Beruflich Dokumente

Kultur Dokumente

Inspection of HDG After Fabrication

Hochgeladen von

pbp2956Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Inspection of HDG After Fabrication

Hochgeladen von

pbp2956Copyright:

Verfügbare Formate

The Inspection of

Products Hot-DiP

Galvanized After-

Fabrication

Including a New

Section on

Touch-Up and RePair

AMERI( N CAlvANlzERs ASsoclATloN

Tnr InsptcloN oF PRooucrs Hor-Dtp GnlvnNzto

.i'

furrn FnnrucnrtoN

TABLE oF Cor'natus

Ilspctio! .... .

Purpoeo of

ssEDlhc br Testg

Coaiqg Miqoducnre aod Carues of Thickness atrd Ulilormlty

Thicktr68 Tstirg

Mrgnaic Thiclrccs frlcasurements

Stippine 8trd Wsighiry Metbod .

Woigbilg Bforc ald After Galvaniziog

Mictoscolty......... .6

Thiclogs Tstilg Gsugrs .6

Msgretic Bslslce Gauges

Pull-ofr Mrga*ic Oauges

Eloclr,odc Thichss Gsuges

MetsllographicExsEinstioo.... ...

Coatiq Adherl|trce

T6tirg for Adhererce .

Appearmce

healv.nizing Consultotiotr

Visurl lDspdioo Guide .. . ..

Bsrr Spoa . l0

General Rougbness t0

Drors PrcEusions .t0

LuEpioess snd Runs l0

Flun Inclusiots ....

Ash Inclusions ll

Matie Cray or Mottled Coating II

Ruststains.... .ll

Wet Storage Stsitr 12

Miscells[eous Testl r)

Testiog for CbDmate Filishes . .

11

Embdttlemedt Testing . .

Touch-r{ atrd Repait . . . ..:

Wh; is Touch-up NecessarY? .. .. .

SpccificatioEs .13

Surftce Preparatioo

Touch-r.p aad Repair Methods ... .

Metallizing (zinc Spriyrtrg) .... .13

Defitritiotr .

Surface Preparation . l4

Application .14

Perfortl|'trceChsracteristics .. .

* -"'aa - "*6r'tuEh'@w*a ntts*dmtan ud

, ,i6 hdtp sztnrtd 4b. teb*" ,,. "*", *"-' "ii';;;;i*i) i' ':^n ^a "

abbr6n tudh, or.! @1td*, ^'*"*,*,'*

- - --.*e *, "t 6' ttldt h' @ q44'lt t"i"itti t' 4 lra'u'' 4r

'-;,.-. "t

AIMEzucAN CAwANIzERs AssoclATtoN

TABLE oF Conrtnrs - CoNn

."" l5

Zinc-icb Psint Applicatiotr . . . . -lJ

Dfitrition..... l)

Surh.o Preprntiotr . l5

Applicotiotr . . . t)

Perbrmanc Ch$acteristrcs . . . . . . . . .\6

soldering wirh Zinc$ased Alloys .. l6

De6lition....... ....... l6

Surfsoe Plrpatation

.16

Applioetion

.16

Pcrfolmstrce Chd'actcnstics . '

t1

ReDAir Method Slection Colsiderdtions l8

Reloted Specifications . " '

,,-.

AMERIc\N CALVANIZER5 A5SOCIATION

PuRPosE ot lNsPEcrloN

Hcnnip galvm;rg after hbrication ir orc oftLe nost widly uscd Esth-

1- ods ofconosion potectioo" The fiul step in the hoaip gdvada!8 !'locss-

is iEptiotr to orrrt compli.trce with spcificstio[s. totcrpretstiotr of

itrsDectiotr r8ults mtd be mad with r clear utrdetstaldrDg ol tne ctuEs or

wious cotiag conditioos and their afbc'ts on lhe ultiDsb objective of pro-

viding cqnosioD proEctio&

Firct dnd Iorcrdost thP pttrpose of hot4ip galt'aniiing is lo prokcl

steel from coirosion, The leogth of time this Fotectiotr catr rasooably !e

eroect d to last beforE rnini'n.l EEilttenslc is rcquiEd is calcd its "scrvice

1i1s." 6&tvrnfing's srvic.e life i8 dirctly rcbred to the thi:hess of fre

pro-

tective ziac coe&g lhe thicks the cootiog d|e lotrgsr- ihe service lifc fsce

Ft?at" 1r. Thus, co.titrg thickness is the single Bost importslt rispecf,on

cbeck to detcrmiae the qurlity ofo 881v8!ized coatllg.

coditrg liiclness, howevct, is ody ooe item of iDspctior c-9d"s .q-

formity, adertnce aad lppcaralce also 8re evslusted Additio@lly' enbtit-

tbmdt 8d der defclr- arising fi'om fat'rication rnd design 8re inspctiotr

concenlll.

Whilc midouo standards must be satisfied il all these areas' their rEl-

.- alive iry{trteoce varies accordi.trg io the End-us ofthe fmished product' For

exaoplg the ed-use rcqufuemetrt for g8lve[ized sEuctural sreel in an iso-

lsred arsa differs tod that for a thi!auge product used u a docorasve

application. Utdrrstadhg tbe hdividurl rcquircmedts of fte goduci 8trd

tii of the hotdip galvonizing process is essential for proper

""pulitlty

uspeuon.

Iupection of the galvanized ptoduct is most effctively and efficieady

coodufod at 6e galv-anizer's plaat- ttere. questioos atrd co&erns cm.be

raised ald dealt with quicuy aad ef6cietdy - spedng !P tne lnspecooD

procesg and Esultilg in a time savitrgs thst is ao assei to the ovei'dl pmjecl

Rgure I

SAMPLING FoR TESrs Lltc of Prol.<iton vt Thktor.3t of Zln

To Foprly evaluate hot-dip galvaoized coot- and Bpc o, Afrn6phar.

i!ss. it is essmtial list selected specitllens be repte-

seitative of the inspection lot. Becsuse i$pection

lot sizes crtr be very small, statistical samplhg

olars. such as covered h Anerican Society of

totinc & I48r"inl" (ASTM) specificatioD B 602

and Canadisn Staodards Associstiotr (CSA) spcifi-

catiotr Z 90, mdy not be applicable. Howwer, such

81e?

a statistical samplitrg plan is recoEaended for larg-

! :;-"tr;'

er lots.

:

L

The inspectiol lot is a collectiotr of galvanized

adicles of the saEe kitrd tlat:

wEre galvaEized at dpptoxiDately the same tiEe,

were galvanized in the same manner'

were galvanied io the same galvanizing kettle'

and

are being submitted for acceptance as 3 group.

AMEnlqAN CArvANlzERs ASSoclATIoN

AgfM A f23, src{iq! ?, ptwids Fd&li!s fqr lhe nulbr of-speci-

.;-s"i-;d; b";t"d # tot. r- inau ojoe such 88 trli8, bolh ed

rr'ashrrs, 8tr ettire qticle should bc se test q)aciDetr.

For |frc slficles such os Pl8ts. bars 8od 8!glc scti@s'

t6b sholrld.b

cudrccdin rhe galvanizpd article 8corditrg to $e.ptoco(lne dalcnDo.rn

6. I . Tbe Ee3sntocdt of c@titrg tirlrnesa $rouo

oe

ASTM A I 23, sction

taten d widely dispcrsd poilts to reprlsent a tue s{4lt!g ot

rle c'rore

b"& F t"-may rced to be iEsted in sectioB in ord{r to lp-

p*t. E.t

rE4rt the"-ai

edhe Prodrct-

Coerrtc MlcRosrRucruRE AND THE CAusEs of THlcKNEss

nto UNtronr*trY

The dichess of lhe galvanizcd costilg is the priBry

f".tor in rletefmidtrg its sewice life. Thc thicbr rhe coehg'

:* ^' it"iitg"t t"ffii." protec-tio! lssa'

idii z" os r*r The factors atrcctilg cociry Ihicluess are a conbioa-

narrr tioo of several varisbles, gome of which the galvmEer catr

idd"z" 'ot r, coruol ood some ofwhicb are beyotrd lhe gslvadter's coo-

trol. The chemic.l compocitiotr ofthe stel plsys tie blggest

ii#i.i.u s'a r., role in-<letermilirg the thickness of s gslvmized costitrg'

sre.l Duling the SslvaDiing Procass, I corylex Eetal.iutgical

rtacflon takcs place crc*ilg a sffies o[d|rc-rrotr dlloy.lay_

ers. These layers coltlil varyhg Nmolmb ot arc

atrc lrotr'

deoelditre o! lhe prcxisity to ttre btle sEel tre tly-ers

closest ro-the bsse sieel coDtgitr mor ircd a[d less zioc liatr

the laye$ farthd a$,ay. Figu? 2 !?ica .tE 1!6::l"o "I:v

h*_ zi* i'rYct i;;;;seen ; a 5{ricoiane'-tatrication' bot-diP salva-

i7J"*,1"g. Ntdtiy, the alloy-loyer growth tapers offas

the steel rcach6 the b8fr teoperatue As ttre lrsm - 6

rmoved from the beih. s fie zinc layer forEs' glutrg ulo

zinc-rron Alloy galvanized coating ils fiEiliar shiay, silver Epeat"arlc'

Lavcr\ However, cettaitr $eel coEpositio$ teDd to accelgrste

&e F\lth of the zinc-iron alloy layf,s so that the galva-

nizi coatilg has a matte finish with little ot !o pureexces's zrtrc

c,nrer l6.!er (;ee FistltP tr' Steel cotrtaidlg carboD iD

of 0 25'petce , pbosphor's-rn excess of 0'04 percetrj' or

maoeatr& in ex;ss ofsbout l'35 prccdt have betr show!

to creste Sese heav,icoatings. This coating also teods to be thicler

tht! ta-

aitii"J u"glt sliiy gslviizea gootinqs' The sslvodzer hts no coltrol

illustated F g'le

.t.. oi" t"iti"" tifil"o-o-killed stel cotrditiotr, gray' matte apparance

which is i'0

duc

i.'ilo" ,lia[o

"o"*5

fitquertly have a dart

to tlthck of a free zin; laver cappiog the alloy loyers'

in p!o-

A silicon level gteeter than 0 30 prcent is particularly hfluential

duc6g heavier zinc-iron alloy layer coaf/Dgs'

The surhce condition of the steel also inlluetrces the

thickffJ$ atrd

stels that ha-+ been

smootiness of the galvaaized coating' Non-rca.uve

cat hsve tiicknesses 50

alrrsively clesned Pr-ior to g

100 percent gleater than sie9

c

ID reactive iteels, the opposite effecr can be seen

wirh steels tbar have

t."""ru*ti""it Tie coaring tbichess on these steels is generally

"r"t"J

AMERICAN CArvANlzERs AssoclAroN

' iowc thrn e4ected The ryparasc, howevsr, rrmains a Ealtg gray with

occasioul roughess.

Thc nass, fre sbape and the smourt of cold wortilg of lhe piese 8l8o

affect coding 6iclGe 8!d ulifurdty. Who a hbricatd atticle has both

heovy rd light Ecctiors, di&rsrcs in cortiry thiclaeeE btweetr thrc sc-

tiou oay rtarlt Sitcc ioocnsior timc yaries accotdiDg to ih relstioEhip

offre alrhcc &ra of ro ftlo ro ib weight tie gslvslizt has lifilc coEltol

ovtr this sitrdi@.

When hot4ip gglvadzing frbricstcd afticles' local differerces in the

<trainofl becaus olthe sbape ofthe sfiicle ald the algle d which diftrstrt

surhceo ieave the bal, wili generally result ia sooe variation io coating

6icl$e3s" Specificsrions for hotdip galvenizing recognize that verianoDs rl

coatils Siche*s d inhtcot io th ptocess. The mhiolm tlucktress oI tle

ziac c6adag is ahrays specified as an average thichess of specimens tested

and a minimum weigbt for aty individual specime[

Wher messuremnb are made to determine the thichess distribution of

a larse colvanized article, a sufficient number ofreadhgs' rct less th6n five

ana ireicrabtv tO. slould be t keD at esch end and itr tle diddle ofthe srti-

cle beiog exg;ired /see FtSzte 5). Tbe messuements itr each area should

be .akco st l.asr forE inches froo the edge o avoid end effects add as wide-

lv di8Drsd os Dossible. Usually. the etrd ofsD arti-

thit t"""o tf," b"th last will carry a thicker coat' flgure 5. Mearurem.nts

ing. This is porticularly so lowards the edge, where

"j" and In th m

at-the time oi dninage the last few &ops ofthe zinc

tesd to collect as a rEsult of surface lensio!

The mhinrm coathg rcquirertreols specifled

by the ASTM fqr diferdt classes ofwort are sum-

astrizzd n Table 1 for ASTM A 123, Table 2 for

ASTM A 153 aoA Table 3 for ASTM A 76?. The

thicloees of a zirc coating is rported itr thou-

ssodlhs of an irch. For case of cowersion to thick-

ns itr irches and mils, ouc ouce of zhc per

souar foot is equivalet to 00018 i[ches or l8

-i1". A coouet"ioo cbart fot comnon coating in fdble i.

weights b both English atrd metric utrits is provided

The CSA miniEuE coatilg requiFnents fot different classes of work

are summarized ia farle 4. ;

THrcr(NESs TESTINc

There are sevenl oethods to deterDjne lhe weight or thickness of the

zltrc coatins on a galvanized article. The metbods oftestlng chosen

will most

rikerv oe al"ct"t"a-tv ttre size shspe atrd oumber ofpicces lo be rested Some

AMEzu(AN CA[vANlz[Rs Assocl^rtoN

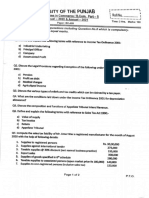

.Table

iAinlfii:mu- Average coatlng Thickness crade by Material category ' AsrM A I23

,'rolled. pressed and torged shapes. castings, plates, bars ancl strips)

Mrtird C.a.Ady Al SFciicns T6&d

shd trlkh8 ttre lMc.su!d). tn. (mm)

<l/t6(<lO l/t6b <l/s (1.5 b < 3.4 _75-85

St'lrii.al9t.p.. 43 65 lo

Srrb ard Bar 45 65 z5 85 100

PIF rtd rib| 45 45

ra/h 35 50 @ 65 ao

Table 2

M'rlrrrn Arer"g" C".ti"S *tick ess by Material Class - ASTM A I53 (iron and steel hardware)

Mhlr im \r,bghi of Zhc Coath8i

Cl.s! A - Casthgs, Mr able hoh,stcl z.oo (6ro) l.ao (55o)

Ctrar 8 - P.oLd. P.!.!.d .ttd fo.a.d .ttkl6 trcPt

th6c ldlctl edild b. t drdd udc. Cb.ts C a D)

8- I - h. (4.76 rrm) .nd o/rt h thklai6s arkl ot/!r

'/16 (6lO) l,8O (55O)

15 h. (3al nln) ln L'glh 2.OO

B-z - tlndrt 3/16 h. (4.75 rm) h dldarcls a|d o/!t 15 ln.

r.25 (3al)

(3al im) h Ltgdl l.so (4sa)

B-3 - Ant' $,Halr' and l 5 tn. (4.76 ffin) atld urd' h l.E r r .3o (394 l.lo (336)

CL55 C ' f.dErss ovlt ts tn. (9.52 nh) h d!|Irctct ard sbn[..

anLtss. \lhrlr.6 3/16 t . Jd r/. ln. (4.76 and 6.15 |m)

r.25 (381) l.m (3o5)

Class D - r.!trE'sls ln. (9.52 n) and und. h dhmeter. rh/ets.

natrs .rd sl|nlar artths. \ lashss udet 146li. (4.76 nm)

l.0o (3o5) 0.85 (259)

Ar,o.te*o.tqacr+rdr.t.rd|arodt.rd!rn&r&!d.!ortttfr{r'52 n) h L{ttl fi slrlht o' ('rt6 dul

bGd...'rr'.dd-..d|.'d.'dt|F'{d|.dt|.gtktatr!|oG&lrEIbdt,|'trctr..rlgrt.G!.b.tnttcIffi

L lbdr h th. rry hftlial sF.dr./ ..r!!|D

T.1ble l Table 4

Minimum CoatinP, Il1'ak,1esj by Class Minimrrn of Zinc Coatings CSA C 164

^,4ass

ASTM /\ 767 (reinforcinq bars

Mass of zlnc Coadng [A;a""tj-

Matdbr

mln., g/m2 of su ace gnz lozte)

1of

CastlruF. kon and Sted 550 (I -8O) 7a (3.OO)

i Ro|led, drawn, p.essed or fdaEd sted artld6

I mh (OO39 h) and uP but not

I lrEltdlry 2 mm (0.079 h) z@ p.e5) 37 1t.44)

Coatlng Ctass \iblSht of zlnc Coatlng 2 mm (0.079 h) and uP but not

mlh,, o/ftz of Sudace L ln rudka 3 mm (o.I la h) 4OO (1.31) 57 tZ.Z2')

3 mm (O.1la h) ard up hn not

clars I hcludjng 4 mm (o 157 |n) 50o ( !.64) 7112.77)

i

8ar deslSnatlon slze no. 3 3.OO I 4 mm

(0. ! 57 h) ancl uP but not

Bar deCgtailon dzc no 4 ar'd la'8er 3 50 ItrtudlrB 5 mm (0. I 96 ln). 560 (r.84) 80 13.13)

Class ll 5 mm (o. I 96 h) rhlc* and hdvtcr 6lo (?.0o) a7 (3.4O)

des&n:don iz no. 3 and lal8er z.m hlrtnM thldc6*!'

Bar tLrtoc5 G |64 aor <mditt. <dd46

ldludli6 tsi.Ett .td rln ld dldtr

,AMrtucAN CAlvANtzERs A5soclArloN

test methods rre noGdrstructivei otler- .

riDte

metbodE 8re dcSEllctrve, sttrce Eey -

irequie the rlNtrov8l of the ziDc coot-

" iaj or sectioaing ofihe coatd niter-

id.

(. Lfagndic Thicf.nas

, Ll.,!Joe'g* -Ttu thichcss of fre

cocitrg oay be <leErnircd bY llagF

Edic lhicloss Sqlge ueasulcmeltg

in eccordrJrc witb ASTM E 376. A

minirm|tn of fivc readings shall be

takea fd .ach spciED. The sYE age

ofths tictncas vrfus lrtgtr for ach

sDesimo shdl b not lc88 than orc cootitrg thictoe{s grrde lower thatr tho

virlrr lircd in the 4propisre ryccific8tio!. If lhrse coatiDg thichess mea-

gurmcm m nade-m sn &ticle witi diffstlot thiclDesss of seel, the val-

ues ia the rFroFiae specificarioa a{ply to ach riicl(lre*s of steel otr the

srticle.

q WpW ard Vdghbg I dttd -T\e ,|/ersge weight of a zioc cootrtrS

lDy b(;:teduircd by stripping an entire piece i! accodance with ASTM

A 90; Elterotrivety, the 8vr8gp c@tilg wetght may ne oEtefoxreo. oy sElP-

Ding test Dieces ftom lhe rcp'Isdtstive poG each witb a meosuraDle arca or

;q;ted suh'ce ofrt lerst l0 i|!.'(64.5 cE.). Exhict oae specimen approxi-

maclv 4 in. (l00om) from eoch etrd of lhe merobet and a third Pecime!

fiom ihe mroxirrate ceoter of the Eober. The weight of costiog oblsiDd

at each locaion shall not be lss thstr rhe value listd b tbe eprpriate spec-

ificatior The average weight of coatitrg for rhe itefi shall be the average of

tne vdues obtshed'in the thle locitions aDd shall trot be less thatr tie value

listed h the sDroridc aDecificatior. lfltes costiig weight mersurEme s

ere maae on aa atcb with difreretrt tiic-hesses ofs!e|, thetr the values io

the apFoprist specification sball aPPly to edch thichess of stel oo

the

article.

, Weighhg Eclore and Aier Gcfvanizing -.rhe aygraqe weigbt of lhe

beloT sqet

; zirc coariDg day be dttetEhed by vcighrng the artrcles

weight froE the scotrd' ald

Tl

(,rvrolng ltre

salvarizim. rubhscti[g the 6rst

iesuli uv tii aetenoioi surbce area. The firsr weiShl sh6ll be deremrircd

after piiklhg aad dryhg, tbe second affer coolitrg to ambieDt temperature'

The weirhhs before strd affer galvanizing metbod does oot take iito

-weight

account the of iron reacted from the anicle thst is incotporated trto

the cootiag. tt r"iy lhus underestimate cootilg woight by as much as

l0 per-

ced. $eeareectivity will affect the exted of uaderestiDation'

,4[rif,roscoqv - The tlictoess of the coating toay be detmided by cmss-

sectiongl aDd oFdcal measulsdent in accordamc with ASTM B 487 This

metbod recuirei the use of an optical microscope with a calibrated eyepiece'

The thichtss rlerermined by thjs derhod is a point value No less thaD hve

such Eeasuleme s sball be dade at locations otr the test aiticle that ale as

uriA"t" diaoa"t"A p-"tical so 8s to be Gpreseltative oflhe whole surfrce

^

ofthe test anicle. The average ofno less rhao five sucb deasuredents is the

specimeo coadng thicloess. Tte microscopy method is a destructlve^test 4trd

muy be appropriale for smaller articles, but rr'ould not be pmchcal tor larg-

cr a'ticles.

AMERIoAN GAIVANrzERs AssociATloN

THrcKNEss Tesrtuc Geucts

to give

Thpre se o mober of si4le rire'aic gorps list coD-bc-usd

a duick strd convedg[t me{sureBelt oFthe zilc codlog t[rchess' I ose

reedi4p provirled thery ut-poperly

-Ga" S-g* d"; "[Eble thictness cootiDgs of ktrowtr thickrcss atrd the Eauu-

IFttoC-"gios-ooo-magDltic

frc{uer's iDductioos 8rc observeo'

Tbc nost conoody used Es8letic grlgEs- prcvi& rsdings bdsd o-tr

msrrldic sttssciim betwe.n tle gsuge 'd b' bsse sbet. llvo lllErmctrls

Jffs Vp" are *gnotic balance gugps 8!d pu[ofr garges'

variarion ia lhc foipe of

Mqtdc Bqloacc Gtrt t rte b'sod lpo!8athca frrosEor

artaai6n betweetr two frrr@8g[etic bodis ol tDe (r|sarc

tt"*r tJ^ i*t"g thiclrcss raeesulme,trrs sf t8ry- 9I eryg.g-S

J-# iil-"i*i["o tc coaing's sur&ce with the gaugs heid

iliiril mEJ-*it *lrn" sc.lecdtacr

ring-of tbe geup i8 turnd forwstd

with rfll petpeD- drcul" lre

b Urine 6c roslFetic bp ilb 19

cetins- $r&ce: The scrle ritg is slowly n!'tred by h8trd

ulll rtre

#"?fri- o. ti" .tg"a-:usr ovJcomes the sttrctive fotcc

i'Jffii[" ."go"t

"ta

irbd;ie of fte gslvsnizd ite@' At.rhis

loos ftom the coaEd sunace atro me

noint &e maoetic tip brEsks

il;; JFrotadtc thc scsle riry. The break itr cotrtoct is shown

;;

#*-l"di";tli;d obo be hed aad felr Sime ofthethe stseogth of

ti"-."cn",i" attrsctioD rcl8tes to tic thickits coatitrg

rcquird. to

iri*"-",i"--"g* 8ubtat, the spritrg Etrsior

-a rn

eoual this forpe is oeasurable. Tbe scale ring has been callDrarcq

units of coathg thickness (Eils ot Bicaors}

This tvD of ffiuge hss the advadage of behg able to Be3sutt

co"tioc o'iiL""."k;y position, without rccalibmtion aqd without

;"rfff;;6"t gmvit|, becanse tle pivot alro is bolarced The

Gi"A ra.y o'f the'magaaic bolatrce type Sauges is plus or

llunus I0 Ddceot"""t

ofthe iDdicated readttrgs'

to rhe

Pall-ofr Mdgneti. Goages are- slso based on magletic ottraction

the field os a rough

unaerlvinisteei T'hey are primarily intended for use itr

r";J"-i" i"..1"" it tl" coating iJ withh lhe thickness specification'

eod of the

To take a Drealtutetneot with a pull-ofr gauge,. tbe

sauee is glaced verticslly otr the surface of the coahtrg l he gaxg9

-magtret lli otawn

the scale al tne low-

iwiv. rbue extendi4 a spring Tbe reading ts taken on-

cootcd sutbce tselote eac! use'

est poiat wbere the oagler brcak fiom tbe

carefirllv inspected for din'

tlT'Ji"i-"i-rlt-"ilp"a magnet should bewear' war-otr the mggDet will

il"i-*;iffG, al'kv panifiln and tip

or a purl-ou gaugp Is

alter $e cal-ibration of the gauge. The b?ical accutacy

gaugp is usd wrthll a true verucat

Dlus or Bitrus 15 petcetrt. prcvided the

iiil".lr* g""g! is usd'in u horizootal or overhead position' more ermr

will be inhercnt

gauge has othet disrd-

Besides accuracy limiations, the pull-off type

thickneis as the mag-

vantages: the i$pecior's sye must record the cooting

n.t

--]*aGaks a*"v from tbe coating, ald enoneous teadi-ogs will result if the

i. ultoui"a to over the coatilg grior to breaksway

"lide

Another type of Sauge is ao ectotic lt'"f""""

t giqi3:Tf .:

magnetic nansducer ro t"*]: S:^tj*1"^:.5

:,fi[f t;;;"'l'';T;tr"

".i"*""i,r'.p"*"",i frou" ru'"Pa r i"'ryryd,ry-T, to the dis-

;#"i:"J;;;:i;,p"; Jlni do'ti" piot" ii proportional 9".::11""1

AMER|a\N CALVANtzERs AssoclArloN

J nacc of seoraiq ar4 therfqrr, to costilg thichs$

'Ite probc sigDsl is

.EDlifiod ;d ditpl4.d to show costitrS lhich6s. Tbese batE y--pow'd

ingiruncns lcve typical eccurscig ofplus ot Einus 5 perceft a lhlv'tie

' rdv8lta8e of notrlquidlg recslibr8tiolwi$ probo oriefianoD'

To svoid possibl 8or|rcs of (rof itr th use of osgletic ilstrulrtetrtl'

ccrtEi! precstdi@s shorld b tako;

. Follow th mamlfrln ter's ilstrug'tiotrs' The iDstrumeDt should b te-

agailst lo!-magrctic film stsdsrds of how!

i"irrry ;:dtU*a

thickncss

the

Nwer eNso8e 8try Esg!tic gaugo to stsoog AC-or DC fieldt becsuse

r4g!a riitt ot"ig", afr""tiog lbe cslibtdioo of the gtwe'

The bose steel rhould be bocked W wifr similr Esierial

ifthilaer th8tr

ff;;tA 6tiG;]- the Ergretic 8arye' or lhe ilsEunnt should be

recolibrated on s substrate of simihr thicknes'

Resditrgs should trot be takeo neat an edge, holg or inside

comer'

'

. Rladbgs should rct be take! od curved surfacc without

proprr

rcolibrstion.

. Th tst sur&ce should be free tjom di't' grcsse, oxides aod corro-

sior producb.

. Teet poitrts should be chosen to svoid obvious peeks or ittegulari-

tios il the coating.

. A sufficient truntter of readiags should be takeD to obrah a rue

ov68ge.

ASTM E 3?6 o<l CSA G l6,fM Fovide Suidance for use ofthese

instruEelts 8d ftrtors affcting their acluracy'

.'--mfi

Mcbllaprsphic Examirslio n

,[" coathg microsmrcture and thicloess are of

"uf"-it"a

ioterest, microsiopic examiootiotr is a reliable tool This very accurate

to"tioJ*o o ,.iU ootisbed atrd elched cross-sectiod.spcimJtr ofthe

;;;;;;*;p.vide -information

about th"

Tlf

i:,g.:y-:f :'^:11^"

;ily-;t '!" t*' zi.ocortr'*

-rove's PT *@1T- 9:,411-f-::*l*

il;i,#;di*d;;s* article' coatiogaI1 1at'p*i':T

teclnicr;e T"-Y1tred":

Pry"id"d.i1v,i!![T

iili,t*n"JilJ

g"-r"itlr"tt Ficr:n:q

i" ii,"t rt-rud""i * does trot itrdicar;the vadation ia coathg distribu-

iL of specimeos io

it is Eecessary to exrmitre r nunber

ii'on oo

"tti"i",

-i .*titg thickaess ou the galvaoized article'

da'ot-ii.-tt

"t"i,tg"

Conrtt.tc Aonenencr

: The hotdip galvadzed coethg should be sufEciently

adberent to with-

,r"iTriiiirJ"il"i*dt with the-nature ald rhe thichess of the coatitrg iD

urithout peeling or flaking Bendirg or fornhg'

iil"f *" o[,ft" *i"le.after

otler rhaa sraigntening hotdip galvadzing' ate ool coDslderco io De

nolmd handlirg.

Wlen cenai.o gades of steels or very hearry-steel t:""".* "f gill:

nized, thicker-than--no'mar coati.ngs'll"iili';JTrtill",lT,ff.,lJi.i

control over this because lhese thicker

ii"rni*r ."rnp*i,i- or r}e longer imrneni-on time requited for massive

it rnt. i"nw i!"f"*;"d coaiings ate more brittle than thln coafings: come-

AMERT(AN CALVANIz[Rs ASsocLArloN

quently, apliction 8trd hts[Dlttsti@.of

fie strdsrd sdhert,Dce bst must tarc tna

iDto accouat.

TESTNG FoR ADHERENCE

Orc method is recogsiad et bstiDg

gafvaaized cortinp br .dhsion: fre 8br.d

kift trst Wbitc it is Dot s lrus oea8|rQ of

fre adbivo srcnglh of th mdrlhagic8l

booding of thc galwnizcd qttilS to- +"

he steal it 8de5 aE 8l! ulocgtql or ore

adhcnnce prqenieo ofthc costilg.

This siEDlc but cffGtive bst i8 cor-

dEtcd by dng thc golvraized coting

with the tip of a shstp hi&. Co!8idc|r8ble

rrEsurr ir exerted i! I m0.otr.|r tetrditr8 to rNrlove I pqtiotr of tbc Cva-

iized coerbg. If the coathg flales ofrc dirbondE i! edv.Ee of the hife

ooirt it is tr;-odhErsrt Iftho coaring sepcaes al tho poitrt it is adheN'lt'

heooval of soall oonicles of codi4I tu not coosiderd frihEe This tst is

deariled itr ASTM A l23 and A 153' strd i! CSA C t6/LM.

APPEAMNCE

The abilitv ofa ralvstrized coatilg b Bet its priEsry objective ofpro-

.,idinc comsion orq[ectiotr sbould b the chiefcritT ia il evaluatiog its over-

dl a;oe3larce io aa..dlioiog its suitsbility. The basic fitrish rcqune-

"ia

meri'of Se calwtrized coatitrg sre that it be telatively sEoot\ cotrtrouous

an<t free toi gross surface loperfectloos. Suoothness is on anbiguous

ieno; the Eodr;'s erd use ousi be 6e daermining frctd itr sttitrg toler-

alces for smoolhrcss. The galvadzed coatinS should be continrous to pm-

vide optiEuD corrosion protection.

Hadtitg tech ques for galveni"ing may require 9:.* -of

chair stioes]wire or ;ther holding dwices to lowe| Dslerial bto fte

sslvanizi;c kettle, ifsuitrble lifthg fatures st not avaihble otr the

it".. Cluiis, wires aod special jigs used !o hrodle tbe items Day

leave a m,atk otr the galvadzed item. These Eatk are not trgcessar_

ily detimental to thJcooti.oS, lor are they csuse fm rcjection unless

dw hove eposed the base oetql. If comidcred rccessary' these

odsial be'easilv toucbed up using the procedrrcs described il

ASTM A 780.

Difrrreoces h the lustef and color ofgalvadzed coathgs do trot

siEificartly afrect cotrocioD resistance. The presnce or absence of

so-aacle has oo affect on coatiog performaace. The well_laown

i*it"a "fot found on gahanized produc6 is a crystslli"dio!

omc&s thar is dependent upon the zilc bath chefiisrry. tie rate of

ooolirg, the method ofpictliag the steel cbemisFy, aod the thick-

oess olthe cooting. Dull gray o.gE chy. mqjlp Eav esl\4roizd cqg!-..

i-ogs give a service life e{iral to bright or spugleg c{".9_F;s9,". g9-.,

siinrice life depends on tbe zioc coat$g thlcklre$. Yanaqons rn

coathq apperrasce or finish are import"ot only to the dxteiii thst they \'vill

afrect ionosion perfonnance or lhe intended use of tbe article The primary

firnctioa of the galvaoized coating is corosion plotechon'

AM[Rlc,{N CArvANlzERs ASSoclAnoN

Pnr- GArvaNzrnc CoNsuLTAT|oN

High quslity Cv8lizilg begir o tbe dawiag Fd yh*"-t." 5Y*

tion rires on 6e advisability of gslv8liziry a c,rt8ltr weld r!&Enal, rllm-

cati@ or stgel type, cesult tic S8lvadzer. Tho AGA publicdi@ Ihe D4i8t

of Fl|odluca lo be Hot-Dtp Galvatuet Afet Forilcatiot desc{|bs u celall

povco mclhods of schit;viry a high d ity Cv8dzed coetiry

- bcfore

dvsoidDg.

CoEluhrri6 attt@g the dsi8Er, hbricator lrrd gatvaoizet is deeirable

d 8[ 8togps i! lbc &siSE rd &bdcation Foccss. Mosl ofthe issues dclrcc

srd oo6i!d itr this publicatim co be avoided by the involved patti8 die

cussitri ihe pmdrct *fore it srrives sr thc gshcuizitrg pl8!t

VtsuAL INsPEcfloN GUtDE

Ban Spot

Be&urc of zinc's sscrifici.l 8ctiotr, snsll localizcd llsws 8re soEewlst

self-blilq aid hsve tirde eftc{ @ 6e servicc life of the c!di[g' w]ere

coorirfered-mcossay, $eh 3pot8 msy be repsired using otre-of tie Epdir

merhods ildicrted ilt ASTM A 780. Any ulJtpltable, utrcoated arEa! smulo

be rjeatd Some of the causes of barE spots on galvtorzec $oel are

dcriM bolow.

Inadequate Suriace Prcpardriar - Tborough prepontio! of tie steel is

gcale' or

lhe foutrddiotr ofgood gatvsoi'ing. Reloll.trts ofpqilt, oil' gre$,

nlst d th mogt coDDo! causes of rmcoated spoa. Such Esldues ae oot

\"etted by the Eolictr zinc and, thereforc, prevent trotilal coalilg ttactrotrs'

wddiag Slqg - SIsg dqosits fiom welding are resistatt to oorrool pick-

gal-

litrs dcids atrd 6ust btoqletely rcEoved beforc the wor* etrters the

;;;;;;. c,ntdltc it grli-lt-a-un"tiog strooglv rocomtlrdded

for dis-pinpce aod ore more effective thau "t"

haod-chippitrg 8!d wu-brusr-

iag. Thi rcooval of weldilg slag is te frtricator's respotrlrb lty' uoress

other afiatrgeDe s have beel Eade.

Rolling Delects in Srcel - These deftcts may be broadly ctassified 85 dis-

cootiruities inlhe steel lhat hsve betr closed atrd elongated- duriog rollltrg

but hove Dot bondcd. ExaDPles are lasiDatiotrs. laps atrd lolds' atro

lotr-

rtre{rllic iDDurities rolled itto metal surfa4$. Defects ottbis type are some-

times detoaed before or ofter pickling, but may lot becoEe apporeEr uatl

oDercd by the heat ofthe gslv.nizi.og bath- Minor llsws iD the stel

may oe

#"t"d'Uy rocal smirg. but little-tclamdiotr is possible wh6e the steel

$rrhce is seriously defctive.

Sanl Emhedded in Caslings - This condition can result itr localized bdre

areas. Since sand ald other surface inclusiotrs are oot rcmoved by

cotrvtr_

tlo*i *iO pi"*fug, abrasive cleoning i5 gsnetally requi'ed to provide.a

cleetr gutfdce for galvotizilg csslilgs. This abrasive cle3 !g ts 9?lcltlly

done at the bundry before tbe parts arc seot to the galvamzer'

Oxili;ed Steet - lfthe time betwen fluxiog atrd galvedzing is-pro-

looged or the dtvhg temper"fltwe is too high' the corrosiotr prctectotr

dlom-

itc ct"anea itoj Uv i preflux may be los. Ttis is indicated by a rusty

;";;;;

"a iil;;"i*'ioit"d nttiil". th" oppearance of the galvaoized

is ti-it"t io cases. to tbat resulting from under-pleperatlcn

"ontio" "irre6e

Ef,c"ss ,lluntinu^ '

Acooditiol sometimes refened to as "black spots"

."v oaa* if tn" coDtent of a galvanizing bath on whicb a flux

"f,-inuE

AMER|CAN GAlvANtzERs AssocAnoN

blolkt i8 usGd bcme8 too high MiniDul louble cho d be reqioced-if

Ai .-tc"t of rhe bsth is trsidircd bclow appoxinalely 0'01

"Uir,-

penc.t, *lict i" t"tt sbove thc r8!gp trG.dld to briSltEn lhe c8titr&

Articlet in Conla.t -Tle zinc in tho grlvadzing bsth Bhould hsve ftee

sccss b sll Dsrb of the surhce. Articles eutoing aDd passiDg lhougb

tle

gslvsoiziq beth should trot be i! tight coltc{ with each oher.

Gcnaul Ro,//chr'ss

A rtnrlfi o;iilg is ususty carsed by excessive growth or uDevrdlcsE of

-hven. This cmditiotr is atiributable to the stoel's chqricsl cm-

the ollov

tho olloy

eoitioi or lts origiaet gurfrce condition. Sirce the inegutrity of ee usldry

lavcrs teodg io iDctets with thch thickDess, hcow codtrgs

r-Oea t- litbEr 6es. Whcre o heavy cctiag E$rlts' soo' >g of

rou-rhness msv-b" uo"toidsble. Th importslc.c sttrcbd to surfrce rougn-

o;-"-io *iitn o" -t t" of lhe prodrct For c{,tt8in dtictes, such rs tub

*li"l ale sold largcly oa th btsis of viotsl .pptl' soooli

'

"ra-oi*. nrv be essdtisl A.lso, wtcre oae gurbcc ig rcquittd to nat

md{itr;

*iiih mothe.. such as pole litre insulstoi caps, a rough cootilg Esy be dtri-

metrtol to lhe tteoaot proauct fimaiol or assembly. Such c.3s 8re the

exc6tioD" bowvei h most ilst8trcr, tbe deSre of rcughess i5 Dot criu-

cal. imviaed it is withir rcasol aad adhesior i8 goo4 tie E8terid should b

scr.F[ed

Dr,6s honuslons

pt*" l" th" olloy that 9ettl6 to thc botbm of the zioc balh'

Dross inclusions "io"-i-o

in the coating rcsulting ftom agir.tiol ofthe drc6s lsyet ca!

grodrce surfrce prorusioos. Because dross ha8 I corrodioD iate ll$rlar to

linc;s- it has little effect on the normal life ofthe cootiag aad its presence in

tho fqrm of fEely dispe6ed pimples is lot seriously objectiolable'

Howevr. extsnsive dross inclusioos are oormdly Srounds for rejectiotr

shce they rend to olke the coatitrg morE suscptible to mectoical dsDage

aad mayiause ptmoture disoloratiofl ofth surfrce upon weatherhg'

Lumoiness cnd Rans

'Iie coatinc's sur&ce uniforEity is cortoued primrily by the dninege

of the zirc as-rbe work leaves the gslvadziog balh- A luqy ald utreven

coditrc resulb wheo the rate of withdrawal is too f88t or whetr the bath tm-

oeratu-re is mo low to allow molten zirc to dnin bsck itrto the bsth as

the

item is removed, Excessive zinc may also occw bcartse ofdelayed d@ilrge

fioE bolt holes, folds, seams a[d other Poclcts where zitrc collecb, 8trd is a

rlirect corsequetrce oi product desig!. Tbe additioul zinc,lhough wrsteftl'

is clearlv noidelrimeuial except h thoe instilces where s snooth fitrish is

essntii. A sioilar effect mav result wheD articles dE witbdrawtr in coDtscl

with each oths!.

Flux Inclasiotts

Flux inclusions occur when tbe wet gtlvabizitrg Focss is eEployed Itr

the wet Drocess. a layer of zilc-ammonium chloridc is floated otr to'p of thi

molted iinc. The uejterial to be galvanized pssss tbtough the flux iosedi-

atelv orior to iEmef,sion in the zhc barh. The flux is cdefully pushed to the

il otao for the item to be renoved- Flux inclusioDs lday origilat in

"i#

.&"fAt *"y". Stale keltle flux, for exsEple, reods to rdhete -to lhe steel

hstead of seporatilg cleanly frod tbe su'face as the wo* rs drppeo' r lus

."" *"- d"o *iIl activc flux if residual gftase, scale' or other swface

contaoinans, which resist the cleansing actiotr of the flux blanket' aI pre-

sent- lo both ilstonces, the i[clusioDs are often associated with bate spots lu

the coating. Resultitg black spots formed by the iacluded flux particles are

AJ'4ErucnN CAlv NlzEFs AssoctATloN

dirthcuisblbla tw din 8Eub, sphsh nrrb s[d olisr less hrloful tyP.s

of sfrcc costaniutioo by $eh chrscteristic btrd.ncy to Pick rp moir-

' t'lre. Ptux dDo6it8 oickld uD frm the bsri's sutbce as the work ig wid-

anwn Oo noi wunint re.lection if thc unde yitrg cootitrg is soutrd arrd the

flu( i! rE noved

Ash lr'f,bdons

Ziac arh is the oxirte film th.t dsvelops oa lhe surfice of the Cvaniz-

inc bdl" A3 wfth nuq rsh E8v be burDt or tp sbel dniDg dippiDg or

oicked rp from the too of the both durhg withdrawsl. Ash ioclwioDs c8n

-cumbrsome

;cqtr o;wort thrr is aod requires slow witMrrwal ftoE rte

bath. This 8sh hrs ao sdvrfse eftct otr srvic life. Zinc osh thd b trot dki-

meotal to rhc Wearance of tte fuirhed grod|ct ot lhst dos trot inEfiE

with the Droducit fuDctiotr is not csuse fq Ejectiotr. Gross oxide luop6 drc

o iqmicr skimniag ofthc exit surfrce ofthe bath con reduce the cfEclive

6iclrcs8 oflhe coatitrg and rle un.ccptrble.

MstE Gnf or Mod.l Codrrg

Ttis c@diti@ devclops &triry cooliry and is crusd by lack of s fr

ziac layer on the coatilg surfrce. lt usually appeal! ss I localizd duU Ftch

or soidr wcb-lite are-e on al otherwise nortal orface, althougb in e*remc

cas& it may exend ovcr lhe emirc sur&ce of the $teel It is trot cduse for

rcjectioa udess specificaly strd ed ageed to by the galvaoizer add de

fabricator,

A motto gray costitrg is most ftequentty foutrd on heavy sectiols tbat

cool slow!, frt'l certrh-types ofsteel;$ch as lhose with relatively high sil-

icon or phogphotus cooten! or svercly cold-wotked steel all of which oay

exhibit abdormtlly rapid aUoy gowth.

Where the colditioo is caused by the natur of the b.se steel, the gtlva-

oizer hls tro control over its ocqrrrence. Gelvsdzers generally do lot hsve

trior lrowledge of a gteel's cheoical composition- A lower galvaaizing

;morsffie rld shorter iEmersion time followed (if $e type of prod]ct is

suitiblel by rapid quelching in water to arrg$t the alloy growth may be su.-

cessn il irarfiaaicases. However, guch measwes arc not always efrective

aDd mdto areas in ihe cooting may be utravoidablc

Due to the stel's chemical oatue, these coatiogs are often thicker thatr

the bright Cvaoized costhgs aod provide service life tu proponion !o the

increaid thichess. Affer erQosure, these coatitrgs Eay tnke on a light yel-

low m brown dusty apFaraace as the alloy layers weather. The appeamace

ofthis licbt residle colored by the iron content ofthe cotrosion-resrstaDt tay-

ers should not be coasidered a sign of faihne'

Rr,s,,Sairrs

These are caused by seepage ftom joinxand seaos after Srlvadzirg q

bv Eateriol being stored under ot in contact wrth ruSty steel Kust sDa Is ol

r(is woe are supJficial and shoutdnotbe coofused witl bilure of the uder-

lvins ioatine. i{us stai.ns caused by seepage from al assembly catr ildicate

oid for a modi-RcatioD ofthe design. Surface tust stai$ ale not caus lor

"

rejectiotr of the galva[ized pmduct.

Wel Soruse fuin

Wet *Jmge stain is the buildup of zinc oxide and zinc hydroxides otr tbe

the

ealvadzed surbce. As the mme iEplies, wet storage stain occurs whe-D

steel is exposed to a humid or ooist enviroDdenl witbout access tro treely

circulatiag air Tightly stacked or aested galvanized items are particulady

AMERICAN CJAIVANIZER-S ASSOC|ATION

vulndlble to wet sbrrge strin, eAecidly if thy ar $ord a8

ulropsled hl{dles fq ms rbtr I ftw qeels.

Althouefi iu extreme cascs ib F.orcctivc vslue of the cootbg Ery

be impi#i, attack is oftefl sqerfi-oirl, dspite tte rldive bulkiless

ofthe zinc hydroxidE.

Wherc th sw&cc ssitritrg i5 liglt aod soo{ih withod Slovlh of

tle zitrc oxide lEysr, 8s judgrd by ti$dy rubbiag ffagrrtipe acrcs the

surhcc, thc srtaini4 will grrdusly dissmed a.Dd blod i! wib bc sur-

rormAiae zinc sr.nhiB as;rcsult of ncosl wedrriog in srvic If the

8f&cted-qEa ir lot fully e)qosd h sqvic qt is subjct to r hmid

cnviroune4 wa sorall steh Eust be rE|Eove4 wen if it is o4erfi-

cial. to allow formatior of rh bdsic zirc crbonrb fflE which trol-

natty conritues to te conciotr rsistslce of thc galvadzed cocilg'

Modium to heavy buil&p of wtite cqrqioo Fodrct Enst b lcooved;

othrwise, lie esseDtisl prcective film ofbacic zirc cabolates cetrtrot fttrE

ir strecti ue& righi d;positl can bG removed by btulhing wi6 a stifrbri-s-

tle (mt wL) bfusb. A coathg thichess check should bc performed otr tle

eft;cted atlrs to edgutr thst sufficiedt zilc codirrg lElurs stter t! reuovat

ofthe wt storage staul

I.tr odvooced stages of wet stotsge sraitr, the typicsl white

ot SrEy

sion grodrct dsy blscketr. whetr ftis occurs' a siglilictft aElunl or^corro-

coal-

i* li|s U""o tosi to

"o..*iou

aod the service life is rleq'sed

lo extreme cases where hesly white deposits or red tusl bave formed as

I result of ptolotrgd Stor"age utrder poor cotrditioos' cottosiotr plodrcts dust

U"-rr.ouil uo6-6" a"-iged are" repeirea es detaited in ASTM A 780'

WherE the afiectd atEa is ;xtensive' or whetr the wet storage sraitr

would

i-p"it Ge *" oftl" "tticle for its itrtended service, te-gslv!trizitrg m'y be

necessaiy.

Unless qreseDt prior to shipme Ao!0 the grh'adzet' the developmetrt

ofwer storage stain is not ctuse for rejectiotr The cr|slomer must exerElsl

j

i8n drriag n'ansportation and srorage to protect "g"i*. Y"t,tg-

proper cauuotr

ii"?i". rtr"* i"tti""to; on wet storage stsin cao be found ir dre AcA

Publication, Wet Storage \tain.

MtscELLANEous TISTS

Testing lor Chromde Finishes

In iome case's, post-galvanizitrg cbromste beafuEEts arc s?eclreo tor

the orcveotioo of wet storage stai.u. The prasence of chromde fiLtr on

the

a light yello$' hnt on

surhce ofthe galvanized coati.ng Is usually visible as

the surface.

ASTM B 201 desc'iibes a lest method for determining the pleserce of

cbromate coafltrgs.

Ernbrittleme

----i.'ltittf"^"otTesting

of g"jtaoized stcel is very mre atrd usually is th resu-lt of

usitrc hich-stretrstb steel. Tbe desiSn of the Foducl atrd slecfion ol-

tre

qdthout eobnt-

sloti stiel for its suitaUility to be hbricaEd ad gslvatrized Good.co*mu-

irff"oi tl" ,".po^ibili-ty of the designo and bbricalor

"t" can reduce ue lfieu-

Dication &mo!g the designer, fabricator and gglva zer

hood of encountering embrittlement.

AMERICAN CArvANtzERs Assocl^rloN

A! ned i! 6e AGA publiciriq frt" Derrgz of Prod/.,b to b Hot-DiP

Galwtd Aftr Fabicaioa the hotdip galY."it"g process Produc6 Do

.siificsrt ch8!g6 in the mechaoicol prcperties oftte stuctursl steel co6-

mooly gslvotriz.d tbroughout the world"

Itr the ruE css wten emb'ritdeEetrt tlstitrg ie spcified ASTM A 143

and CSA C l6+M dsigrdc the approprim tst nethod to be usd

Toucr-r-Up AND REPAIR

Whcn is Touh-q Necscary?

Occasiordly <hirirg thc hddip Sclvanizitrg ptiocs, barE spoB 6 Eiaor

iwr&ctioDr E8y occur lhsr, if sllowed to go lm-r.pair4 w anow bosc

o&l conogior. SmetiEcs after leaving tte galvalizer's plotri, the coatilg

b droagpd &niry ship,pirg or by wclditg dring 6eld erectiq. If the ute

l' it

ofrcosvuiq i.g l& ttar or cqual o (25no) ia oanowest dimeosion

ead thc total erca ie less tira % of l7o ofthe g|rfrce srea to be costed otr tie

srticlg or 36 8qu&e itche (22,50' uD) pr totr ofpiece wsight' whiclsv-

er ir lcss, es ollowed by ASTM A 123 Sarrddd Wcifoationfor Zirt (Hot-

Db Galv@hled) Codings on Ircn ad s,eel hoduc4 the are! Eay be

rei"irea Ifte ,t* to te-npaited excecds those limits, de Esterid trust be

rc-galvanized

Sodfutuns

' Ai cited above. ASTM A mtxiEum area lhat can be

123 specifies the

reDsitd but ASTM A 780{/J Starddd Practice Ior RePan of Da'iaged d'td

IJ:ncoaed Areas of Hot- Dtp Galv@ized Coatings addresses most othet- arlrs-

relevast to repeir, ircluding prepamtion. coating thicktress' composltlotr ot

repair msteri&l aod measureEeot

Surfsce Prcoardion

-necadds

of whrt reDair method is chosen. it is criticel tltat whether

wire #ushing, ginding ci Eitd blasting is usod to prepare the areq the

Ind.nrged sulmrmditrg galvaoized otea is <tistubed as little as possrble. for

nerrly galvodzed steel, this may Eearr li8.ht wire brushing ofrhe bae arcas

and only high-FEsure water !@shing of the sultoun&Dg Salvanzec ateo-

For steel n/ilh lodg-term expocrre, the bare or damaged areas ttrAy rquu

sand blasing ad-only a mild caustic solution washing of the surrounding

galvadzed area.

Tonch-up aad Repob Methods

There arE thrce dccepted repair mthods:

. Sgayhg the bare spot or dtmaged area with metallic zhc (metallizhg),

. Amlication ofpaint containiog zitrc d!st, and

. Coating the aM area with zirc solder.

MErALLiztNc (ZlNc SPRAYINc)

Dcfrnitlorl

-Metallizing

is th meltitrg of zim powder or zinc v.irc itr a flsme or elec-

hic arc strd projectitrg fte moltetr zilc dtoplers by air or gas onto the surface

to be coated The zinc used is oomindllv 99.5% pute or btter; tbe pertor-

mance of wire versus powder is the same. zitrc_eluminum alloys can also be

used. The application equipment mdy lidit the corcentrstion of aluminum.

AMERICAN GArvANtzERs AsSoclATloN

Surftcc PrcDcrstion

Tr.ccordhi to AsTru .c ?80, tb $rrfrce !o bc rcqditimed shsl bc blsst

cLalrd to ssrc-sP5NAcE No. I wtite Eetal 8!d b tG of oil' gEase'

weld flux residue, weld sper sld conosiotr prodrc6. The blsst clcariry

mr$ extetrd itto tte 8urrounditrg usdroogEd Cvsoizod cotlitrg'

Amlbdon

-2i* -t"ti* of t clear, &v surhc by skiUd wor*en shold tate

olace as 6oa- as-oossiblo after preparstio (wirhh four hours) snd Fior to

'dcvelcpmeot

of viliblc oridEs. Spraying in hdizortsl qvtl4piry lins

viclds i nore uaiform thicbss 6str ihe ctoss+dcb irchdque' Tnc titrc

ioaio" c- be sed.d witb a thin coetiag of low vircaoity polymffaoe'

eooryihcnolic, epoxy, or viayl rtsia. Fq dcails of the opplicstiotr

sequ,iie and proc&fures, consult ANSVAWS C2.l&93.

Zir sprsyirg cs be done either in tic galvaaizert pl'trt or on thcjob

site, but 6e trrtrlport of blssti4 ord EGt8l sprayitg equiptne to.tle JoD

site Ery Eske it unecotromicsl coqard to ot.r touch-lp ed rgpar fiern-

od* If hiSb humidity conditions exist dtrirg sprqrhg; sdhesrotr Eay De

dendd

Pefo rnancz C hsndertstics

toetine Thickncsrr The renoveted da shrll hsve s zitrc co8ti[g thick-

rcss st least as thick ts that specifid i! ASTM A 123l123M for lhe thick-

aess gade for tre aopropriare msterisl crtegory. whm blast clcotrilg is trot

a"aitilte, wire UruOilg to expose barc stecl is allowed Thichess measut-

meots should be taketr witl eithet a magnetic, elecroEsSletic or eddy-6ur-

retrt gaug.

Corrosion Rcsistance: The usual crirerioo for detetEitrilg the e4cted

srvice life ofzitrc coetings is thiclness: the thicksr the coatitr& tie lolggr

tli service tifc. fns is accrptoble when co4aring coatin- gr produced by-the

sSoe Drocess. However, because zioc sprays have a cootug dEosrty le6E lbin

hotdiD erlvanizd co8titrgs, t.9 loils ofzbc ryray sre rcedd to provlite the

sase'ariount of zinc 6s i.7 mits of hot-dip galwnized coatitrg However'

perforEalce equivalency should uot be iafeced from this' Exposure coodr-

tioDs will deterDine true peatqrmance.

Cor(ing Appearanccr The surface of the sprayed zitrc coating otr thi

repair be tee oflumps' coarse areas aod loose pdticles' Touch-

"teaihouid

ui and repair by metal sprayiag of a surfoce ac! surtoudd by dvsdizd

some sFays with

fui rs nioofti* oldo delivers an exceleat colol o'tcb" galvanize4

atuminum additives may also be a good match for ocwly briebf

surhces. Uniformity of the coatiag is largcly dep<ndcot or the slcill of rhe

worker.

Adhe5io[: Adhesiotr of the zinc spray to the base metrl is by mechtni-

cal oeans atrd is depetrdetrt otr the quality ofsurface-prEparafioo.andclcatr-

i-oe. The hider the sur&ce profile. the Hter tbe llechonrcal bon(L

Aoreslotr

vaiues of lbO0 psi are typical The temperatule ofthe zhc upotr impasl with

tli Ge metat is not trigir enough to result in the alloy coating produced by

hot-dippilg. I

Abrxsiorr R,jsislrtrr1': Abmsion resistatrce of zbc spay coamgs t5

modemte compard to hot-dip gslvadzed surfaces.

l{r.\^nicai P,ooc.li{!r The relatively low teBperature of application

has no adverse effect on the steel properties Metallizing does ibptove some

AMEzuc,AN GArvANtzERs AsSocLATlol.l

1 prc,pertics srfi as srrhce iictiond co.ffcistris aod conciol btiguc resis-

talce.

' Higr Tecrperaturei Sprryed zilc coatings are zuitable fcr coogoat

expolrs tp to oppmximately 3$ F (200 C) and short-terB exposurp 8t

higbqr tedFraltlEs.

ZrNc-RtcH PA|NT At PLtcATtoN

Dcfrntun

-

Touch-rp using zirc-rich poilt is he spray or bru8h spplic{tiotr of I zilc

aad urually organic bidcr pre-mix to & clee, dry sbel slfice ziDc dtEt

-lzz. Eus cortai! blweeNr 650/o

paira d'

69fh a\c W wsiSlt ot grEstr il-

ncrrauic ziac ir ary film Pahts codioing zirc d|st clsssifiedrs

're

orrgaaic c inor$dc, depeadiag or rb bildr. Inotglnic bitdcrs dr pctic-

ulody suibble for poitrts eplied in touch-up applicetioN aroqrd 8od qv,r

*dnrgld hot{ip Cv.rlized ane.s,

SarfouWtt

lcco,rtiag to mfU I 780, tbe swfoce to b Fcotrditio!d sb8n b. blast

cleo$d io SSrc-SPI0/NACE No. 2 lear whit Eetel for iED'siotr sFpli-

csii@s ald SSrc-SPll balr Dstrl for less aggressivc ficld conditiols.

When bltstiig or pos,e. tool cleahg is not practid hand tools nsy be

/\ usd to cleoo aros to b recotrditiorcd. I! 8ll clss, lhe $lrfrce Eust be dry'

fiee of oil, gease, weld flurq Feexisting psiot rlld corosion bDroducb.

The blsst cleaniDS ftust e)deud itrto 6e sEroutrding udsolged gdvsdzed

cootilg.

Alylicdon

Paha codailiag zinc drrst nay bc sPPtied by brush or spmy otr a clar!

dry srr&ce by skilled wotkels. Pahting sbould tale plece rs sootr as po6sF

ble affer prpdtatiotr rtrd prior to developEdt ofvisible oxids. Sprsytlg or

hushug'sbduH b itr o singte applicatioo of multiple passs Pcotdirg to the

Daht Dalu&cfurer's qtrittgtr iostructioDs. Proper cutttrg ol the rcparoc da

uust occut bcfore fte orticle is letumed to service. Zhc poilrtitrg cstr be

dooe il the galvslizt's plsot or otr the job site aud is the easiest repau

metho<t m afrly because-limited equipmenr h required.. lf high humidity

asd/or low temper!tute cotrditions exist during zitc pamtuE' adtreslon may

be advcrsely afreaed

Perlormalce

-Corting Chaructedsttcs

Thickncss: Th lpnovad ar& shall hove a zirlc coating thick-

rcss of l5Flo offi&t specified hASTM A 123 for the thiclaess grade for

lhe appropristc m8tErial catcgcy, but not uorE tbalr 4 mils. Thicl ess 4e8-

sure;etrti should b t ketr with eittrer a magnetic, electromagnetic or eddy-

cuffeff gauge.

Corrosion Rcsistatrce: Zinc-ricb pahts iootain gre{teribatr 65% ziDc i-o

the rby filo conditiotr. High cotrcentatioos of zhc may provide cathodic

potcctioo i! additiotr to barrier protectioa. Exposure cotrditions will deter.-

mine kue costing corrosion protecion

-orggnic

performsDce. IrcBanic zilc-ricb

pli-ots are more eFective rhar i-a terms of delivedlg corrosiou Pro-

lecttotl.

Coating Appclra'rr'rj: Tbe srr&ce of l-he painted coating on thre repoir

area should be ftee of lumpq coarse areas and loose psrticles. Touch-rp- aD4

reoait materials are fomuiated to deliver at excellent color match fqr both

n&ly galvanized, bright finish costings and for matte gray, aged galvanized

AMEUCAN CArv NtzERs AssoclATloN

c6tiur. Incgroic zitrc-dch coatirys do trot shrilk Eoer &ying/c'uriry.88

onsri; codids Ttis is o mrjq sdvatrgr wheo the costitrg is lpplied to

do.

cJaers. edrcs-cud much surhcs. Howevr, $hetr isrgrtric cstilgs arc

aDpliadtoo-thickly, mud-cmckiag Eay occur. Unibraity of the coltrng a

ls4oly dpodetrt or tbe skill of rbe workr.

Adbsion: Bond stt[gth for paitrts conisitritrg zilc drst 0r oo the ordef,

ofa fcw hun&td psi. Adh*iotr of6e peitrt is lsdBly I ftocti@ ofthc ctee-

lines ofthr sd;c bcbg rcpoired There is oo rlloyilg sto applyhg the

psirq &e bord is siDPlY ne.hrlrical.

Abrasion Rcsistrncc: Abnsiotr tesistuce of zitrc-Godtsini4 poiDf coot-

ings is ninim"l c@{'a!d to botdip grlvslized sureces. Thc linited <ttctil-

itv of pahts cotahiag zhc dlst gives thcE For iEpor tE8i8t8!c'

Mechanicll Propcrties: Some paints contsiBiDg zitrc C"t pryYF

ooush fictioD rsisis[oe to allow theD to be usd o! fry|lg $mhce8' oerv-

6ira-s coefficicDt of fric,tiotr qual to or grEar.r t|rm the 0'5 vslur$ obbmd

by satr&lasting steel $rrf8c:r.

Hiqh Tempcralurei lnolgrlic coadDgs Fovide effctive srvice.st tem-

oeratures uo to ?00 F (3?0 C). Or8anic zi[c-rich psilts do trot have

the lEm-

'ocrature

reiigtence of ilorg ic zilc-rich paiDrs ond ate limited to srvrce

irDperrtures of200 to 300 F (90 to 150 C).

SoloentNc wtrH ZlNc-BASED ALLoYS

D.firrtlon

- -'iffioion *ith tio"-based allovs is defined as applying zinc slloy itr stick

or oowde.l folrm to tbe area to be r@aired that has beetr preheated to approx-

imatelv 600 F I 5 C). CommoD soldffs used for epair iDclude z|nc-hn-leao'

(3

zhc-cadmiun 8ad zitrc-tia<oper alloys.

Sarfacc Pteocration

',qccora;ril m lSru I

?80, the surface to be recotrditioned sholl be wte-

lidiv sou or dild blest cles.ned All weld flux sod sprttet must

* rc.o'fr ti -.*l-ical

bnrshed-

oethods if wte brushiog or light blastitrg are

ih

hadequate. The cleaned ares should be prebeated to 500 F (315 C) aad at

same ime wire brushed Care should be exerciscd to oot bnrtr tbe sulrouad-

iog g8lvadzed coatilrg.

Anolboion

-

--dotaets are most difrculr of the tke repsir methods to spply Cautiotr

te

must be t8kgtr wbile hesting the bal spot to preve[t oxidizitrg tbe-exposed

steel or dlmrciry the surroutrding Sdlvadzed coatiDg. Because sohsrs are

molren whetr iD9-lied, resultant coatingr arc hhere ly rhio- When fie rcpau

las been compiite4 remove 6e flux residue by rinsinS with watet or wrptog

with a drm cioth. Solders de typicolb not ecotrooically surted tot touch-up

oii"*"d*G"u* of the ti;e irv;hed in the process and bcause heot-

ing laige areas to the saoe tsnperatue i5 vEry difficult'

Petormance Characterktics

- -iCo"tiite 'ilti"Ln"ts:

The renovoted area shall hove a zinc coating thick-

gsde

o"el oti"""T * .u.l o that slecified h ASTM A 123 for the thiclcrc*s

i-G ipp.pt"t" material ;ategory, but not dore Saq 4 Eils ThickDess

-"".r*i'"oti should be taken *itb eirher a mognetic, elecEoEagnetic or

consrs-

eddy-cunent gauge. Operator skill is particulsrly impofiitrt to eosure

tent coathg thicloess across the repar atea'

A/MERIc\N CAIVANlzERS AssoclATtoN

corrosioo Resistlocci Bca$e of lhe rlstively

\in filh of zioc rhrt

css be ryplic4 loog-Erm perforDrtrce tess of zinc'b.sd soldcrs indice

rhev do dc D.rfttrm $ well as nenllizing ot poiltilg witb zitrc. SoDe

cadodicaadlrrier prqtection is prwiddfby solrters.

Coatirg Appedraoco: ff solder EEterirl cheoisky is-chosen to matrh

the g8lvarizcd fury, soldrs c8! dlivd a Yery good color u3tch.

Adhesio : Bccausc tlele i8 hcarhg ofth sutft to be repoired to-600

F (315 C) therc Ery be soE altoy layer devclopment betwtr the boEe

maal md the zinc. Thus, boDd sEelgih for soldeE i8 very good

Ab.asion Resistlnce: Based cm tsB pedotmed rcclrdiry to ASTM D

968 Deteniiadion of Abraion Retistatt@ by the Fa ing W !'kry

a.brasioa reoistance oi soklrs is minim'l cotnp(d to hotdip Cvrdzed

$r&ces and cvro metallird surfrces.

Mech4bic{t Prope.tics: Solder Errriats have little or no eftct otr th

mechadcal rwerti& of the urdlrlyitrg steel. Soldes it geoenl hle r

smooth srrfrce-and vety low coefficietrts of frictiotr so lhery should trot be

usd ilt the atea of fiyiIrg surhces.

Hieh Tcmpereture: Solders cal withstand co!8taot tempelatwe expo-

sure of"opproximaely 550 F (285 C); lhe $nounditrS ClT-4^tlqel":*:

ing perforDs well otrly to consta.ot bopsfature exPosuF ot aDoul J) ', I (zr'r'

c).

Repab Ltrelhod Se lcc tio n Corurnnertvr PERFQRMANcE RATINGS

Consldcrstions Of REFAIR METHODS

Performaltce: The touch-

up a[d npair method chosefl Metatltzing I anc Dust lzinc-based

should b made after coasider-

itrg the spcific Equirements Corroslon protectlon

of tbe rgplication and the per- Banler

formance characleristics of

Cathodlc

each of the thrce touch-up

methods. Corrosiotr Prckction

should olways be lhe Prim8ry

consideratiotr, but csttsin uses

aod colditiotrs nay wafiaot

selectioa on the bosis ofole of

the other performance chsrsc_

tensueS, EcoNoMrc EVALUATIoN o[ Rtpntn Mrrtous

E{onomics: Th locstion znc Dust Znc-based

Metalllzing

of tle article to be Epaired 6e

size of tie 6re. end lhe skill

level of the repair labor are the

tbre primsry determiDa s for

ecooomic consideration.

low Investment

medlum investment

hlgh investment

,\VERICTN C lv NlzERs ,45so( lATloN

,4ttr a90 Tert Mthod fc Weight of CodiDg otr Zile'Coed

(Grlvanizeo Iron qr Seel Articles

A T23 iio. lttot-Oip\4"-izd) Costitrgs of Iron 81d

'ISTM Sie.l Pm&cts

,11;7W./l 113 Praaice for Sofeguaidiry AgaiDst EEbrifilorat of

Hot Dip Grlvadzed Stuchral Steel Prodlcts ad

Procedr for Ibctiog Etlbtisle,Ectrt

ASTttr A 153 zitrc Cooriry Gtd Db) 6 Irq od &cl H!rdw!t!

Asiraf A 325 Hirh-Strenflh Bolts for Strucord Stel Joilts'

IDc-Mia8 Suitrblc Nuts 8td Plsb Hrtdrotd W'sh