Beruflich Dokumente

Kultur Dokumente

X20 (C) BC0083-ENG V2.33

Hochgeladen von

Teh Boon SiangOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

X20 (C) BC0083-ENG V2.33

Hochgeladen von

Teh Boon SiangCopyright:

Verfügbare Formate

X20(c)BC0083

X20(c)BC0083

1 General information

The bus controller makes it possible to connect X2X Link I/O nodes to POWERLINK. It is also possible to operate

the X2X Link cycle synchronously 1:1 or synchronous to POWERLINK using a prescaler.

POWERLINK is a standard protocol for Fast Ethernet with hard real-time properties. The Ethernet POWERLINK

Standardization Group (EPSG) ensures that the standard remains open and is continually developed: www.ether-

net-powerlink.org

POWERLINK

I/O configuration and Firmware update via the fieldbus

Integrated hub for efficient cabling

2 Coated modules

Coated modules are X20 modules with a protective coating for the electronics component. This coating protects

X20c modules from condensation and corrosive gases.

The modules' electronics are fully compatible with the corresponding X20 modules.

For simplification purposes, only images and module IDs of uncoated modules are used in this data

sheet.

The coating has been certified according to the following standards:

Condensation: BMW GS 95011-4, 2x 1 cycle

Corrosive gas: EN 60068-2-60, Method 4, exposure 21 days

Data sheet V 2.33 1

X20(c)BC0083

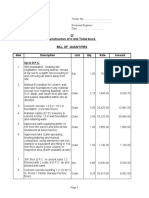

3 Order data

Model number Short description Figure

Bus controllers

X20BC0083 X20 bus controller, 1 POWERLINK interface, integrated 2-port

hub, 2x RJ45, order bus base, power supply module and termi-

nal block separately.

X20cBC0083 X20 bus controller, coated, 1 POWERLINK interface, integrated

2-port hub, 2x RJ45, order bus base, power supply module and

terminal block separately

Required accessories

System modules for bus controllers

X20BB80 X20 bus base, for X20 base module (BC, HB, etc.) and X20 pow-

er supply module, X20 end plates (left and right) X20AC0SL1/

X20AC0SR1 included

X20PS9400 X20 power supply module, for bus controller and internal I/O

supply, X2X Link supply

X20PS9402 X20 supply module, for bus controller and internal I/O supply,

X2X Link supply, supply not electrically isolated

X20cBB80 X20 bus base, coated, for X20 base module (BC, HB, etc.)

and X20 power supply module, X20 end plates (left and right)

X20AC0SL1/X20AC0SR1 included

X20cPS9400 X20 power supply module, coated, for bus controller and internal

I/O supply, X2X Link supply

Terminal blocks

X20TB12 X20 terminal block, 12-pin, 24 VDC keyed

Table 1: X20BC0083, X20cBC0083 - Order data

4 Technical data

Model number X20BC0083 X20cBC0083

Short description

Bus controller POWERLINK (V1/V2) controlled node

General information

B&R ID code 0x1F1E 0xE216

Status indicators Module status, bus function

Diagnostics

Module status Yes, using status LED and software

Bus function Yes, using status LED and software

Power consumption

Bus 2W

Additional power dissipation caused by the actua- -

tors (resistive) [W]

Electrical isolation

Fieldbus - X2X Link Yes

Fieldbus - I/O Yes

Certification

CE Yes

KC Yes -

UL cULus E115267

Industrial Control Equipment

HazLoc cCSAus 244665 -

Process Control Equipment

for Hazardous Locations

Class I, Division 2, Groups ABCD, T5

ATEX Zone 2, II 3G Ex nA nC IIA T5 Gc

IP20, Ta = 0 - max. 60C

FTZ 09 ATEX 0083X

DNV GL Temperature: B (0 - 55C)

Humidity: B (up to 100%)

Vibration: B (4g)

EMC: B (Bridge and open deck)

LR ENV1

GOST-R Yes

Interfaces

Fieldbus POWERLINK (V1/V2) controlled node

Design 2x shielded RJ45 (hub)

Cable length Max. 100 m between 2 stations (segment length)

Transfer rate 100 Mbit/s

Table 2: X20BC0083, X20cBC0083 - Technical data

2 Data sheet V 2.33

X20(c)BC0083

Model number X20BC0083 X20cBC0083

Transmission

Physical layer 100BASE-TX

Half-duplex Yes

Full-duplex No

Autonegotiation Yes

Auto-MDI / MDIX Yes

Hub runtime 0.96 to 1 s

Min. cycle time 1)

Fieldbus 200 s

X2X Link 200 s

Synchronization between bus systems possible Yes

Operating conditions

Mounting orientation

Horizontal Yes

Vertical Yes

Installation at elevations above sea level

0 to 2000 m No limitations

>2000 m Reduction of ambient temperature by 0.5C per 100 m

EN 60529 protection IP20

Environmental conditions

Temperature

Operation

Horizontal installation -25 to 60C

Vertical installation -25 to 50C

Derating -

Storage -40 to 85C

Transport -40 to 85C

Relative humidity

Operation 5 to 95%, non-condensing Up to 100%, condensing

Storage 5 to 95%, non-condensing

Transport 5 to 95%, non-condensing

Mechanical characteristics

Note Order 1x X20TB12 terminal block separately Order 1x X20TB12 terminal block separately

Order 1x X20PS9400 or X20PS9402 Order 1x X20cPS9400 pow-

power supply module separately er supply module separately

Order 1x X20BB80 bus base separately Order 1x X20cBB80 bus base separately

Spacing 2) 37.5 +0.2 mm

Table 2: X20BC0083, X20cBC0083 - Technical data

1) The minimum cycle time defines how far the bus cycle can be reduced without communication errors occurring.

2) Spacing is based on the width of the X20BB80 bus base. In addition, an X20PS9400 or X20PS9402 supply module is always required for the bus controller.

Data sheet V 2.33 3

X20(c)BC0083

5 LED status indicators

Figure LED Color Status Description

S/E1) Green Off No power supply or mode NOT_ACTIVE.

The controlled node (CN) is either not getting power, or it is in the NOT_ACTIVE

state. The CN waits in this state for about 5 seconds after a restart. Communi-

cation is not possible with the CN. If no POWERLINK communication is detect-

ed during these 5 seconds, the CN switches to the BASIC_ETHERNET state

(flickering).

If POWERLINK communication is detected before this time expires, however,

the CN switches immediately to the PRE_OPERATIONAL_1 state.

Flickering BASIC_ETHERNET mode.

The CN has not detected any POWERLINK communication. It is possible to com-

municate directly with the CN in this state (e.g. with UDP, IP, etc.).

If POWERLINK communication is detected while in this state, the CN switches

to the PRE_OPERATIONAL_1 state.

Single flash PRE_OPERATIONAL_1 mode.

When operated on a POWERLINK V1 manager, the CN immediately switches

to the PRE_OPERATIONAL_2 state.

When operated on a POWERLINK V2 manager, the CN waits until an SoC frame

is received and then switches to the PRE_OPERATIONAL_2 state.

Double flash PRE_OPERATIONAL_2 mode.

The CN is normally configured by the manager in this state. Issuing a command

(POWERLINK V2) or setting the data valid flag in the output data (POWERLINK

V1) then switches to the READY_TO_OPERATE state.

Triple flash READY_TO_OPERATE mode.

In a POWERLINK V1 network, the CN automatically switches to the OPER-

ATIONAL state as soon as input data is present.

In a POWERLINK V2 network, the manager switches to the OPERATIONAL

state by issuing a command.

On OPERATIONAL mode.

PDO mapping is active and cyclic data is being evaluated.

Blinking STOPPED mode.

No output data is produced or input data supplied. It is only possible to switch to

or leave this state after the manager has given the appropriate command.

Red On The controlled node (CN) is in an error state (failed Ethernet frames, increased

number of collisions on the network, etc.).

If an error occurs in the following states, then the green LED blinks over the red

LED:

PRE_OPERATIONAL_1

PRE_OPERATIONAL_2

READY_TO_OPERATE

Status

Green

t

Error

Red

t

"S/E" LED

t

Note:

The LED blinks red several times immediately after startup. This is not

an error, however.

The LED is lit red for CNs with configured physical node number 0 but that

have not yet been assigned a node number via dynamic node allocation

(DNA).

L/A IFx Green On Link established to the remote station

Blinking A link to the remote station has been established and there is activity on bus.

1) The Status/Error LED "S/E" is a green/red dual LED.

Status LEDs - Blinking patterns

Triple flash

200 200 200 200 200 1000

Double flash

200 200 200 1000

Single flash

200 1000

Blinking

200 200

Flickering

All times in ms

4 Data sheet V 2.33

X20(c)BC0083

6 Operating and connection elements

LED status indicators

Node number switches

Terminal block for bus controller

and I/O power supply

POWERLINK interface with

2x RJ45 ports for easy wiring

7 POWERLINK node number

The node number for the POWERLINK node is set using the two number switches.

Switch position Description

0x00 Only permitted when operating the POWERLINK node in DNA mode.

0x01 - 0xEF Node number of the POWERLINK node Operation as a controlled node.

0xF0 - 0xFF Reserved, switch position not permitted

Data sheet V 2.33 5

X20(c)BC0083

8 Dynamic node allocation (DNA)

The node numbers of all POWERLINK bus controllers can be assigned dynamically. This has the following ad-

vantages:

No need to set the node number switch

Easier installation

Reduced error sources

For information about configuration as well as an example, see the AS help system (Communication POWER-

LINK General information Dynamic node allocation (DNA)).

Information:

The IF1 interface must always be used as the input from the preceding node.

9 Ethernet interface

Information about cabling X20 modules with an Ethernet interface can be found in the module's download section

on the B&R website (www.br-automation.com).

IF1

IF2

Interface Pinout

Pin Ethernet

1 RXD Receive data

2 RXD\ Receive data\

1

3 TXD Transmit data

4 Termination

5 Termination

6 TXD\ Transmit data\

Shielded RJ45 7 Termination

8 Termination

10 SG3

This module is not supported on SG3 targets.

11 SG4

This module comes with preinstalled firmware. The firmware is also part of the Automation Runtime operating

system for the PLC. If the two versions are different, the Automation Runtime firmware is loaded to the module.

The latest firmware is made available automatically when updating Automation Runtime.

6 Data sheet V 2.33

Das könnte Ihnen auch gefallen

- Planas V Comelec - FinalDokument2 SeitenPlanas V Comelec - FinalEdwino Nudo Barbosa Jr.100% (1)

- X20CM0985 1 Eng - V1.42Dokument72 SeitenX20CM0985 1 Eng - V1.42rushaNoch keine Bewertungen

- Electrostatic Discharge Immunity TestDokument6 SeitenElectrostatic Discharge Immunity Testratheesh vidyadharanNoch keine Bewertungen

- Control and Relay PanelDokument104 SeitenControl and Relay Panelbakien-can100% (1)

- Linear IC Applications: A Designer's HandbookVon EverandLinear IC Applications: A Designer's HandbookBewertung: 4 von 5 Sternen4/5 (1)

- Moparm Action - December 2014 USADokument100 SeitenMoparm Action - December 2014 USAenricoioNoch keine Bewertungen

- Prepositions Below by in On To of Above at Between From/toDokument2 SeitenPrepositions Below by in On To of Above at Between From/toVille VianNoch keine Bewertungen

- X20BC0083-cabeça Rede AutomaçãoDokument5 SeitenX20BC0083-cabeça Rede AutomaçãoWillian ErthalNoch keine Bewertungen

- X20bc0083-Eng V2.40Dokument6 SeitenX20bc0083-Eng V2.40dalitso ngomaNoch keine Bewertungen

- X20 (C) PS9400: 1 General InformationDokument7 SeitenX20 (C) PS9400: 1 General InformationAgus SuwardonoNoch keine Bewertungen

- X20bc8084-Eng V2.42Dokument9 SeitenX20bc8084-Eng V2.42tori widayatNoch keine Bewertungen

- X20 (C) PS2100Dokument5 SeitenX20 (C) PS2100Claiton Costa Nunes0% (1)

- X20 (C) DO8332: 1 General InformationDokument12 SeitenX20 (C) DO8332: 1 General InformationKader SllNoch keine Bewertungen

- X20if1072-Eng V2.34Dokument4 SeitenX20if1072-Eng V2.34ВладимирNoch keine Bewertungen

- X20 (C) DC1198: 1 General InformationDokument8 SeitenX20 (C) DC1198: 1 General InformationOmar AzzainNoch keine Bewertungen

- X20BC8083 EngDokument5 SeitenX20BC8083 Engbarbisan.fabioNoch keine Bewertungen

- 1 General InformationDokument45 Seiten1 General InformationNikolayNoch keine Bewertungen

- X20di9371-Eng V3.23Dokument7 SeitenX20di9371-Eng V3.23smdsahinNoch keine Bewertungen

- X20at4222-Eng V3.12Dokument10 SeitenX20at4222-Eng V3.12Asif MehmoodNoch keine Bewertungen

- X20bc0063-Eng V2.24Dokument4 SeitenX20bc0063-Eng V2.24ArielistoNoch keine Bewertungen

- 1 General Information: Nettime Timestamp For OutputDokument8 Seiten1 General Information: Nettime Timestamp For OutputOscar Enríquez MorenoNoch keine Bewertungen

- X20 (C) BB80: 1 General InformationDokument3 SeitenX20 (C) BB80: 1 General InformationOscar Enríquez MorenoNoch keine Bewertungen

- X20do9322-Eng V3.15Dokument8 SeitenX20do9322-Eng V3.15dhiyaulhaq05071991Noch keine Bewertungen

- X20AT4222-Entrada RTDDokument10 SeitenX20AT4222-Entrada RTDWillian ErthalNoch keine Bewertungen

- X20dc1376-Eng V2.31Dokument19 SeitenX20dc1376-Eng V2.31Lajos SütőNoch keine Bewertungen

- X20 (C) AT6402: 1 General InformationDokument12 SeitenX20 (C) AT6402: 1 General InformationOscar Enríquez MorenoNoch keine Bewertungen

- 1 General Information: Model Number Short Description Counter Functions Required Accessories Bus ModulesDokument11 Seiten1 General Information: Model Number Short Description Counter Functions Required Accessories Bus Modulesroni kurniawanNoch keine Bewertungen

- X20di9371-Eng V3.11Dokument7 SeitenX20di9371-Eng V3.11Behzad MirzaeiNoch keine Bewertungen

- 1 General Information: Nettime Timestamp of The Position and Trigger TimeDokument51 Seiten1 General Information: Nettime Timestamp of The Position and Trigger TimeСтив АааNoch keine Bewertungen

- If1020 (RS232)Dokument3 SeitenIf1020 (RS232)Mikhail PetuninNoch keine Bewertungen

- X20 (C) BM11: 1 General InformationDokument3 SeitenX20 (C) BM11: 1 General Informationroni kurniawanNoch keine Bewertungen

- 1 General Information: Model Number Short Description Analog InputsDokument32 Seiten1 General Information: Model Number Short Description Analog InputsOscar Enríquez MorenoNoch keine Bewertungen

- X20do9322 EngDokument8 SeitenX20do9322 Engbarbisan.fabioNoch keine Bewertungen

- X20ao4622 EngDokument8 SeitenX20ao4622 Engbarbisan.fabioNoch keine Bewertungen

- 8BVI0055HWD0.000-3 en V1.3Dokument21 Seiten8BVI0055HWD0.000-3 en V1.3Dorin SerbanNoch keine Bewertungen

- QTP-M 2X26 32: Product DatasheetDokument7 SeitenQTP-M 2X26 32: Product DatasheetSakahi SharmaNoch keine Bewertungen

- Esdcan01 2blyDokument13 SeitenEsdcan01 2blyAdlan MessaoudNoch keine Bewertungen

- 8V1320.001-2 en V1.8Dokument14 Seiten8V1320.001-2 en V1.8JlavieraNoch keine Bewertungen

- Highbury DC Bi Directional BrochureDokument2 SeitenHighbury DC Bi Directional BrochureBad BradNoch keine Bewertungen

- 8V1640.001-2 en V1.8Dokument14 Seiten8V1640.001-2 en V1.8JlavieraNoch keine Bewertungen

- Information:: Model Number Short Description Image Bus TransmitterDokument7 SeitenInformation:: Model Number Short Description Image Bus TransmitterOSAMANoch keine Bewertungen

- EVBox Liviqo Datasheet - INTLDokument4 SeitenEVBox Liviqo Datasheet - INTLCarlos VillamarNoch keine Bewertungen

- X20TB06/X20TB12: 1 General InformationDokument3 SeitenX20TB06/X20TB12: 1 General Informationroni kurniawanNoch keine Bewertungen

- 1 General Information: Model Number Short Description Servo DrivesDokument14 Seiten1 General Information: Model Number Short Description Servo DrivesMr.K ch100% (1)

- Product Comparison Chart ECB SeriesDokument2 SeitenProduct Comparison Chart ECB SeriesErdinc KlimaNoch keine Bewertungen

- ZMP 56503 QTP-DL 2X36 40Dokument6 SeitenZMP 56503 QTP-DL 2X36 40ch tcNoch keine Bewertungen

- Susol VCB E 1401Dokument220 SeitenSusol VCB E 1401Lucian CucliNoch keine Bewertungen

- X67SM2436Dokument57 SeitenX67SM2436MirrorNoch keine Bewertungen

- 8B0C0160HW00.001-1: 1 General InformationDokument6 Seiten8B0C0160HW00.001-1: 1 General InformationИльнур ТагировNoch keine Bewertungen

- CATALOGUEDokument27 SeitenCATALOGUEparahu ariefNoch keine Bewertungen

- SN65HVD1050Dokument19 SeitenSN65HVD1050ZaegorNoch keine Bewertungen

- TDC & Specification of CSS&RMU - RevisedDokument31 SeitenTDC & Specification of CSS&RMU - RevisedShatrughna SamalNoch keine Bewertungen

- C2383 ToshibaSemiconductorDokument5 SeitenC2383 ToshibaSemiconductorAdriano HenriqueNoch keine Bewertungen

- X20CS1030 EngDokument42 SeitenX20CS1030 Engbarbisan.fabioNoch keine Bewertungen

- 2SC2230,2SC2230A: High-Voltage General Amplifier Applications Color TV Class-B Sound Output ApplicationsDokument5 Seiten2SC2230,2SC2230A: High-Voltage General Amplifier Applications Color TV Class-B Sound Output ApplicationsLuis AntunesNoch keine Bewertungen

- Aliant Ommunications: - 101 To - 104 Protocol ConverterDokument2 SeitenAliant Ommunications: - 101 To - 104 Protocol Convertertran TXPNoch keine Bewertungen

- Automotive Dual-Line TVS in SOT323-3L For CAN Bus: Esdcanxx-2BwyDokument14 SeitenAutomotive Dual-Line TVS in SOT323-3L For CAN Bus: Esdcanxx-2BwyЕвгений ИвановNoch keine Bewertungen

- X20PS9600-en V1.20Dokument10 SeitenX20PS9600-en V1.20PREVENCIONISTA HUAQUIANNoch keine Bewertungen

- 1756 IF8 DatasheetDokument2 Seiten1756 IF8 Datasheet朱迎安Noch keine Bewertungen

- DO880Dokument4 SeitenDO880sitaNoch keine Bewertungen

- 1SVR405622R3000 CR U230ac3Dokument3 Seiten1SVR405622R3000 CR U230ac3Cristhian MartinezNoch keine Bewertungen

- 22kV GTPDokument41 Seiten22kV GTPSundaresan Sabanayagam100% (1)

- Kaco-02xi 02x Specifications PDFDokument2 SeitenKaco-02xi 02x Specifications PDFProyectos SunshineNoch keine Bewertungen

- Ex5 PDFDokument14 SeitenEx5 PDFJuan Pablo LorenzoNoch keine Bewertungen

- Click PLC CommunicationDokument40 SeitenClick PLC Communicationobinnabenedict100% (1)

- Art of WarDokument51 SeitenArt of Warshortey364Noch keine Bewertungen

- Full Design of A Low-Cost Quadrotor UAV by Student TeamDokument7 SeitenFull Design of A Low-Cost Quadrotor UAV by Student TeamTeh Boon SiangNoch keine Bewertungen

- Mapp300 - 400-Eng V2 - 42 PDFDokument604 SeitenMapp300 - 400-Eng V2 - 42 PDFTeh Boon Siang100% (1)

- Ex 6Dokument16 SeitenEx 6Pardhasaradhi NallamothuNoch keine Bewertungen

- An 1003 BrochureDokument8 SeitenAn 1003 BrochureTeh Boon SiangNoch keine Bewertungen

- The Basics of CANopen - National InstrumentsDokument5 SeitenThe Basics of CANopen - National InstrumentsTeh Boon SiangNoch keine Bewertungen

- For All For Me For Me For Me For Me For Me: Two Can Dine Two Can DineDokument1 SeiteFor All For Me For Me For Me For Me For Me: Two Can Dine Two Can DineTeh Boon SiangNoch keine Bewertungen

- 1.4 What Is Cfd?: M M ⟹ Ρva Dm Dt ∑F ⟹ F=Ma, M=Mv, Dm Dt D (Mv) DtDokument43 Seiten1.4 What Is Cfd?: M M ⟹ Ρva Dm Dt ∑F ⟹ F=Ma, M=Mv, Dm Dt D (Mv) DtTeh Boon SiangNoch keine Bewertungen

- Stab and Control PrintDokument1 SeiteStab and Control PrintTeh Boon SiangNoch keine Bewertungen

- 1 s2.0 S0956053X13000147 Main PDFDokument14 Seiten1 s2.0 S0956053X13000147 Main PDFcahyoaamNoch keine Bewertungen

- MemorandumDokument1 SeiteMemorandumTeh Boon SiangNoch keine Bewertungen

- Winter 2015 ScheduleDokument1 SeiteWinter 2015 ScheduleTeh Boon SiangNoch keine Bewertungen

- Visa LetterDokument1 SeiteVisa LetterTeh Boon SiangNoch keine Bewertungen

- AnemometerDokument4 SeitenAnemometerTeh Boon SiangNoch keine Bewertungen

- Lecture 9 Summary For SubmissionDokument1 SeiteLecture 9 Summary For SubmissionTeh Boon SiangNoch keine Bewertungen

- Bruun Hot WireDokument8 SeitenBruun Hot WireTeh Boon SiangNoch keine Bewertungen

- Lecture 15 Summary For SubmissionDokument1 SeiteLecture 15 Summary For SubmissionTeh Boon SiangNoch keine Bewertungen

- Lecture 9 Summary For SubmissionDokument1 SeiteLecture 9 Summary For SubmissionTeh Boon SiangNoch keine Bewertungen

- Carleton University AERO 4304: Computational Fluid Dynamics Assignment 1: Simulation of A Laminar Pipe FlowDokument2 SeitenCarleton University AERO 4304: Computational Fluid Dynamics Assignment 1: Simulation of A Laminar Pipe FlowTeh Boon SiangNoch keine Bewertungen

- Lecture 10 Summary For SubmissionDokument1 SeiteLecture 10 Summary For SubmissionTeh Boon SiangNoch keine Bewertungen

- AnemometerDokument4 SeitenAnemometerTeh Boon SiangNoch keine Bewertungen

- Fact That INS Functions On The Basis of Integrating Measured Parameters Such As Linear and Rotational Acceleration To Obtain Velocity and Position of The AircraftDokument1 SeiteFact That INS Functions On The Basis of Integrating Measured Parameters Such As Linear and Rotational Acceleration To Obtain Velocity and Position of The AircraftTeh Boon SiangNoch keine Bewertungen

- Writing Requirements RightDokument21 SeitenWriting Requirements RightTeh Boon SiangNoch keine Bewertungen

- SatcomDokument11 SeitenSatcomTeh Boon SiangNoch keine Bewertungen

- Ansys Structural Analysis GuideDokument402 SeitenAnsys Structural Analysis Guideemiltheone100% (1)

- 2014 4th - Year Fall Project MemoDokument8 Seiten2014 4th - Year Fall Project MemoTeh Boon SiangNoch keine Bewertungen

- Ewellery Ndustry: Presentation OnDokument26 SeitenEwellery Ndustry: Presentation Onharishgnr0% (1)

- จัดตารางสอบกลางภาคภาคต้น53Dokument332 Seitenจัดตารางสอบกลางภาคภาคต้น53Yuwarath SuktrakoonNoch keine Bewertungen

- Solutions To Questions - Chapter 6 Mortgages: Additional Concepts, Analysis, and Applications Question 6-1Dokument16 SeitenSolutions To Questions - Chapter 6 Mortgages: Additional Concepts, Analysis, and Applications Question 6-1--bolabolaNoch keine Bewertungen

- Annotated Portfolio - Wired EyeDokument26 SeitenAnnotated Portfolio - Wired Eyeanu1905Noch keine Bewertungen

- MOL Breaker 20 TonDokument1 SeiteMOL Breaker 20 Tonaprel jakNoch keine Bewertungen

- Surge Arrester: Technical DataDokument5 SeitenSurge Arrester: Technical Datamaruf048Noch keine Bewertungen

- 254 AssignmentDokument3 Seiten254 AssignmentSavera Mizan ShuptiNoch keine Bewertungen

- Coca-Cola Summer Intern ReportDokument70 SeitenCoca-Cola Summer Intern ReportSourabh NagpalNoch keine Bewertungen

- Aisc Research On Structural Steel To Resist Blast and Progressive CollapseDokument20 SeitenAisc Research On Structural Steel To Resist Blast and Progressive CollapseFourHorsemenNoch keine Bewertungen

- POM 3.2 Marketing Management IIDokument37 SeitenPOM 3.2 Marketing Management IIDhiraj SharmaNoch keine Bewertungen

- Mathematical Geophysics: Class One Amin KhalilDokument13 SeitenMathematical Geophysics: Class One Amin KhalilAmin KhalilNoch keine Bewertungen

- Permit To Work Audit Checklist OctoberDokument3 SeitenPermit To Work Audit Checklist OctoberefeNoch keine Bewertungen

- S200 For Sumber RezekiDokument2 SeitenS200 For Sumber RezekiIfan JayusdianNoch keine Bewertungen

- Brother Fax 100, 570, 615, 625, 635, 675, 575m, 715m, 725m, 590dt, 590mc, 825mc, 875mc Service ManualDokument123 SeitenBrother Fax 100, 570, 615, 625, 635, 675, 575m, 715m, 725m, 590dt, 590mc, 825mc, 875mc Service ManualDuplessisNoch keine Bewertungen

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Dokument6 SeitenType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheNoch keine Bewertungen

- DFUN Battery Monitoring Solution Project Reference 2022 V5.0Dokument50 SeitenDFUN Battery Monitoring Solution Project Reference 2022 V5.0A Leon RNoch keine Bewertungen

- Qa-St User and Service ManualDokument46 SeitenQa-St User and Service ManualNelson Hurtado LopezNoch keine Bewertungen

- Mutual Fund Insight Nov 2022Dokument214 SeitenMutual Fund Insight Nov 2022Sonic LabelsNoch keine Bewertungen

- How To Unbrick Tp-Link Wifi Router Wr841Nd Using TFTP and WiresharkDokument13 SeitenHow To Unbrick Tp-Link Wifi Router Wr841Nd Using TFTP and WiresharkdanielNoch keine Bewertungen

- Oasis 360 Overview 0710Dokument21 SeitenOasis 360 Overview 0710mychar600% (1)

- Drug Study TemplateDokument2 SeitenDrug Study TemplateKistlerzane CABALLERONoch keine Bewertungen

- Kit 2: Essential COVID-19 WASH in SchoolDokument8 SeitenKit 2: Essential COVID-19 WASH in SchooltamanimoNoch keine Bewertungen

- Fast Binary Counters and Compressors Generated by Sorting NetworkDokument11 SeitenFast Binary Counters and Compressors Generated by Sorting Networkpsathishkumar1232544Noch keine Bewertungen

- How Can You Achieve Safety and Profitability ?Dokument32 SeitenHow Can You Achieve Safety and Profitability ?Mohamed OmarNoch keine Bewertungen

- Apst GraduatestageDokument1 SeiteApst Graduatestageapi-253013067Noch keine Bewertungen

- BS As On 23-09-2023Dokument28 SeitenBS As On 23-09-2023Farooq MaqboolNoch keine Bewertungen

- MMMDokument6 SeitenMMMReet KanjilalNoch keine Bewertungen