Beruflich Dokumente

Kultur Dokumente

Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design Code

Hochgeladen von

Andres Rodriguez HerreraOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design Code

Hochgeladen von

Andres Rodriguez HerreraCopyright:

Verfügbare Formate

See

discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/263895528

Design Calculation Of Nozzle Junction Based On

ASME Pressure Vessel Design Code

ARTICLE MAY 2014

READS

6,587

4 AUTHORS, INCLUDING:

Maharshi J. Bhatt Ashish Gohil

1 PUBLICATION 0 CITATIONS Nirma University

11 PUBLICATIONS 13 CITATIONS

SEE PROFILE

SEE PROFILE

Available from: Ashish Gohil

Retrieved on: 07 April 2016

International Journal of Advance Engineer ing and Research Development (IJAERD)

Volume 1,Issue 5,May 2014, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

Design Calculation Of Nozzle Junction Based On ASME P ressure

Vessel Design Code

Asst. Prof. Maharshi J. Bhatt1 , Asst. Prof. Ashish Gohil2 , Hardic Shah 3, Nikunj Patel4

1

Production Engineering Department, SSEC, Bhavnagar maharshibhatt6@gmail.com

2

Mechanical Engg. Department, Nirma University, Ahmadabad ashish.gohil@nirmauni.ac.in

3

Manager L &T, Ranoli, Baroda, hardicshah@gmail.com

4

Asst. manager L &T, Ranoli, Baroda, nikunjpatel@gmail.com

Abstract: Nozzle is a device designed to control the direction or characteristics of fluid

(especially to increase velocity) as it exits (or enters) an enclosed chamber or pipe. Under

different loading conditions, the stress will occur at the nozzle to head or shell junction area.

Thus reliable and accurate design calculation for head or shell to nozzle junction is necessary.

The calculation for nozzle design gives the information whether the design is adequate for

given parameters. In this paper, design calculation of nozzle junction based on ASME

pressure vessel design code is carried out for nozzle to head junction subjected to applied

external load, internal pressure and moments. The equations are as per ASME Section VIII

Division I. This paper gives methodize steps and format for design calculation for

reinforcement of nozzle. The results are also compared with PV-Elite code.

Keywords- Reinforcement area, Nozzle shell junction, Parallel limit, Normal Limit,

Layout Angle.

I. INTRODUCTION

Providing additional material in the region of the opening by thickening the shell or

adding a pad material is known as reinforcement. It may be inside or outside. Generally

distance is kept equal to diameter [D] from the center of the nozzle It is called boundary limit

of effective Reinforcement.

1.1. Need of reinforce ment

Openings in pressure vessels in the regions of shells or heads are required to serve the

following purposes: Manways for letting personnel in and out of the vessel to perform,

routine maintenance and repair, Holes for draining or cleaning the vessel, Handhole openings

for inspecting the vessel from outside, Nozzles attached to pipes to convey the working fluid

inside and outside of the vessel, For all openings, however, nozzles may not be necessary. In

some cases nozzles and piping that are attached to the openings, while in other cases there

could be a manway cover plate or a handhole cover plate that is welded or attached by bolts

to the pad area of the opening. Nozzles or openings may be subjected to internal or external

pressure, along with attachment loads coming from equipment and piping due to different ial

thermal expansion and other sources. From reinforcement calculation following parameters

can be obtained: Wall Thicknesses required (Shell and Nozzle), Area of Reinforcement

required, Area of Reinforcement available, Cross-sectional area of various welds available

for reinforcement, Cross-sectional area of material added as reinforcement, Total area

available Size of reinforcing pad (if required), Size of fillet welds (inside, outside and

reinforcing pad fillet- if required), Maximum nozzle distance projects beyond the inner

surface of the vessel wall.

@IJAERD-2014, All rights Reserved 1

International Journal of Advance Engineer ing and Research Development (IJAERD)

Volume 1,Issue 5,May 2014, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

II. METHODOLGY AND STEPS FOR NOZZLE DESIGN CALCULATION

Figure 1.Reinforced nozzle

2.1 Steps for Nozzle Design Calculation

Fig 1. Show the cross-sectional view of reinforced nozzle that indicates nozzle and shell

thickness area, reinforcement locations and weld paths, parallel and normal limits with its equations.

1. Mi ni mum required shell thickness is given by:

Tr s = (P*R)/(2*S*E-0.2*P)

Figure 2.Nozzle Shell junction area Figure 3.main parameters for reinforcement

2. Mini mum required nozzle thickness is given by:

Tr n = R( exp([P/(SE)] - 1 )

3. The reinforcement area required is Ar:

Ar = (d * tr * F + 2 * tn * tr* F * (1-fr1 ))

4 LIMITS:

Parallel limit:

(a) d (b) tn + ts+ R (Use greater value.)

Normal limit:

(a) 2:5* ts (b) 2:5 *tn + te (Use smaller value)

@IJAERD-2014, All rights Reserved 2

International Journal of Advance Engineer ing and Research Development (IJAERD)

Volume 1,Issue 5,May 2014, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

5. The reinforcement area avail able in the shell (up to a distance d), A 1 is given by:

A 1 =d (E1 * ts f * tr) -2 * tn (E1 * ts F * tr) * (1-fr1 )

A 1 =2 (t s tn ) *(E1 * t F* tr) -2 * t n (E1 * t s F * tr) * (1-fr1 ) (Use larger value.)

6. The reinforcement area available in nozzle wall is available in two parts A 2 :

A2=5 (t n -t rn ) * fr2 *ts

A2=5 (t n -t rn ) * fr2 * tn (Use smaller value.)

7. Area available in inward nozzle:

A 3 =5tt j * fr2

=5tit j * fr2

= 2ht i * fr2 (Use smaller value.)

The total area available for reinforcement :

Atotal = Ar +A1+ A2+ A41 + A43+ A6

If the available area exceeds than the required area Design is adequate.

Ar< Atotal

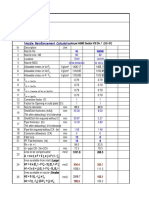

III. NOZZLE REINFORCEMENT CALCULATION

Figure 4.Geometrical Diementions

3.1 Nozzle

Dimensions of the self reinforced nozzle are shown in Fig. 4. The reinforcement

calculation is carried out as per ASME guidelines and it shows that the total area available is

more than the required area. The nozzle Inside Diameter (ID) is 101.6 mm and hub thickness

is 46 mm. Table 2 shows the other parameters of nozzle. To determine the reinforcement

requirements following parameters are given as input.

@IJAERD-2014, All rights Reserved 3

International Journal of Advance Engineer ing and Research Development (IJAERD)

Volume 1,Issue 5,May 2014, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

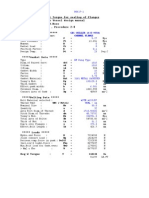

Table 1.Shell Parameters Table 2.Nozzle Parameter

Internal pressure 15.69 MPa Material SA-105

(P) Allowab le Stress at Temperature 138 MPa

Design temperature 70 C Sn

(Temp) Allowab le Stress At Ambient 138 MPa

Shell Material SA-516 ,60 Sna

Diameter Basis ID

Shell Allowable Stress 118 MPa

(at design Temperature) Layout Angle 90

Shell Allowable Stress 118 MPa Diameter 101.6 mm

(at Amb ient temperature) Hub Height of Integral Nozzle 105 mm.

Inside Diameter of Hemispherical 1878 mm h

Head D Height of Beveled Transition 9.2 mm.

Head Finished (M inimu m) 66 mm L`

Thickness t Hub Thickness of Integral 46 mm.

Head Internal Corrosion 0 mm Nozzle tn

Allowance C

Head External Corrosion 0 mm

Allowance C0

Distance from Head Centerline 600 mm

.

L1

User Entered Minimu m Design -29.00 C

Metal Temperature

3.2. Reinforcement calculations:

3.2.1Checking nozzle in the meridional direction:

a. Required thickness of spherical head(Inte rnal Pressure):as per UG 37(a)

Tr s = (P*R)/ (2*S*E-0.2*P) per UG-27 (d) (i)

= (1.61*939.0001)/ (2*12*1.00-0.2*1.61)

= 63.8624 mm.

Required thickness of nozzle wall:

(Here nozzle radius (50.8) and nozzle thickness (30.15) so Tn > Rn so use Appendix 1-2(a)

(1))

Tr n = R (exp ([P/ (SE)] - 1) per Appendix 1-2 (a)(1) (ii)

= 50.800(exp ([1.61/ (14.06*1.00]-1)

= 6.1639 mm.

b. He re, hub height=105 mm and hub thickness=46 mm

If h > (2:5 * hub thickness) use UG: 40 fig(e-2)

If h < (2:5 * hub thickness) use UG: 40 fig(e-1)

Here, using UG: 40 fig (e-1)

c. Limits:

Parallel limit:

(a) d =323.8 mm

@IJAERD-2014, All rights Reserved 4

International Journal of Advance Engineer ing and Research Development (IJAERD)

Volume 1,Issue 5,May 2014, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

(b) tn + ts+ R= 161.9 mm (iii)

Normal limit:

(a) 2:5* ts= 2:5* 66 = 165 mm

(b) 2:5 *tn + te= 2:5 * (30.15) + te= 102.828 mm (iv)

te= Hub Thickness-Neck Thickness (v)

cos30

= 4630:50

cos30

= 27.4530

So,

Parallel Limit: 323.8 mm. For parallel limit consider larger value.

Normal Limit: 102.828 mm. For normal limit consider smaller value.

d. Weld strength reduction factor:

f r1 = 1 or fr1 = Sn = 1.16 Where , Sn =14.06 and Sa=14.02

Sa

f r2 =1 or f r2 =1.16

fr3 = f r2 = 1 (use minimum values) (vi)

e. To calculate the ope ning chord length at mid surface of the required shell thickness

procedure is as follows:(use Appendix-L,L7.7)

Rm= Rs+trs2 = 939 +63.740 = 970.87 (vii)

2

Calculation of area:

Ar = (d * tr * F + 2 * tn * tr* F * (1-fr1 )) UG-37(c) . (viii)

= (129.4663 * 63.8624 * 1.0 + 2 * 46.0000 * 63.8340 * 1.0 * (1-1))

= 8254.566 mm

Reinforcement areas per figure UG-37.1

Area available in s hell (A1 ): A1 = 229:616 mm2 or

A1 = 434.598 mm2 (use large values)

Area available in nozzle outward (A2 ):

If A2 upper side should smaller than A2 inside use UG 37(b)

If not less than 0.5 require reinforcement each side opening So A2 on inside should not

greater than A2 upside.

Therefore , A2 = 5890.77 mm2

@IJAERD-2014, All rights Reserved 5

International Journal of Advance Engineer ing and Research Development (IJAERD)

Volume 1,Issue 5,May 2014, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

Area available in inward + outward weld (A41+ A43) or (A4+ A5):

= (leg2 * fr2) = 0 (viiii)

Area (A41+ A43) will not consider because welds vary from fillet to butt type weld.

Area available in Hub section A6 :

A6 = (2 * [min (Tlnp.h0.. Hub height (h))] * (Hub thickness - t n ) * fr2 (3:23)) (x)

= (2 * [min (102.8, 400, 105)] * (46 - 30.15) * 1

= 3269.04 mm2

Ar = Area required = 8254.566 mm2

A1 = Area required in shell = 434.5986 mm2

A2 = Area required in nozzle wall = 5890.77 mm2

A41 + A43 =Area required in weld = 0 mm2

A6 = Area required in Hub = 3269.04 mm2

Atotal = Ar +A1+ A2+ A41 + A43+ A6

= 9594:408 mm2

Ar= 8254 mm2

Here, Ar< Atotal

This condition indicates that for the given design parameters required area is less than the

total area. Hence, there is no need to add any extra amount of material. So, opening is

adequately Reinforced. If the required area is more than te total area then the reinforcement

pad is required.

IV. CONCLUSION

The above mentioned detailed Calculation is carried out to determine the requirement of the

reinforcement pad for the given loading condition as per ASME Section VIII, Div. I. This

calculation steps simplifies the reinforcement calculation. The calculation result suggests that

there is no need for providing reinforcement pad and hence self reinforced nozzle is used. If

condition is Ar> Atotal than only additional reinforcement would be required.

VII. R EFERENCES

[1] Eckart WeiB & Jiirgen Rudolph, Finite element analyses concerning the fatigue strength of nozzle -to-

spherical shell intersections, University of Dort mund, Depart ment of Chemical Engineering, Working

Group Pressure Vessel Design, Dort mund, Germany, page 101-109, 1995.

[2] Z. F. Sang, L. Li, H. L. Qien, Effect of geometric gap between cylinder and reinforcement pad on local

stresses (axial thrust load on nozzle), page 113-120,1997.

[3] J. Ascough and W. M. G. Malalasekera, Stress analysis of hemis pherical shells with single nonradially

penetrated nozzles, Depart ment of Mechanical Engineering, Loughborough University, Loughborough,

page 894-900 1996.

[4] C. J. Dekker and H. J. Bos, Nozzles -on external loads and internal pressure, Amsterdam, The Netherlands,

page 1-18, 1997.

@IJAERD-2014, All rights Reserved 6

International Journal of Advance Engineer ing and Research Development (IJAERD)

Volume 1,Issue 5,May 2014, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

[5] V.N. Skopinsky and A.B. Smetankin, Paramet ric study of reinforcement of pressure vessel head with offset

nozzle, Moscow, Russian Federation, page 333-343, 2002.

[6] J.S. Liua, G.T. Parksb, P.J. Clarksonb, Shape optimization of axisymmet ric cylindrical nozzles in spherical

pressure vessels subject to stress constraints, International Journal o f Pressure Vessels and Piping, page 1-9,

2001.

[7] H. F. Wang et al, Elastic Stresses of Pressurized Cylinders with Hillside Nozzle, Depart ment of Mechanical

and Power Engineering, Nanjing University of Technology, Nan jing, Ch ina, page 625-631, 2008.

[8] ASME, Bo iler and Pressure Vessel Code, Section Vlll, Div ision 1 and Division 2, 1995 Ed ition, A merican

Society Of Mechanical Eng ineers, 2010, UG 36-46.

[9] ASME, Bo iler and Pressure Vessel Code, section II, part d, division 2, A merican Society of Mechanical

Engineers, 2007.

@IJAERD-2014, All rights Reserved 7

Das könnte Ihnen auch gefallen

- Eqn Reference ASME BPVC r1sDokument5 SeitenEqn Reference ASME BPVC r1sagarcia654127Noch keine Bewertungen

- Flange calculation as per ASME Section VIIIDokument9 SeitenFlange calculation as per ASME Section VIIIDarshan PanchalNoch keine Bewertungen

- Mozzle Repad Design ToolDokument2 SeitenMozzle Repad Design ToolSiddiqui Muhammad AshfaqueNoch keine Bewertungen

- Pressure Design Straight Pipe (Run Pipe)Dokument6 SeitenPressure Design Straight Pipe (Run Pipe)gembirasekaliNoch keine Bewertungen

- Seismic Load Calculation Using G-Values in PV EliteDokument3 SeitenSeismic Load Calculation Using G-Values in PV EliteMas Arman TewoNoch keine Bewertungen

- Calculo Brida Ejemplo PV - EliteDokument8 SeitenCalculo Brida Ejemplo PV - ElitePedro Montes MarinNoch keine Bewertungen

- Pipe Cap Thickness Calculation for ASME Section VIIIDokument9 SeitenPipe Cap Thickness Calculation for ASME Section VIIILcm TnlNoch keine Bewertungen

- EJMA Calculation Report For Cryostat DNB 7HL9UC v1 3Dokument25 SeitenEJMA Calculation Report For Cryostat DNB 7HL9UC v1 3zstNoch keine Bewertungen

- Weldolet InfoDokument4 SeitenWeldolet InfoChoon Wei WongNoch keine Bewertungen

- Figure 9.5-3 Spherical Shell With A Non Radial Nozzle en 13445-3 - Figure 9.5-3Dokument5 SeitenFigure 9.5-3 Spherical Shell With A Non Radial Nozzle en 13445-3 - Figure 9.5-3met-calcNoch keine Bewertungen

- Elliptical Head Design ToolDokument1 SeiteElliptical Head Design ToolssierroNoch keine Bewertungen

- Shell Thickness CalculationsDokument2 SeitenShell Thickness CalculationsskocogluNoch keine Bewertungen

- Internal Pipe Distributor Design ProcedureDokument5 SeitenInternal Pipe Distributor Design Proceduresenthil kumarNoch keine Bewertungen

- 300 - F&D Head Design Tool Ver E4.01Dokument1 Seite300 - F&D Head Design Tool Ver E4.01Mo ZeroNoch keine Bewertungen

- Coupling UW16.2 KL Ver 1.1Dokument4 SeitenCoupling UW16.2 KL Ver 1.1gopaltryNoch keine Bewertungen

- Paulin Research Group - FE107 Experimental ValidationDokument5 SeitenPaulin Research Group - FE107 Experimental ValidationNikunj KNoch keine Bewertungen

- PED 2014-68-EU Guidelines EN v4Dokument235 SeitenPED 2014-68-EU Guidelines EN v4Nav TalukdarNoch keine Bewertungen

- Burst PR Calculation PDFDokument1 SeiteBurst PR Calculation PDFAranga KeerthiNoch keine Bewertungen

- Pipe Thickness & RF Pad Calculations As Per Asme b313Dokument3 SeitenPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeNoch keine Bewertungen

- Engineering Example CalculationDokument78 SeitenEngineering Example Calculationkae kaeNoch keine Bewertungen

- PCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Dokument2 SeitenPCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Abhay UpadhyayNoch keine Bewertungen

- Bolt Torq. (Moss+Farr)Dokument9 SeitenBolt Torq. (Moss+Farr)Bahtiar Anak LaNang100% (1)

- Nozzle Reinforcement Calculation Excel SheetDokument3 SeitenNozzle Reinforcement Calculation Excel Sheetramesh punjabiNoch keine Bewertungen

- Sample21 SpreadsheetDokument20 SeitenSample21 SpreadsheetSivateja NallamothuNoch keine Bewertungen

- UG-37 F FactorDokument7 SeitenUG-37 F FactorjamesNoch keine Bewertungen

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDokument49 SeitenDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Noch keine Bewertungen

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDokument5 SeitenASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNoch keine Bewertungen

- Asme Guide For Sec Viii Div 1Dokument1 SeiteAsme Guide For Sec Viii Div 1siddharth pawarNoch keine Bewertungen

- Compress CalculationDokument106 SeitenCompress CalculationKrupal Patel100% (1)

- S275JR PDFDokument1 SeiteS275JR PDFEmrahCayboylu100% (1)

- Blind Flange Design CalculationsDokument4 SeitenBlind Flange Design CalculationsamaNoch keine Bewertungen

- Saddle design calculationsDokument9 SeitenSaddle design calculationsduf fuNoch keine Bewertungen

- Sa 420Dokument10 SeitenSa 420Widya widyaNoch keine Bewertungen

- ASME VIII-1 Calculations for Sample Pressure VesselDokument21 SeitenASME VIII-1 Calculations for Sample Pressure VesselTrishul Nath Pallay100% (1)

- What Is An ASME Appendix 2 Flange Design PDFDokument1 SeiteWhat Is An ASME Appendix 2 Flange Design PDFMangesh BanaleNoch keine Bewertungen

- Pipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Dokument9 SeitenPipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Oswaldo GuerraNoch keine Bewertungen

- Toriconical Head Ver 1.1Dokument4 SeitenToriconical Head Ver 1.1Iqbal AhmadsNoch keine Bewertungen

- Spherical Shells en 13445-3 - 7.4.3Dokument3 SeitenSpherical Shells en 13445-3 - 7.4.3met-calc100% (1)

- Nozzle Design CalculationDokument1 SeiteNozzle Design CalculationSachin5586Noch keine Bewertungen

- VERIFICATIONDokument3 SeitenVERIFICATIONshaishavNoch keine Bewertungen

- EN13445 TWR OutDokument124 SeitenEN13445 TWR OutCosimoNoch keine Bewertungen

- Ejma7r2 Bellows Worksheet-1Dokument11 SeitenEjma7r2 Bellows Worksheet-1odormicchiNoch keine Bewertungen

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDokument8 SeitenDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeYakubu100% (1)

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDokument7 SeitenDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodebiniamNoch keine Bewertungen

- Design of Large Opening Nozzle by Bulletin WRC-107Dokument12 SeitenDesign of Large Opening Nozzle by Bulletin WRC-107ALONSO GOMEZNoch keine Bewertungen

- NTF (Vendedor)Dokument11 SeitenNTF (Vendedor)SICAAM QUERETARONoch keine Bewertungen

- Stress Analysis of Pressure Vessel Using ANSYSDokument4 SeitenStress Analysis of Pressure Vessel Using ANSYSVitor OlivettiNoch keine Bewertungen

- Design Analysis and Optimization of PistonDokument12 SeitenDesign Analysis and Optimization of PistonPranav RajNoch keine Bewertungen

- Designing of Pressure Vessel FinalDokument18 SeitenDesigning of Pressure Vessel FinalTeuku Muhammad ArrahmanNoch keine Bewertungen

- Design Methodology of Pressure Vessel NozzleDokument5 SeitenDesign Methodology of Pressure Vessel NozzleLiu YangtzeNoch keine Bewertungen

- MD PV ASME v0.1Dokument35 SeitenMD PV ASME v0.1rizalramaNoch keine Bewertungen

- N11 Nozzle CalDokument9 SeitenN11 Nozzle Calגרבר פליקסNoch keine Bewertungen

- Bolts TheoryDokument30 SeitenBolts TheoryIbrahim Mesfin100% (1)

- Optimum Design of Pressure Vessel-3Dokument3 SeitenOptimum Design of Pressure Vessel-3evrim77Noch keine Bewertungen

- Thermal Analysis and Optimization of I.C. Engine Piston Using Finite Element MethodDokument11 SeitenThermal Analysis and Optimization of I.C. Engine Piston Using Finite Element MethodDekassyah IdNoch keine Bewertungen

- PV EliteDokument6 SeitenPV ElitevikrantgulhaneNoch keine Bewertungen

- 73 ThermalDokument10 Seiten73 ThermalShashank DubeyNoch keine Bewertungen

- Ijsetr Vol 5 Issue 9 2820 2823 PDFDokument4 SeitenIjsetr Vol 5 Issue 9 2820 2823 PDFVinothkumarNoch keine Bewertungen

- Lecture 8 - MDPE - Design of Nozzles & FlangeDokument26 SeitenLecture 8 - MDPE - Design of Nozzles & FlangePatel DhruvilNoch keine Bewertungen

- Gaskets For Lined Pipe Flanges - TECHNICAL BULLETINDokument3 SeitenGaskets For Lined Pipe Flanges - TECHNICAL BULLETINAndres Rodriguez HerreraNoch keine Bewertungen

- A0K5Y4 - Attachment No. 1 - Specification SP 51-32 Rev. 2Dokument32 SeitenA0K5Y4 - Attachment No. 1 - Specification SP 51-32 Rev. 2BoulHich BoulHichNoch keine Bewertungen

- CilindrosDokument1 SeiteCilindrosAndres Rodriguez HerreraNoch keine Bewertungen

- Abrasion EnsayosDokument19 SeitenAbrasion EnsayosAndres Rodriguez HerreraNoch keine Bewertungen

- GRP Pipes FEA UndergroundDokument9 SeitenGRP Pipes FEA UndergroundAndres Rodriguez HerreraNoch keine Bewertungen

- Design of Laminated Pressure VesselDokument7 SeitenDesign of Laminated Pressure VesselAndres Rodriguez HerreraNoch keine Bewertungen

- P Blisters PDFDokument5 SeitenP Blisters PDFAndres Rodriguez HerreraNoch keine Bewertungen

- ADA307702Dokument234 SeitenADA307702Andres Rodriguez HerreraNoch keine Bewertungen

- Scrubber Design For Phosphoric Acid Production FacilityDokument57 SeitenScrubber Design For Phosphoric Acid Production FacilityAndres Rodriguez Herrera100% (2)

- Enzymatic Browning and Its Prevention-American Chemical Society (1995)Dokument340 SeitenEnzymatic Browning and Its Prevention-American Chemical Society (1995)danielguerinNoch keine Bewertungen

- 405 Econometrics Odar N. Gujarati: Prof. M. El-SakkaDokument27 Seiten405 Econometrics Odar N. Gujarati: Prof. M. El-SakkaKashif KhurshidNoch keine Bewertungen

- Sektion Installation Guide Fy21 Web ADokument16 SeitenSektion Installation Guide Fy21 Web AmroliverridleyNoch keine Bewertungen

- Surface-Based Transport Model For Mixed-Size Sediment: Peter R. Wilcock, M.ASCE, and Joanna C. CroweDokument9 SeitenSurface-Based Transport Model For Mixed-Size Sediment: Peter R. Wilcock, M.ASCE, and Joanna C. CroweEdwinNoch keine Bewertungen

- Chips Unlimited Blend LibraryDokument20 SeitenChips Unlimited Blend Librarymizan sallehNoch keine Bewertungen

- Sap MRP ConfigDokument23 SeitenSap MRP Configsharadapurv100% (1)

- The Indonesian Food Processing Industry (Final)Dokument48 SeitenThe Indonesian Food Processing Industry (Final)patalnoNoch keine Bewertungen

- Caffeine Extraction 1 PDFDokument25 SeitenCaffeine Extraction 1 PDFShanay ShahNoch keine Bewertungen

- Kerr Injection WaxesDokument1 SeiteKerr Injection WaxesmarosnaxNoch keine Bewertungen

- June 2023 BillingDokument10 SeitenJune 2023 BillingEsther AkpanNoch keine Bewertungen

- Galaxy NanoporeDokument11 SeitenGalaxy NanoporeDeborah ShirleenNoch keine Bewertungen

- Improving MV Underground Cable Performance - Experience of TNB MalaysiaDokument4 SeitenImproving MV Underground Cable Performance - Experience of TNB Malaysialbk50Noch keine Bewertungen

- TATA Gluco PDFDokument5 SeitenTATA Gluco PDFsidharth dasNoch keine Bewertungen

- Lesson Plan 2aDokument5 SeitenLesson Plan 2aapi-332424736Noch keine Bewertungen

- Design of Goods & Services: Tanweer Ascem KharralDokument10 SeitenDesign of Goods & Services: Tanweer Ascem KharralHadeed GulNoch keine Bewertungen

- Crusher Type Part Number Description Weight (KG)Dokument3 SeitenCrusher Type Part Number Description Weight (KG)Juvenal CorreiaNoch keine Bewertungen

- CH 2 Atoms, Ions, and MoleculesDokument64 SeitenCH 2 Atoms, Ions, and MoleculesBritney SimmsNoch keine Bewertungen

- Rom BlonDokument8 SeitenRom BlonCharlesJustin AyunonNoch keine Bewertungen

- Comparing characteristics and properties of various crude oilsDokument2 SeitenComparing characteristics and properties of various crude oilsnishant bhushanNoch keine Bewertungen

- Final StereogramDokument16 SeitenFinal StereogramsimNoch keine Bewertungen

- Word Trek Lesson OutlinesDokument8 SeitenWord Trek Lesson Outlinesapi-289048378Noch keine Bewertungen

- Data Sheet 2.07 Issue A: Water Flow Detector Model: WFDENDokument2 SeitenData Sheet 2.07 Issue A: Water Flow Detector Model: WFDENOvidiu GavrilasNoch keine Bewertungen

- Audit Reveals Optimization Opportunities for Cement Ball Mill SystemDokument19 SeitenAudit Reveals Optimization Opportunities for Cement Ball Mill SystemVijay Bhan100% (2)

- CSS9 TQ PT 3rd4thDokument8 SeitenCSS9 TQ PT 3rd4thJevan Hope BaltazarNoch keine Bewertungen

- Design Basis Events FOR Pressurised Heavy Water Reactor: Aerb Safety Guide No - Aerb/Sg/D-5Dokument36 SeitenDesign Basis Events FOR Pressurised Heavy Water Reactor: Aerb Safety Guide No - Aerb/Sg/D-5Anuj DeoNoch keine Bewertungen

- Network FYPDokument3 SeitenNetwork FYPla tahzanNoch keine Bewertungen

- Introduction To The Philosophy of Science First PartDokument138 SeitenIntroduction To The Philosophy of Science First PartChandra Sekhar Sahu100% (1)

- MỘT SỐ CÂU HỎI TRẮC NGHIỆM ÁP DỤNG CHUYÊN ĐỀ GIỚI TỪ TRONG ĐỀ THI ĐHDokument6 SeitenMỘT SỐ CÂU HỎI TRẮC NGHIỆM ÁP DỤNG CHUYÊN ĐỀ GIỚI TỪ TRONG ĐỀ THI ĐHPhương ThảoNoch keine Bewertungen

- Experimental Validation of The BAC Factor Method For Lighting SystemsDokument5 SeitenExperimental Validation of The BAC Factor Method For Lighting SystemsJireh AngNoch keine Bewertungen

- Portland Traffic Crash Report 2021Dokument11 SeitenPortland Traffic Crash Report 2021KGW NewsNoch keine Bewertungen