Beruflich Dokumente

Kultur Dokumente

3506 Powermax Spec Sheet

Hochgeladen von

Fernando LopezCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

3506 Powermax Spec Sheet

Hochgeladen von

Fernando LopezCopyright:

Verfügbare Formate

3506/3506LB

POWERMAX COUPLING

Certified to NSF/ANSI-61.

Scope

The intent of the specification is to receive 2 - 16 diameter ductile iron bolted PowerMax

couplings which require only one common sleeve and corresponding set of end glands per

nominal pipe size. The coupling furnished shall be equivalent to Model 3506/3506LB

PowerMax Coupling as manufactured by PowerSeal Pipeline Products Corporation. Meets or

exceeds AWWA C219.

Ductile Iron Gland

*Low Alloy Steel Bolts

*SBR Gasket

Ductile Iron PowerMax

Standard Barrel

*Low Alloy Steel Nuts

*Optional Material Available

Features and Benefits

1. Flexible and secure connection ensure excellent performance under

which allows the repair of damaged varying pressures. Suitable for mild

sections of pipe which are too long acids, water and salt media with a

to be repaired by a PowerSeal Repair temperature range of -25 to +200F.

Clamp. 4. Standard Barrel and glands receive

2. Longest standard barrel in the an interior and exterior Epoxy

industry coating.

3. The SBR transition gasket is 5. Angular deflection up to 8

produced from 100% new rubber to

1-800-800-0932 940-767-5566 www.powerseal.com FITTING SOLUTIONS FOR HARSH ENVIRONMENTS

3506/3506LB

POWERMAX COUPLING

Certified to NSF/ANSI-61.

Design and Material Specification

1. The PowerMax Coupling shall meet 4. The laying length of the PowerMax

or exceed all material specifications sleeve shall be as specified (i.e.,

as listed below and AWWA C219. standard or Long-Barrel), and the

2. Gaskets shall be vulcanized, molded minimum quantity of bolts shall be

or extruded, SBR (Styrene Butadiene as noted per the nominal diameter.

Rubber) free from porous areas,

foreign materials, and visible Material Specifications

defects. Reclaimed rubber shall not Part Name Material Mat. specs

be used. Gaskets shall meet the Gland Ductile Iron ASTM A536

requirements of ASTM D2000 to Gasket SBR ASTM D2000

ensure superior storage

PowerMax Ductile Iron ASTM A536

characteristics, permanence, and Barrel

resistance to set. Also available in Bolts Low Allow Steel/ ASTM A325/

EPDM or Viton. Stainless Steel 304/316 ASTM A193

3. Bolts and nuts shall be in Low Nuts Low Alloy Steel / ASTM A325/

Stainless Steel 304/316 ASTM A194

Alloy Steel. Stainless Steel type 304

Coating Epoxy Coated AWWA C210

Nut & Bolts and SST type 316 are

available.

NOMINAL PIPE

BOLTS & NUTS

SIZE STANDARD BARREL LONG BARREL WEIGHT

PIPE RANGE

LENGTH (IN.) LENGTH (IN.) (LB.)

OD (in) QTY

2 A 2.30-2.90 5 12 2 16

3 A 3.40-4.20 5 12 3 21

4 A 4.20-5.33 6 12 4 27

6 A 6.25-7.45 6 12 5 36

8 A 8.40-9.79 10 12 6 60

10 A 10.70-12.12 10 12 7 69

12 A 12.75-14.38 10 12 8 83

14 A 15.25-16.90 10.5 12 10 130

16 A 16.00-17.80 12 12 10 155

16 B 17.40-19.00 12 12 10 165

1-800-800-0932 940-767-5566 www.powerseal.com FITTING SOLUTIONS FOR HARSH ENVIRONMENTS

Das könnte Ihnen auch gefallen

- Tube Fittings: Size From 1/16" Thru 2" (2mm Thru 50mm)Dokument5 SeitenTube Fittings: Size From 1/16" Thru 2" (2mm Thru 50mm)Jit BNoch keine Bewertungen

- 4-1. Hy-Lok Tube Fittings (2020)Dokument76 Seiten4-1. Hy-Lok Tube Fittings (2020)Jit BNoch keine Bewertungen

- 4-1. Hy-Lok Tube Fittings (2020)Dokument76 Seiten4-1. Hy-Lok Tube Fittings (2020)bernaNoch keine Bewertungen

- Astm A105 A105nDokument1 SeiteAstm A105 A105nestimationNoch keine Bewertungen

- Butterfly Valves Gd-381: SpecificationDokument2 SeitenButterfly Valves Gd-381: SpecificationJOSE GABRIELNoch keine Bewertungen

- TDS CatalogTWP PDFDokument26 SeitenTDS CatalogTWP PDFpankaj_paul6451Noch keine Bewertungen

- Bermad: FP/FS 400Y Torrent Valve Engineering DataDokument12 SeitenBermad: FP/FS 400Y Torrent Valve Engineering Dataeitan-daliaNoch keine Bewertungen

- S-LOK Tube FittingsDokument58 SeitenS-LOK Tube FittingsCesar YalanNoch keine Bewertungen

- Spring Materials PDFDokument25 SeitenSpring Materials PDFyatin chhabra0% (1)

- Ductile Iron Casting Specfications and Details All StandardsDokument15 SeitenDuctile Iron Casting Specfications and Details All StandardsN.Palaniappan100% (1)

- KEDDCO BinderDokument74 SeitenKEDDCO BinderWillian FigueroaNoch keine Bewertungen

- Product Description Wire RodDokument3 SeitenProduct Description Wire RodEngr Farrukh RehanNoch keine Bewertungen

- GHCABLE CatelogDokument161 SeitenGHCABLE CatelogChristian Mauricio Aldás Solís0% (1)

- Datasheet For Stainless Steel Super Duplex 2507Dokument10 SeitenDatasheet For Stainless Steel Super Duplex 2507Prem EditsNoch keine Bewertungen

- Sec 04 Steel PlatesDokument39 SeitenSec 04 Steel PlatesEndy GunawanNoch keine Bewertungen

- 2205 InfoDokument6 Seiten2205 InfoMave75Noch keine Bewertungen

- 14B Overhead SwitchesDokument28 Seiten14B Overhead SwitchesRhiannon HaynesNoch keine Bewertungen

- 6C High Strength Reinforcement G HalstedDokument36 Seiten6C High Strength Reinforcement G HalstedRafid RabbaniNoch keine Bewertungen

- Duplex Stainless Steel WeldingDokument25 SeitenDuplex Stainless Steel WeldingcfcshakerNoch keine Bewertungen

- Dembla Gate ValvesDokument20 SeitenDembla Gate ValvesMohit AroraNoch keine Bewertungen

- MS-01-174 Gaugeable SAF 2507 Super Duplex Tube FittingsDokument12 SeitenMS-01-174 Gaugeable SAF 2507 Super Duplex Tube FittingsJacques StrappeNoch keine Bewertungen

- Pipe CatalogueDokument6 SeitenPipe CatalogueirfanNoch keine Bewertungen

- Nutron TM Trunnion Mounted Ball Valve FlyerDokument2 SeitenNutron TM Trunnion Mounted Ball Valve FlyerAlbert RubianoNoch keine Bewertungen

- Sandvik SAF 2507: Duplex Stainless SteelDokument8 SeitenSandvik SAF 2507: Duplex Stainless SteelmattiaNoch keine Bewertungen

- Cold Formed Carbon Structural Steel Tubing Made From Metallic Precoated Sheet SteelDokument3 SeitenCold Formed Carbon Structural Steel Tubing Made From Metallic Precoated Sheet SteelDanZel DanNoch keine Bewertungen

- SAF 2507 Seamless Super Duplex Tubing: Fractional SizesDokument2 SeitenSAF 2507 Seamless Super Duplex Tubing: Fractional SizesAlexNoch keine Bewertungen

- 285 PSI Ductile Iron Butterfly Valve: WD 5022 LD 5022Dokument2 Seiten285 PSI Ductile Iron Butterfly Valve: WD 5022 LD 5022Instratec InstratecNoch keine Bewertungen

- Ansi Asabe S217-12-2001Dokument2 SeitenAnsi Asabe S217-12-2001StephanNoch keine Bewertungen

- Ductile Iron Butterfly Valves: LD/WD1000/2000Dokument4 SeitenDuctile Iron Butterfly Valves: LD/WD1000/2000Anonymous X3PnFL6Noch keine Bewertungen

- Corrugated Steel Pipe, Metallic-Coated For Sewers and DrainsDokument15 SeitenCorrugated Steel Pipe, Metallic-Coated For Sewers and Drainsjavier martinezNoch keine Bewertungen

- Ductile Iron SpecificationsDokument12 SeitenDuctile Iron SpecificationsDouglas BooyensNoch keine Bewertungen

- Hansun Tube Fitting - (S-LOK TYPE)Dokument60 SeitenHansun Tube Fitting - (S-LOK TYPE)qasim_maqboolNoch keine Bewertungen

- A1 Fence Specs For WebsiteDokument22 SeitenA1 Fence Specs For WebsitetajlandNoch keine Bewertungen

- Specification For Fire Pump - Part 10Dokument5 SeitenSpecification For Fire Pump - Part 10Melisa MackNoch keine Bewertungen

- ANSI ValvesDokument28 SeitenANSI ValvesBenadict JoshuaNoch keine Bewertungen

- SAF 2507 Tubing (MS-02-151) R2Dokument2 SeitenSAF 2507 Tubing (MS-02-151) R2herysyam1980Noch keine Bewertungen

- Duplex Stainless Steel WeldingDokument25 SeitenDuplex Stainless Steel Weldingkdsenipah6667Noch keine Bewertungen

- Model 2400-L: Lug WaferDokument1 SeiteModel 2400-L: Lug WaferNicolás FriasNoch keine Bewertungen

- Flexible Metalic Hose Braid & AssembliesDokument44 SeitenFlexible Metalic Hose Braid & AssembliesiJordanScribdNoch keine Bewertungen

- Electrode Booklet F Web 100Dokument1 SeiteElectrode Booklet F Web 100satnamNoch keine Bewertungen

- ASMe Sec2 PartcDokument53 SeitenASMe Sec2 PartcSARSAN NDTNoch keine Bewertungen

- Kaiser Aluminum Soft Alloy Tube PDFDokument31 SeitenKaiser Aluminum Soft Alloy Tube PDFgerrzen64Noch keine Bewertungen

- Structural SpecsDokument42 SeitenStructural SpecsJosh Jaymes MasseNoch keine Bewertungen

- Boiler Valve CatalogDokument74 SeitenBoiler Valve CatalogEduardo DiegoNoch keine Bewertungen

- Acero Estructural PDFDokument42 SeitenAcero Estructural PDFnico_v180Noch keine Bewertungen

- UL FM Wafer Butterfly Valve - Fire Protection - Model 2400-WDokument1 SeiteUL FM Wafer Butterfly Valve - Fire Protection - Model 2400-WCarlos MedinaNoch keine Bewertungen

- 01 Tube FittingsDokument60 Seiten01 Tube FittingsBien NguyenNoch keine Bewertungen

- Series Description: Universal Product Line: Steel Externals - Jacketed PumpsDokument9 SeitenSeries Description: Universal Product Line: Steel Externals - Jacketed PumpsAnonymous uCYIu1Noch keine Bewertungen

- Engels ASME BPEDokument39 SeitenEngels ASME BPEMario de Jesus CastañedaNoch keine Bewertungen

- Swagelok Tubing SpecificationsDokument8 SeitenSwagelok Tubing SpecificationsAugustine Owo UkpongNoch keine Bewertungen

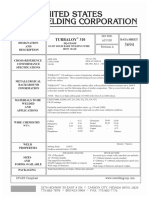

- Turbaloy 310 (SS-310) Data SheetDokument1 SeiteTurbaloy 310 (SS-310) Data SheetcandraNoch keine Bewertungen

- Industrial Valve CatalogDokument126 SeitenIndustrial Valve CatalogHung Nguyen VietNoch keine Bewertungen

- Gaseous Hydrogen Piping SpecificationDokument5 SeitenGaseous Hydrogen Piping SpecificationAndri DoemeriNoch keine Bewertungen

- A516 NormalizedDokument3 SeitenA516 Normalizediran1362Noch keine Bewertungen

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopVon EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Castellated Beams PropertiesDokument3 SeitenCastellated Beams Propertiesyiar66Noch keine Bewertungen

- Chap5 1Dokument53 SeitenChap5 1Fernando LopezNoch keine Bewertungen

- Fachada PrincipalDokument1 SeiteFachada PrincipalFernando LopezNoch keine Bewertungen

- Chap5 1Dokument53 SeitenChap5 1Fernando LopezNoch keine Bewertungen

- Design of Castellated BeamsDokument54 SeitenDesign of Castellated BeamsFernando LopezNoch keine Bewertungen

- Castellated Beams - New DevelopmentsDokument5 SeitenCastellated Beams - New DevelopmentsAlexandru Stefan BothNoch keine Bewertungen

- Structural Design of Swimming PoolsDokument12 SeitenStructural Design of Swimming Poolsale hopeju200975% (20)

- EM 1110-2-2504 - Design of Sheet Pile Walls 1Dokument75 SeitenEM 1110-2-2504 - Design of Sheet Pile Walls 1PDHLibrary100% (2)

- Chapter 6 Transformed SectionDokument1 SeiteChapter 6 Transformed SectionFernando LopezNoch keine Bewertungen

- Swimming Pool Design Sheet2Dokument3 SeitenSwimming Pool Design Sheet2Dipak Poudel100% (1)

- CASA NIDO - Plan View - N+6.84 BIS PDFDokument1 SeiteCASA NIDO - Plan View - N+6.84 BIS PDFFernando LopezNoch keine Bewertungen

- EccentricFooting PDFDokument3 SeitenEccentricFooting PDFFernando LopezNoch keine Bewertungen

- CASA NIDO - Elevation View - N BISDokument1 SeiteCASA NIDO - Elevation View - N BISFernando LopezNoch keine Bewertungen

- CASA NIDO - Plan View - N+6.84 BIS PDFDokument1 SeiteCASA NIDO - Plan View - N+6.84 BIS PDFFernando LopezNoch keine Bewertungen

- MSE Wall Design ManualDokument230 SeitenMSE Wall Design Manualnicholas_terzisNoch keine Bewertungen

- Deck Design GuideDokument63 SeitenDeck Design GuideLê Ngọc-HàNoch keine Bewertungen

- MSE Construction Procedure PDFDokument47 SeitenMSE Construction Procedure PDFFernando LopezNoch keine Bewertungen

- Alzado Transversal EstructuraDokument1 SeiteAlzado Transversal EstructuraFernando LopezNoch keine Bewertungen

- Sdi Ansi0 C 2011 (Deck)Dokument37 SeitenSdi Ansi0 C 2011 (Deck)Ricardo MontachanaNoch keine Bewertungen

- Box Culvert Design ManualDokument40 SeitenBox Culvert Design ManualAnil Kumar Kothamacha71% (21)

- 3121Dokument12 Seiten3121Fernando LopezNoch keine Bewertungen

- Alzado Transversal Estructura PDFDokument1 SeiteAlzado Transversal Estructura PDFFernando LopezNoch keine Bewertungen

- RCC Box Culvert - Methodology and Designs Including Computer MethodDokument31 SeitenRCC Box Culvert - Methodology and Designs Including Computer Methodmohan1441Noch keine Bewertungen

- Group Effect On Driven PilesDokument8 SeitenGroup Effect On Driven PilesFernando LopezNoch keine Bewertungen

- Manual Techos InsulpanelDokument14 SeitenManual Techos InsulpanelFernando LopezNoch keine Bewertungen

- Frame WoodDokument0 SeitenFrame WoodAdoba Francisc100% (2)

- Blast Wall PanelsDokument24 SeitenBlast Wall PanelsjachoijachoiNoch keine Bewertungen

- Blast Design OswaldDokument21 SeitenBlast Design OswaldFrancisco Garrido100% (1)

- Masonry Design GuideDokument62 SeitenMasonry Design GuideFernando Lopez100% (10)

- Precast PCFQA AuditDokument14 SeitenPrecast PCFQA AuditNguyễn Thanh Cường100% (2)

- WSDOT Chapter5Dokument618 SeitenWSDOT Chapter5정영철Noch keine Bewertungen

- Printing Ink and Overprint VarnishDokument137 SeitenPrinting Ink and Overprint VarnishSutopo100% (2)

- ME6403-Engineering Materials and MetallurgyDokument12 SeitenME6403-Engineering Materials and Metallurgysanthanam102Noch keine Bewertungen

- Poly SurfDokument13 SeitenPoly SurfRajNoch keine Bewertungen

- Renu MathurDokument4 SeitenRenu MathurShrey YaduNoch keine Bewertungen

- Creep Damage Evaluation 9 - 12 CR SteelsDokument22 SeitenCreep Damage Evaluation 9 - 12 CR SteelsDilip Gajanan Namjoshi100% (1)

- Notes: Castings: V501Dokument2 SeitenNotes: Castings: V501Katracho2100% (1)

- Architecturally Exposed Structural Steel PDFDokument8 SeitenArchitecturally Exposed Structural Steel PDFJagatheesh RadhakrishnanNoch keine Bewertungen

- Bill 001Dokument401 SeitenBill 001Anonymous yniiLtiNoch keine Bewertungen

- Paper IndustryDokument8 SeitenPaper IndustryBasil BabymNoch keine Bewertungen

- Codification of Precast Seismic Structural Systems: An UpdateDokument4 SeitenCodification of Precast Seismic Structural Systems: An Updateamirsh78Noch keine Bewertungen

- PolyesterDokument20 SeitenPolyesterShailendra MishraNoch keine Bewertungen

- English Trenton Wax Tape SystemsDokument16 SeitenEnglish Trenton Wax Tape SystemsTaylorNoch keine Bewertungen

- Nitoseal MS600Dokument3 SeitenNitoseal MS600Balasubramanian AnanthNoch keine Bewertungen

- Weber Dry 110 FX: Flexible High-Performance Cement-Based Waterproof CoatingDokument2 SeitenWeber Dry 110 FX: Flexible High-Performance Cement-Based Waterproof CoatingRamzi MusthafaNoch keine Bewertungen

- 5cfef CANNABRIC Technical Data Sheet and TestsDokument5 Seiten5cfef CANNABRIC Technical Data Sheet and TestsPaulNoch keine Bewertungen

- Catalogo LaminaDokument320 SeitenCatalogo LaminaHumberto José Reyes CevallosNoch keine Bewertungen

- FRP Ships: Rules and Guidance For The Classification ofDokument103 SeitenFRP Ships: Rules and Guidance For The Classification ofseyed mohamadreza MousaviNoch keine Bewertungen

- Restorative ResinsDokument71 SeitenRestorative ResinsAhmed DolaNoch keine Bewertungen

- 12.QC The Frequency of Various TestsDokument3 Seiten12.QC The Frequency of Various TestsRsjBugtongNoch keine Bewertungen

- DSMTS-0093.2 NiCoCrAlYDokument5 SeitenDSMTS-0093.2 NiCoCrAlYjpereiraucNoch keine Bewertungen

- DWA Concrete SpecDokument38 SeitenDWA Concrete SpecLouisAucampNoch keine Bewertungen

- Concrete & CKD Shelters PDFDokument4 SeitenConcrete & CKD Shelters PDFReno SaibihNoch keine Bewertungen

- Product Catalogue 2012-2013Dokument220 SeitenProduct Catalogue 2012-2013Ilija RunjajicNoch keine Bewertungen

- Integra Kitchen Design by Pedini San FranciscoDokument68 SeitenIntegra Kitchen Design by Pedini San FranciscoPedinisfNoch keine Bewertungen

- Flexible Polymer-Cement Repair Materials PDFDokument6 SeitenFlexible Polymer-Cement Repair Materials PDFBiggie Tafadzwa GanyoNoch keine Bewertungen

- Metrotile Installation ManualDokument42 SeitenMetrotile Installation ManualJapheth Areso100% (1)

- Mix Design M-40Dokument10 SeitenMix Design M-40psjjoshiNoch keine Bewertungen

- Sika SwellDokument4 SeitenSika SwellZivadin LukicNoch keine Bewertungen