Beruflich Dokumente

Kultur Dokumente

3 Karadzic Bergant ZL p369 380

Hochgeladen von

SasankOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

3 Karadzic Bergant ZL p369 380

Hochgeladen von

SasankCopyright:

Verfügbare Formate

Strojniki vestnik - Journal of Mechanical Engineering 55(2009)6, 369-380 Paper received: 22.12.

2008

UDC 621.22 Paper accepted: 08.07.2009

A Novel Pelton Turbine Model for Water Hammer Analysis

Uro Karadi1,* - Anton Bergant2 - Petar Vukoslavevi1

1

University of Montenegro, Faculty of Mechanical Engineering, Montenegro

2

Litostroj Power d.o.o., Slovenia

This paper presents a novel Pelton turbine model for water hammer analysis. Water hammer

phenomena have been investigated in Peruica high-head hydropower plant (HPP), Montenegro. During

its first phase of modernisation and refurbishment new distributors (needle valves) have been installed on

the first two Pelton turbine units. Closure of the Pelton turbine distributors for the case of emergency

shut-down and load rejection under governor control is modelled by two different closing laws i.e. the

two-speed closing law and the law that considers actual (measured) needle stroke. Dissipation torques in

turbine housing and shaft bearings are considered in the model. Stop procedure of the turbine unit is

also investigated. Numerical results using the standard quasi-steady friction model and the convolution

based unsteady friction model for different distributor closing laws are compared with the results of

measurements. The agreement between computed and measured results is reasonable. It is shown that the

effect of unsteady friction on water hammer events in Peruica HPP is of little importance (slow varying

transients).

2009 Journal of Mechanical Engineering. All rights reserved.

Keywords: water hammer, Pelton turbine, high-head HPP, turbine speed change, unsteady friction

0 INTRODUCTION hammer equations are presented. Water hammer

is fully described by two hyperbolic partial

Water hammer control is essential to differential equations, the equation of continuity

assure safe operation of hydropower plant (HPP). and the momentum equation [3] and [4]. These

Excessive transient loads may disturb the overall equations are solved by the method of

operation of the plant and damage the system characteristics (MOC) using efficient staggered

components, for example pipe rupture may occur. (diamond) grid [3]. Friction losses in tunnels and

In hydropower plants water hammer is induced penstocks of hydropower plants are traditionally

by turbine load acceptance and reduction, load estimated by the quasi-steady friction model. It is

rejection under governor control, emergency shut- clear that the role of friction in one-dimensional

down and unwanted runaway, and closure and pipe flow depends on the system under analysis; it

opening of the safety shutoff valve. Water is important for systems that are unsteady friction

hammer causes pressure to rise or drop in dominant (i.e., unsteady friction dominates over

penstocks of the hydropower plants, rotational steady friction). Unsteady friction arises from the

speed change of turbine units and level variations extra losses from the two-dimensional nature of the

in surge tanks [1]. The water hammer unsteady velocity profile. It is desirable to have a

phenomenon is traditionally described by one- model that takes into account higher dimensional

dimensional unsteady pipe flow equations and velocity profile behaviour, but still can be

equations describing boundary elements efficiently implemented in the one-dimensional

(reservoir, valve, surge tank, turbine). In contrast analysis. In doing so, a convolution based

to reaction type water turbines that are well unsteady friction model [7] is used in this paper.

defined in literature as boundary conditions for Two different closing laws for the distributor

water hammer analysis [2] to [4], the impulse (needle valve) of the Pelton turbine are

type Pelton turbine is not well defined; usually it investigated. Precise modelling of Pelton turbine

is represented as an end-valve boundary condition distributor stroke is essential for accurate

[5] and [6]. numerical results. A novel model for calculation

This paper presents a novel Pelton turbine of Pelton turbine rotational speed change during

model for water hammer analysis that includes emergency shut-down is presented in detail. In

dynamics of the distributor (end-valve) with a jet the second part of the paper comparisons of

deflector and the turbine wheel. In the first part of computed and experimental results are made for

the paper mathematical tools for solving water turbine load rejection cases (load rejection under

*

Corr. Author's Address: Faculty of Mechanical Engineering, Dzordza Vasingtona nn, 81000 Podgorica,

369

Montenegro, uros.karadzic@ac.me

Strojniki vestnik - Journal of Mechanical Engineering 55(2009)6, 369-380

governor control, emergency shut-down) from 2

different initial powers and for turbine unit stop 1 6.9 1.11

= 1.8 log + , (4)

from speed no-load conditions. All the presented

numerical models give very good fit with results

fq

Re 3 .7 D

of measurements. It is shown that unsteady where Re is Reynolds number and is absolute

friction effects have a small impact on water pipe roughness. The unsteady friction factor is

hammer events in the Peruica HPP flow-passage calculated using a convolution based model

system (slow varying transients). (CBM) [7]. In computationally efficient and

accurate CBM the unsteady friction factor is

1 THEORETICAL MODEL expressed as a finite sum of Nk functions yk(t) [11],

Nk

32A

Water hammer is the transmission of

pressure waves along the pipeline resulting from a

fu =

DQ Q

y (t ) ,

k =1

k (5)

change in flow velocity. The simplified continuity

and momentum equations, appropriate for most with

engineering applications, which are solved to e nk Kt yk (t ) + ,

yk (t + 2t ) = e nk Kt (6)

mk [Q(t + 2t ) Q(t )]

compute the liquid unsteady pipe flow are [3] and

[4],

2 where is kinematic viscosity, Nk is number of

H a Q exponential terms (Nk,max = 10), t is time step, and

+ =0, (1)

t gA x K is constant equal to 4/D2. Coefficients mk and

nk have been developed for Zielke's [7] and

H 1 Q f Q| Q | Vardy-Brown's [12] and [13] weighting functions

+ + =0 , (2)

x gA t 2 gDA

2 and can be found in [11]. In addition, a

momentum correction factor (), defined by Eq.

where H is piezometric head (head), Q is

(7), is incorporated into the MOC solution when

discharge, a is pressure wave speed, D is pipe

CBM model is used [14],

diameter, A is pipe area, g is gravitational

acceleration, f is Darcy-Weisbach friction factor, 1 2

= v dA , (7)

x is distance along the pipe, and t is time. For AV A

2

solving Eqs. (1) and (2) the staggered (diamond)

where v is flow velocity. The momentum

grid [3] in applying the method of characteristics

correction factor can be determined from either the

(MOC) is used in this paper. At a boundary

log or power laws for the velocity distribution [15].

(reservoir, Pelton turbine), a device-specific

equation replaces one of the MOC water hammer

2 A NOVEL PELTON TURBINE MODEL

compatibility equations.

Pelton turbine distributor (needle valve) is

1.1 Modelling Friction Losses

utilized for control of discharge and consequently

for control of the turbine output. Discharge is

Friction losses in tunnels and penstocks of

adjusted by closing or opening the nozzle mouth

hydropower plants are usually calculated by

by means of a needle (Fig. 1) and with an

quasi-steady friction model. This model does not

appropriate position of the jet deflector. It should

give satisfactory results for fast transients when

be noted that the discharge through the nozzle is

numerical results are compared with experiments

solely dependent on the position of the needle; it

[8]. The friction factor f can be expressed as the

is not dependent on the turbine speed [16].

sum of the quasi-steady part fq and the unsteady

Consequently, water hammer equations and the

part fu [9],

dynamic equation of the turbine unit rotating

f = f q + fu . (3) parts can be solved separately. In this way the

instantaneous head at the nozzle inlet and the

The quasi-steady friction factor depends

instantaneous discharge through the nozzle are

on the Reynolds number and relative pipe

calculated by the MOC algorithm and these

roughness and it is updated every time step. In this

values are used as input in the solution method

paper the Halland explicit equation [10] is used,

370 Karadi, U. - Bergant, A. Vukoslavevi, P.

Strojniki vestnik - Journal of Mechanical Engineering 55(2009)6, 369-380

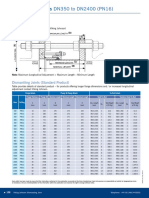

Fig. 1. Pelton turbine distributor (needle valve)

for the dynamic equation of the unit rotating Em1

t

parts.

= i ( i f ) , (10)

The instantaneous discharge through the

nozzle ((Qu)t) is calculated by the following

t c1

equation, and for tp t tc,

Em 2

(Qu ) t = K Q Am 2 g ( H u ,t H d ) , (8) t tp

= 1 ( 1 f ) , (11)

where KQ is nozzle discharge coefficient, Am is t t

nozzle area, Hu,t is head at the nozzle inlet, and Hd

c p

is constant head downstream the nozzle. Typical where i is initial opening of the nozzle, f is final

functional dependency of the discharge opening of the nozzle, 1 is nozzle opening at

coefficient KQ and the ratio of needle stroke s and time t = tp, tp is natural damping starting time

nozzle diameter dm is depicted in Fig. 2. The (time at the begining of the second step of the

needle closing law is expressed as follows, needle closure), tc is needle closing time, tc1 is

closure time for the one speed closure case, Em1,

s = s max , (9)

Em2 are nozzle closure parameters.

where is dimensionless nozzle opening, and smax For the case of load rejection under

is maximum needle stroke. governor control the two speed closure is not

employed because the needle finally stays in

1.0 speed no-load position that is larger than the

0.8 needle position when the second closure step

KQ / (KQ)max (-)

begins [17]. In this case the actual (measured)

0.6 needle stroke (ANS) is used.

0.4

2.1 Pelton Turbine Emergency Shut-down

0.2

The emergency shut-down of the turbine

0.0

0.0 0.2 0.4 0.6 0.8 1.0 unit is the most severe normal operating transient

regime [4]. The turbine is disconnected from the

s/dm / (s/dm)max (-)

electrical grid followed by simultaneous gradual

Fig. 2. Typical discharge coefficient of Pelton full-closure of the needle(s) and rapid activation

turbine nozzle of the jet deflector(s) (deflection of the jet from

The dimensionless nozzle opening for the the wheel). The equation that describes dynamic

case of emergency shut-down of the turbine unit behaviour of the Pelton turbine unit rotating parts

can be calculated using two-speed closing law during emergency shut-down is,

[17]. A model with a two-speed closure better d

attenuates pressure pulses compared to the model J (

= M h M fr + M air , )

(12)

with one-speed closure (classical linear closure). dt

This means that at the end of the closure the where J is polar moment of inertia of the turbine

needle actually moves a little bit slower (natural unit rotating parts, is angular velocity, Mh is

damping). For the time t < tp the dimensionless hydraulic torque, Mfr is shaft bearing friction

nozzle opening is expressed as follows, torque, and Mair is fluid damping torque

A Novel Pelton Turbine Model for Water Hammer Analysis 371

Strojniki vestnik - Journal of Mechanical Engineering 55(2009)6, 369-380

(ventilation losses in the turbine housing). A where Db is shaft bearing diameter, and b is shaft

novel solution of Eq. (12) including a hydraulic bearing friction coefficient. The resultant forces in

brake is presented in this paper; a simplified the shaft bearings RAb, RBb of the horizontal-shaft

solution of Eq. (12) that considers only the effect unit are due to hydraulic force, weight of the

of jet deflector can be found in [17]. By wheels, weight of the shaft and weight of the

introducing the relative speed change , generator.

n The dimensionless fluid damping torque is

= 1 , (13) expressed by [21],

nr

M air 1

K air n r ( + 1) ,

2 2

and the mechanical starting time Ta [1], [2] and mair = = (21)

[4], Mr Mr

Jnr where Kair is fluid (air) damping coefficient. It

Ta = , (14) should be noted that complex flow phenomena in

30 M r the turbine housing could be investigated by

into Eq. (12), after rearrangement it follows, modern flow visualization techniques [22].

If we introduce expressions,

d

Ta = mh m fr mair , (15) Dk Qm D n

K1 = Vm k r

dt M r Ta 60

where n is turbine rotational speed (traditionally DR K n 2

in rpm), r is rated, Mr is rated torque, and m is b b Ab air r , (22)

M r Ta M r Ta

dimensionless torque (m = M/Mr).

The dimensionless hydraulic torque is Dk2nr Qm 2 K air nr2

expressed as follows, K 2 = + , (23)

Mh 1 Dk 60 M T

r a

M r a

T

mh = = Fh , (16) 2

Mr Mr 2 K air nr

K3 = , (24)

where Fh is jet hydraulic force [18] and [19], M r Ta

Fh = 2 Qm (Vm u ) , (17) then the dynamic equation reads as follows,

where u is peripheral velocity, d 2

= K 3 + K 2 + K 1 , (25)

Dk n r dt

u= ( + 1) , (18) with the following solutions for the speed change

60 during t tdef [23],

where Dk is wheel diameter, is water mass 2

if ( 4 K 1 K 3 > K 2 ) then,

density, Qm is discharge to the turbine wheel, and

Vm is jet velocity (Vm = Qm / Am). 4K K K 2

1 3 2

(t t0 ) +

The discharge that acts on the turbine wheel 4 K1 K 3 K

2

2 K2

= 2

tan

can be evaluated from the following equation (t (26)

2K3 + tan 1 2 K 3 0 + K 2 2 K 3

tdef) [20], 4 K K K 2

1 3 2

0.11

t

Qm = Qu 1 , (19) 2

if ( 4 K 1 K 3 < K 2 ) then

t

def

p

where tdef is jet deflector operating time. p m q exp K 3 ( p q )(t t0 ) + ln 0

0 q

The dimensionless shaft bearing friction = (27)

p

torque is [19] and [21], 1 m exp K 3 ( p q )(t t0 ) + ln 0

0 q

M fr 1 Db

m fr = = b (R Ab + RBb ) , (20) where 0 is value of the relative speed

Mr Mr 2 at initial time t = t0, p and q are defined as,

372 Karadi, U. - Bergant, A. Vukoslavevi, P.

Strojniki vestnik - Journal of Mechanical Engineering 55(2009)6, 369-380

K 2 + K 22 4K1 K 3 Dk Qhb 4Qhb Dk nr

K1 = 2 +

p= 2M r Ta d hb 60

2K3

(22b)

(28) b Db RAb K air nr2

,

K 2 K 4K1 K 3

2

2 M r Ta M r Ta

q= .

2K 3

Dk2nr Qhb 2

2 K air nr

The hydraulic torque affects the turbine K 2 = + , (23b)

wheel until the jet deflector deflects all the water 120 M rTa M rTa

into the tailrace (t=tdef). At t > tdef the hydraulic

2

torque is set to zero and Eqs. (26) and (27) are K air n r

K3 = , (24b)

still valid with tdef and def instead t0 and 0 where M r Ta

def is relative speed at t = tdef. Expressions Ki (i =

1, 2, 3) are, where thb is hydraulic brake starting time (time

when the hydraulic brake is switched on), and hb

b Db R Ab K air n r 2

is relative speed at t = thb.

K 1 = + , (22a)

M r Ta M r Ta

2.2 Other Transient Operating Regimes

2

2 K air n r

K2 = , (23a) The solution method that describes

M r Ta dynamic behaviour of the Pelton turbine unit

2 rotating parts during load rejection under

K air n r governor control has been developed in a similar

K3 = . (24a)

M r Ta way. The turbine is disconnected from the

electrical grid followed by simultaneous gradual

When the turbine speed drops to n = 0.6nr

closure of the needle(s) to the speed-no load

(standard value) a hydraulic brake is switched on;

position and controlled manouvre of the jet

then Eq. (15) is modified to,

deflector(s) i.e. rapid activation at the first instant

d followed by gradual adjustment of the deflector to

Ta = m fr mair mhb . (29)

dt the speed-no load position. At the needle speed

In our case study the hydraulic brake is a no-load position the distributor provides

nozzle mounted on the opposite side of the wheel. sufficient discharge to maintain the rated turbine

The hydraulic brake is fed by a pipe connected to rotational speed. In this case the hydraulic torque

the main pipeline between the nozzle and the is balanced with disipation torques and the

spherical valve. The dimensionless hydraulic turbine speed is calculated by the following

brake torque is [24], equation,

M hb 1 D 2

mhb = = Qhb k K 2 + K 2 4 K1 K 3

Mr Mr 2 = , (32)

4Q D n (30) 2K 3

hb + k r ( + 1) ,

d2 60

hb with,

with hydraulic brake discharge, D n

K1 = Dk Qm Vm k r +

d 2

60 (22c)

Qhb = 0.9 hb

2gH hb , (31)

4 + b Db RAb + K air nr ,

2

where Hhb is available head at hydraulic brake

2

(Hhb Hu) and dhb is hydraulic brake nozzle Dk n r Qm 2

K2 = + 2 K air n r , (23c)

diameter. Eqs. (26) and (27) are still valid with thb 60

and hb instead t0 and 0. Expressions Ki (i = 1, 2,

3) are, K 3 = K air n r .

2

(24c)

A Novel Pelton Turbine Model for Water Hammer Analysis 373

Strojniki vestnik - Journal of Mechanical Engineering 55(2009)6, 369-380

In this case all the discharge through the LT = 3335 m, diameter DT = 4.8 m), orifice type

nozzle acts on the turbine wheel i.e. Qm Qu. surge tank (inflow and outflow orifice head loss

For turbine start-up the jet deflector(s) is coefficients: in = 1.65 and out = 2.48) of

moved from closed to its open position followed cylindrical cross-section (diameter DST = 8.0 m)

by gradual opening of the needle(s) to speed-no with an expansion at elevation z = 611.0 m (DST =

load position. The discharge through the nozzle(s) 12.0 m) and overflow (elevation: zov = 628.0 m;

acts on the turbine wheel and, after some time, width of the overflow weir: bov = 7.98 m with

the hydraulic torque is balanced with dissipation discharge coefficient ov = 0.4) and three parallel

torques resulting in rated turbine speed at the end steel penstocks with horizontal-shaft Pelton

of the process. The turbine is connected to the turbines built at their downstream ends (Fig. 3)

electrical grid followed by further opening of the [17] and [20]. The length of each penstock is

needle(s) to the position controlled by the turbine about 2000 m (see Table 1 for details) whereby

governor. penstock I feeds two turbine units (A1 and A2)

Turbine stop procedure from the speed no- with rated unit power of 39 MW, penstock II

load conditions to the turbine stand-still using feeds three turbine units (A3, A4 and A5) of 39

hydraulic brake is as follows. Needle(s) and jet MW each and penstock III feeds two units (A6

deflector close from their speed no-load positions and A7) of 59 MW each. A new turbine unit (A8)

and the turbine is assumed to slow-down only by with a rated power of 59 MW is to be installed in

dissipation torques until the turbine speed drops the near future. The maximum water level at the

to n = 0.6nr when the hydraulic brake is switched intake is 613 m and the minimum one is 602.5 m.

on. Now, the turbine stop becomes faster and The Pelton wheel diameter of units A1 to

finally the turbine is stopped (n = 0 min-1). A5 is Dk = 2400 mm and for units A6 and A7 is

Dk = 2100 mm. Basic characteristics of the Pelton

3 PERUICA HPP FLOW-PASSAGE SYSTEM turbine units are presented in Table 2. The turbine

inlet spherical valves diameters are Dz = 1000

Peruica HPP flow-passage system is a mm and Dz = 1200 mm, respectively. The valves

complex system comprised of an intake structure are equipped with a passive actuator comprised of

with a guard gate [25], a concrete tunnel T (length a hydraulic servomotor.

Fig. 3. Layout of Peruica HPP

374 Karadi, U. - Bergant, A. Vukoslavevi, P.

Strojniki vestnik - Journal of Mechanical Engineering 55(2009)6, 369-380

Table 1. Geometrical characteristics of penstocks

Penstock I Penstock II Penstock III

Pipe Pipe wall Pipe Pipe wall Pipe Pipe wall

Section Length

diameter thickness diameter thickness diameter thickness

(m)

(mm) (mm) (mm) (mm) (mm) (mm)

T1-T2 75.0 2200 10 2200 10 2650 12

T2-T3 61.0 2200 10 2200 10 2650 12

T3-T4 330.5 2200-2100 10 2200 10-16 2650 12-13

T4-T5 318.0 2100-2000 16-25 2200 17-23 2650 13-21

T5-T6 123.0 2000 26-29 2200 24-27 2650 21-24

T6-T7 672.0 1900 27.5 2200-2100 26 2500 23

T7-T8 238.0 1800 27-39 2100 26-34 2500 24-29

I: 53.0

T8-T9 II: 99.8 1800 39 2100 34 2500 29

III: 146.6

Table 2. Characteristics of Pelton turbine units

Rated unit power Rated net head Rated speed

Turbine unit

(MW) (m) (min-1)

A1,A2,A3,A4 39 526 375

A5 39 526 375

A6,A7 59 526 428

Number of runners The polar moment of inertia of the Number of needles per

Turbine unit per turbine unit unit rotating parts J (tm2) turbine runner

A1,A2,A3,A4 2 168.75 1

A5 2 168.75 1

A6,A7 2 200 2

Opening time of the

Stroke of the needle Closing time of the needle

Turbine unit needle

(mm) (s)

(s)

A1,A2,A3,A4 150 85 30

A5 195 80 30

A6,A7 166 80 50

Influental quantities were continuously speed was measured using inductive sensor

measured during transient operating regimes Balluff BES M18MI-PSC50B-S04K (uncertainty

including pressure at the upstream end of the in measurement 0.03%).

distributor, stroke of the needle, stroke of the jet

deflector and turbine rotational speed. These 4 COMPARISONS OF NUMERICAL AND

measurements were carried out on turbine units FIELD TEST RESULTS

A1 and A2. Pressures were measured by

absolute high-pressure piezoelectric transducers During commissioning of the turbine

Cerabar T PMP 131-A1101A70 Endress + units A1 and A2 the following regimes were

Hauser (range 0 to 100 bar, uncertainty in investigated: the unit start-up and stop, load

measurement 0.5%). The needle stroke and the acceptance and reduction, load rejection under

stroke of the jet deflector were measured by governor control and emergency shut-down, and

discplacement transducers Balluff BTL5-S112- closure of turbine safety valve against the

M0175-B-532 and Balluff BTL5-S112-M0275- discharge. Numerical results from the standard

B-532, respectively. Uncertainty of these quasi-steady friction model (QSF) and the

sensors is 0.03 mm. The turbine rotational convolution based unsteady friction model

A Novel Pelton Turbine Model for Water Hammer Analysis 375

Strojniki vestnik - Journal of Mechanical Engineering 55(2009)6, 369-380

(CBM) for different needle's closing laws are turbine unit A1 are shown in Fig. 4 (Test A).

compared with the results of measurements. The The calculated and the measured total needle

following results of measurements and closing times are the same (tc = 56.1 s see Fig.

corresponding numerical simulations are 4a). The closing time is much larger than the

presented: water hammer reflection time of 2LI/aI = 3.84 s.

1. Emergency shut-down of turbine unit A1 The maximum measured head of 557.7 m

from initial power P0 = 37 MW (Test occurs at the end of the nozzle closure period

A1P37MW is Test A), with the head rise of 24.5 m. The maximum

2. Simultaneous load rejection under governor calculated heads match the measured i.e. 557.5

control of turbine units A1 and A2 from m obtained by QSF (see Fig. 4b) and 557.8 m

initial power of P0 = 42 MW each (Test obtained by CBM (see Fig. 4c). The calculated

A1&A2P42MW is Test B), and measured heads are much lower than the

In addition, speed change during stop maximum permissible head of 602 m. The

procedure of the turbine unit A1 is included too. numerical results using two-speed needle stroke

The main initial parameters for the two test [17] show very good agreement with the

cases are presented in Tables 3, 4 and 5. The measured results during the nozzle closure

flow in penstock I is turbulent with a large period. After this, a slight phase shift of

Reynolds number (ReI). Pressure wave speeds numerical results is evident from the third

for all tests are as follows, aT = 1354 m/s, aI = pressure pulse but with good attenuation at all

1148 m/s, aII = 1123 m/s and aIII = 1152 m/s. times. Friction losses are described slightly

better by the CBM model during the decay

4.1 Comparison of Numerical and Measured period of transient process. It is evident that the

Head at the Turbine Inlet Peruica flow-passage system is not an unsteady

friction dominant system during water hammer

Transient head and discharge for the events. Comparisons between numerical results

power plant flow-passage system were using two-speed (theoretical) needle stroke

computed using a staggered grid MOC code. (TNS) and actual (measured) needle stroke

Basic time step was t = 0.04 s. Computed and (ANS) (see Fig. 4d) show that TNS model

measured results are shown in Figs. 4, 5 and 6. adequately simulates water hammer events

Computed and measured heads at the during emergency shut-down of the turbine unit.

turbine inlet for emergency shut-down of the

Table 3. Initial discharges through tunnel (QT) and penstocks (QI, QII, QIII)

Test QI (m3/s) ReI 106 QII (m3/s) QIII (m3/s) QT (m3/s)

A 8.45 5.5 0 19.7 28.15

B 18.2 11.8 0 5.7 23.9

Table 4. Steady friction factors (f0) and momentum correction factors () for all tests

Penstock I Penstock II Penstock III Tunnel

Test

f0 f0 f0 f0

A 0.0107 1.0106 0.0118 1.0115 0.0155 1.0151 0.0146 1.0143

B 0.0104 1.0102 0.0118 1.0115 0.0156 1.0153 0.0146 1.0143

Table 5. Intake level (zR), needle closing time (tc), initial opening of the nozzle (s0) and jet deflector

operating time (tdef)

Test zR (m) tc (s) s0 (mm) tdef (s)

A 605.8 56.1 117 1.6

B 604.8 85.3 146 2.0

376 Karadi, U. - Bergant, A. Vukoslavevi, P.

Strojniki vestnik - Journal of Mechanical Engineering 55(2009)6, 369-380

a) b)

c) d)

Fig. 4. Comparison of needle stroke (s) and head at the turbine inlet (datum level z = 65.8 m; time step

t=0.04 s). Emergency shut-down of A1 from P0 = 37 MW (Test A).

The computed and measured heads at the Finally, it should be noted that the used

turbine inlet for simultaneous load rejection staggered grid MOC code was thoroughly tested

under governor control of turbine units A1 and for convergence and stability in [17] and [20].

A2 are compared in Fig. 5. Test B produces The code proved to be numerically robust.

maximum measured head of 573.9 m at the end

4.2 Comparison of Calculated and Measured

of the nozzle closure period with head rise of

Turbine Rotational Speed

57.2 m. For all numerical calculations the ANS

model was employed. The maximum calculated Turbine rotational speed change during

head obtained by QSF is 574.0 m (see Fig. 5b) emergency shut-down of turbine unit A1 (Test

and by CBM is 574.4 (see Fig. 5c). The needle A) and during simultaneous load rejection under

closure process to its speed-no load position governor control of turbine units A1 and A2

(3.25%) is governed by the turbine control (Test B) was calculated using appropriate

system and is followed by gradual adjustment of solution method of the dynamic equation of the

the jet deflector to its appropriate position (see unit rotating parts (Eq. (12)). The instantaneous

Fig. 5a). Up to this time all numerical models head and discharge through the nozzle during

show reasonable agreement with results of these transient regimes were previously

measurement. The maximum calculated heads calculated by the MOC (see Section 4.1). Fig. 6

are well below the maximum permissible head shows comparison between calculated and

of 602 m. Numerical models produce practically measured rotational speed change for both case

the same results after the closure period (see studies.

Fig. 5d).

A Novel Pelton Turbine Model for Water Hammer Analysis 377

Strojniki vestnik - Journal of Mechanical Engineering 55(2009)6, 369-380

a) b)

c)

d)

Fig. 5. Comparison of needle stroke (s) and head at the turbine inlet (datum level z = 65.8 m; time step

t=0.04 s). Simultaneous load rejection under governor control of A1 and A2 from P0 = 42 MW (Test B).

Fig. 6. Rotational speed change (n0 = 375 min-1) during emergency shut-down of A1 from P0 = 37 MW

(Test A) and simultaneous load rejection under governor control of A1 and A2 from P0 = 42 MW

(Test B).

378 Karadi, U. - Bergant, A. Vukoslavevi, P.

Strojniki vestnik - Journal of Mechanical Engineering 55(2009)6, 369-380

The maximum measured turbine speed 5 CONCLUSIONS

rise for Test A of 8.1% occurs at time t = tdef.

The maximum calculated turbine speed rise of Comparisons of computed and

8.1% perfectly agrees with measured one (see experimental results given for quasi-steady

Fig. 6a). After the jet deflector deflects all the friction model (QSF) and convolution based

water into the tailrace, the turbine wheel is not unsteady friction model (CBM) for different

affected by hydraulic torque and the turbine needle closing laws are made for turbine load

speed decrease is influenced by dissipation rejection cases (load rejection under governor

torques. During this period the calculated control, emergency shut-down). Turbine unit

turbine speed reasonably agrees with measured stop procedure is also investigated. Numerical

one. There is a very good agreement between results obtained by QSF and CBM models are

the maximum measured and computed turbine practically the same because the investigated

speed rise for Test B of 11.2% and 11.1%, case studies represent slow varying transients in

respectively (see Fig. 6b). There are some long pipelines. The effect of unsteady friction

discrepancies in the phase of speed decrease due for these cases is negligible. Numerical results

to complex flow behaviour in the turbine obtained by the model with two-speed needle

stroke (TNS) agree well with the results of

housing. The ventilation losses are dependent

measurement and with numerical results

on fluid density inside the turbine housing. The

obtained by the model that considers actual

fluid is basically air but it does contain a mist of

(measured) needle stroke (ANS) for the case of

water and this will increase complexity of flow emergency shut-down of the turbine unit. The

behaviour. In both investigated cases the TNS model captures natural damping effect in

maximum turbine speed rise is well below the the needle hydraulic servomotor close to its

permissible speed rise of 25%. fully closed position and successfully simulates

Turbine rotational speed change during real nature of water hammer events during

stop procedure of the turbine unit A1 from emergency shut-down of the turbine unit. For

speed no-load conditions using hydraulic brake the case of load rejection under governor

is shown in Fig. 7. There is a good agreement control the TNS model is not employed because

between measured and computed results. The the speed no-load needle position is larger than

process of turbine stopping lasts for about 560 s. the needle position when the second closure

step begins. A novel model of Pelton turbine

rotational speed change is used for calculating

transient rotational speed. There is a reasonable

agreement between the calculated and measured

results for all the investigated cases.

6 REFERENCES

[1] Pejovi, S., Boldy, A.P., Obradovi, D.

(1987), Guidelines to hydraulic transient

analysis, Gower Technical Press Ltd.,

Aldershot, UK, ISBN 0-291-39723-9.

[2] Krivchenko, G.I., Arshenevskij, N.N.,

Kvjatovskaja, E.V., Klabukov, V.M.

(1975), Hydraulic transients in hydro-

electric power plants, Energija, Moscow,

Russia (in Russian).

Fig. 7. Stop of unit A1 from speed no- [3] Wylie, E.B., Streeter, V.L. (1993), Fluid

load conditions using hydraulic brake (n0 = 375 transients in systems, Prentice Hall,

min-1) Englewood Cliffs, USA, ISBN 0-13-

322173-3.

A Novel Pelton Turbine Model for Water Hammer Analysis 379

Strojniki vestnik - Journal of Mechanical Engineering 55(2009)6, 369-380

[4] Chaudhry, M.H. (1987), Applied hydraulic Strojniki Vestnik Journal of Mechanical

transients, Van Nostrand Reinhold Engineering, 51(11), p. 692-710.

Company, New York, USA, ISBN 0-442- [15] Chen, C.L. (1992), Momentum and energy

21514-2. coefficients based on power-law velocity

[5] Evangelisti, G., Boari, M., Guerrini, P., profile, Journal of Hydraulic Engineering,

Rossi, R. (1973 & 1974), Some ASCE, 118(11), p. 1571-1584.

applications of waterhammer analysis by [16] Beniek, M. (1998), Hydraulic turbines,

the method of characteristics, LEnergia Faculty of Mechanical Engineering,

Elettrica, 50(1), 1-12 & 51(6), 309-324. Belgrade, Serbia, (in Serbian), ISBN 86-

[6] Fasol, K.H. (1964), Consideration of 7083-323-9.

dynamic characteristics of Pelton turbine [17] Karadi, U., Bergant, A., Vukoslavevi,

nozzles in water hammer analysis, ZE - P. (2008), Parameters affecting water

sterreichische Zeitschrift fr hammer in a high-head hydropower plant

Elektrizittwirtschaft, 17(8), p. 453-456 (in with Pelton turbines. Proceedings of the

German). 10th International Conference on Presure

[7] Zielke, W. (1968), Frequency-dependent Surges, BHR Group, Edinburgh, UK, p.

friction in transient pipe flow, Journal of 351-364.

Basic Engineering, ASME, 90(1), 109-115. [18] Nechleba, M. (1957), Hydraulic turbines

[8] Bergant, A., Simpson, A.R., Vtkovsk, J. their design and equipment, Artia, Prague,

(2001). Developments in unsteady pipe Czech Republic.

flow friction modeling, Journal of [19] Zhang, Zh., Mller, J. (2007), Efficiency

Hydraulic Research, IAHR, 39(3), p. 249- and runaway characteristics of a Pelton

257. turbine. Hydro 2007, Granada, Spain.

[9] Vardy, A.E. (1980), Unsteady flows: Fact [20] Karadi, U. (2008), Modelling of complex

and friction. Third International boundary conditions for transients in

Conference on Pressure Surges, BHRA, hydraulic systems, PhD Thesis, Faculty of

Canterbury, UK, p. 15-26. Mechanical Engineering, University of

[10] Haaland, S.E. (1983). Simple and explicit Montenegro, Podgorica, Montenegro (in

formulas for the friction factor in turbulent Montenegrian).

pipe flow, Journal of Fluids Engineering, [21] Thake, J. (2000). The micro-hydro Pelton

ASME, 105(3), p. 89-90. turbine manual. ITDG Publishing, London,

[11] Vtkovsk, J., Stephens, M., Bergant, A., UK, ISBN 1-85339-460-2.

Lambert, M., Simpson, A. (2004), Efficient [22] Bajcar, T., irok, B., Eberlinc, M. (2009),

and accurate calculation of Zielke and Quantification of flow kinematics using

Vardy-Brown unsteady friction in pipe computer-aided visualization, Strojniki

transients, Proceedings of the 9th Vestnik Journal of Mechanical

International Conference on Pressure Engineering, 55(4), p. 215-223.

Surges, BHR Group, Chester, UK, 15 pp. [23] Spiegel, M.R. (1968), Handbook of

[12] Vardy, A.E., Brown, J.M.B. (2003), mathematical formulas. Rensselaer

Transient turbulent friction in smooth pipe Polytechnic Institute, Troy, New York,

flows, Journal of Sound and Vibration, USA, ISBN 0-07-060224-7.

259(5), p. 1011-1036. [24] Edelj, J.U. (1963), Impulse water turbines

[13] Vardy, A.E., Brown, J.M.B. (2004), theory, research, analysis, Mashgiz,

Transient turbulent friction in fully rough Moscow, Russia (in Russian).

pipe flows, Journal of Sound and [25] Rek, Z., Bergant, A., Rthl, M., Rodi, P.,

Vibration, 270(1-2), p. 233-257. un, I. (2008), Analysis of hydraulic

[14] Bergant, A., Karadi, U., Vtkovsk, J., characteristics of guard-gate for hydropower

Vuanovi, I., Simpson, A.R. (2005), A plant, Strojniki Vestnik Journal of

discrete gas-cavity model that considers the Mechanical Engineering, 54(1), p. 3-10.

frictional effects of unsteady pipe flow,

380 Karadi, U. - Bergant, A. Vukoslavevi, P.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Dismantling Joint DN350 To DN2400 PN16 VJ DSDokument1 SeiteDismantling Joint DN350 To DN2400 PN16 VJ DSVignesh NadimuthuNoch keine Bewertungen

- Thrust Ball Bearings, Double DirectionDokument1 SeiteThrust Ball Bearings, Double DirectionSasankNoch keine Bewertungen

- Advanced Composite Bearings for Hydro Power PlantsDokument12 SeitenAdvanced Composite Bearings for Hydro Power PlantsSasankNoch keine Bewertungen

- SCI Flanged Fittings PDFDokument14 SeitenSCI Flanged Fittings PDFJosmar CristelloNoch keine Bewertungen

- RT765E 2 Product Guide ImperialDokument1 SeiteRT765E 2 Product Guide ImperialAnonymous 6XyAh3DNoch keine Bewertungen

- National Pension System (Enps) - Subscriber Registration FormDokument8 SeitenNational Pension System (Enps) - Subscriber Registration FormSasankNoch keine Bewertungen

- Thrust Ball Bearings, Double DirectionDokument1 SeiteThrust Ball Bearings, Double DirectionSasankNoch keine Bewertungen

- Dismantling Joints GuideDokument2 SeitenDismantling Joints GuideSasankNoch keine Bewertungen

- Energies 10 00103Dokument19 SeitenEnergies 10 00103SasankNoch keine Bewertungen

- Quantifiable Crack Detection in Newly Installed Pelton TurbineDokument4 SeitenQuantifiable Crack Detection in Newly Installed Pelton TurbineSasankNoch keine Bewertungen

- RT765E 2 Product Guide ImperialDokument1 SeiteRT765E 2 Product Guide ImperialAnonymous 6XyAh3DNoch keine Bewertungen

- SCI Flanged Fittings PDFDokument14 SeitenSCI Flanged Fittings PDFJosmar CristelloNoch keine Bewertungen

- Spherical Roller Bearings-22210 EDokument2 SeitenSpherical Roller Bearings-22210 EManoj TyagiNoch keine Bewertungen

- C-2208-CARB Toroidal Roller BearingsDokument1 SeiteC-2208-CARB Toroidal Roller BearingsSasankNoch keine Bewertungen

- Effects of Load Variation On A Kaplan Turbine Runner: ArticleDokument13 SeitenEffects of Load Variation On A Kaplan Turbine Runner: ArticleSasankNoch keine Bewertungen

- 10 11648 J Ijepe 20150404 14 PDFDokument11 Seiten10 11648 J Ijepe 20150404 14 PDFbacuoc.nguyen356Noch keine Bewertungen

- CARB Toroidal Roller Bearings PDFDokument1 SeiteCARB Toroidal Roller Bearings PDFSasankNoch keine Bewertungen

- C-2208-CARB Toroidal Roller Bearings PDFDokument1 SeiteC-2208-CARB Toroidal Roller Bearings PDFSasankNoch keine Bewertungen

- Bolted JointsDokument3 SeitenBolted JointsGiuseppe GiuseppeNoch keine Bewertungen

- Piping Elbows - Thrust Block ForcesDokument5 SeitenPiping Elbows - Thrust Block ForcesSasankNoch keine Bewertungen

- Remark : HMC3-280S-46p-B3Dokument1 SeiteRemark : HMC3-280S-46p-B3SasankNoch keine Bewertungen

- Pre-Proposal Conference Cum Webinar - FlyeDokument3 SeitenPre-Proposal Conference Cum Webinar - FlyeSasank0% (1)

- SCI Flanged Fittings PDFDokument14 SeitenSCI Flanged Fittings PDFJosmar CristelloNoch keine Bewertungen

- DCP NcovDokument5 SeitenDCP NcovNicoleta MNoch keine Bewertungen

- Article - Bolted Joint DesignDokument15 SeitenArticle - Bolted Joint DesignPiyush YardiNoch keine Bewertungen

- FSAF 22314: SAF and SAW Pillow Blocks With Bearings With A Cylindrical BoreDokument4 SeitenFSAF 22314: SAF and SAW Pillow Blocks With Bearings With A Cylindrical BoreSasankNoch keine Bewertungen

- Calculation of The Parameters of Model Hydraulic Turbine Using The Value of The Specific SpeedDokument28 SeitenCalculation of The Parameters of Model Hydraulic Turbine Using The Value of The Specific SpeedSasankNoch keine Bewertungen

- Small Hydropower Standards GuideDokument62 SeitenSmall Hydropower Standards GuideSasank100% (1)

- Bureau of Indian Standards-List For StudentsDokument23 SeitenBureau of Indian Standards-List For StudentsSasankNoch keine Bewertungen

- QSMicrohydroSEP2005 PDFDokument57 SeitenQSMicrohydroSEP2005 PDFSasank0% (1)

- Steam Traps - Engineering Data ManualDokument50 SeitenSteam Traps - Engineering Data ManualThitikorn Wassanarpheernphong100% (1)

- Backflow Irrigation Control Station BIC-1000 Installation InstructionsDokument8 SeitenBackflow Irrigation Control Station BIC-1000 Installation InstructionsWattsNoch keine Bewertungen

- Maximum Water Hammer Sensitivity Analysis: AbstractDokument4 SeitenMaximum Water Hammer Sensitivity Analysis: AbstractKarl Angelo CuellarNoch keine Bewertungen

- Allievi PDFDokument33 SeitenAllievi PDFluis_enrique_cv100% (1)

- Fluid Mechanics & Hydraulics Civil Engineering - PRACTICE PROBLEMS - 2017 INSTRUCTION: Select The Correct Answer For Each of The FollowingDokument36 SeitenFluid Mechanics & Hydraulics Civil Engineering - PRACTICE PROBLEMS - 2017 INSTRUCTION: Select The Correct Answer For Each of The FollowingFrancis Philippe CariñoNoch keine Bewertungen

- APCO Silent Check PDFDokument8 SeitenAPCO Silent Check PDFtanvir04169Noch keine Bewertungen

- Study The Water Hammer Phenomena It's Causes and Solutions: M.SC. Mudafer Kadum Kredi M.SC. Lammia'a Abdulrudah AbdDokument25 SeitenStudy The Water Hammer Phenomena It's Causes and Solutions: M.SC. Mudafer Kadum Kredi M.SC. Lammia'a Abdulrudah AbdYazNoch keine Bewertungen

- Instrucal IIIDokument46 SeitenInstrucal IIINorberto Soto100% (1)

- MDF-L Iwaki Instruction Manual 5-05 PDFDokument32 SeitenMDF-L Iwaki Instruction Manual 5-05 PDFManuel FernizaNoch keine Bewertungen

- GUYER 2012 Introduction To Pumping Stations For Water Supply Systems PDFDokument42 SeitenGUYER 2012 Introduction To Pumping Stations For Water Supply Systems PDFKaniz PriyangkaNoch keine Bewertungen

- Elbi Vessel Data SheetDokument20 SeitenElbi Vessel Data SheetMAZENNoch keine Bewertungen

- Alfa Laval Gphe Industrial Small Manual enDokument46 SeitenAlfa Laval Gphe Industrial Small Manual enjohnPolancotafurNoch keine Bewertungen

- Centrifugal Pumps - Part III - Shutoff PressureDokument7 SeitenCentrifugal Pumps - Part III - Shutoff PressurefifieNoch keine Bewertungen

- Hydropower WCSDokument36 SeitenHydropower WCSKathiravan ParameswaranNoch keine Bewertungen

- Abasyn University Hydrology Course OverviewDokument8 SeitenAbasyn University Hydrology Course OverviewAsfahan AliNoch keine Bewertungen

- Alfa Laval PHE Instr. ManualDokument24 SeitenAlfa Laval PHE Instr. ManualWALTER DELGADONoch keine Bewertungen

- Surge Analysis and Design - Case StudyDokument10 SeitenSurge Analysis and Design - Case StudyRaghuveer Rao PallepatiNoch keine Bewertungen

- Numerical Simulacion of Watter HammerDokument4 SeitenNumerical Simulacion of Watter HammerWilliam Lopez AyalaNoch keine Bewertungen

- Designing Hydraulic Air Chamber in Water Transmission Systems Using Genetic AlgorithmDokument8 SeitenDesigning Hydraulic Air Chamber in Water Transmission Systems Using Genetic AlgorithmdeajahNoch keine Bewertungen

- Water Hammer Calculation Software (WHC) : IMEC04-3065Dokument7 SeitenWater Hammer Calculation Software (WHC) : IMEC04-3065Souvik DasNoch keine Bewertungen

- Conduit Dynamics in Herand Power Plant NTNU ThesisDokument89 SeitenConduit Dynamics in Herand Power Plant NTNU ThesisRodrigo SaraivaNoch keine Bewertungen

- Datasheet Municipal Bladder Surge TanksDokument4 SeitenDatasheet Municipal Bladder Surge TanksjdNoch keine Bewertungen

- PIPENET Sunrise PDFDokument4 SeitenPIPENET Sunrise PDFsammar_10100% (1)

- AVK Check ValvesDokument4 SeitenAVK Check ValvesgdpNoch keine Bewertungen

- Designing Efficient Sewage Pumping SystemsDokument10 SeitenDesigning Efficient Sewage Pumping SystemsPriyanka Rupasinghe67% (3)

- Krehl 2001Dokument142 SeitenKrehl 2001bernardo.favini6840Noch keine Bewertungen

- Building Services: Group PresentationDokument65 SeitenBuilding Services: Group PresentationSAANO SOLOMENoch keine Bewertungen

- KLM Piping SizingDokument58 SeitenKLM Piping SizingxflyNoch keine Bewertungen

- D 3309 - 96a R02 RDMZMDKDokument11 SeitenD 3309 - 96a R02 RDMZMDKHumberto GutierrezNoch keine Bewertungen

- Pumped Storage Plants Supply Peak PowerDokument26 SeitenPumped Storage Plants Supply Peak PowerJoshua S4j Oryem OpidoNoch keine Bewertungen