corrosion reaction involving moisture, available either from the constant-deflection type specimens should be made of the same

hydrated salt, trapped as fluid inclusions in nonhydrated salt, or or a similar alloy as the material to be tested in order to avoid

from humidity in the test atmosphere if absent in the salt galvanic effects. The requirement for the use of a fixture to

crystals. Because of this fact, considerable variation in test apply stress can be avoided when testing sheet materials by

results can be obtained, simply from the method of salt utilizing a self-stressed specimen design.3

deposition on the test specimen, even when effective controls 6.2.1.2 Racks, suitable for supporting specimens in the oven

on other test variables are realized. Efforts should be made to and for transferring specimens should be made of the same or

--````,``,,,`,````,,`,`,,,`,``,-`-`,,`,,`,`,,`---

standardize the salt deposition techniques and to control or a similar alloy as the material to be tested. Open circuit

monitor humidity in order to achieve desired test validity. conditions should be maintained, although galvanic effects are

5.2 The effects of cycling time at temperature to achieve a considered to be highly localized on the surface.

given total cumulative exposure have been shown to have a 6.2.2 If a constant-deflection type specimen is utilized, care

significant effect on test results, with shorter cycle duration and must be taken to either avoid or take into account differences

greater cycle frequency generally resulting in less damage for in thermal expansion between test specimen and test fixture.

the same cumulative exposure time. For this reason, selection Thermal expansion differences can substantially change the

between continuous and cyclic exposure, duration, and fre- stress level applied at ambient temperature when specimens are

quency of cycling, and heating and cooling rates must be made heated to the test temperature.

with the end purpose of the test in mind. 6.2.3 If a constant-load type specimen is to be utilized,

5.3 Variations in heat to heat or product forms, or both, have provision must be made to combine both heating and loading

been shown to have a significant effect on damage thresholds equipment. Vertical-tube resistance-wound furnaces can be

determined from experimental testing. This effect may be more utilized with dead-weight loading or conventional creep frame

pronounced than is observed in more conventional stress equipment for low and high loading conditions, respectively

corrosion testing of the aqueous type. For this reason, it is (Note 2). Direct induction or resistance heating of the specimen

important to obtain and document to the fullest extent possible itself is not recommended.

all certified analyses and tests associated with the material to be NOTE 2When using vertical-tube furnaces care must be taken to

tested and associated fabrication and treatment histories. Inter- avoid a chimney effect through the furnace, which could result in

stitial concentration levels, chemical contaminants, and ther- excessive airflow and uneven temperature distribution along the specimen

momechanical processing should be included in the documen- length. Sealing at both ends will allow control of air flow and improve

tation (see Section 12). temperature distribution within the furnace.

5.4 Details regarding general surface preparation and use of

7. Reagents and Materials

bent-beam stress-corrosion specimens are outlined in Practice

G 39. Procedures for making and using direct tension stress- 7.1 Reagent grade salts shall be used when preparing

corrosion specimens is described in Practice G 49. However, solutions from which the salt coating is derived. Sodium

because of the highly localized nature of onset of attack at the

surface in hot salt exposure testing, it is desirable to charac- 3

See A Stress Corrosion Test for Structural Sheet Materials, Materials

terize as fully as possible the surface condition of the material. Research and Standards, Vol 5, No. 1, January 1965, pp. 1822.

Copyright ASTM International 2

Provided by IHS under license with ASTM Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Mendez, Fernan

No reproduction or networking permitted without license from IHS Not for Resale, 12/21/2006 16:18:05 MST

G 41 90 (2006)

chloride (NaCl) should be used for routine testing. Other salts considered as a potential cause of data scatter. In tests for

that may be encountered in service can be used for specialized ascertaining the effects of humidity on cracking behavior,

applications. Synthetic sea water (Note 3), should be used for moisture levels can be adjusted by mixing various ratios of

characterizing alloys for use in marine environments. saturated and dry air to oven or furnace air inlet. Sampling of

dew point at oven or furnace inlet will allow determination of

NOTE 3If tests are to be conducted on specimens with salt deposits

derived from substitute ocean water, solutions should be prepared in humidity of the air at ambient conditions.

accordance with Specification D 1141. 9.4 AirflowCare must be taken to prevent airflow veloci-

ties beyond that achieved in recirculating ovens (30 to 120

7.2 Purity of WaterUnless otherwise indicated, references

m/min (100 to 400 ft/min)). Variations in this factor have been

to water shall be understood to mean Type IV water prepared

shown to produce differences in test results. If airflow is an

in accordance with Specification D 1193.

experimental variable to be investigated, it should be con-

8. Hazards trolled and monitored.

8.1 Shatterproof glasses with side shields should be worn 10. Procedure

when handling and examining stressed samples. Generally the

required safety equipment is similar to that used for conducting 10.1 Cleaning of SpecimensBefore salt coating, thor-

routine mechanical tests. oughly clean the specimens to remove all identification mark-

8.2 Appropriate heat-resistant equipment, for example, ings, grease, oil, or other hydrocarbon contaminants. Speci-

gloves, may be required when exposing test samples to high mens may be cleaned in a variety of cleaning media, but end

temperatures. the cleaning procedure with a hot and cold water rinse. Do not

clean the specimens with chlorinated hydrocarbons such as

9. Calibration and Standardization trichloroethylene because these compounds can chemisorb,

and decompose after heating, which will affect exposure test

9.1 When conducting elevated temperature exposure tests,

results. Information contained in Practice G 1 on clearing

determination of the temperature profile within the oven or

methods may be utilized where appropriate.

furnace should be made, including temperature sampling along

10.2 Salt Coating of Specimens:

the width, depth, and height of the hot zone to ensure that

10.2.1 Salt coat the specimens in such a manner as to

temperatures within all locations of specimen exposure are

provide many small separate particles. This is best accom-

within prescribed limits. Deviation from the desired test

plished by preparing a salt solution for spraying the specimens.

temperature should not be more than 62 % of the absolute

The concentration of the salt solution should provide a reason-

temperature.

able salt deposit for each spray-drying cycle. The 3.5 % salt

9.1.1 Temperature control of the exposure test shall be

solution has been shown to produce very satisfactory results

accomplished by determining true specimen temperature. This

and, because of its widespread use in other tests, is arbitrarily

can be done by means of affixing a thermocouple of appropri-

selected as a baseline for the test described herein.

ate sensitivity for the temperature range to be investigated onto

10.2.2 Spray the specimens with the prepared solution by a

a control specimen either by spotwelding or mechanical

means that provides atomization of the solution and uniform

fastening. In either instance it must be determined that the

coverage of the test specimen. A conventional air brush will

technique of thermocouple fastening does not introduce any

provide satisfactory results. Spray specimens horizontally to

interference effects.

minimize run-off prior to drying. Specimens are normally

9.2 The degree of control required on the applied stress of a

sprayed on the surface(s) that is or will be stressed in tension

test specimen depends on the nature and purpose of the test.

during the exposure. Spray constant-deflection type specimens

When determining threshold values of time-temperature-stress

after stressing so that salt deposits do not spall off during the

for onset of embrittlement or cracking for a given alloy as a

stressing operation. After spraying, dry the specimens in a

secondary design consideration, control should be more strin-

humidity- and temperature-controlled atmosphere. Tempera-

gent than that for indication of trends or determination of

ture selection for the drying cycle should be based on the salt

relative material susceptibilities.

composition utilized. Generally, higher drying temperatures

9.2.1 In determining threshold values for onset of embrittle-

will result in less water entrapment within the crystal. Desired

ment or cracking, constant-load type specimens, for which the

salt densities can be accomplished by repetitive spray-drying

level of applied stress can be more tightly controlled, are

cycles. Salt densities in the range from 0.155 to 155 g/m2 (0.1

recommended. Deviation from the desired target stress level

to 100 mg/in.2) are reasonable minimum and maximum levels,

should not be more than 62 %.

respectively (Note 4). For routine testing and materials screen-

9.2.2 When utilizing constant-deflection type specimens for

ing, utilize a salt coating of 15.5 g/m2 (10 mg/in.2).

the determination of behavior trends or relative material

susceptibilities, specimen geometry should be limited such that NOTE 4Cracking initiates at salt-metal-air interfaces on the surface of

control of the applied stress level can be maintained within a test specimen. Because of this fact, the distribution and size of salt

610 % of the desired stress level. particles can play a significant role in the incidence of cracking and the

time to stress rupture. Larger salt particles may result in fewer cracks

9.3 Humidity ControlFor routine testing, active control of initiating which may, in turn, affect time to stress rupture. If the salt

humidity is not considered mandatory. Most testing is accom- coating is dry and continuous such that the atmosphere cannot reach the

plished using ambient laboratory air. However, daily monitor- salt-metal interface, cracking will not initiate. An example of such a

ing and recording of humidity should be made and humidity situation would be in the application of a thicker paste type of salt coating

--````,``,,,`,````,,`,`,,,`,``,-`-`,,`,,`,`,,`---

Copyright ASTM International 3

Provided by IHS under license with ASTM Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Mendez, Fernan

No reproduction or networking permitted without license from IHS Not for Resale, 12/21/2006 16:18:05 MST

G 41 90 (2006)

which may not produce cracking within the test section at all. It is based tion and a general reduction in failure load (compared to

on this explanation that the method of application and coating density control specimens which were not salt coated), or by the

limits were selected. Efforts should be made to document salt film decrease in strength and elongation and the appearance of

appearance as well as to record the density in order to fully characterize

test conditions.

numerous small cracks in the vicinity of the primary fracture of

the test specimens. The former indicator is generally observed

10.3 Exposure: in slow strain-rate testing prior to time for actual cracking to

10.3.1 After salt coating, expose the specimens to the occur. By stepwise reduction of exposure duration, tempera-

desired test temperature for a predetermined exposure time. ture, or stress, or a combination thereof, thresholds can be

The temperature range of investigation is from 230 to 540C determined for the desired range of exposure conditions for a

(450 to 1000F). Most of the testing is accomplished at the given material.

expected service temperature. If the specimens are of the 11.2 When a constant-deflection type specimen is utilized

constant-deflection type, insert them into the laboratory oven, (for example, a bent-beam specimen), the subsequent room

which should be at test temperature before insertion (Note 5). temperature test should be a bending test with the bend radius

Remove the specimens from the oven and allow to air cool to located in the test section of the specimen. When a constant-

ambient temperature before examination or recycling. load type specimen is utilized (for example, a direct tension

10.3.2 If the specimens are of the constant-load type, place specimen), the subsequent room-temperature test should be a

them in the test furnace, seal for necessary atmosphere control, conventional tension test of the specimen to determine residual

and bring to test temperature before loading. Begin the mechanical properties of the specimen. However, strain rate

duration of the exposure test following specimen loading. should be kept constant at 0.005/min throughout the test.

Unload the specimens following the desired exposure time 11.3 Following the subsequent room-temperature testing,

interval (if less than time to rupture is desired) and allow to specimens should be examined visually or at low-power

cool with furnace power off and end seals removed prior to magnification (103 to 1003), or by both methods, to verify

examination or recycling. Keep the time for heat-up and that failure or damage was caused by exposure under stress to

cool-down as short as possible and note as a potential source of hot salt. Cracks may be small and will often emanate from a

data scatter. salt crystal. If cracks are heat tinted, they occurred during the

NOTE 5When utilizing constant-deflection type specimens for el- exposure. If they are not, they occurred during subsequent

evated temperature testing, exercise caution to ensure that excessive stress testing but still may be attributed to exposure damage. Salt

relaxation of the specimens does not occur. This can be determined by crystals, however, often spall off during the subsequent room-

exposure of control specimens (generally not salt coated) along with the temperature test in the areas of greatest damage because of

test specimens and examination of control specimens after exposure by high levels of strain in those areas. Fracture surfaces may also

unloading and observing whether or not permanent deformation of the

be examined using various fractography techniques to ascertain

specimen has occurred. Stress level of control specimens after exposure

can also be determined by measurement of stress using X-ray techniques. the extent of area on the fracture surface affected by the hot

Both of these methods have been shown to effectively indicate stress salt. Any unusual failures or test anomalies should be carefully

relaxation. scrutinized to ascertain failure cause and determine whether or

not associated data shall or shall not be included in the report.

10.4 Exposure DurationDetermine the exposure duration

by the inherent resistance of the alloy tested, the specimen 12. Report

configuration and dimensions, and the desired criterion to be 12.1 It is recommended the following information be in-

used as the damage indicator. For instance, the time to cluded in the report of the test results:

complete rupture of the specimen will always be longer than 12.1.1 Identification and composition of the alloy, hardness

the time for initiation of cracking, which in turn will be longer and grain size.

than time for embrittlement of the material to occur. All three 12.1.2 The alloy heat, mill product form, and heat treatment

factors may be used as criteria for failure. However, embrittle- of material tested, including the specification to which the

ment and cracking are considered more appropriate from a parent material was prepared.

design consideration standpoint. Appropriate exposure periods 12.1.3 Detailed producer-certified chemical and mechanical

can be determined by trial and error at a given test temperature property analysis of the lot of material tested. This is manda-

by high initial loadings, which will result in shorter exposure tory for materials characterization, and desirable for qualifying

times to failure or damage. Subsequent tests can be conducted a given batch of material for service.

--````,``,,,`,````,,`,`,,,`,``,-`-`,,`,,`,`,,`---

at lower stress levels for longer exposure times. Exposure 12.1.4 Location and orientation of specimens tested.

times can also be determined from expected service conditions 12.1.5 Specimen details; type and dimensions. See Practices

if simulation of service application is desired. G 30, G 38, G 39, and G 49 for details regarding specimen

types, fabrication, and analysis.

11. Interpretation of Results 12.1.6 Specimen cleaning procedures and surface condition

11.1 The interpretation of results will vary with the type of of specimen, including special surface treatments.

specimen utilized. Generally, cracks will not be visible on 12.1.7 Type of salt coating, density, and method of applica-

specimens after exposure if the exposure has been terminated tion, including documentation of drying-cycle temperature and

prior to stress rupture. However, if specimens are subsequently humidity control or monitoring, or both, and documentation of

tested in tension or bending at room temperature following the salt crystal distribution and appearance.

exposure test, damage will become evident either by elonga- 12.1.8 Details of the Exposure Test:

Copyright ASTM International 4

Provided by IHS under license with ASTM Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Mendez, Fernan

No reproduction or networking permitted without license from IHS Not for Resale, 12/21/2006 16:18:05 MST

G 41 90 (2006)

12.1.8.1 Exposure temperature, time, and stress level of test 12.1.12 Supporting information derived either visually or

specimens. metallurgically, from post-test examination, which will aid the

12.1.8.2 Whether exposure was continuous or cyclic, and potential receiver in the understanding of the behavior of the

details of the type of cycles used. material tested.

12.1.8.3 Statement on humidity control and monitoring.

12.1.9 Details of subsequent room-temperature testing. 13. Keywords

12.1.10 Notation of any deviations in the test procedure

from that set forth as described herein. 13.1 hot (230540C) salt simulated service environment;

12.1.11 The number of specimens tested per condition and laboratory test; sodium chloride coated stressed specimens

the range of scatter in the test results.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--````,``,,,`,````,,`,`,,,`,``,-`-`,,`,,`,`,,`---

Copyright ASTM International 5

Provided by IHS under license with ASTM Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Mendez, Fernan

No reproduction or networking permitted without license from IHS Not for Resale, 12/21/2006 16:18:05 MST

Das könnte Ihnen auch gefallen

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingVon EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNoch keine Bewertungen

- Determining Cracking Susceptibility of Metals Exposed Under Stress To A Hot Salt EnvironmentDokument5 SeitenDetermining Cracking Susceptibility of Metals Exposed Under Stress To A Hot Salt Environmentmohammed karasnehNoch keine Bewertungen

- Astm G-41Dokument5 SeitenAstm G-41Alper BasNoch keine Bewertungen

- Astm G 111 1997 R 2006 PDFDokument5 SeitenAstm G 111 1997 R 2006 PDFJORGE ARTURO TORIBIO HUERTA100% (1)

- Oil and Gas Corrosion Prevention: From Surface Facilities to RefineriesVon EverandOil and Gas Corrosion Prevention: From Surface Facilities to RefineriesBewertung: 5 von 5 Sternen5/5 (6)

- Astm G 39 1999 R 2005 PDFDokument8 SeitenAstm G 39 1999 R 2005 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- Brittle Fracture in Steel StructuresVon EverandBrittle Fracture in Steel StructuresG.M. BoydNoch keine Bewertungen

- ASTM G4 - 01 (Reapproved 2008)Dokument9 SeitenASTM G4 - 01 (Reapproved 2008)Sofia YuliNoch keine Bewertungen

- Astm G39-99 (2016)Dokument8 SeitenAstm G39-99 (2016)cenando100% (1)

- Preparation and Use of Bent-Beam Stress-Corrosion Test SpecimensDokument8 SeitenPreparation and Use of Bent-Beam Stress-Corrosion Test SpecimensmgarayamNoch keine Bewertungen

- Astm G39-99-2021Dokument8 SeitenAstm G39-99-2021hashem Al-NasserNoch keine Bewertungen

- G 129 - 00 (2013)Dokument7 SeitenG 129 - 00 (2013)Pavan KumarNoch keine Bewertungen

- Norma ASTM G1.1207483-1Dokument9 SeitenNorma ASTM G1.1207483-1Laisa Candido Maia100% (1)

- Astm G1 - 03 - Evaluating Corrossion PDFDokument9 SeitenAstm G1 - 03 - Evaluating Corrossion PDFVasu RajaNoch keine Bewertungen

- Corrosion Tests in High Temperature or High Pressure Environment, or BothDokument5 SeitenCorrosion Tests in High Temperature or High Pressure Environment, or Bothvuqar0979Noch keine Bewertungen

- Astm B117 PDFDokument11 SeitenAstm B117 PDFAndres Fitria FarrelNoch keine Bewertungen

- ASTM G35 - 98 (Reapproved 2010)Dokument3 SeitenASTM G35 - 98 (Reapproved 2010)Ali Ali Asjari100% (1)

- Astm G-4-2008 Corrosion Test in Field Applic PDFDokument9 SeitenAstm G-4-2008 Corrosion Test in Field Applic PDFMaria Clara Pinto CruzNoch keine Bewertungen

- Slow Strain Rate Testing To Evaluate The Susceptibility of Metallic Materials To Environmentally Assisted CrackingDokument7 SeitenSlow Strain Rate Testing To Evaluate The Susceptibility of Metallic Materials To Environmentally Assisted CrackingSandeep BhatiaNoch keine Bewertungen

- Preparation and Use of Direct Tension Stress-Corrosion Test SpecimensDokument6 SeitenPreparation and Use of Direct Tension Stress-Corrosion Test SpecimensCristian DíazNoch keine Bewertungen

- Operating Salt Spray (Fog) Apparatus: Standard Practice ForDokument11 SeitenOperating Salt Spray (Fog) Apparatus: Standard Practice ForakmlogaNoch keine Bewertungen

- Astm G49-85 (2019)Dokument6 SeitenAstm G49-85 (2019)damaso taracena100% (1)

- Ensayo-De-Corrosion-Bajo-Esfuerzos-De-Flexion. G 39-99 PDFDokument7 SeitenEnsayo-De-Corrosion-Bajo-Esfuerzos-De-Flexion. G 39-99 PDFSantiago RubioNoch keine Bewertungen

- Exposure of Metals and Alloys by Alternate Immersion in Neutral 3.5 % Sodium Chloride SolutionDokument5 SeitenExposure of Metals and Alloys by Alternate Immersion in Neutral 3.5 % Sodium Chloride Solutionjose floresNoch keine Bewertungen

- Astm G 157 1998 R-2005 PDFDokument6 SeitenAstm G 157 1998 R-2005 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- ASTM G1 90 1999 E1Dokument4 SeitenASTM G1 90 1999 E1NettyNoch keine Bewertungen

- Astm GDokument9 SeitenAstm GAjesh kumarNoch keine Bewertungen

- Astm B117Dokument11 SeitenAstm B117kashif ehsanNoch keine Bewertungen

- Preparation and Use of Direct Tension Stress-Corrosion Test SpecimensDokument6 SeitenPreparation and Use of Direct Tension Stress-Corrosion Test SpecimensHadi HowaidaNoch keine Bewertungen

- Astm G 47 - 98 - RZQ3LTK4Dokument6 SeitenAstm G 47 - 98 - RZQ3LTK4Samuel EduardoNoch keine Bewertungen

- Astm G44Dokument5 SeitenAstm G44Ridho D'Boice100% (1)

- Determination of Susceptibility of Metals To Embrittlement in Hydrogen Containing Environments at High Pressure, High Temperature, or BothDokument8 SeitenDetermination of Susceptibility of Metals To Embrittlement in Hydrogen Containing Environments at High Pressure, High Temperature, or BothShikhar KhatriNoch keine Bewertungen

- ASTM-G4 - Guide For Conducting Corrosion Coupon PDFDokument9 SeitenASTM-G4 - Guide For Conducting Corrosion Coupon PDFFelix CruzNoch keine Bewertungen

- Conducting Corrosion Tests in Field Applications: Standard Guide ForDokument9 SeitenConducting Corrosion Tests in Field Applications: Standard Guide ForZabihullah SafiNoch keine Bewertungen

- Conducting Corrosion Tests in Field Applications: Standard Guide ForDokument9 SeitenConducting Corrosion Tests in Field Applications: Standard Guide ForAries MarteNoch keine Bewertungen

- Astm G 123 - 00 - RzeymwDokument11 SeitenAstm G 123 - 00 - RzeymwSamuel EduardoNoch keine Bewertungen

- G031 PDFDokument8 SeitenG031 PDFManuel ContrerasNoch keine Bewertungen

- Astm - G168.12911Dokument10 SeitenAstm - G168.12911Bryan de BarrosNoch keine Bewertungen

- Astm G 36 1994 R 2006 PDFDokument6 SeitenAstm G 36 1994 R 2006 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- Astm G32Dokument16 SeitenAstm G32GilmarBosNoch keine Bewertungen

- Astm G 4 - 95 - RzqtotuDokument9 SeitenAstm G 4 - 95 - RzqtotuCordova RaphaelNoch keine Bewertungen

- Evaluating Stress-Corrosion-Cracking Resistance of Metals and Alloys in A Boiling Magnesium Chloride SolutionDokument7 SeitenEvaluating Stress-Corrosion-Cracking Resistance of Metals and Alloys in A Boiling Magnesium Chloride Solutionmohammed karasnehNoch keine Bewertungen

- Astm G 37 - 98 R04 - RZM3Dokument4 SeitenAstm G 37 - 98 R04 - RZM3Cordova RaphaelNoch keine Bewertungen

- ASTM G31-1972 Standard Practice For Lab Immersion CorrosionDokument8 SeitenASTM G31-1972 Standard Practice For Lab Immersion CorrosionPlinio Lavinas100% (1)

- ASTM G31-72 - Laboratory Immersion Corrosion Testing of MetalsDokument8 SeitenASTM G31-72 - Laboratory Immersion Corrosion Testing of Metalsnengsintanovita100% (17)

- G 31 - 72 r99 Rzmxltcyujk5Dokument8 SeitenG 31 - 72 r99 Rzmxltcyujk5Catia Julie AuliaNoch keine Bewertungen

- Determining Susceptibility To Stress-Corrosion Cracking of 2XXX and 7XXX Aluminum Alloy ProductsDokument6 SeitenDetermining Susceptibility To Stress-Corrosion Cracking of 2XXX and 7XXX Aluminum Alloy Productsmohammed karasnehNoch keine Bewertungen

- Making and Using Precracked Double Beam Stress Corrosion SpecimensDokument10 SeitenMaking and Using Precracked Double Beam Stress Corrosion Specimens秦川Noch keine Bewertungen

- ASTM B 117-03 - Salt SprayDokument10 SeitenASTM B 117-03 - Salt SprayDouglas RodriguesNoch keine Bewertungen

- Evaluating Stress-Corrosion Cracking Resistance of Low Copper 7XXX Series Al-Zn-Mg-Cu Alloys in Boiling 6 % Sodium Chloride SolutionDokument4 SeitenEvaluating Stress-Corrosion Cracking Resistance of Low Copper 7XXX Series Al-Zn-Mg-Cu Alloys in Boiling 6 % Sodium Chloride Solutionjose floresNoch keine Bewertungen

- Astm G47Dokument6 SeitenAstm G47brunodrNoch keine Bewertungen

- Determining The Susceptibility of Stainless Steels and Related Nickel-Chromium-Iron Alloys To Stress-Corrosion Cracking in Polythionic AcidsDokument3 SeitenDetermining The Susceptibility of Stainless Steels and Related Nickel-Chromium-Iron Alloys To Stress-Corrosion Cracking in Polythionic AcidsIvan AlanizNoch keine Bewertungen

- Making and Using U-Bend Stress-Corrosion Test Specimens: Standard Practice ForDokument7 SeitenMaking and Using U-Bend Stress-Corrosion Test Specimens: Standard Practice ForHadi HowaidaNoch keine Bewertungen

- A 923 - 01 Qtkymy0wmqDokument7 SeitenA 923 - 01 Qtkymy0wmqPRASANTH PRASANTHNoch keine Bewertungen

- Corrosion Testing of Products of Zirconium, Hafnium, and Their Alloys in Water at 633°K or in Steam at 673°K (Metric)Dokument8 SeitenCorrosion Testing of Products of Zirconium, Hafnium, and Their Alloys in Water at 633°K or in Steam at 673°K (Metric)Carlos Olivares ZegarraNoch keine Bewertungen

- Astm B 117 16 PDFDokument12 SeitenAstm B 117 16 PDFsingaravelan narayanasamyNoch keine Bewertungen

- Astm b0117Dokument10 SeitenAstm b0117Anjali AnjuNoch keine Bewertungen

- B 117 - 03 Qjexnw - PDFDokument10 SeitenB 117 - 03 Qjexnw - PDFMourad SeloughaNoch keine Bewertungen

- Astm e 797 PDFDokument7 SeitenAstm e 797 PDFrazormebackNoch keine Bewertungen

- Astm e 648 Rev A 2006 PDFDokument14 SeitenAstm e 648 Rev A 2006 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- Astm E164 19Dokument11 SeitenAstm E164 19JORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- E 631 - 93a (Reapproved 1998) E1 Standard Terminology of Building Constructions1 PDFDokument46 SeitenE 631 - 93a (Reapproved 1998) E1 Standard Terminology of Building Constructions1 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- Astm E682-92 R00 PDFDokument8 SeitenAstm E682-92 R00 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- Astm e 516 Rev A 1995 R 2005 PDFDokument10 SeitenAstm e 516 Rev A 1995 R 2005 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- Astm e 502 Rev A 2006 PDFDokument6 SeitenAstm e 502 Rev A 2006 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- E 566 - 99 Standard Practice For Electromagnetic (Eddy-Current) Sorting of Ferrous Metals1 PDFDokument5 SeitenE 566 - 99 Standard Practice For Electromagnetic (Eddy-Current) Sorting of Ferrous Metals1 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- ASTM F 468m-03a PDFDokument10 SeitenASTM F 468m-03a PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- Astm F 439-02 E03 PDFDokument8 SeitenAstm F 439-02 E03 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- Astm F 561 Rev A 2005 PDFDokument16 SeitenAstm F 561 Rev A 2005 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- Astm F 679-03Dokument6 SeitenAstm F 679-03JORGE ARTURO TORIBIO HUERTA100% (1)

- Astm F 437-99 PDFDokument4 SeitenAstm F 437-99 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- ASTM F 683-03a PDFDokument34 SeitenASTM F 683-03a PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- Enzym Med - MSDSDokument9 SeitenEnzym Med - MSDSPan SoapNoch keine Bewertungen

- Physicochemical Models For Ore Formation Processes at Mercury Deposits A.A. Obolensky, L.V. Gushchina, and A.S. BorisenkoDokument17 SeitenPhysicochemical Models For Ore Formation Processes at Mercury Deposits A.A. Obolensky, L.V. Gushchina, and A.S. BorisenkoPatricio Castillo ManquecoyNoch keine Bewertungen

- Discharge Permit MemorandumDokument1 SeiteDischarge Permit MemorandumVic TorsecretNoch keine Bewertungen

- Business Opportunities in MizoramDokument27 SeitenBusiness Opportunities in MizoramAshwani SinghNoch keine Bewertungen

- Synthesis of Bio Lubricants With High Viscosity and High Oxidation StabilityDokument6 SeitenSynthesis of Bio Lubricants With High Viscosity and High Oxidation StabilityDoris AngNoch keine Bewertungen

- Checklist For CRZ ClearanceDokument3 SeitenChecklist For CRZ ClearancekaandiNoch keine Bewertungen

- Rainfall Runoff ModellingDokument23 SeitenRainfall Runoff ModellingmansikakaniNoch keine Bewertungen

- 2012 - A Review of Research On The Kalina Cycle PDFDokument10 Seiten2012 - A Review of Research On The Kalina Cycle PDFWilliam ChangNoch keine Bewertungen

- Summative Assessment: Answer Key For The Exercises in The LessonDokument4 SeitenSummative Assessment: Answer Key For The Exercises in The Lessonరామకృష్ణ పాశలNoch keine Bewertungen

- DRR Semi-Final ExamDokument6 SeitenDRR Semi-Final ExamVerna M. Reyes100% (3)

- 9.0 Traps and Interceptors: RNPC Reviewer (Part 2) by Engr. Roger de DiosDokument6 Seiten9.0 Traps and Interceptors: RNPC Reviewer (Part 2) by Engr. Roger de Diosfreanne_0527Noch keine Bewertungen

- Kiln Shell Corrosion PDFDokument29 SeitenKiln Shell Corrosion PDFfatamorgganaNoch keine Bewertungen

- DNV PropellerDokument20 SeitenDNV PropellerTay Chu YenNoch keine Bewertungen

- Proposal-REVISED-1 (1) 1Dokument27 SeitenProposal-REVISED-1 (1) 1leeash2797Noch keine Bewertungen

- Rose - 2001 - Pesticides and Public Health Integrated Methods of Mosquito Management PDFDokument7 SeitenRose - 2001 - Pesticides and Public Health Integrated Methods of Mosquito Management PDFYrllan SincuráNoch keine Bewertungen

- Tata 409Dokument37 SeitenTata 409Singer JerowNoch keine Bewertungen

- C 1167 - 03 Clay Roof Tile - Genteng KeramikDokument7 SeitenC 1167 - 03 Clay Roof Tile - Genteng KeramikAzisMiftakhulPutraNoch keine Bewertungen

- Wiki Water PDFDokument25 SeitenWiki Water PDFAmanuel MaruNoch keine Bewertungen

- Basf Compounded Lubricants Product CatalogueDokument4 SeitenBasf Compounded Lubricants Product Catalogueapi-233668671Noch keine Bewertungen

- Recovery of Coliform in Presence of Free ChlorineDokument7 SeitenRecovery of Coliform in Presence of Free ChlorineTanvir ShawonNoch keine Bewertungen

- Sta416 AssignmentDokument28 SeitenSta416 AssignmentNisa HassanNoch keine Bewertungen

- Environmental Factors Affecting HealthDokument4 SeitenEnvironmental Factors Affecting Healthshahi_jassNoch keine Bewertungen

- Iranian Cheetah Society Report 2021-2023Dokument21 SeitenIranian Cheetah Society Report 2021-2023Roel PlmrsNoch keine Bewertungen

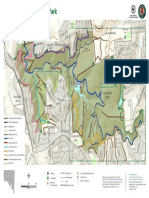

- Sturt Gorge Recreation Park Trail MapDokument1 SeiteSturt Gorge Recreation Park Trail MapEstherNoch keine Bewertungen

- Unit-11 Theory and Design of Sedimentation PDFDokument31 SeitenUnit-11 Theory and Design of Sedimentation PDFDaiber VeraNoch keine Bewertungen

- Water Treatment System Control Panel-Model PDFDokument1 SeiteWater Treatment System Control Panel-Model PDFClifford GatonNoch keine Bewertungen

- CVG 3106 Chp1 Review 2018 Summer FinalDokument67 SeitenCVG 3106 Chp1 Review 2018 Summer FinalNathanNoch keine Bewertungen

- Conexiones DomiciliariasDokument49 SeitenConexiones DomiciliariasEduardo MendozaNoch keine Bewertungen

- Bid Soliciting Documents RWCS-13Dokument43 SeitenBid Soliciting Documents RWCS-13Naveed ShaheenNoch keine Bewertungen

- Developing The Concept of A Marine Cadastre An Australian Case StudyDokument12 SeitenDeveloping The Concept of A Marine Cadastre An Australian Case Studyprotech2Noch keine Bewertungen