Beruflich Dokumente

Kultur Dokumente

GSB MORTH (Fifth Revision) - Part-1

Hochgeladen von

kartik mehtaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

GSB MORTH (Fifth Revision) - Part-1

Hochgeladen von

kartik mehtaCopyright:

Verfügbare Formate

Sub-Bases, Bases (Non-Bituminous) and Shoulders Section 400

401 GRANULAR SUB-BASE

401.1 Scope

This work shall consist of laying and compacting well-graded material on prepared subgrade

in accordance with the requirements of these Specifications. The material shall be laid in

one or more layers as sub-base or lower sub-base and upper sub-base (termed as sub-

base hereinafter) as necessary according to lines, grades and cross-sections shown on the

drawings or as directed by the Engineer.

401.2 Materials

401.2.1 The material to be used for the work shall be natural sand, crushed gravel,

crushed stone, crushed slag, or combination thereof depending upon the grading required.

Use of materials like brick metal, Kankar and crushed concrete shall be permitted in the lower

sub-base. The material shall be free from organic or other deleterious constituents and shall

conform to the gradings given in Table 400-1 and physical requirements given in Table 400-2.

Gradings III and IV shall preferably be used in lower sub-base. Gradings V and VI shall be

used as a sub-base-cum-drainage layer. The grading to be adopted for a project shall be as

specified in the Contract. Where the sub-base is laid in two layers as upper sub-base and

lower sub-base, the thickness of each layer shall not be less than 150 mm.

401.2.2 If the water absorption of the aggregates determined as per IS:2386

(Part 3) is greater than 2 percent, the aggregates shall be tested for Wet Aggregate Impact

Value (AIV) (IS:5640). Soft aggregates like Kankar, brick ballast and laterite shall also be

tested for Wet AIV (IS:5640).

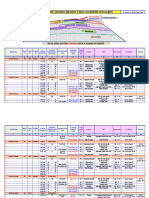

Table 400-1 : Grading for Granular Sub-base Materials

IS Sieve Percent by Weight Passing the IS Sieve

Designation Grading I Grading II Grading III Grading IV Grading V Grading VI

75.0 mm 100 - - - 100 -

53.0 mm 80-100 100 100 100 80-100 100

26.5 mm 55-90 70-100 55-75 50-80 55-90 75-100

9.50 mm 35-65 50-80 - - 35-65 55-75

4.75 mm 25-55 40-65 10-30 15-35 25-50 30-55

2.36 mm 20-40 30-50 - - 10-20 10-25

0.85 mm - - - - 2-10 -

0.425 mm 10-15 10- 15 - - 0-5 0-8

0.075 mm <5 <5 <5 <5 - 0-3

109

PDF created with pdfFactory Pro trial version www.pdffactory.com

Section 400 Sub-Bases, Bases (Non-Bituminous) and Shoulders

Table 400-2 : Physical Requirements for Materials for Granular Sub-base

Aggregate Impact Value (AIV) IS:2386(Part4) 40 maximum

or IS:5640

Liquid Limit IS:2720 (Part 5) Maximum 25

Plasticity Index IS:2720 (Part 5) Maximum 6

CBR at 98% dry density IS:2720 (Part 5) Minimum 30 unless otherwise

(at IS:2720-Part 8) specified in the Contract

401.3 Construction Operations

401.3.1 Preparation of Sub-grade

Immediately prior to the laying of sub-base, the subgrade already finished to Clause 301 or

305 as applicable shall be prepared by removing all vegetation and other extraneous matter,

lightly sprinkled with water, if necessary and rolled with two passes of 80-100 kN smooth

wheeled roller.

401.3.2 Spreading and Compacting

The sub-base material of the grading specified in the Contract and water shall be mixed

mechanically by a suitable mixer equipped with provision for controlled addition of water

and mechanical mixing. So as to ensure homogenous and uniform mix. The required water

content shall be determined in accordance with IS:2720 (Part 8). The mix shall be spread on

the prepared subgrade with the help of a motor grader of adequate capacity, its blade having

hydraulic controls suitable for initial adjustment and for maintaining the required slope and

grade during the operation, or other means as approved by the Engineer.

Moisture content of the mix shall be checked in accordance with IS:2720 (Part 2) and suitably

adjusted so that, at the time of compaction, it is from 1 to 2 percent below the optimum

moisture content.

Immediately after spreading the mix, rolling shall be done by an approved roller. If the

thickness of the compacted layer does not exceed 100 mm, a smooth wheeled roller of 80 to

100 kN weight may be used. For a compacted single layer upto 200 mm the compaction shall

be done with the help of a vibratory roller of minimum 80 to 100 kN static weight capable of

achieving the required compaction. Rolling shall commence at the lower edge and proceed

towards the upper edge longitudinally for portions having unidirectional crossfall or on super-

elevation. For carriageway having crossfall on both sides, rolling shall commence at the

edges and progress towards the crown.

110

PDF created with pdfFactory Pro trial version www.pdffactory.com

Sub-Bases, Bases (Non-Bituminous) and Shoulders Section 400

Each pass of the roller shall uniformly overlap not less than one-third of the track made in the

preceding pass. During rolling, the grade and crossfall (camber) shall be checked and any

high spots or depressions which become apparent, corrected by removing or adding fresh

material. The speed of the roller shall not exceed 5 km per hour.

Rolling shall be continued till the density achieved is at least 98 percent of the maximum

dry density for the material determined as per IS:2720 (Part 8). The surface of any layer

of material on completion of compaction shall be well closed, free from movement under

compaction equipment and from compaction planes, ridges, cracks or loose material. All

loose, segregated or otherwise defective areas shall be made good to the full thickness of

layer and re-compacted.

401.4 Surface Finish and Quality Control of Work

The surface finish of construction shall conform to the requirements of Clause 902. Control

on the quality of materials and works shall be exercised by the Engineer in accordance with

Section 900.

401.5 Arrangements for Traffic

During the period of construction, arrangements for the trafficshall be provided and maintained

in accordance with Clause 112.

401.6 Measurements for Payment

Granular sub-base shall be measured as finished work in position in cubic metres.

The protection of edges of granular sub-base extended over the full formation as shown in

the drawing shall be considered incidental to the work of providing granular sub-base and as

such no extra payment shall be made for the same.

401.7 Rate

The Contract unit rate for granular sub-base shall be payment in full for carrying out the

required operations including full compensation for:

i) making arrangements for traffic to Clause 112 except for initial

treatment to verges, shoulders and construction of diversions;

ii) supplying all materials to be incorporated in the work including all

royalties, fees, rents where applicable with all leads and lifts;

iii) all labour, tools, equipment and incidentals to complete the work to the

Specifications;

iv) carrying out the work in part widths of road where directed; and

v) carrying out the required tests for quality control.

111

PDF created with pdfFactory Pro trial version www.pdffactory.com

Das könnte Ihnen auch gefallen

- Morth - Section400Dokument34 SeitenMorth - Section400sudhreddy72% (25)

- 4sec.400 (Sub-Bases, Bases)Dokument36 Seiten4sec.400 (Sub-Bases, Bases)GCLNoch keine Bewertungen

- Methodology For Dry Lean Cement Concrete (D.L.C)Dokument3 SeitenMethodology For Dry Lean Cement Concrete (D.L.C)Anish Panchal100% (2)

- CTB Specification MORTH V RevDokument4 SeitenCTB Specification MORTH V RevL V Laxmipathi Rao100% (1)

- GSB Mix Design NSK-66 PDFDokument63 SeitenGSB Mix Design NSK-66 PDFJalgaon100% (3)

- Mix BM & SDBCDokument3 SeitenMix BM & SDBChafsal90% (10)

- Mix Design DLC-DelDokument9 SeitenMix Design DLC-DelSanjay Constructions100% (1)

- Tests, Codes and Frequency of Tests PDFDokument3 SeitenTests, Codes and Frequency of Tests PDFShabnam Joiya84% (70)

- Sieve Analysis of Wet Mix MacadamDokument2 SeitenSieve Analysis of Wet Mix Macadamjitendra100% (1)

- Grading For Close Graded Granular MaterialDokument7 SeitenGrading For Close Graded Granular MaterialBilal A Barbhuiya100% (1)

- GSB Density ExamplesDokument65 SeitenGSB Density ExamplesV Venkata Narayana82% (38)

- Mix Design For Dry Lean ConcreteDokument3 SeitenMix Design For Dry Lean ConcreteKunal Paul100% (2)

- What Is PQC PDFDokument19 SeitenWhat Is PQC PDFLASA VADODARANoch keine Bewertungen

- DBM Mix DesignDokument22 SeitenDBM Mix DesignImran Khan56% (9)

- WMM Density ExamplesDokument65 SeitenWMM Density ExamplesV Venkata Narayana75% (8)

- Tests, Codes and Frequency of Tests-2Dokument6 SeitenTests, Codes and Frequency of Tests-2Mohamed86% (7)

- MoRTH 4th RevisionDokument92 SeitenMoRTH 4th RevisionHegdeVenugopal100% (2)

- Morth 1700 Structural ConcreteDokument23 SeitenMorth 1700 Structural ConcreteRamesh88% (40)

- WMM Mix DesignDokument24 SeitenWMM Mix DesignEnd End71% (14)

- Section 900 Quality Control For Road WorksDokument24 SeitenSection 900 Quality Control For Road WorksAmul Kotharkar73% (11)

- Mistake in Bitumen Content Assessment in OGPC and SC in APDokument14 SeitenMistake in Bitumen Content Assessment in OGPC and SC in APPrakasam VemavarapuNoch keine Bewertungen

- Inspection Test PlanDokument21 SeitenInspection Test Planrandeepdadwal100% (3)

- Calibration of Pouring CylinderDokument16 SeitenCalibration of Pouring CylinderAnonymous drBWfwhNoch keine Bewertungen

- Test Frequency and Acceptance Criteria: Subgrade/Shoulder/MedianDokument6 SeitenTest Frequency and Acceptance Criteria: Subgrade/Shoulder/MedianAshish yadav67% (3)

- Annexure 5.14 BC Mix DesignDokument10 SeitenAnnexure 5.14 BC Mix Designmiesty50% (2)

- Methodology For Filter Media Behind The Structure MaterialDokument5 SeitenMethodology For Filter Media Behind The Structure MaterialKunal Paul100% (1)

- BC Mix Design G-2 STKKDokument99 SeitenBC Mix Design G-2 STKKImran Khan100% (7)

- WMM Plant CalibrationDokument5 SeitenWMM Plant CalibrationAnonymous zyIPjL9vNoch keine Bewertungen

- MoRTH 1700 Structural COncreteDokument30 SeitenMoRTH 1700 Structural COncreteApurv PatelNoch keine Bewertungen

- MORTH ClausesDokument3 SeitenMORTH Clausesupeida dox100% (2)

- Venkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersDokument68 SeitenVenkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersV Venkata Narayana96% (28)

- National Highways Authority of India.: Design Mix Summary of Semi Dense Bituminous Concrete (Grade-2)Dokument37 SeitenNational Highways Authority of India.: Design Mix Summary of Semi Dense Bituminous Concrete (Grade-2)Rahul Goyal100% (2)

- Grading Analysis For WMM, DBM, BM, BCDokument5 SeitenGrading Analysis For WMM, DBM, BM, BCBilal Ahmed Barbhuiya91% (11)

- Morth Section 900Dokument256 SeitenMorth Section 900VikasMauryaNoch keine Bewertungen

- BC, BM, WMM & DBM & GSBDokument5 SeitenBC, BM, WMM & DBM & GSBikreddy68% (38)

- PQC Mix DesignDokument60 SeitenPQC Mix DesignAshok amlapure67% (9)

- DBMDokument29 SeitenDBMEnd EndNoch keine Bewertungen

- Venkats Interpretation On Configuration of MORTHDokument29 SeitenVenkats Interpretation On Configuration of MORTHV Venkata Narayana100% (3)

- BC Mix Design SqmeDokument39 SeitenBC Mix Design SqmePrasanna S Kulkarni0% (1)

- BC Job MixDokument3 SeitenBC Job MixSOIGNE ENGINEERING CONSULTANTSNoch keine Bewertungen

- Concrete Mix Design PQC M40Dokument5 SeitenConcrete Mix Design PQC M40Pirpasha Ujede50% (2)

- M 30 Concrete Mix Design FinalDokument10 SeitenM 30 Concrete Mix Design FinalRakesh ReddyNoch keine Bewertungen

- Is: 8887:2018Dokument13 SeitenIs: 8887:2018Indira Banerjee100% (7)

- Draft Letter Regarding Source Approval For Bituminous Concrete Grade-1 With BPCL - VG - 30 BitumenDokument3 SeitenDraft Letter Regarding Source Approval For Bituminous Concrete Grade-1 With BPCL - VG - 30 BitumenAmol Jadhav67% (3)

- Original Ground Level-Ogl CompactionDokument3 SeitenOriginal Ground Level-Ogl CompactionCheng Engi100% (2)

- Amendment No. 5 July 2019 TO Is 456: 2000 Plain and Reinforced Concrete - Code of PracticeDokument7 SeitenAmendment No. 5 July 2019 TO Is 456: 2000 Plain and Reinforced Concrete - Code of Practiceraviteja036Noch keine Bewertungen

- WMM Calibration of PlantDokument7 SeitenWMM Calibration of PlantKaushlendra Singh80% (5)

- Recommended Revisions To MORTH Specifications Section 500 by Prof. Kandhal 18 May 2009Dokument44 SeitenRecommended Revisions To MORTH Specifications Section 500 by Prof. Kandhal 18 May 2009Prof. Prithvi Singh Kandhal100% (1)

- DBM Mix Design No.-1Dokument81 SeitenDBM Mix Design No.-1pujan patel100% (1)

- IS 516-1959 (Reaffirmed 2018)Dokument27 SeitenIS 516-1959 (Reaffirmed 2018)Sai Pavan100% (1)

- SAMIDokument14 SeitenSAMIPURUSHOTTAM100% (3)

- Morth400 Sub-Bases and Bases Tables of Gradation Tests LimitsDokument5 SeitenMorth400 Sub-Bases and Bases Tables of Gradation Tests LimitsV Venkata Narayana100% (2)

- Sec 400 MORTH Orange Book Fifth Edition Searchable 2013Dokument9 SeitenSec 400 MORTH Orange Book Fifth Edition Searchable 2013tally3tallyNoch keine Bewertungen

- Sec 400 (Most Version)Dokument37 SeitenSec 400 (Most Version)abhijit_xpNoch keine Bewertungen

- 04-400. Sub-Bases, (Non-Bituminous) and ShouldersDokument29 Seiten04-400. Sub-Bases, (Non-Bituminous) and ShouldersAnonymous g1LSaANoch keine Bewertungen

- Granular Sub Base-GsbDokument4 SeitenGranular Sub Base-GsbCheng EngiNoch keine Bewertungen

- Section 400 - (Granular-Sub-Base) - Finally CorrectedDokument16 SeitenSection 400 - (Granular-Sub-Base) - Finally CorrectedTousifAnwar MundaragiNoch keine Bewertungen

- UntitledDokument902 SeitenUntitledAvinash TiwaryNoch keine Bewertungen

- Method Statement For Granular Sub BaseDokument5 SeitenMethod Statement For Granular Sub Basemadhu arepelli100% (1)

- Section 1200 (Subbase, Base, Hard Shoulder and Gravel)Dokument28 SeitenSection 1200 (Subbase, Base, Hard Shoulder and Gravel)AmitNoch keine Bewertungen

- Flood Memorandum 2021Dokument454 SeitenFlood Memorandum 2021kartik mehta100% (1)

- General 1. Short Title and Commencement. - : NotificationDokument32 SeitenGeneral 1. Short Title and Commencement. - : Notificationkartik mehta100% (1)

- Smart PlanDokument44 SeitenSmart Plankartik mehtaNoch keine Bewertungen

- Sectors Covered: Power Transportation Telecom PortsDokument43 SeitenSectors Covered: Power Transportation Telecom Portskartik mehtaNoch keine Bewertungen

- Kartik CVDokument2 SeitenKartik CVkartik mehtaNoch keine Bewertungen

- Din 48204Dokument3 SeitenDin 48204Thanh Dang100% (4)

- Pitch AnythingDokument8 SeitenPitch AnythingDoland drumb100% (1)

- English 2 Q3 Week 7 DLLDokument7 SeitenEnglish 2 Q3 Week 7 DLLEste R A BulaonNoch keine Bewertungen

- Model Personal StatementDokument2 SeitenModel Personal StatementSwayam Tripathy100% (1)

- Miata Wiring NA8 DiagramDokument65 SeitenMiata Wiring NA8 DiagramseanNoch keine Bewertungen

- Konsep Negara Hukum Dalam Perspektif Hukum IslamDokument11 SeitenKonsep Negara Hukum Dalam Perspektif Hukum IslamSiti MasitohNoch keine Bewertungen

- 01 GUL ZXRAN Basestation Hardware Structure-LDokument59 Seiten01 GUL ZXRAN Basestation Hardware Structure-Lmengistu yirga100% (1)

- 96 Dec2018 NZGeoNews PDFDokument139 Seiten96 Dec2018 NZGeoNews PDFAditya PrasadNoch keine Bewertungen

- Advocating For Appropriate Educational ServicesDokument32 SeitenAdvocating For Appropriate Educational ServicesTransverse Myelitis AssociationNoch keine Bewertungen

- Analog Electronics-2 PDFDokument20 SeitenAnalog Electronics-2 PDFAbhinav JangraNoch keine Bewertungen

- KV4BBSR Notice ContractuaL Interview 2023-24Dokument9 SeitenKV4BBSR Notice ContractuaL Interview 2023-24SuchitaNoch keine Bewertungen

- Stellite 6 FinalDokument2 SeitenStellite 6 FinalGumersindo MelambesNoch keine Bewertungen

- Change LogDokument145 SeitenChange LogelhohitoNoch keine Bewertungen

- Historical Roots of The "Whitening" of BrazilDokument23 SeitenHistorical Roots of The "Whitening" of BrazilFernandoMascarenhasNoch keine Bewertungen

- Aug 21 Lab PhET Motion Graphs QuDokument8 SeitenAug 21 Lab PhET Motion Graphs QureynandcpcNoch keine Bewertungen

- History of JavaDokument3 SeitenHistory of JavaKyra ParaisoNoch keine Bewertungen

- CNC Manuel de Maintenance 15i 150i ModelADokument526 SeitenCNC Manuel de Maintenance 15i 150i ModelASebautomatismeNoch keine Bewertungen

- Solutions Jet FuelDokument4 SeitenSolutions Jet FuelkevinNoch keine Bewertungen

- 103-Article Text-514-1-10-20190329Dokument11 Seiten103-Article Text-514-1-10-20190329Elok KurniaNoch keine Bewertungen

- PST SubjectDokument2 SeitenPST SubjectCarol ElizagaNoch keine Bewertungen

- Practical Organic ChemistryDokument598 SeitenPractical Organic ChemistryGerardo Estrada99% (127)

- Application of A HAZOP Study Method To Hazard Evaluation of Chemical Unit of The Power StationDokument8 SeitenApplication of A HAZOP Study Method To Hazard Evaluation of Chemical Unit of The Power Stationshinta sariNoch keine Bewertungen

- CYPE 2021 + CYPE ArchitectureDokument15 SeitenCYPE 2021 + CYPE ArchitectureHajar CypeMarocNoch keine Bewertungen

- Revised PARA Element2 Radio LawsDokument81 SeitenRevised PARA Element2 Radio LawsAurora Pelagio Vallejos100% (4)

- Highway Journal Feb 2023Dokument52 SeitenHighway Journal Feb 2023ShaileshRastogiNoch keine Bewertungen

- Concise Beam DemoDokument33 SeitenConcise Beam DemoluciafmNoch keine Bewertungen

- Building g5Dokument45 SeitenBuilding g5ammarsteel68Noch keine Bewertungen

- Read The Dialogue Below and Answer The Following QuestionDokument5 SeitenRead The Dialogue Below and Answer The Following QuestionDavid GainesNoch keine Bewertungen

- Mass and Heat Balance of Steelmaking in Bof As Compared To Eaf ProcessesDokument15 SeitenMass and Heat Balance of Steelmaking in Bof As Compared To Eaf ProcessesAgil Setyawan100% (1)

- CV TitchievDokument3 SeitenCV TitchievIna FarcosNoch keine Bewertungen