Beruflich Dokumente

Kultur Dokumente

Design of Moment Connection

Hochgeladen von

Carlos Eduardo González RamírezCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design of Moment Connection

Hochgeladen von

Carlos Eduardo González RamírezCopyright:

Verfügbare Formate

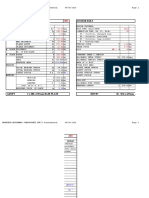

Extended H. Plate Mom. Conn.

DAR AL-HANDASAH DESIGN OF MOMENT CONNECTION

SHAIR&PARTNERS Extended End Plate Moment Connection - Eight bolts Type

Project Prepared by Dr.Hany El-Rashidy/Eng.Walaa El-Mohandis Computed by

Building Checked by

Subject Approved by

Reference AISC - ASD 9th edition

Section Dimensions Extended End

BEAM H (Total) (cm) t (web) (cm) B (fl.) (cm) t (fl.) (cm)

50.00 1.00 30.00 2.00

COLUMN H (Total) (cm) t (web) (cm) B (fl.) (cm) t (fl.) (cm) r(fillet) (cm)

65.00 2.00 40.00 4.00 0.00

Straining Actions

Moment (m.t) Shear (t.) Tension (t.)

100.00 60.00 50.00

Normal Grad

FY= 3.45 t/cm2

Check No. and Diameter of Bolts:

Ft= M/(d-tf)

= 208.33 ton

T/bolt = Ft/6

= 34.72 ton

V / total no. = V/16

= 3.75 ton

MAX.TENSION FORCE/BOLT= 37.85 ton

MAX.SHEAR FORCE/BOLT= 3.75 ton

db(bolt diameter)= 3.6 cm

USE BOLTS = M36 Grade (10.9) - DIN 6914 - No Torque Tightened Grade (8.8)

F all.ten. (No Torque T.) = 33.50 ton Grade (10.9

F all.ten. (With Torque T) = 35.70 ton

F all.shear = 20.40 ton ###

M16

U.C due to tension = 1.13 > 1 (unsafe) M20

U.C due to shear = 0.18 < 1 (safe) M22

M24

Weld Size of Beam Flange to H. Plate: AWS Table 4.1.1

Allowable weld stress M30

Electrode specification= E70XX M36

Tensile strength = 3.48 t/cm2

= .3*nominal tensile strength of weld metal AISC - ASD

= 1.04 t/cm2 Table J2.5

= .4*yield stress of base metal

= 1.38 t/cm2

f all. = 1.04 t/cm2

Sw fillet = Ft/((2*(bf+tf)-tw)*f all.)

= 3.17 cm ###

Sw(min.)= 32.00 mm Use Full Pentration , w = 0.5 cm

E70XX

E60XX

352030919.xls - Rev 0 1/2 04/18/2017

Extended H. Plate Mom. Conn.

Weld Size of Beam Web to H. Plate: ###

Sw req. = V/(f all.*(d-2tfb)) = 1.25 cm

Sw(min.)= 13.00 mm

Calculation of End Plate Thickness:

bp = Max. effective width in design = Bf + 1``

= 32.54 cm

Pf= 0 cm

g= 0 cm

pb=3dp= 10.8

Ma= T*Pf

Ma= 0.00 cm.t

Ca = Constant depending on the yield stress of the beam

= 1.11

Cb= (bfb/bp)^0.5

= 0.96

Af/Aw = 1.30

m Ca*Cb*(Af/Aw)^1/3*(Pe/dp)^1/4

C.F= Correction Factor

C.F= SQRT(((g^2+Pf^2 )^0.5)/(5*2.54))

C.F= 1

Required Plate Thickness

tp= ((6*Ma)/(0.75*Fy*bp))^0.5*C.F

= 0.00 cm

tp(min.)= 0.00 mm

Columns Stiffeners:

1- Check column web yielding

k= 4.00 cm

Pbf= 5/3*flange foce

= 347.22 ton

Pbf (allow)= Fyc*twc*(tfb+6K+2tp+2w) AISC - ASD

= 223.56 ton < Pbf NOT O.K. K1 - 1

Use Horizontal Column Stiffeners

2- Check Column Web Buckling

Pbf (allow)= 4100*twc^3*SQRT(Fy)/dc

= 547.93 kips

= 246.57 ton < Pbf NOT O.K. AISC - ASD

Use Horizontal Column Stiffeners K1 - 8

3- Check Column Flange Bending

bp= tflb+2pf+3.5pb

bp= 39.8 cm

k1= 1.00 cm K1

COLUMN

Pec= (g/2)-k1-(db/4)

= -1.90 cm

Ca= 1.11

Cb= 1 K

Af/Aw= 1.40

m = Ca*Cb*(Af/Aw)^1/3*(Pe/dp)^1/4

= #VALUE!

Me= m *Ft *Pe/4

= #VALUE! cm.t.

Required tfc= ((6*Me)/(Fy*bp))^.5

= #VALUE! cm #VALUE!

#VALUE!

352030919.xls - Rev 0 2/2 04/18/2017

Das könnte Ihnen auch gefallen

- Design Beam For Shear & TorsionDokument332 SeitenDesign Beam For Shear & Torsionsidiq7Noch keine Bewertungen

- Brace Load CalculationDokument14 SeitenBrace Load CalculationmaheshbandhamNoch keine Bewertungen

- Crack Width Calculation For Rectangular RC BeamDokument1 SeiteCrack Width Calculation For Rectangular RC BeamRomyMohanNoch keine Bewertungen

- Purlin DesignDokument9 SeitenPurlin DesignAjayvidyanand SharmaNoch keine Bewertungen

- ProkonDokument7 SeitenProkonTravel DiariesNoch keine Bewertungen

- Isolated Footing Con LoadDokument5 SeitenIsolated Footing Con Loadsaubhagya majhiNoch keine Bewertungen

- Connection DesignDokument14 SeitenConnection DesignarjunNoch keine Bewertungen

- R.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateDokument10 SeitenR.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateMarkNoch keine Bewertungen

- Corbel Design AllenDokument3 SeitenCorbel Design Allenmanoj_structureNoch keine Bewertungen

- Design of Non Composite Beams With Circular OpeningsDokument70 SeitenDesign of Non Composite Beams With Circular OpeningsbalaNoch keine Bewertungen

- ROOF PURLIN DESIGN FOR MID BAYDokument3 SeitenROOF PURLIN DESIGN FOR MID BAYUtkarsh BhardwajNoch keine Bewertungen

- Sample DBR With MonoslopeDokument27 SeitenSample DBR With MonoslopeNitish TakalkarNoch keine Bewertungen

- Floor Vibrations1Dokument10 SeitenFloor Vibrations1sidiq7Noch keine Bewertungen

- Circular WeldDokument12 SeitenCircular WeldJohn Paul UmaliNoch keine Bewertungen

- Design of Boiler Foundation Anchor RodsDokument370 SeitenDesign of Boiler Foundation Anchor RodsharsharanmannNoch keine Bewertungen

- Foundation Pads - MPA - EC2Dokument1 SeiteFoundation Pads - MPA - EC2mayphyoNoch keine Bewertungen

- Torsion Irregularity Check UBC 97-1630.7 Story Load Case/Combo Label UX Drif Label UX Drif Max DrifDokument2 SeitenTorsion Irregularity Check UBC 97-1630.7 Story Load Case/Combo Label UX Drif Label UX Drif Max DrifOmer HayatNoch keine Bewertungen

- 4.T&Angle-Brace Connection (M Project) - 0618Dokument49 Seiten4.T&Angle-Brace Connection (M Project) - 0618Omprakash KhodkeNoch keine Bewertungen

- INFASO 9.4 Example FinalDokument28 SeitenINFASO 9.4 Example Finalpperic13Noch keine Bewertungen

- TCC81 Foundation Pads-1Dokument21 SeitenTCC81 Foundation Pads-1Yap Wei XianNoch keine Bewertungen

- ACI Beam DesignDokument1 SeiteACI Beam DesigndantevariasNoch keine Bewertungen

- U G TankDokument5 SeitenU G TankVikram GaikwadNoch keine Bewertungen

- H H H H: Calculation Sheet Vertical Irregularity of StructuresDokument14 SeitenH H H H: Calculation Sheet Vertical Irregularity of StructuresPrima AdhiyasaNoch keine Bewertungen

- Beam DesignDokument7 SeitenBeam DesignKasi ViswanathanNoch keine Bewertungen

- New SlabDokument1 SeiteNew SlabParthiban ArivazhaganNoch keine Bewertungen

- Design of Flush Extended End Plate ConnectionsDokument3 SeitenDesign of Flush Extended End Plate ConnectionsMai CNoch keine Bewertungen

- NMDC Limited 3.0 Mtpa Integrated Steel Plant: at Nagarnar, ChhattisgarhDokument9 SeitenNMDC Limited 3.0 Mtpa Integrated Steel Plant: at Nagarnar, ChhattisgarhDanish AhmadNoch keine Bewertungen

- Kns5 Axially Loaded FTNG DSNDokument23 SeitenKns5 Axially Loaded FTNG DSNKanaiyalal N. ShethNoch keine Bewertungen

- Curved BeamDokument2 SeitenCurved Beamلازلت احلمNoch keine Bewertungen

- Universal Beam, Column and W Section PropertiesDokument14 SeitenUniversal Beam, Column and W Section PropertiesmaheshbandhamNoch keine Bewertungen

- Design of Base PlateDokument14 SeitenDesign of Base Plateruel galutanNoch keine Bewertungen

- Small Deflection of Simply Supported Uniformly Distributed Loaded PlatesDokument16 SeitenSmall Deflection of Simply Supported Uniformly Distributed Loaded Platesrahulmenon995030Noch keine Bewertungen

- Strip Footing Analysis and Design PDFDokument3 SeitenStrip Footing Analysis and Design PDFcleophasNoch keine Bewertungen

- Spreadsheets To BS 8110: Henry Level - 1 Base B1 RMW 113Dokument1 SeiteSpreadsheets To BS 8110: Henry Level - 1 Base B1 RMW 113ojok100% (1)

- RCC32R Rigorous Ribbed SlabsDokument554 SeitenRCC32R Rigorous Ribbed SlabsCioabla Bogdan100% (1)

- TCC94 Two Way Slabs TablesDokument5 SeitenTCC94 Two Way Slabs TablesMihai JNoch keine Bewertungen

- Anchor BoltsDokument41 SeitenAnchor BoltsJigarNoch keine Bewertungen

- Bearing Design Design NoteDokument4 SeitenBearing Design Design Notearepelli madhuNoch keine Bewertungen

- One Way Simply Supported Slab: #Value!Dokument25 SeitenOne Way Simply Supported Slab: #Value!Kanaiyalal N. ShethNoch keine Bewertungen

- Reference Output Calculations & FormulasDokument4 SeitenReference Output Calculations & FormulasAddrien DanielNoch keine Bewertungen

- Ribbed Slab Design-1Dokument2 SeitenRibbed Slab Design-1HAITHAM ALI100% (2)

- Short Span Coefficient: (Alpha - X: Depth Ok Move OnDokument4 SeitenShort Span Coefficient: (Alpha - X: Depth Ok Move OnAmok BajracharyaNoch keine Bewertungen

- ACI-Bend by ExcelDokument6 SeitenACI-Bend by Excelmahmoud IbrahemNoch keine Bewertungen

- D 250 Fixed Base PlateDokument3 SeitenD 250 Fixed Base PlateUday UdmaleNoch keine Bewertungen

- Spreadsheets To BS 8110: Single Column BaseDokument4 SeitenSpreadsheets To BS 8110: Single Column BaseBobby A MathewNoch keine Bewertungen

- General Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Dokument14 SeitenGeneral Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Maharajan McsNoch keine Bewertungen

- Design of Strap Footing PDFDokument3 SeitenDesign of Strap Footing PDFVasanthakumarNoch keine Bewertungen

- Nib CalculationDokument1 SeiteNib CalculationKen LuuNoch keine Bewertungen

- Geometrical Properties Material Properties: Design of Helicoidal StairDokument5 SeitenGeometrical Properties Material Properties: Design of Helicoidal StairPrashant Verma100% (1)

- RAFTER-COLUMN CONNECTION DESIGNDokument6 SeitenRAFTER-COLUMN CONNECTION DESIGNpriantomoNoch keine Bewertungen

- 1 Input Data: Hilti PROFIS Engineering 3.1.1Dokument10 Seiten1 Input Data: Hilti PROFIS Engineering 3.1.1Zaido Al HalabiNoch keine Bewertungen

- Design of Base Plate 3Dokument2 SeitenDesign of Base Plate 3Andro RebuyasNoch keine Bewertungen

- Planning, Analysis and Design of Open Air Cricket Stadium: Presented byDokument12 SeitenPlanning, Analysis and Design of Open Air Cricket Stadium: Presented byCatherine J. RoseNoch keine Bewertungen

- Base Plate DesignMS601aDokument3 SeitenBase Plate DesignMS601aduazo2009Noch keine Bewertungen

- Design of Moment ConnectionDokument2 SeitenDesign of Moment ConnectionDushyantha Jayawardena100% (1)

- Design of Moment ConnectionDokument2 SeitenDesign of Moment Connectiongops1963Noch keine Bewertungen

- Design of Moment Connection Extended End Plate Moment Connection - Eight Bolts TypeDokument2 SeitenDesign of Moment Connection Extended End Plate Moment Connection - Eight Bolts TypeMazenMowafyNoch keine Bewertungen

- Reference BS 449 Part 2: Design of Moment Connection Flush End Plate Moment ConnectionDokument2 SeitenReference BS 449 Part 2: Design of Moment Connection Flush End Plate Moment ConnectionMazenMowafyNoch keine Bewertungen

- Moment Conn-FlDokument2 SeitenMoment Conn-Flmahmoud Ibrahem100% (1)

- Design of Moment Connection 2Dokument2 SeitenDesign of Moment Connection 2gops1963Noch keine Bewertungen

- Expansion JointsDokument86 SeitenExpansion JointsTomas Merkevicius100% (4)

- Expansion JointsDokument86 SeitenExpansion JointsTomas Merkevicius100% (4)

- Seismic Design of Precast Concrete DiaphragmsDokument45 SeitenSeismic Design of Precast Concrete DiaphragmsCarlos Eduardo González RamírezNoch keine Bewertungen

- Seismic Evaluation of Multistorey Building With The Effect of Ground Soft Storey PDFDokument4 SeitenSeismic Evaluation of Multistorey Building With The Effect of Ground Soft Storey PDFCarlos Eduardo González RamírezNoch keine Bewertungen

- Elementary Structural Analysis and Design of Buildings PDFDokument272 SeitenElementary Structural Analysis and Design of Buildings PDFΑνδρέας Θεοδώρου100% (2)

- ACI 318-14: The Building of A New Structural Concrete CodeDokument73 SeitenACI 318-14: The Building of A New Structural Concrete Codest_luiseNoch keine Bewertungen

- Performance Based Design HistoryDokument323 SeitenPerformance Based Design Historybetzy_honey154380100% (1)

- Fundamentals of VolleyballDokument2 SeitenFundamentals of VolleyballLawrence CezarNoch keine Bewertungen

- Datasheet De14h (II) HC 1500v May2019 NTDokument2 SeitenDatasheet De14h (II) HC 1500v May2019 NTkrishnakumar paamireddyNoch keine Bewertungen

- Metric Heavy Hex Nuts: ASME B18.2.4.6M-2010Dokument16 SeitenMetric Heavy Hex Nuts: ASME B18.2.4.6M-2010CarlitosNoch keine Bewertungen

- Inakyd 3623-X-70Dokument2 SeitenInakyd 3623-X-70roybombomNoch keine Bewertungen

- Site Master FileDokument51 SeitenSite Master FileMilonhg100% (2)

- Engineering Mechanics Lectures PDFDokument83 SeitenEngineering Mechanics Lectures PDFluay adnanNoch keine Bewertungen

- SB632B Connecting Rod IdentificationDokument20 SeitenSB632B Connecting Rod IdentificationLuisCheukoCheuquianNoch keine Bewertungen

- MICROPAR PPT Group ADokument43 SeitenMICROPAR PPT Group AEben Alameda-PalapuzNoch keine Bewertungen

- SI44M 60H 80H-DeN1730-V12web DownloadedDokument4 SeitenSI44M 60H 80H-DeN1730-V12web DownloadedtauraimukumbaNoch keine Bewertungen

- Reference Design Hardware Guide for EVM CE-2Dokument7 SeitenReference Design Hardware Guide for EVM CE-2Angie FoleyNoch keine Bewertungen

- VCDS Scan Reveals Faults in HVAC, ABS and Transmission SystemsDokument4 SeitenVCDS Scan Reveals Faults in HVAC, ABS and Transmission SystemsDan MirceaNoch keine Bewertungen

- Procedure - AC Circuits and Signal Modulation - W20Dokument6 SeitenProcedure - AC Circuits and Signal Modulation - W20ChocoNoch keine Bewertungen

- Diesel HatchbackDokument14 SeitenDiesel HatchbackloganathprasannaNoch keine Bewertungen

- Self-Balancing Two-Wheeler Using GyroscopeDokument33 SeitenSelf-Balancing Two-Wheeler Using Gyroscopemilan mottaNoch keine Bewertungen

- Polycab HT XlpeDokument33 SeitenPolycab HT Xlpezafrikhan875Noch keine Bewertungen

- MACRO-ETCHING SOLUTIONS FOR ALUMINIUM ALLOYSDokument1 SeiteMACRO-ETCHING SOLUTIONS FOR ALUMINIUM ALLOYSsensoham03Noch keine Bewertungen

- Gas Turbine Performance Enhancement Update: GE Energy ServicesDokument45 SeitenGas Turbine Performance Enhancement Update: GE Energy Servicesesteban100% (1)

- Ringing On A Transmission LineDokument33 SeitenRinging On A Transmission LinePrem BhaskaraNoch keine Bewertungen

- Total Tattoo-June 2021Dokument114 SeitenTotal Tattoo-June 2021Comicgek100% (2)

- English Qualification TestDokument5 SeitenEnglish Qualification TestMoh FaisolNoch keine Bewertungen

- Parts of Speech 15Dokument16 SeitenParts of Speech 15lost finNoch keine Bewertungen

- TICSA - Diesel Uno Petroleos Guatemala (13.01.23)Dokument1 SeiteTICSA - Diesel Uno Petroleos Guatemala (13.01.23)Luis M LópezNoch keine Bewertungen

- Jurnal Risna YantiDokument14 SeitenJurnal Risna YantiRisnayantiNoch keine Bewertungen

- Kaustubh Laturkar Fuel Cell ReportDokument3 SeitenKaustubh Laturkar Fuel Cell Reportkos19188Noch keine Bewertungen

- ASME B31.4-2016 Pipeline Transportation Systems For Liquids and SlurriesDokument1 SeiteASME B31.4-2016 Pipeline Transportation Systems For Liquids and SlurriesJose Rodrigo Salguero DuranNoch keine Bewertungen

- LirikDokument537 SeitenLirikMuhamad Iqbal FahmiNoch keine Bewertungen

- Akshay 71 Seminar ReportDokument22 SeitenAkshay 71 Seminar ReportSanket Yadav25% (4)

- Demo DLLDokument2 SeitenDemo DLLArlene Diokno100% (1)

- Tiger 690 Conversion PDFDokument8 SeitenTiger 690 Conversion PDFGerardo Esteban Lagos RojasNoch keine Bewertungen

- LTE Speech Traffic Dimenshioning For VoipDokument6 SeitenLTE Speech Traffic Dimenshioning For VoipRahul GuptaNoch keine Bewertungen