Beruflich Dokumente

Kultur Dokumente

03 20 00 - Concrete Reinforcing

Hochgeladen von

ahmad ibrahinOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

03 20 00 - Concrete Reinforcing

Hochgeladen von

ahmad ibrahinCopyright:

Verfügbare Formate

Fort Carson SOF Battalion Operations Complex A14031BLDG

W9128F-14-C-0024 IFC April 24, 2015

SECTION 03 20 00.00 10

CONCRETE REINFORCING

05/14

PART 1 GENERAL

1.1 REFERENCES

The publications listed below form a part of this specification to the

extent referenced. The publications are referred to within the text by the

basic designation only.

AMERICAN CONCRETE INSTITUTE INTERNATIONAL (ACI)

ACI 117 (2010; Errata 2011) Specifications for

Tolerances for Concrete Construction and

Materials and Commentary

ACI 318 (2011; Errata 1 2011; Errata 2 2012;

Errata 3-4 2013) Building Code

Requirements for Structural Concrete and

Commentary

ACI SP-66 (2004) ACI Detailing Manual

AMERICAN WELDING SOCIETY (AWS)

AWS D1.4/D1.4M (2011) Structural Welding Code -

Reinforcing Steel

ASTM INTERNATIONAL (ASTM)

ASTM A1035/A1035M (2014) Standard Specification for Deformed

and Plain, Low-carbon, Chromium, Steel

Bars for Concrete Reinforcement

ASTM A1064/A1064M (2013) Standard Specification for

Carbon-Steel Wire and Welded Wire

Reinforcement, Plain and Deformed, for

Concrete

ASTM A370 (2014) Standard Test Methods and

Definitions for Mechanical Testing of

Steel Products

ASTM A615/A615M (2014) Standard Specification for Deformed

and Plain Carbon-Steel Bars for Concrete

Reinforcement

ASTM A675/A675M (2003; R 2009) Standard Specification for

Steel Bars, Carbon, Hot-Wrought, Special

Quality, Mechanical Properties

ASTM A706/A706M (2014) Standard Specification for

Low-Alloy Steel Deformed and Plain Bars

for Concrete Reinforcement

SECTION 03 20 00.00 10 Page 1

Fort Carson SOF Battalion Operations Complex A14031BLDG

W9128F-14-C-0024 IFC April 24, 2015

ASTM A767/A767M (2009) Standard Specification for

Zinc-Coated (Galvanized) Steel Bars for

Concrete Reinforcement

ASTM A884/A884M (2014) Standard Specification for

Epoxy-Coated Steel Wire and Welded Wire

Reinforcement

CONCRETE REINFORCING STEEL INSTITUTE (CRSI)

CRSI 10MSP (2009; 28th Ed) Manual of Standard Practice

U.S. GREEN BUILDING COUNCIL (USGBC)

LEED (2002; R 2005) Leadership in Energy and

Environmental Design(tm) Green Building

Rating System for New Construction

(LEED-NC)

LEED NC (2009) Leadership in Energy and

Environmental Design(tm) New Construction

Rating System

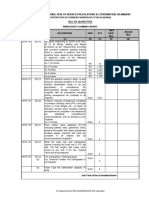

1.2 SUBMITTALS

Government approval is required for submittals with a "G" designation;

submittals not having a "G" designation are for information only. When

used, a designation following the "G" designation identifies the office

that will review the submittal for the Government. Submit the following in

accordance with Section 01 33 00 SUBMITTAL PROCEDURES:

SD-02 Shop Drawings

Reinforcement; G

SD-03 Product Data

LEED Documentation; (LEED NC)

SD-06 Test Reports

Tests, Inspections, and Verifications; G

1.3 LEED DOCUMENTATION

Refer to 01 33 29 LEED Documentation for specific information on LEED

documentation requirements. Provide LEED documentation for the following

credits:

MR Credit 4: Recycled Content

MR Credit 5: Regional Material

1.4 QUALITY ASSURANCE

1.4.1 Welding Qualifications

Welders are required to be qualified in accordance with AWS D1.4/D1.4M.

Perform qualification test at the worksite and notify the Contracting

Officer 24 hours prior to conducting tests. Special welding procedures and

SECTION 03 20 00.00 10 Page 2

Fort Carson SOF Battalion Operations Complex A14031BLDG

W9128F-14-C-0024 IFC April 24, 2015

welders qualified by others may be accepted as permitted by AWS D1.4/D1.4M.

Submit a list of qualified welders names.

1.5 DELIVERY, STORAGE, AND HANDLING

Store reinforcement and accessories off the ground on platforms, skids, or

other supports.

PART 2 PRODUCTS

2.1 DOWELS

Provide dowels conforming to ASTM A675/A675M, Grade 80 or ASTM A1035/A1035M.

2.2 REINFORCING STEEL

Reinforcing steel of deformed bars conforming to ASTM A615/A615M,

ASTM A706/A706M, or ASTM A1035/A1035M grades and sizes as indicated. Cold

drawn wire used for spiral reinforcement must conform to ASTM A1064/A1064M.

Submit certified copies of mill reports attesting that the reinforcing

steel furnished contains no less than 25 percent recycled scrap steel and

meets the requirements specified herein, prior to the installation of

reinforcing steel.

2.2.1 Zinc-Coated (Galvanized) Bars

Zinc-coated (galvanized) bars complying with the requirements of

ASTM A767/A767M, Class II coating, galvanized after fabrication.

2.3 WELDED WIRE REINFORCING

Welded wire reinforcing conforming to ASTM A1064/A1064M. When directed by

the Contracting Officer for special applications, use welded wire

reinforcing conforming to ASTM A884/A884M. For wire with a specified yield

strength (fy) exceeding 60,000 psi, fy must be the stress corresponding to

a strain of 0.35 percent.

2.4 WIRE TIES

Use wire ties that are 16 gauge or heavier black annealed steel wire.

2.5 SUPPORTS

Design bar supports for formed surfaces in accordance with CRSI 10MSP and

fabricate of steel. Coat steel supports for coated or galvanized bars with

electrically compatible material for a distance of at least 2 inches beyond

the point of contact with the bar. Where concrete formed surfaces will be

exposed to weather or where surfaces are to be painted, use galvanized,

plastic protected or stainless steelsteel supports within 1/2 inch of

concrete surface. Concrete supports used in concrete exposed to view must

have the same color and texture as the finish surface. For slabs on grade

and topping slabs on steel deck, supports use plastic coated steel

fabricated with bearing plates, or specifically designed wire-fabric

supports fabricated of plastic.

2.6 TESTS, INSPECTIONS, AND VERIFICATIONS

Perform material tests, specified and required by applicable standards, by

SECTION 03 20 00.00 10 Page 3

Fort Carson SOF Battalion Operations Complex A14031BLDG

W9128F-14-C-0024 IFC April 24, 2015

an approved laboratory and certified to demonstrate that the materials are

in conformance with the specifications. Perform and certify tests,

inspections, and verifications and certify. Submit certified tests reports

of reinforcement steel showing that the steel complies with the applicable

specifications for each steel shipment and identified with specific lots

prior to placement. Submit three copies of the heat analyses for each lot

of steel furnished certifying that the steel conforms to the heat analyses.

2.6.1 Reinforcement Steel Tests

Perform mechanical testing of steel in accordance with ASTM A370 except as

otherwise specified or required by the material specifications. Perform

tension tests on full cross-section specimens using a gage length that

spans the extremities of specimens with welds or sleeves included. From

chemical analyses of steel heats report the percentages of carbon,

phosphorous, manganese, sulphur and silicon present in the steel.

PART 3 EXECUTION

3.1 REINFORCEMENT

Fabricate and place reinforcement steel and accessories as specified, as

indicated, and as shown on approved shop drawings. Fabrication and

placement details of steel and accessories not specified or shown must be

in accordance with ACI SP-66 and ACI 318. Cold bend reinforcement unless

otherwise authorized. Bending may be accomplished in the field or at the

mill. Mill bend zinc-coated bars prior to coating. Bend all steel cold

unless authorized. Do not bend bars after embedment in concrete. Place

safety caps on all exposed ends of vertical concrete reinforcement bars

that pose a danger to life safety. Face wire tie ends away from the

forms. Submit detail drawings showing reinforcing steel placement,

schedules, sizes, grades, and splicing and bending details. Show support

details including types, sizes and spacing.

3.1.1 Placement

Reinforcement must be free from loose rust and scale, dirt, oil, or other

deleterious coating that could reduce bond with the concrete. Place

reinforcement in accordance with ACI 318 at locations indicated plus or

minus one bar diameter. Do not continue reinforcement through expansion

joints and place as indicated through construction or contraction joints.

Cover with concrete coverage as indicated or as required by ACI 318. If

bars are moved more than one bar diameter to avoid interference with other

reinforcement, conduits or embedded items, the resulting arrangement of

bars, including additional bars required to meet structural requirements,

requires approval before concrete is placed.

3.1.2 Placing Tolerances

Conform bar spacing and concrete cover to ACI 117.

3.1.3 Splicing

Conform splices of reinforcement to ACI 318 and make only as required or

indicated. Bars may be spliced at alternate or additional locations at no

additional cost to the Government subject to approval. Splicing must be by

lapping or by mechanical connection; except that lap splices must not be

used for bars larger than No. 11 unless otherwise indicated.

SECTION 03 20 00.00 10 Page 4

Fort Carson SOF Battalion Operations Complex A14031BLDG

W9128F-14-C-0024 IFC April 24, 2015

3.1.3.1 Lap Splices

Place lapped bars in contact and securely tied or spaced transversely apart

to permit the embedment of the entire surface of each bar in concrete. Do

not space lapped bars farther apart than 1/5 the required length of lap or

6 inches.

3.2 WELDED-WIRE REINFORCEMENT PLACEMENT

Place welded-wire reinforcement in slabs as indicated. Reinforcement

placed in slabs on grade must be continuous between expansion,

construction, and contraction joints. Reinforcement placement at joints

must be as indicated.

May lap splices in such a way that the overlapped area equals the distance

between the outermost crosswires plus 2 inches. Stagger laps to avoid

continuous laps in either direction. Wire or clip together reinforcement

at laps at intervals not to exceed 4 feet. Position reinforcement by the

use of supports.

3.3 DOWEL INSTALLATION

Install dowels at locations indicated and at right angles to joint being

doweled. Accurately position and align dowels parallel to the finished

concrete surface before concrete placement. Rigidly support dowels during

concrete placement. Coat one end of dowels with a bond breaker.

-- End of Section --

SECTION 03 20 00.00 10 Page 5

Das könnte Ihnen auch gefallen

- Steel Structure SpecsDokument61 SeitenSteel Structure SpecstOMNoch keine Bewertungen

- Changes in Blue Are in Response To A ACI TAC Comment On Record 18-1669Dokument1 SeiteChanges in Blue Are in Response To A ACI TAC Comment On Record 18-1669أبومحمدالزياتNoch keine Bewertungen

- Codes Standards For Structural Steel Fabrication ErectionDokument7 SeitenCodes Standards For Structural Steel Fabrication Erectionelangorenga67% (3)

- Deformed and Plain Carbon-Steel Bars For Concrete ReinforcementDokument6 SeitenDeformed and Plain Carbon-Steel Bars For Concrete ReinforcementJhon Paul EstopinNoch keine Bewertungen

- Standard Specifications For Composite Steel Joist CatalogDokument37 SeitenStandard Specifications For Composite Steel Joist CatalogAziz MohsenNoch keine Bewertungen

- Preengineer Building SpecsDokument35 SeitenPreengineer Building SpecstOMNoch keine Bewertungen

- Standard Specification: For Cj-Series Composite Steel JoistsDokument39 SeitenStandard Specification: For Cj-Series Composite Steel JoistsVigneshNoch keine Bewertungen

- Tcsq11305r0 CmuDokument24 SeitenTcsq11305r0 CmuAJEC IndiaNoch keine Bewertungen

- Astma615 615MDokument6 SeitenAstma615 615MRahul Bhardwaj100% (1)

- Structural Steel Framing SpecificationDokument11 SeitenStructural Steel Framing SpecificationsivaNoch keine Bewertungen

- Structural Steel Framing Specs - AISCDokument5 SeitenStructural Steel Framing Specs - AISCSteve HuppertNoch keine Bewertungen

- Fusion-Bonded Epoxy-Coated Structural Steel H-Piles and Sheet PilingDokument5 SeitenFusion-Bonded Epoxy-Coated Structural Steel H-Piles and Sheet PilingSama UmateNoch keine Bewertungen

- Composite Steel Floor Deck - Slabs: C - 2011 Standard ForDokument37 SeitenComposite Steel Floor Deck - Slabs: C - 2011 Standard ForArnel DodongNoch keine Bewertungen

- SECTION 05500 Metal FabricationsDokument7 SeitenSECTION 05500 Metal FabricationsJohanesTangdiNoch keine Bewertungen

- Corrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and ArchesDokument8 SeitenCorrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and ArchesDarwin DarmawanNoch keine Bewertungen

- CSSBI S17-2005 Steel BuildingDokument8 SeitenCSSBI S17-2005 Steel BuildingEric NolascoNoch keine Bewertungen

- Astm - A761 A761m 04 (2009)Dokument8 SeitenAstm - A761 A761m 04 (2009)nugroho teguhNoch keine Bewertungen

- Sdi Ansi0 C 2011 (Deck)Dokument37 SeitenSdi Ansi0 C 2011 (Deck)Ricardo MontachanaNoch keine Bewertungen

- Astm A615-A615m-06Dokument6 SeitenAstm A615-A615m-06NadhiraNoch keine Bewertungen

- Astm A 615 PDFDokument6 SeitenAstm A 615 PDFVo Hong Kiet0% (1)

- Sdi Ansi NC 2010Dokument15 SeitenSdi Ansi NC 2010Vitelio PinzonNoch keine Bewertungen

- Astm A761Dokument8 SeitenAstm A761Carlos Andres Caballero ReyesNoch keine Bewertungen

- Opss-Prov 908 - 2021 - Construction Specification For Metal Railings For StructuresDokument10 SeitenOpss-Prov 908 - 2021 - Construction Specification For Metal Railings For StructuresPubcrawlNoch keine Bewertungen

- ASTM A 615-06 - Standard Specification For Deformed or Plain Billet Steel For Concrete ReinforcementDokument6 SeitenASTM A 615-06 - Standard Specification For Deformed or Plain Billet Steel For Concrete ReinforcementEmre DalgicNoch keine Bewertungen

- Supplement Number 1 Standard Specifications For Composite Steel Joists AND Code of Standard PracticeDokument47 SeitenSupplement Number 1 Standard Specifications For Composite Steel Joists AND Code of Standard PracticeJuan Carlos ZamoraNoch keine Bewertungen

- Astm A615-A615m-07Dokument6 SeitenAstm A615-A615m-07NadhiraNoch keine Bewertungen

- Plant InspectionDokument9 SeitenPlant InspectionSyed SulaimanNoch keine Bewertungen

- 12 Samss 007 PDFDokument30 Seiten12 Samss 007 PDFMohammadAseef100% (1)

- ASTM A615-A615M-06aDokument6 SeitenASTM A615-A615M-06aNadhiraNoch keine Bewertungen

- Roof & Wall Panels SpecsDokument53 SeitenRoof & Wall Panels SpecstOM0% (1)

- CSSBI S17-2017:: Guide Specification For Steel Building SystemsDokument7 SeitenCSSBI S17-2017:: Guide Specification For Steel Building SystemsFarid RezaeianNoch keine Bewertungen

- SDI-C-2011 Standard for Composite Steel Floor Deck-SlabsDokument36 SeitenSDI-C-2011 Standard for Composite Steel Floor Deck-SlabsDiego Torres100% (1)

- PCA-Soil Cement Construction Handbook 1Dokument11 SeitenPCA-Soil Cement Construction Handbook 1Carlos Guillermo Somoza AlvarengaNoch keine Bewertungen

- LINE-000-AC-4-0007 Structural Steel Fabrication and Erection Procedure - Rev.ADokument32 SeitenLINE-000-AC-4-0007 Structural Steel Fabrication and Erection Procedure - Rev.Atomy.jipNoch keine Bewertungen

- H Proc Notices Notices 030 K Notice Doc 29803 883010837Dokument165 SeitenH Proc Notices Notices 030 K Notice Doc 29803 883010837XTINCT Mobile LegendsNoch keine Bewertungen

- A 950 - A 950M - 99 (Reapproved 2003) PDFDokument5 SeitenA 950 - A 950M - 99 (Reapproved 2003) PDFhectoriturbeNoch keine Bewertungen

- Essar Oil Limited Vadinar Refinery Expansion: 1O1O1O (O1Dokument17 SeitenEssar Oil Limited Vadinar Refinery Expansion: 1O1O1O (O1ashish_rocksNoch keine Bewertungen

- Composite Steel Floor Deck SlabsDokument37 SeitenComposite Steel Floor Deck SlabsFelipe CantillanoNoch keine Bewertungen

- 20 SDMS 01Dokument43 Seiten20 SDMS 01tapas_jitu100% (1)

- Part S30Fabrication Structural Steelwork ContentsDokument7 SeitenPart S30Fabrication Structural Steelwork ContentsFerhat KahveciNoch keine Bewertungen

- ITCC in Riyadh Residential Complex J10-13300 05120-1 Structural SteelDokument6 SeitenITCC in Riyadh Residential Complex J10-13300 05120-1 Structural SteeluddinnadeemNoch keine Bewertungen

- Technical Specification: Exhibit II: Specifications, Standards AND CodesDokument7 SeitenTechnical Specification: Exhibit II: Specifications, Standards AND CodesAgnel StanleyNoch keine Bewertungen

- STS05120Dokument20 SeitenSTS05120JunaidAhmedNoch keine Bewertungen

- Shop Fabrication of Structural SteelDokument12 SeitenShop Fabrication of Structural SteelAris WicaksonoNoch keine Bewertungen

- Sdi Ansi NC 2010 XDokument15 SeitenSdi Ansi NC 2010 XNyein ZawNoch keine Bewertungen

- Epoxy-Coated Prefabricated Steel Reinforcing Bars: Standard Specification ForDokument17 SeitenEpoxy-Coated Prefabricated Steel Reinforcing Bars: Standard Specification ForDarwin DarmawanNoch keine Bewertungen

- Astm A500 A500m-21Dokument6 SeitenAstm A500 A500m-21alvin duey100% (1)

- Steel Stud Assemblies For Shear Reinforcement of ConcreteDokument5 SeitenSteel Stud Assemblies For Shear Reinforcement of ConcreteDarwin DarmawanNoch keine Bewertungen

- Epoxy-Coated Prefabricated Steel Reinforcing Bars: Standard Specification ForDokument17 SeitenEpoxy-Coated Prefabricated Steel Reinforcing Bars: Standard Specification ForNada KhlifNoch keine Bewertungen

- Astm C 645Dokument6 SeitenAstm C 645Camilo OrozcoNoch keine Bewertungen

- Astm A955Dokument6 SeitenAstm A955歐昱辰Noch keine Bewertungen

- Astm A615Dokument6 SeitenAstm A615Muhammad sheryarNoch keine Bewertungen

- Volume 2 - Specifications Books 1 To 8 - 2054Dokument13 SeitenVolume 2 - Specifications Books 1 To 8 - 2054Fares ateNoch keine Bewertungen

- Steel Deformed and Plain Bars For Concrete Reinforcement': Low-AlloyDokument5 SeitenSteel Deformed and Plain Bars For Concrete Reinforcement': Low-AlloyamerNoch keine Bewertungen

- Astm A1055Dokument9 SeitenAstm A1055Nsidibe EtimNoch keine Bewertungen

- Design of Steel Structures: Materials, Connections, and ComponentsVon EverandDesign of Steel Structures: Materials, Connections, and ComponentsNoch keine Bewertungen

- Structural Steel Design to Eurocode 3 and AISC SpecificationsVon EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNoch keine Bewertungen

- Reinforced Concrete Buildings: Behavior and DesignVon EverandReinforced Concrete Buildings: Behavior and DesignBewertung: 5 von 5 Sternen5/5 (1)

- Score Report - LEED AP BD+C Practice ExamDokument14 SeitenScore Report - LEED AP BD+C Practice Examahmad ibrahin100% (1)

- LEED GA Practice PDFDokument18 SeitenLEED GA Practice PDFahmad ibrahin0% (1)

- 15E - 11 AllowableVOClimitsDokument1 Seite15E - 11 AllowableVOClimitsahmad ibrahinNoch keine Bewertungen

- Scheduling NotesDokument1 SeiteScheduling Notesahmad ibrahinNoch keine Bewertungen

- Scheduling Tips - ConstructionDokument4 SeitenScheduling Tips - Constructionahmad ibrahinNoch keine Bewertungen

- Allowable VOC LimitsDokument2 SeitenAllowable VOC Limitsahmad ibrahinNoch keine Bewertungen

- Documentation Instructions: SS Prereq 1 Construction Activity Pollution PreventionDokument8 SeitenDocumentation Instructions: SS Prereq 1 Construction Activity Pollution Preventionahmad ibrahinNoch keine Bewertungen

- Gas Line Pressure Testing ProcedureDokument1 SeiteGas Line Pressure Testing Procedureahmad ibrahinNoch keine Bewertungen

- Generator Enclosure 900REOZMDDokument8 SeitenGenerator Enclosure 900REOZMDahmad ibrahinNoch keine Bewertungen

- Chapter 6Dokument2 SeitenChapter 6ahmad ibrahinNoch keine Bewertungen

- Exam 1 AnswersDokument19 SeitenExam 1 Answersahmad ibrahinNoch keine Bewertungen

- Ahmad Ibrahim - Es2162: Astm C 91Dokument1 SeiteAhmad Ibrahim - Es2162: Astm C 91ahmad ibrahinNoch keine Bewertungen

- Ahmad Ibrahim - Es2162: Astm C 91Dokument1 SeiteAhmad Ibrahim - Es2162: Astm C 91ahmad ibrahinNoch keine Bewertungen

- The Hong Kong Steel Code "Structural Use of Steel Using Limiting State Approach"Dokument13 SeitenThe Hong Kong Steel Code "Structural Use of Steel Using Limiting State Approach"uhu_plus6482100% (1)

- Hollow Brick Work & JaliDokument29 SeitenHollow Brick Work & JaliSOMYA AGARWALNoch keine Bewertungen

- Substation Civil Design and Construction StandardDokument4 SeitenSubstation Civil Design and Construction StandardEma WeismanNoch keine Bewertungen

- Multi-Column Water Tank Construction SpecificationsDokument8 SeitenMulti-Column Water Tank Construction SpecificationsJorge León IllanesNoch keine Bewertungen

- Pressure Vessels Lectures 94Dokument1 SeitePressure Vessels Lectures 94Adeel NizamiNoch keine Bewertungen

- UC07 PL Sewerage Line in Future Colony B Area Street No 9 DMC MalirDokument4 SeitenUC07 PL Sewerage Line in Future Colony B Area Street No 9 DMC MalirJohn WickNoch keine Bewertungen

- Pape GimpDokument23 SeitenPape GimpRobert MoenNoch keine Bewertungen

- (IJETA-V11I1P1) :gaurav Singh Raghav, Mohsin Khan AgwanDokument10 Seiten(IJETA-V11I1P1) :gaurav Singh Raghav, Mohsin Khan AgwanIJETA - EighthSenseGroupNoch keine Bewertungen

- RSP and Other External Platform ChecklistDokument3 SeitenRSP and Other External Platform ChecklistVikas YamagarNoch keine Bewertungen

- Area Planner - Nadeem Manjar Resume 15.03.21Dokument3 SeitenArea Planner - Nadeem Manjar Resume 15.03.21Manjar NadeemNoch keine Bewertungen

- Fiberizer F2Dokument108 SeitenFiberizer F2Reinaldo RamirezNoch keine Bewertungen

- Temporary Ladder Scaffold InstallationDokument6 SeitenTemporary Ladder Scaffold InstallationAnjo MolinaNoch keine Bewertungen

- As 4118 2 1 1995 Fire Sprinkler Systems Piping General PDFDokument7 SeitenAs 4118 2 1 1995 Fire Sprinkler Systems Piping General PDFMarwaNoch keine Bewertungen

- FESB-Admin-DID-Bau-2020-0323 Non Conformance (NCR) No.2 and No.3Dokument3 SeitenFESB-Admin-DID-Bau-2020-0323 Non Conformance (NCR) No.2 and No.3Kevin Chang Wei KiatNoch keine Bewertungen

- Terram 700 Data Sheet For SubmissionDokument6 SeitenTerram 700 Data Sheet For Submissionarthur chungNoch keine Bewertungen

- Bollard: Installation and Maintenance ManualDokument28 SeitenBollard: Installation and Maintenance ManualqweNoch keine Bewertungen

- Realistic, Hands-On Fire Extinguisher TrainingDokument3 SeitenRealistic, Hands-On Fire Extinguisher TrainingJoel CummingsNoch keine Bewertungen

- Water Absorbing Pavements by Using Porous Concrete: A Project ReportDokument17 SeitenWater Absorbing Pavements by Using Porous Concrete: A Project ReportSɪᴅᴅʜᴀɴᴛ Sᴀɢᴀʀ100% (1)

- Section 321313 - Concrete Paving: Part 1 - GeneralDokument13 SeitenSection 321313 - Concrete Paving: Part 1 - Generalery achjariNoch keine Bewertungen

- 1 - Introduction To Structural Steel Design-Chapter 1Dokument3 Seiten1 - Introduction To Structural Steel Design-Chapter 1Abera DeressaNoch keine Bewertungen

- 4-Storey Steel Structure Residential Building: Toe Myint Naing Curtin Malaysia InternDokument26 Seiten4-Storey Steel Structure Residential Building: Toe Myint Naing Curtin Malaysia InternMg ToecherrymyayNoch keine Bewertungen

- ACE REVIEWED - Submittal - TAS Concrete - Concrete Column Reinforcement - Shop Drawings - Reviewed PDFDokument5 SeitenACE REVIEWED - Submittal - TAS Concrete - Concrete Column Reinforcement - Shop Drawings - Reviewed PDFTyler StoneNoch keine Bewertungen

- DESIGN AND ANALYSIS OF RESIDENTIAL BUILDING (C+G+5) Using E-Tabs PaperDokument2 SeitenDESIGN AND ANALYSIS OF RESIDENTIAL BUILDING (C+G+5) Using E-Tabs PaperMohammed Abdul RazzakNoch keine Bewertungen

- Concrete Mix DesignDokument19 SeitenConcrete Mix DesignObaidurRahamanNoch keine Bewertungen

- When The Going Gets ToughDokument11 SeitenWhen The Going Gets ToughPedro PabloNoch keine Bewertungen

- Bsi BS en 12602+a1 - 2013Dokument190 SeitenBsi BS en 12602+a1 - 2013alferedNoch keine Bewertungen

- OLC15984 Handbook July 2016 FA V3 LR PDFDokument52 SeitenOLC15984 Handbook July 2016 FA V3 LR PDFNima MoaddeliNoch keine Bewertungen

- BOQ FF NIH IslamabadDokument1 SeiteBOQ FF NIH IslamabadTariq MahmoodNoch keine Bewertungen

- Concrete Crack Repair ManualDokument62 SeitenConcrete Crack Repair ManualShamsul Bahrin Sulaiman100% (1)

- Project Delivery Method Report1Dokument18 SeitenProject Delivery Method Report1Prince AJ100% (1)