Beruflich Dokumente

Kultur Dokumente

How We Calculate Thread Consumption in Garment

Hochgeladen von

Shaaban NoamanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

How We Calculate Thread Consumption in Garment

Hochgeladen von

Shaaban NoamanCopyright:

Verfügbare Formate

Introduction

It is important to know the amount of thread consumed in a sewn product so you can: 1) Estimate

the number of cones needed; and 2) Calculate the cost of the thread needed to manufacture the

finished product. Thread consumption can be determined in several ways.

To calculate the amount of thread in a seam, you can:

Measure the actual amount of thread consumed in a specific length of seam.

Calculate the thread consumption by using mathematical stitch formulas based on the thickness

of the seam and the number of stitches per inch.

Calculate the thread consumption using thread consumption estimates.

Measuring Actual Thread Consumed

A specified length of the seam, for example 3 inches, is measured on the seam and then the

thread is removed by carefully unraveling the stitch. You can then calculate the amount of thread

consumed in one inch and multiply this factor times the total length of the seam measured in

inches. (Obviously, you must do this for each seam to determine the total amount of thread

consumed in the finished product.)

Example:

Length of seam is 42 inches or 1.17 yards.

Stitch and seam construction: 401 SSa-1.

Specified length of thread removed from a seam equals 3 inches.

Needle thread removed = 9 inches

Looper thread removed = 8 inches

Calculation:

Needle thread factor = 9 3 = 3 inches of needle thread per inch of seam.

Looper thread factor = 8 3 = 2.67 inches of looper thread per inch of seam.

Total needle thread consumed = factor 3 X 1.17yds = 3.51 yds

Total looper thread consumed = factor 2.67 X 1.17yds = 3.12 yds

Total Thread = 3.51 + 3.12 = 6.63 yards per seam.

Generally a 15 to 20% waste factor is added due to chaining-off, thread breaks, repairs, etc.

If a waste factor of 15% is selected then:

6.63 yards/seam X 1.15 = 7.62 yards/seam including 15% waste factor.

Das könnte Ihnen auch gefallen

- Technova 2011Dokument32 SeitenTechnova 2011kartiksoodNoch keine Bewertungen

- Ijset 26 PDFDokument9 SeitenIjset 26 PDFShaaban NoamanNoch keine Bewertungen

- Krueger Fan Coil EngineeringDokument15 SeitenKrueger Fan Coil EngineeringYutt WattNoch keine Bewertungen

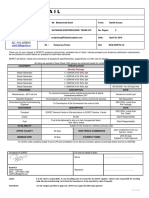

- Metel Engineering W.L.L.: Total: Fifty One Thousand Qatar Riyals OnlyDokument1 SeiteMetel Engineering W.L.L.: Total: Fifty One Thousand Qatar Riyals OnlyShaaban NoamanNoch keine Bewertungen

- Wcms 228220Dokument166 SeitenWcms 228220ranjann349Noch keine Bewertungen

- Take Some Time Out and Read These Beautiful Words Carefully. Later, Reflect On What You Have Just Read. Surely You Will Understand A Lot of ThingsDokument20 SeitenTake Some Time Out and Read These Beautiful Words Carefully. Later, Reflect On What You Have Just Read. Surely You Will Understand A Lot of ThingsMurali Krishna GbNoch keine Bewertungen

- Sustainable HVACDokument28 SeitenSustainable HVACaravoof84Noch keine Bewertungen

- Doha - MBA Schedule - 2016 - 2017Dokument1 SeiteDoha - MBA Schedule - 2016 - 2017Shaaban NoamanNoch keine Bewertungen

- API 650 Tank Nozzle Stand Out - EditableDokument20 SeitenAPI 650 Tank Nozzle Stand Out - EditableShaaban NoamanNoch keine Bewertungen

- RKQ Qwetc 16Dokument2 SeitenRKQ Qwetc 16Shaaban NoamanNoch keine Bewertungen

- Complete Piping Training Course PresentationDokument446 SeitenComplete Piping Training Course Presentationrammech85100% (1)

- @accessibility Factors - Human Factor Guide LineDokument9 Seiten@accessibility Factors - Human Factor Guide Lineabs0001Noch keine Bewertungen

- Carrier - Water Piping Systems and Pumps PDFDokument33 SeitenCarrier - Water Piping Systems and Pumps PDFShaaban NoamanNoch keine Bewertungen

- Rental Quotation For QWET-GEN-QT1380Dokument3 SeitenRental Quotation For QWET-GEN-QT1380Shaaban NoamanNoch keine Bewertungen

- Woven Fabric Consumption FormulaDokument2 SeitenWoven Fabric Consumption FormulaShaaban NoamanNoch keine Bewertungen

- Metel Engineering W.L.L.: Total: Fifty One Thousand Qatar Riyals OnlyDokument1 SeiteMetel Engineering W.L.L.: Total: Fifty One Thousand Qatar Riyals OnlyShaaban NoamanNoch keine Bewertungen

- 03 2 PDFDokument20 Seiten03 2 PDFShaaban NoamanNoch keine Bewertungen

- IE PG Brochure 2014Dokument113 SeitenIE PG Brochure 2014Shaaban NoamanNoch keine Bewertungen

- Pdm7a0jf PDFDokument36 SeitenPdm7a0jf PDFShaaban NoamanNoch keine Bewertungen

- Strategic Sourcing and Supplier Selection: A Review of Survey-Based Empirical ResearchDokument32 SeitenStrategic Sourcing and Supplier Selection: A Review of Survey-Based Empirical ResearchShaaban NoamanNoch keine Bewertungen

- IE PG Brochure 2014Dokument113 SeitenIE PG Brochure 2014Shaaban NoamanNoch keine Bewertungen

- SCPS Fa11Dokument100 SeitenSCPS Fa11Shaaban NoamanNoch keine Bewertungen

- Packing List DATE:9-6-2015: Men'S 100% Poly Active Knited Shorts 46425 / 46426Dokument1 SeitePacking List DATE:9-6-2015: Men'S 100% Poly Active Knited Shorts 46425 / 46426Shaaban NoamanNoch keine Bewertungen

- Woven Fabric Consumption FormulaDokument2 SeitenWoven Fabric Consumption FormulaShaaban NoamanNoch keine Bewertungen

- Estimating Thread Consumption 2-4-10Dokument4 SeitenEstimating Thread Consumption 2-4-10Nishkarsh MauryaNoch keine Bewertungen

- Ewing Thread Consumption FormulaDokument3 SeitenEwing Thread Consumption FormulaShaaban NoamanNoch keine Bewertungen

- How To Sew Extra Heavy Thread Sizes in Denim JeansDokument5 SeitenHow To Sew Extra Heavy Thread Sizes in Denim JeansShaaban NoamanNoch keine Bewertungen

- How To Sew Extra Heavy Thread Sizes in Denim JeansDokument5 SeitenHow To Sew Extra Heavy Thread Sizes in Denim JeansShaaban NoamanNoch keine Bewertungen

- Denim Sewing ThreadsDokument7 SeitenDenim Sewing ThreadsShaaban NoamanNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)