Beruflich Dokumente

Kultur Dokumente

Strut and Waling

Hochgeladen von

Chan Kin CheungOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Strut and Waling

Hochgeladen von

Chan Kin CheungCopyright:

Verfügbare Formate

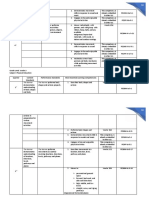

Job No. Sheeet No.

Rev

Calculation Sheet

Member Location

Strut & Waling

Job Title Drg. Ref.

-

Made By Date Chd.

Steel Section Design

Critical Section UC 203x203x71 HKSC:2011 APPROACH UC 203x203x71

104 101

Load Case 0

Member Forces Fc Axial Compression = 250 kN 1. Shear Capacity 0.730 O.K.

Ft Axial Tension = 0 kN 3. Bending Capacity 0.893 O.K.

V Shear Force = 250 kN 3. LTB 0.758 O.K.

Mx Major Bending = 150 kNm 4.Compression Capacity 0.137 O.K.

My Minor Bending = 0 kNm 5.Tensile Capacity 0.000 O.K.

6. Combined Axial & Bending 0.951 O.K.

Section Properties

Note: This Spreadsheet is Applicable to Hot-Rolled I- and H-section (Equal flanges) and Channel only.

Spreadsheet is Not for Designing Slender Sections.

Dimensions mm Length mm

Depth, D 215.8 L = 3000

Width, B 206.4 Lex = 1.0 L 3000

Flange Thk, T 17.3 Ley = 1.0 L 3000

Web Thk, t 10.0

depth, d 161.0 d/t = 16.1

width, b 103.3 b/T = 5.97

S275

Steel Grade 2 Radius of Gyration ; Cl. 3.1.2 Table 3.2

py = 265 N/mm2 rx = 91.8 mm

pyw = 275 N/mm2 355 ry = 53 mm

=(275/py)1/2 1.02 web = 1.00

E= 205000 N/mm2

Area Ag = 9040 mm2

Second Moment of Area

Ix = 7.618E+07 mm4

Iy = 2.537E+07 mm4

Section Modulus

Elastic: Zx = 7.060E+05 mm3 Plastic: Sx = 7.990E+05 mm3

Zy = 2.460E+05 mm3 Sy = 3.740E+05 mm3

Limiting Width-to-Thickness Ratios ; Cl. Table 7.1 and 7.2

Compression Element Limiting Value Ratio Classification

Design Type Compression due to Bending

1 Class 1 Class 2 Class 3

Plastic Compact Semi-Compact

Flange Compression due to Bending 28e 32e 40e b/T Plastic

28.52 32.60 40.75 5.97

Web Neutral Axis at Mid-Depth 80e 100e 120e d/t Plastic

80.00 100.00 120.00 16.10

Web Generally (>= 40= 40 ) 80e/ (1+r1) 100e / (1+1.5r1) 120e/ (1+2r2) d/t Plastic

51.13 43.31 99.91 16.10

Stress Ratios for Classification

r1 = Fc / d t pyw ; -1 < r1 <= 1 r2 = Fc / Agpyw ; Cl. 7.3 (a) & (c)

= 0.56 = 0.10

= 0.56

Shear Capacity

Vc = Py Av / 3 1 1.00 ; Cl. 8.2.1

Av = tD 1

= 2158 mm2

Vc = 343 kN High Shear Condition > V, OK

Moment Capacity ; Cl. 7.5.2

S x,eff =

3w 3 f S y,eff =

3 f

1 1 1

d /t b /T B /T

Z x (S x Z x ) Z x (S x Z x ) Z y ( S y Z y )

3 3 w 1 3 f 3 1 3 3 f 1

= 963503 mm

3 2 w

2 mm

2873054 = 3228613 mm 2f

= 963503 mm f

2

2V

Sv = 77616 mm3 = V 1 2.13

c

Strut-Member-Design.xls I or H or Channel Page 1 of 2

Job No. Sheeet No. Rev

Calculation Sheet

Member Location

Strut & Waling

Job Title Drg. Ref.

-

Made By Date Chd.

Steel Section Design

Critical Section UC 203x203x71 HKSC:2011 APPROACH UC 203x203x71

104 101

Mc = py x (S - p.Sv) <= 1.2.py(Z - p.Sv / 1.5) 1.2.py.Zx / 1000 = 225 kNm ; Cl. 8.2.2

1.2.py.Zy / 1000 = 78 kNm

Mcx = py x (Sx - p.Sv) = 168 kNm Mcx = 168 kNm > Mx, OK

Mcy = py x (Sy - p.Sv) = 55 kNm Mcy = 55 kNm > My, OK

Moment Capacity to Lateral Torsional Buckling

M b mLT Mx ; Cl. 8.3.5.2

mLT = 1.0 ; Table 8.4a

Mb = pb Sx ;(8.20 - 8.24)

LT = uv w ; Cl. 8.3.5.3

1

u = 0.9 1.00

Hot-rolled Section

= LE / ry = Ley / ry = 56.60 1

x= D/T= 12.47

1 1

v 0.84

1 0.05 / x

2 0. 25

w 1.0 (Plastic & Compact Sections)

LT = 42.68 1

pb = 248 N/mm2 Rolled Section 1 ; 8.3.5.2 App. 8.1

1

Mb = 198 kNm > mLT Mx, OK

1

Compression Resistance 2.00

Lex = L = 3000 mm rx = 91.8 mm x = Lex/rx = 32.7 Rolled H-Section2.00

Ley = L = 3000 mm ry = 53 mm y = Ley/ry = 56.6 2.00

pcx = 250 N/mm2 Pcx = pcx . A = 2257 kN ; Cl. 8.7.5

pcy = 201 N/mm2 Pcy = pcy . A = 1820 kN ; Table 8.7, App. 8.4

Pcy Ag pc

Pc = 1820 kN > Fc, OK

Compression Members under Combined Axial Force and Moments

Cross-section Capacity

Fc / Ag Py Mx / Mcx My / Mcy 1 ; Cl. 8.9.1

= 0.10 0.893 0.000

= 1.00

< 1.00 < 1, OK

Member Buckling Resistance

my = 1.0 my = 1.0 ; Table 8.9

Mcx = py Zx Mcy = py Zy ; Cl. 8.9.2

= 187.09 kNm = 65.19 kNm

Fc / Pc mx Mx / Mcx my My / Mcy 1 ; Cl. 8.9.2

= 0.14 0.81 0.00

= 0.95

< 1.00 < 1, OK

Fc / Pcy mLT Mx / Mb m y M y / M cy 1 ; Cl. 8.9.2

= 0.14 0.77 0.00

= 0.91

< 1.00 < 1, OK

Tension Resistance

Ke = 1.2

Ae = Ke an ag Hole Area = 0 mm2

2

= 9040 mm

Pt = py . Ae a1 = 1610 mm2

2

= 2396 kN a2 = 7430 mm > Ft, OK

Tension Members under Combined Axial Force and Moments

Fc / Pt Mx / Mcx My / Mcy 1 ; Cl. 8.8

= 0.00 0.893 0.000

= 0.89

< 1.00 < 1, OK

Strut-Member-Design.xls I or H or Channel Page 2 of 2

Das könnte Ihnen auch gefallen

- Pile RectifyingDokument2 SeitenPile RectifyingAnonymous O404LiV4CNoch keine Bewertungen

- Bored Pile - Estimated Pile Length & Capacity: RB6191-DASHDokument6 SeitenBored Pile - Estimated Pile Length & Capacity: RB6191-DASHHoihogo HoiNoch keine Bewertungen

- Design of Raft SlabDokument6 SeitenDesign of Raft SlabVenkatesha HebbarNoch keine Bewertungen

- Raft FoundationDokument12 SeitenRaft FoundationAasif ShaikNoch keine Bewertungen

- Wing WallDokument4 SeitenWing WallFaizal AryanovNoch keine Bewertungen

- Design of Two Way Slab and ETABS Column Reaction.Dokument9 SeitenDesign of Two Way Slab and ETABS Column Reaction.tuansteelsNoch keine Bewertungen

- Steelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiesDokument56 SeitenSteelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiessubamanivelNoch keine Bewertungen

- Beam Design As Per IS 456 and IS 13920Dokument41 SeitenBeam Design As Per IS 456 and IS 13920Anish PathakNoch keine Bewertungen

- 2 Way Slab OkDokument4 Seiten2 Way Slab OkMikeNoch keine Bewertungen

- Slab Design:-Out House Room: (One Long & One Short Edge Discontineous) (Two Way)Dokument12 SeitenSlab Design:-Out House Room: (One Long & One Short Edge Discontineous) (Two Way)shiv kumarNoch keine Bewertungen

- Crack Width CalculationsDokument1 SeiteCrack Width CalculationsdfdgggNoch keine Bewertungen

- Sagging Med+ (KNM) Hogging Med - (KNM)Dokument13 SeitenSagging Med+ (KNM) Hogging Med - (KNM)nagasabaNoch keine Bewertungen

- Fixed Column Base DesignDokument24 SeitenFixed Column Base DesignMayuresh KudveNoch keine Bewertungen

- Wingwall Soil LoadsDokument4 SeitenWingwall Soil LoadsSharyn PolleyNoch keine Bewertungen

- Bukit Keteri (Pg3-Pc2) : Table 3.25: Minimum Percentages of ReinforcementDokument4 SeitenBukit Keteri (Pg3-Pc2) : Table 3.25: Minimum Percentages of ReinforcementazwanNoch keine Bewertungen

- Rectangular Tank Design-Bluetax ETP-1Dokument23 SeitenRectangular Tank Design-Bluetax ETP-1monaliNoch keine Bewertungen

- Continous Composite Beam13Dokument27 SeitenContinous Composite Beam13Matthew ChinNoch keine Bewertungen

- TW-02 Inverted T-Shape TypeDokument28 SeitenTW-02 Inverted T-Shape TypeDanni Arman, STNoch keine Bewertungen

- Design of Long Wall: Tank Full and No Soil PressureDokument6 SeitenDesign of Long Wall: Tank Full and No Soil PressureAshoka YadavNoch keine Bewertungen

- Water RetainingDokument8 SeitenWater RetainingSrishti Project ConsultantsNoch keine Bewertungen

- Effective Length MODULE 7Dokument16 SeitenEffective Length MODULE 7Carmel NavinNoch keine Bewertungen

- Jacking Pad DesignDokument3 SeitenJacking Pad DesignAmarjit KulkarniNoch keine Bewertungen

- Design of A UbDokument8 SeitenDesign of A UbGihan Chathuranga100% (1)

- Jurutera Perunding Bersama SDN BHD Free Standing RC Retaining Wall Project Date Designed by Assumptions / PreamblesDokument34 SeitenJurutera Perunding Bersama SDN BHD Free Standing RC Retaining Wall Project Date Designed by Assumptions / PreamblesKokKeiNoch keine Bewertungen

- 8 No. 25 MM Diameter Longitudinal Bars Max Link Spacing 400 MM Generally, 240 MM For 500 MM Above and Below Slab/beam and at LapsDokument7 Seiten8 No. 25 MM Diameter Longitudinal Bars Max Link Spacing 400 MM Generally, 240 MM For 500 MM Above and Below Slab/beam and at LapsYHK3001100% (1)

- Deck SheetDokument3 SeitenDeck SheetPoulomi BiswasNoch keine Bewertungen

- Composite Column DesignDokument95 SeitenComposite Column DesignYanfei JinNoch keine Bewertungen

- Splice Check - 07282020 PDFDokument3 SeitenSplice Check - 07282020 PDFAngelo MoralNoch keine Bewertungen

- NBC105-2020 Torsion Irregularity Check-2021!08!12Dokument2 SeitenNBC105-2020 Torsion Irregularity Check-2021!08!12Prakash Singh RawalNoch keine Bewertungen

- Short Reinforcement Long Reinforcement: +ive in Span Due ToDokument15 SeitenShort Reinforcement Long Reinforcement: +ive in Span Due Topsconsultants0% (1)

- Bored Pile Design - Deep FoundationDokument5 SeitenBored Pile Design - Deep FoundationALI ASGHARNoch keine Bewertungen

- Strip Beam Design 24 07 19Dokument37 SeitenStrip Beam Design 24 07 19Ahammad KabeerNoch keine Bewertungen

- Chapter 2 Design For Serviceability PDFDokument14 SeitenChapter 2 Design For Serviceability PDFChee Fong MakeNoch keine Bewertungen

- Beam Design (SSB)Dokument6 SeitenBeam Design (SSB)Er Sai KiranNoch keine Bewertungen

- Design of Pile CapDokument3 SeitenDesign of Pile Capabhi aroteNoch keine Bewertungen

- RCCe11 Element DesignDokument8 SeitenRCCe11 Element DesignZayyan RomjonNoch keine Bewertungen

- Design of Steel ColumnDokument7 SeitenDesign of Steel ColumnKim Javier EstaNoch keine Bewertungen

- Project: Pahang Cement Plant, New Raw Material Weightbridge Date: 27.10.2015 Ref. Calculations Output SpecificationDokument31 SeitenProject: Pahang Cement Plant, New Raw Material Weightbridge Date: 27.10.2015 Ref. Calculations Output SpecificationMuhamad Amirul Md. RazdiNoch keine Bewertungen

- 3PB Pilecap DesignDokument3 Seiten3PB Pilecap DesignJONAS NGNoch keine Bewertungen

- Column Rolled Section (Rev.2.00)Dokument3 SeitenColumn Rolled Section (Rev.2.00)Harjasa AdhiNoch keine Bewertungen

- ZPurlinR1 OdsDokument21 SeitenZPurlinR1 OdsRamachandra SahuNoch keine Bewertungen

- Crack WidthDokument5 SeitenCrack WidthchanakyaNoch keine Bewertungen

- RR Masonary Retaing Wall DesignDokument41 SeitenRR Masonary Retaing Wall DesignAbhay KumarNoch keine Bewertungen

- Single Bolt Capacity To EN 1993-1-8: Bolts Diameters, Hole Sizes and AreasDokument17 SeitenSingle Bolt Capacity To EN 1993-1-8: Bolts Diameters, Hole Sizes and AreasabhijitNoch keine Bewertungen

- 7.0 Punching Check: 7.1 Punching of Column in Column CapitalDokument6 Seiten7.0 Punching Check: 7.1 Punching of Column in Column CapitalVikasNoch keine Bewertungen

- Rectangular Combined Footing: Input DataDokument2 SeitenRectangular Combined Footing: Input DataAnonymous 5pQf43AJwNoch keine Bewertungen

- PDF Wind Load Calculations As Per Is 875 Part 3xls CompressDokument85 SeitenPDF Wind Load Calculations As Per Is 875 Part 3xls CompressNews Side Effects.Noch keine Bewertungen

- RCC Slab DesignDokument4 SeitenRCC Slab DesignarghyadeepNoch keine Bewertungen

- 3 Pile CapDokument40 Seiten3 Pile Capsoumi bhattacharyaNoch keine Bewertungen

- Jack Well - Well FoundationDokument3 SeitenJack Well - Well FoundationRamakanth PuttyNoch keine Bewertungen

- PIle FoundationDokument6 SeitenPIle FoundationsaravananNoch keine Bewertungen

- For Battened Columns For Strength Cal 10% Increase in The KL/RDokument4 SeitenFor Battened Columns For Strength Cal 10% Increase in The KL/RvineetukNoch keine Bewertungen

- Abutment A1 On Counterfort Wall - 03.07.2020 1.04 PMDokument34 SeitenAbutment A1 On Counterfort Wall - 03.07.2020 1.04 PMVikas KushwahaNoch keine Bewertungen

- RC Corbel Design EC2Dokument3 SeitenRC Corbel Design EC2Tommaso PasconNoch keine Bewertungen

- Reinforced Concrete Retaining Wall Design To BS 8110Dokument10 SeitenReinforced Concrete Retaining Wall Design To BS 8110thabisoNoch keine Bewertungen

- Design of RCC Footing As Per ACI 318 95 EdDokument2 SeitenDesign of RCC Footing As Per ACI 318 95 EdMaad Ahmed Al-MaroofNoch keine Bewertungen

- UC 305x305x118 Hksc:2011 Approach: StrutDokument2 SeitenUC 305x305x118 Hksc:2011 Approach: StrutChan Kin CheungNoch keine Bewertungen

- 4.2b SB2 UC CheckDokument3 Seiten4.2b SB2 UC CheckBQ HeNoch keine Bewertungen

- Access Stairs (AISC Steel Design-CHS) - 1Dokument1 SeiteAccess Stairs (AISC Steel Design-CHS) - 1yolittle shiNoch keine Bewertungen

- Tension Member Double AngleDokument1 SeiteTension Member Double AnglechaNoch keine Bewertungen

- Design Calculation of Falsework For Construction of 1800mm Thick Slab - r3Dokument14 SeitenDesign Calculation of Falsework For Construction of 1800mm Thick Slab - r3Chan Kin Cheung100% (1)

- Faleswork Design Checking - RC Beam - (Updated - 2)Dokument3 SeitenFaleswork Design Checking - RC Beam - (Updated - 2)Chan Kin CheungNoch keine Bewertungen

- Design Calculation of Formwork and Falsework of Column - r2Dokument14 SeitenDesign Calculation of Formwork and Falsework of Column - r2Chan Kin Cheung100% (1)

- Faleswork Design Checking - RC Beam - (Updated)Dokument5 SeitenFaleswork Design Checking - RC Beam - (Updated)Chan Kin CheungNoch keine Bewertungen

- TC2 56300 49400 STAGE 2 - Upon GM/F Completion - Install TC1 & TC3 After GM/F Complete. - Change TC2 Jib To Shorter 40m-Long Jib TC1 TC3 TC2Dokument3 SeitenTC2 56300 49400 STAGE 2 - Upon GM/F Completion - Install TC1 & TC3 After GM/F Complete. - Change TC2 Jib To Shorter 40m-Long Jib TC1 TC3 TC2Chan Kin CheungNoch keine Bewertungen

- YLPMSA Lift Traffic AnalysisDokument1 SeiteYLPMSA Lift Traffic AnalysisChan Kin CheungNoch keine Bewertungen

- Design Report For Steel Frame System: ST 355 y - 355 Q - 355 Q - 355 ST - 355 3Dokument10 SeitenDesign Report For Steel Frame System: ST 355 y - 355 Q - 355 Q - 355 ST - 355 3Chan Kin CheungNoch keine Bewertungen

- 400x400 Pile Capacity With 6T25 & 12mm LinkDokument9 Seiten400x400 Pile Capacity With 6T25 & 12mm LinkChan Kin CheungNoch keine Bewertungen

- Painting and FRP System For CP4E Link Bridge RevA - HPTDokument81 SeitenPainting and FRP System For CP4E Link Bridge RevA - HPTChan Kin CheungNoch keine Bewertungen

- Piling Schedule - SampleDokument1 SeitePiling Schedule - SampleChan Kin CheungNoch keine Bewertungen

- Strip ForceDokument4 SeitenStrip ForceChan Kin CheungNoch keine Bewertungen

- 2-1-9 - The Processing of High Strength Prestressed Spun ConcreteDokument5 Seiten2-1-9 - The Processing of High Strength Prestressed Spun ConcreteChan Kin CheungNoch keine Bewertungen

- Installation of Prestressed Spun High Strength Concrete Piles by Hydraulic JackingDokument7 SeitenInstallation of Prestressed Spun High Strength Concrete Piles by Hydraulic JackingChan Kin CheungNoch keine Bewertungen

- 108 Shear Strength - Undrained Shear StrengthDokument1 Seite108 Shear Strength - Undrained Shear StrengthChan Kin CheungNoch keine Bewertungen

- Wong & Cheng Consulting Engineers LTDDokument2 SeitenWong & Cheng Consulting Engineers LTDChan Kin CheungNoch keine Bewertungen

- UC 305x305x118 Hksc:2011 Approach: StrutDokument2 SeitenUC 305x305x118 Hksc:2011 Approach: StrutChan Kin CheungNoch keine Bewertungen

- Column 6mDokument6 SeitenColumn 6mChan Kin CheungNoch keine Bewertungen

- Line Input 1Dokument3 SeitenLine Input 1Chan Kin CheungNoch keine Bewertungen

- Frew Oasys Frew Suite For WindowsDokument1 SeiteFrew Oasys Frew Suite For WindowsChan Kin CheungNoch keine Bewertungen

- EN 50122-1 January 2011 Corrientes RetornoDokument81 SeitenEN 50122-1 January 2011 Corrientes RetornoConrad Ziebold VanakenNoch keine Bewertungen

- Upes School of Law Lac & Adr Association: PresentsDokument7 SeitenUpes School of Law Lac & Adr Association: PresentsSuvedhya ReddyNoch keine Bewertungen

- Business-Communication Solved MCQs (Set-3)Dokument8 SeitenBusiness-Communication Solved MCQs (Set-3)Pavan Sai Krishna KottiNoch keine Bewertungen

- ADC of PIC MicrocontrollerDokument4 SeitenADC of PIC Microcontrollerkillbill100% (2)

- Brigade Product Catalogue Edition 20 EnglishDokument88 SeitenBrigade Product Catalogue Edition 20 EnglishPelotudoPeloteroNoch keine Bewertungen

- ThorpeDokument267 SeitenThorpezaeem73Noch keine Bewertungen

- Concrete Repair Manual (2017)Dokument59 SeitenConcrete Repair Manual (2017)Fernando EscriváNoch keine Bewertungen

- PE MELCs Grade 3Dokument4 SeitenPE MELCs Grade 3MARISSA BERNALDONoch keine Bewertungen

- Ritesh Agarwal: Presented By: Bhavik Patel (Iu1981810008) ABHISHEK SHARMA (IU1981810001) VISHAL RATHI (IU1981810064)Dokument19 SeitenRitesh Agarwal: Presented By: Bhavik Patel (Iu1981810008) ABHISHEK SHARMA (IU1981810001) VISHAL RATHI (IU1981810064)Abhi SharmaNoch keine Bewertungen

- Toh MFS8B 98B 003-11114-3AG1 PDFDokument92 SeitenToh MFS8B 98B 003-11114-3AG1 PDFDmitry NemtsoffNoch keine Bewertungen

- SyncopeDokument105 SeitenSyncopeJohn DasNoch keine Bewertungen

- Midi Pro Adapter ManualDokument34 SeitenMidi Pro Adapter ManualUli ZukowskiNoch keine Bewertungen

- CAA Safety Plan 2011 To 2013Dokument46 SeitenCAA Safety Plan 2011 To 2013cookie01543Noch keine Bewertungen

- Semi Detailed Lesson PlanDokument2 SeitenSemi Detailed Lesson PlanJean-jean Dela Cruz CamatNoch keine Bewertungen

- 385C Waw1-Up PDFDokument4 Seiten385C Waw1-Up PDFJUNA RUSANDI SNoch keine Bewertungen

- Binge Eating Disorder ANNADokument12 SeitenBinge Eating Disorder ANNAloloasbNoch keine Bewertungen

- Standard Test Methods For Rheological Properties of Non-Newtonian Materials by Rotational (Brookfield Type) ViscometerDokument8 SeitenStandard Test Methods For Rheological Properties of Non-Newtonian Materials by Rotational (Brookfield Type) ViscometerRodrigo LopezNoch keine Bewertungen

- Futures Volume 1 Issue 3 1969 (Doi 10.1016/0016-3287 (69) 90026-3) Dennis Livingston - Science Fiction As A Source of Forecast MaterialDokument7 SeitenFutures Volume 1 Issue 3 1969 (Doi 10.1016/0016-3287 (69) 90026-3) Dennis Livingston - Science Fiction As A Source of Forecast MaterialManticora VenerabilisNoch keine Bewertungen

- Practical Modern SCADA Protocols. DNP3, 60870.5 and Related SystemsDokument4 SeitenPractical Modern SCADA Protocols. DNP3, 60870.5 and Related Systemsalejogomez200Noch keine Bewertungen

- Lab Report SBK Sem 3 (Priscilla Tuyang)Dokument6 SeitenLab Report SBK Sem 3 (Priscilla Tuyang)Priscilla Tuyang100% (1)

- Maritta Koch-Weser, Scott Guggenheim - Social Development in The World Bank - Essays in Honor of Michael M. Cernea-Springer (2021)Dokument374 SeitenMaritta Koch-Weser, Scott Guggenheim - Social Development in The World Bank - Essays in Honor of Michael M. Cernea-Springer (2021)IacobNoch keine Bewertungen

- Fundamentals of Signal and Power Integrity PDFDokument46 SeitenFundamentals of Signal and Power Integrity PDFjaltitiNoch keine Bewertungen

- Final WMS2023 HairdressingDokument15 SeitenFinal WMS2023 HairdressingMIRAWATI SAHIBNoch keine Bewertungen

- Top 100 Chemical CompaniesDokument11 SeitenTop 100 Chemical Companiestawhide_islamicNoch keine Bewertungen

- Mathematics Mock Exam 2015Dokument4 SeitenMathematics Mock Exam 2015Ian BautistaNoch keine Bewertungen

- TraceDokument5 SeitenTraceNorma TellezNoch keine Bewertungen

- Lesson Plan For Implementing NETSDokument5 SeitenLesson Plan For Implementing NETSLisa PizzutoNoch keine Bewertungen

- Marketing Channels: A Strategic Tool of Growing Importance For The Next MillenniumDokument59 SeitenMarketing Channels: A Strategic Tool of Growing Importance For The Next MillenniumAnonymous ibmeej9Noch keine Bewertungen

- Eurocode 3: Design of Steel Structures "ReadyDokument26 SeitenEurocode 3: Design of Steel Structures "Readywazydotnet80% (10)

- BLP#1 - Assessment of Community Initiative (3 Files Merged)Dokument10 SeitenBLP#1 - Assessment of Community Initiative (3 Files Merged)John Gladhimer CanlasNoch keine Bewertungen