Beruflich Dokumente

Kultur Dokumente

Padeye Design

Hochgeladen von

Chiedu OkonduOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Padeye Design

Hochgeladen von

Chiedu OkonduCopyright:

Verfügbare Formate

Date:

CLIENT: - BY:

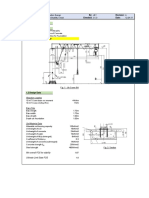

PROJECT: standard padeye

SUBJECT: standard padeye CHK:

Revision A0

REFERENCES

1. "Recommended Practice for Planning, Designing and Constructing Fixed Offshore Platforms", API RP 2A WSD. 2005

2. "Specification for Structural Steel Buildings", AISC 360-05

3. "Guidelines for lifting operations by floating crane vessels" Noble Denton 0027/ndi Rev. 5

4. "Riggers Handbook" A.Noble & Son

5. "Manual of Steel Construction ASD", AISC Ed.9 1989

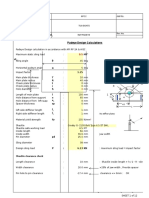

1.0 INPUT

LOADS

W ed Le C

Normal tension force (W) = 784.8 kN

Sling Angle Transverse () = 2.87 degrees 5%

In plane angle () = 0.0 degrees

Number of Lift Points (n) = 1

DAF = 1.30 Ref [3]

DNV CN 2.7.1 Load Factor = 0.00 Wc

Consequence factor (fc) 1.30 DNV RMO P2 Ch5 4.1.2 Les

Loadfactor (fL) (fc.(Max of(DAF and Lf)) = 1.69

Design Force (Fdyn = W.fL) = 1326 kN = 135.2 Tonne

SHACKLE GEOMETRY Ref [4], Nobles Riggers Handbook (Safety Alloy Bow Shackle Grade 'S') Type: Crosby G-2140

Shackle size = 150.0 Tonne 6

Nominal Size (C) = 111 mm

Pin diameter (dp) = 96.0 mm

clearance for pin in hole = 3 mm

Inside width (A) = 133 mm

Inside length (E) = 372 mm

Shackle base diameter (B) = 203 mm

d cable Thimble + gap (g) = 100 mm d cable 93

PADEYE GEOMETRY

Pipe OD diameter (Pd) = 406.4 mm

Main plate Radius (Rmp) = 190 mm 144 168 tp 152

Padeye plate thickness (tmp) = 40 mm 24 38.4

Cheek plate radius (rcp) = 160 mm 170 tcp

Cheek plate thickness (tcp) = 20 mm 14.4 28.8

Cheek plate width at base (wcpb) = 0 mm ed

Cheek plate thickness base (tcpb) 0 mm

rcp

Base of padeye to pin centre (H) = 220 mm

Stiffener plate to pin centre (Hs) = 220 mm cL

Main plate width (Wd) at shackle pin 388 mm

Main plate width (Wb) at base = 475 mm

Ls (or effective "slotted" length) = 400 mm

total thickness (t = tmp + 2.tcp) = 80 mm

Deye (Hole) advice ~1.04x d pin = 100 mm 99.84

Yield Stress plates (Fyp) = 335 Mpa (N/mm2) S355

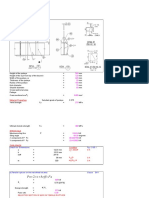

2.0 OUTPUT

GEOMETRY CHECKS

Check clearance pin hole - shackle pin (~ 1.04* d pin) 100 OK

Check for sufficient clearance below pin hole to fit shackle (+10mm), H or Hs > (B/2 + 10) 111.5 OK

Check main plate plate width fit to pipe OD (+30 mm), Wb > OD+30 OK

Check padeye plate and sling will fit in shackle, E > Rmp + g 290 OK

Check cheek plate fits on padeye main plate, rcp < H OK

Check clearance padeye thickness / inside shackle (+5mm), ttot < (A-5) OK

LOCAL DESIGN CHECKS

Bearing Stress

Allow. Bearing Stress (Fp = 0.9*Fy) 302 MPa Ref [2] : J.7 commentary

2

Bearing Area (Ab = dp (tp + 2tcp)) = 7680 mm

Bearing Stress (fp = Fdyn/Ab) = 173 MPa

Unity Check (fp/Fp) = 0.57 Check U.C. < 1.0 OK IN BEARING

Tensile Stress

Allow Tensile Stress (Ft = 0.6Fy) = 201 MPa Ref [1] : equation 3.2.1-1

Min. tensile length at hole (Wd) = 388 mm

Tensile Stress Area (Ateye) = 20320 mm2 At = (Wd-Deye).tp + 2.(2rcp -Deye).tcp (including cheek plates)

Tensile Stress (fteye) = 65 MPa

Unity Check (fteye/Ft) = 0.32 Check U.C. < 1.0 OK IN TENSION

Shear Tear Out

Allow. Shear Stress (Fv = 0.4Fy) = 134 MPa Ref [1] : equation 3.2.4-2

xmp = Rmp - Deye/2 = 140 mm

xcp = rcp - Deye/2 = 110 mm

2

Shear Area (Aseye = 2[tp.xmp + 2.tcp.xcp]) = 20000 mm

Shear Stress (fseye = T/Aseye) = 66 MPa

Unity Check (fseye/Fv) = 0.49 Check U.C. < 1.0 OK IN SHEAR TEAR OUT

PADEYE STG CBK revA0 2013 04 29.4/13/2017.2:53 PM

Date:

CLIENT: - BY:

PROJECT: standard padeye

SUBJECT: standard padeye CHK:

Revision A0

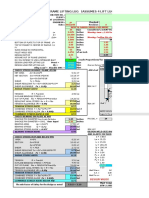

GLOBAL DESIGN CHECKS MAIN -/ CHEEK PLATE

Axial Tensile Stress (ft)

Allow. Tensile Stress (Ft = 0.6Fy) = 201 MPa Ref [1] : equation 3.2.1-1

2

Axial Area (Atb = Wb * tp) = 19000 mm

Axial Stress at base (ftb = T.cos/Atb) = 70 MPa

Unity Check (ftb/Ft) = 0.35 Check U.C. < 1.0 OK IN TENSION

2

I = (I+Ad )

Y Aty base Weak axes Ixb = 2533333 mm

4

using actual Cheekplate width at base/stiffener

4

A1 tcp Strong axes Iyb = 357239583 mm

A2 tp using actual Cheekplate width at base/stiffener

X Les

A3

W

2*rcp

Wc

Strong Axis (In-plane) Bending Stress (fby)

Allow. Bend Stress (Fb = 0.75Fy) = 251 MPa Ref [1] : equation 3.2.3-1a

Moment (Myb = T.cos.sin.Hs) = 0 Nmm at base

Section Modulus (Wyb = Iyb/(Wb/2)) = 1504167 mm3

Bending Stress (fby = Myb/W yb) = 0 MPa

Unity Check (fby/Fb) = 0 Check U.C. < 1.0 OK IN PLANE BENDING

Weak Axis (Out-of-plane) Bending Stress (fbx)

Allow. Bend Stress (Fb = 0.75Fy) = 251 MPa Ref [1] : equation 3.2.3-1a

Moment (Mxb = T.sin.Hs) = 14609859 Nmm at base

Section Modulus (Wxb = Ixb/(tp/2+tcpb) = 126667 mm3

Bending Stress (fbx = Mxb/Wxb) = 115 MPa

Unity Check (fbx/Fbx) = 0.46 Check U.C. < 1.0 OK TRANSVERSE BENDING

Shear in Main plate (mp) Allow. Shear Stress (Ts=0.4Fy) 134 MPa

Shear Area (Asb=W b.tp +W cpb.tcpb) = 19000

Shear force (Fsmp=Fdyn.cos.sin) = 0 kN mp=Fs/Asb

Shear Stress (fseye = T/Aseye) = 0.0 MPa

Unity Check (mp/Ts) = 0.00

Combined Stress [Ref. 1 : equation 3.3.1-2]

2 2 1/2

ft/Ft + (fbx + fby ) /Fb = 0.81 Check U.C. < 1.0 OK FOR COMBINED STRESS

Combined Stress [Ref. 5 : equation H2-1]

ft/Ft + ( fbx + fby)/Fb = 0.81 Check U.C. < 1.0 OK FOR COMBINED STRESS

Combined Normal- and Shear Stress (Von Misses) Allow. vma=0.66Fy 221.1 Mpa

2 2 1/2

vm = ((t + bx + by) + 3.(mp) ) = 70 MPa

Unity check (vm / vma) = 0.32 Check U.C. < 1.0 OK FOR VON MISSES

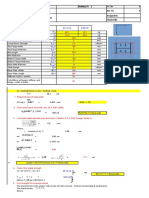

CHEEK PLATE WELD CHECK tw

Electrode Type = 7018

Ultimate Weld yield (Fyw) = 248 MPa Lowest value plate/elec used

Weld thickness (twcp) (leg) = 15 mm

Load on one cheek plate (Fcp) = 332 kN (Fcp = T.tcp/ttot)

Allow. Shear Stress (Fw=0.4Fy) = 99 MPa Ref [1] : equation 3.2.4-2

Effective weld length (Lwcp=2*.rcp) = 1005 mm some times 1/2 A used

2

Awcp throat a =Lwcp*twcp/(21/2) = 10663 mm

Shear stress in weld Fcp/Awcp (cp) = 31.1 MPa

Unity Check (pw/Pw) = 0.23 Check U.C. < 1.0 FILLET WELD OK

PADEYE PLATE WELD TO STRUCTURAL MEMBER CHECK tw

Electrode Type = 7018

Ultimate Weld yield (Fyw) = 248 MPa Lowest value plate/elec used

Weld thickness (tws) (leg) = 15 mm

Force on padeye plate (Fdyn) = 1326 kN

Allow. Weld Shear (Fws=0.4Fuw) = 99 MPa Ref [1] : equation 3.2.4-2

Effective length of weld (Lws=4.Ls) = 1600 mm Double fillet weld

1/2 2

Aws throat a =Lws*tws/2 = 16971 mm

Shear stress in weld Fdyn/Aws (slot) = 78.2 MPa

Unity Check (pw/Pw) = 0.58 Check U.C. < 1.0 FILLET WELD OK

PADEYE STG CBK revA0 2013 04 29.4/13/2017.2:53 PM

Das könnte Ihnen auch gefallen

- Padeye 7Dokument24 SeitenPadeye 7Ramesh SelvarajNoch keine Bewertungen

- Sfex Pad Eyes Calculations 35T - 32MMDokument1 SeiteSfex Pad Eyes Calculations 35T - 32MMJohn Rom CabadonggaNoch keine Bewertungen

- Pad Eye Connected To Bottom PieceDokument7 SeitenPad Eye Connected To Bottom PieceAsaru Deen0% (1)

- Padeye .5MT CHKDokument12 SeitenPadeye .5MT CHKDhanraj VasanthNoch keine Bewertungen

- Padeye DolphinDokument38 SeitenPadeye DolphinMuhammad FadelNoch keine Bewertungen

- Gross weight lifting lug dimensionsDokument10 SeitenGross weight lifting lug dimensionsReda Elawady100% (1)

- LiftingLug TrunnionDokument22 SeitenLiftingLug Trunnionrichardchiam100% (2)

- Padeye PATIDokument43 SeitenPadeye PATIbayu_23RNoch keine Bewertungen

- 17 TonsDokument8 Seiten17 Tonsabuzahrau100% (3)

- Section Properties: Design of Padeye As Per Aisc 360-2005Dokument5 SeitenSection Properties: Design of Padeye As Per Aisc 360-2005Fadil WimalaNoch keine Bewertungen

- Padeye - 01Dokument9 SeitenPadeye - 01ramNoch keine Bewertungen

- CEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveDokument5 SeitenCEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveLaurentiu TeacaNoch keine Bewertungen

- Horizontal Lifting LugDokument1 SeiteHorizontal Lifting LugTushar MangratiNoch keine Bewertungen

- Calculation of DavitDokument2 SeitenCalculation of DavitpiziyuNoch keine Bewertungen

- 8 Padeye - Spreadsheet Check1Dokument4 Seiten8 Padeye - Spreadsheet Check1oluomo1Noch keine Bewertungen

- Padeye8t (Without Cheek Plate)Dokument2 SeitenPadeye8t (Without Cheek Plate)Mohd Khir Johari100% (1)

- Book 3Dokument6 SeitenBook 3Sasikumar Jothi100% (1)

- Spreader Beam (Planning)Dokument28 SeitenSpreader Beam (Planning)AKSHAY BHATKARNoch keine Bewertungen

- Libro 1Dokument6 SeitenLibro 1Mario ManzanoNoch keine Bewertungen

- PadeyeDokument14 SeitenPadeyeMarshall Minggat AmpiNoch keine Bewertungen

- LIFTING LUG AND LIFTING COVER DESIGN REFERENCEDokument4 SeitenLIFTING LUG AND LIFTING COVER DESIGN REFERENCERohith V VNoch keine Bewertungen

- #754 v-3103 Spreader & Lifting 60 DegreeDokument12 Seiten#754 v-3103 Spreader & Lifting 60 DegreeHafizi HZnumismatic100% (1)

- LIFTING LUG Weld Check KGDokument4 SeitenLIFTING LUG Weld Check KGjoerijiNoch keine Bewertungen

- Davit Cal 2251B Davit Arm CalculationDokument4 SeitenDavit Cal 2251B Davit Arm Calculationnitin400Noch keine Bewertungen

- Lifting Lug CalculationsDokument6 SeitenLifting Lug CalculationsYash RamiNoch keine Bewertungen

- Padeye Calculation LatestDokument10 SeitenPadeye Calculation LatestPavan RayNoch keine Bewertungen

- Load analysis and strength evaluation of vessel lifting lugDokument3 SeitenLoad analysis and strength evaluation of vessel lifting lugMudasir MughalNoch keine Bewertungen

- Spreader Beam DesignDokument3 SeitenSpreader Beam DesignCHENoch keine Bewertungen

- Lift Calculation DemoDokument4 SeitenLift Calculation Demoa_toups0% (1)

- Pad-Eye MainDokument8 SeitenPad-Eye MainPradeep ChitluriNoch keine Bewertungen

- Pad Eye Design AnalysisDokument10 SeitenPad Eye Design AnalysisRaza AidanNoch keine Bewertungen

- Padeye CalculationDokument6 SeitenPadeye CalculationKarun DasNoch keine Bewertungen

- Lifting Lug AnalysisDokument3 SeitenLifting Lug Analysisராபர்ட் ஆன்றோ ரெனி67% (3)

- Lifting LugDokument39 SeitenLifting LugSasikumar JothiNoch keine Bewertungen

- Lifting Analysis GuideDokument3 SeitenLifting Analysis GuideNwosu Augustine100% (1)

- SWI PadeyeDokument11 SeitenSWI PadeyeFian ArdiyanaNoch keine Bewertungen

- Shear Strength Calculation For Lifting Lug For Plate FlippingDokument16 SeitenShear Strength Calculation For Lifting Lug For Plate FlippingKarthikeyan VisvakNoch keine Bewertungen

- Lifting Analysis Report - Mahadi KurniawanDokument31 SeitenLifting Analysis Report - Mahadi KurniawanDian SasNoch keine Bewertungen

- Lifting Calculation REV ADokument1 SeiteLifting Calculation REV APohn Myint HanNoch keine Bewertungen

- Calculation Sheet: Padeye Calculations LoadsDokument14 SeitenCalculation Sheet: Padeye Calculations Loadsandi_nu0% (1)

- Lashing FormulaDokument1 SeiteLashing FormulaMuhammad FitrahNoch keine Bewertungen

- Offshore PadeyeDokument2 SeitenOffshore PadeyeFAR_A_DAYNoch keine Bewertungen

- Input Rev. NO: L + (c1 + c2) TWDokument6 SeitenInput Rev. NO: L + (c1 + c2) TWMudasir MughalNoch keine Bewertungen

- Latest Lifting LugDokument8 SeitenLatest Lifting Lugjagannadha varmaNoch keine Bewertungen

- Anchor Bolt Loading Calculation For 101-B-10 29.02.16Dokument6 SeitenAnchor Bolt Loading Calculation For 101-B-10 29.02.16kkaranagNoch keine Bewertungen

- Lifting Lug Calc-Single CPI - RFDokument7 SeitenLifting Lug Calc-Single CPI - RFRustam RiyadiNoch keine Bewertungen

- TrunnionDokument7 SeitenTrunnionRUDHRA DHANASEKAR100% (1)

- Sample Section Modulas CalculationDokument18 SeitenSample Section Modulas CalculationShamik ChowdhuryNoch keine Bewertungen

- Pveng: Pressure Vessel Engineering LTDDokument5 SeitenPveng: Pressure Vessel Engineering LTDBruno TrujilloNoch keine Bewertungen

- Unlocked Copy LiftingLugStress Rev 1.5 Modified YH 10.21.2015Dokument20 SeitenUnlocked Copy LiftingLugStress Rev 1.5 Modified YH 10.21.2015Afzalul Karim NirvickNoch keine Bewertungen

- Calc Sheet Design PadeyeDokument8 SeitenCalc Sheet Design PadeyeFernando Humberto100% (1)

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADokument1 Seite2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanNoch keine Bewertungen

- Padeye Calculation Design AssumptionsDokument7 SeitenPadeye Calculation Design AssumptionsRajat KatyalNoch keine Bewertungen

- AISC2005 Anchor Bolt5 Pin Connection NewDokument6 SeitenAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNoch keine Bewertungen

- Base Plate Design for Column Base ConnectionDokument6 SeitenBase Plate Design for Column Base ConnectionThuyTranNoch keine Bewertungen

- Ibr Stand PipeDokument11 SeitenIbr Stand PipeP s JagatheesanNoch keine Bewertungen

- Moment connection design for node 21Dokument3 SeitenMoment connection design for node 21jatin kalraNoch keine Bewertungen

- Anchor Bolt - AISC ASDDokument7 SeitenAnchor Bolt - AISC ASDameyyammaiNoch keine Bewertungen

- DESIGN OF LOWER PADEYE - Connected With Spreader Beam BottomDokument11 SeitenDESIGN OF LOWER PADEYE - Connected With Spreader Beam BottomAsaru DeenNoch keine Bewertungen

- Solution Manual for an Introduction to Equilibrium ThermodynamicsVon EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNoch keine Bewertungen

- Beam Design Formulas With Shear and MomentDokument20 SeitenBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- Standard Series Limits Size-Unified and American Screw ThreadsDokument19 SeitenStandard Series Limits Size-Unified and American Screw ThreadsChiedu OkonduNoch keine Bewertungen

- Torque Requirement (Impact Wrench)Dokument1 SeiteTorque Requirement (Impact Wrench)Chiedu OkonduNoch keine Bewertungen

- An Introduction To Foundation EngineeringDokument43 SeitenAn Introduction To Foundation EngineeringkamaNoch keine Bewertungen

- Naval Architecture 1 Class Notes: Omar Bin YaakobDokument126 SeitenNaval Architecture 1 Class Notes: Omar Bin Yaakobronny-su100% (1)

- Clamped Cover Plate DesignDokument7 SeitenClamped Cover Plate DesignChiedu OkonduNoch keine Bewertungen

- Weld StrengthDokument9 SeitenWeld StrengthChiedu OkonduNoch keine Bewertungen

- Torque Requirement (Impact Wrench)Dokument1 SeiteTorque Requirement (Impact Wrench)Chiedu OkonduNoch keine Bewertungen

- Design of Offshore PlatformDokument16 SeitenDesign of Offshore PlatformMd Azahary100% (1)

- Dev Child GeniusDokument17 SeitenDev Child GeniusAnita RadhakrishnanNoch keine Bewertungen

- IMCA Wind and Current Load Coefficient Calculation PDFDokument4 SeitenIMCA Wind and Current Load Coefficient Calculation PDFChiedu OkonduNoch keine Bewertungen

- Lashing and Securing Deck CargoesDokument15 SeitenLashing and Securing Deck CargoesmajdirossrossNoch keine Bewertungen

- IMCA Wind and Current Load Coefficient CalculationDokument4 SeitenIMCA Wind and Current Load Coefficient CalculationChiedu OkonduNoch keine Bewertungen

- Training MetoceanDokument68 SeitenTraining MetoceanChiedu Okondu100% (3)

- Chapter 16 - Structural Design PDFDokument28 SeitenChapter 16 - Structural Design PDFTefera TemesgenNoch keine Bewertungen

- Worked Examples Ec2 Def080723Dokument120 SeitenWorked Examples Ec2 Def080723dan_ospir67% (3)

- E1658062513 PDFDokument9 SeitenE1658062513 PDFuroskNoch keine Bewertungen

- Mooring DynamicsDokument16 SeitenMooring DynamicsChiedu OkonduNoch keine Bewertungen

- Dolphin-Design Example PDFDokument12 SeitenDolphin-Design Example PDFChiedu OkonduNoch keine Bewertungen

- Processing Manual VCO PICT - Chap1-6Dokument102 SeitenProcessing Manual VCO PICT - Chap1-6pradeep johnNoch keine Bewertungen

- 5 Design of Steel Truss FootbridgeDokument106 Seiten5 Design of Steel Truss FootbridgePAYANGDO100% (2)

- Jib Foundation Sizing and Stability AnalysisDokument4 SeitenJib Foundation Sizing and Stability AnalysisChiedu Okondu50% (2)

- FOUNDATION DESIGN OPTIMIZATION FOR ROTATING EQUIPMENTDokument38 SeitenFOUNDATION DESIGN OPTIMIZATION FOR ROTATING EQUIPMENTChiedu OkonduNoch keine Bewertungen

- Tutorial MathcadDokument13 SeitenTutorial MathcadFabrizziobiNoch keine Bewertungen

- Design of Equipment FoundationsDokument28 SeitenDesign of Equipment Foundationsapi-379773793% (42)

- Soil LiquefactionDokument13 SeitenSoil LiquefactionUmange RanasingheNoch keine Bewertungen

- Compression 1Dokument33 SeitenCompression 1KSHITIJ MODINoch keine Bewertungen

- Introduction to Prestressed Concrete TechniquesDokument20 SeitenIntroduction to Prestressed Concrete TechniquesHezb KhanNoch keine Bewertungen

- 3) Bearing CapacityDokument19 Seiten3) Bearing CapacityhaftamuTekle100% (1)

- Introduction to Earthquakes & Earthquake HazardsDokument16 SeitenIntroduction to Earthquakes & Earthquake HazardsJeanelyn RodegerioNoch keine Bewertungen

- Mechanical Behavior of Materials - Lecture Slides - Chapter 9Dokument73 SeitenMechanical Behavior of Materials - Lecture Slides - Chapter 9Jun-Dong LeeNoch keine Bewertungen

- API RP 1102 SpreadsheetDokument5 SeitenAPI RP 1102 SpreadsheetJorge Rodriguez0% (1)

- MAT FOUNDATION ENGINEERINGDokument70 SeitenMAT FOUNDATION ENGINEERINGKarim SadekNoch keine Bewertungen

- UNITEC-Geotechnical Engineering B 6045 2013 s2Dokument9 SeitenUNITEC-Geotechnical Engineering B 6045 2013 s2donNoch keine Bewertungen

- Vibroreplacement PDFDokument9 SeitenVibroreplacement PDFthadikkaranNoch keine Bewertungen

- Steel MidtermDokument3 SeitenSteel MidtermDave JarangueNoch keine Bewertungen

- Reinforced Concrete Design Problems SolvedDokument11 SeitenReinforced Concrete Design Problems Solvedacurvz2005Noch keine Bewertungen

- A Review On A Gear Tooth Failure AnalysisDokument13 SeitenA Review On A Gear Tooth Failure AnalysisKKDhNoch keine Bewertungen

- A Presentation On Final Year Project: Birla Institute of Technology Mesra (Ranchi)Dokument18 SeitenA Presentation On Final Year Project: Birla Institute of Technology Mesra (Ranchi)Dhruv VashisthaNoch keine Bewertungen

- Chopra, Dynamic Stiffness Matrices For Homogeneous ViscoelasticDokument134 SeitenChopra, Dynamic Stiffness Matrices For Homogeneous ViscoelasticCarlos Eduardo Cueva CallerNoch keine Bewertungen

- Inelastic Torsion of Multistorey Buildings Under Earthquake ExcitationsDokument17 SeitenInelastic Torsion of Multistorey Buildings Under Earthquake Excitationssobah assidqiNoch keine Bewertungen

- CEC'10 Sample PaperDokument2 SeitenCEC'10 Sample PaperNoram Irwan RamliNoch keine Bewertungen

- Timoshenko CoefficientDokument6 SeitenTimoshenko CoefficientwarterflyNoch keine Bewertungen

- Sudden Quiz 3 StrucDokument8 SeitenSudden Quiz 3 StrucVincent TayagNoch keine Bewertungen

- Shear Strength of Inverted T - BeamsDokument1 SeiteShear Strength of Inverted T - Beamsfoush bashaNoch keine Bewertungen

- Multi CellDokument10 SeitenMulti CellLuis Alejandro MuñozNoch keine Bewertungen

- Lame ConstantsDokument2 SeitenLame ConstantsAldi NurseptaNoch keine Bewertungen

- Chapter 4 Earthquake HazardsDokument25 SeitenChapter 4 Earthquake HazardsJacinthe Angelou D. PeñalosaNoch keine Bewertungen

- Group 1 Final Project: Schedule of ColumnDokument1 SeiteGroup 1 Final Project: Schedule of ColumnJohn Vincent PinedaNoch keine Bewertungen

- Astm E6Dokument12 SeitenAstm E6Nacer KisyNoch keine Bewertungen

- ACI Building Code Requirements for Thin Shells and Folded PlatesDokument84 SeitenACI Building Code Requirements for Thin Shells and Folded PlateskrishnanunniNoch keine Bewertungen

- Tos Notes 1,2,3Dokument13 SeitenTos Notes 1,2,3Star Youtuber Prashant100% (1)

- Me 45 Strength of MaterialsDokument243 SeitenMe 45 Strength of MaterialsJhonny Perez Saldaña100% (1)

- Direct Shear TestDokument11 SeitenDirect Shear Testshahrolhazrien91% (34)

- Braced Frames: and New York. The 57-Story, 792-Ft-High, Braced Steel Woolworth Tower, ComDokument24 SeitenBraced Frames: and New York. The 57-Story, 792-Ft-High, Braced Steel Woolworth Tower, ComMickey DalbeheraNoch keine Bewertungen