Beruflich Dokumente

Kultur Dokumente

Sesion 4 Delivering Lean Results For Healthcare Using Virtual Building The Last Planner System

Hochgeladen von

carloscib911Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sesion 4 Delivering Lean Results For Healthcare Using Virtual Building The Last Planner System

Hochgeladen von

carloscib911Copyright:

Verfügbare Formate

Delivering Lean Results for Healthcare 18 July 2005

Using Virtual Building & the Last

Planner System

Presentation to

Australian Construction

Creating value

Eliminating waste

Industry Conference

Sydney, Australia

18 July 2005

Sutter Healths Challenge

Delivering Lean Results for

Healthcare Using Virtual Building

& the Last Planner System

Dean Reed

DPR Construction, Inc.

2

Sutter Health Adopts The Five Big Ideas of Lean Project

Lean Project Delivery Delivery

1. Collaborate; really collaborate,

throughout design, planning, and

execution

2. Increase relatedness among all project

participants

3. Projects are networks of commitments

4. Optimize the project not the pieces

5. Tightly couple action with learning

3 4

Collaborate; Really Collaborate

Projects as Networks of Commitment

Virtual Building and the Last Planner

System require collaboration and

strengthen the network of commitments

Will be the focus of this presentation

5 6

Dean Reed, DPR Construction, Inc.

2005 1

Delivering Lean Results for Healthcare 18 July 2005

Using Virtual Building & the Last

Planner System

The Five Big Ideas of Lean Project Delivery Translating into Action on Camino

#1 Collaborate; really collaborate, throughout

design, planning, and execution Collaborate; Really Collaborate

Constructable, maintainable, and affordable design

requires the participation of the range of project

performers and constituencies. Since abandoning the

master-builder concept, and separating design from

construction, we have been patching a poorly

conceived design practice. Value engineering, design Share incomplete information early and often

assist, and constructability reviews mask an underlying Identify the Last Responsible Moment for taking action and

assumption that design can be successful when use the time to make the best possible decision

separated from engineering and construction. Design Form cross functional teams of Designers and Builders for

is an iterative conversation; the choice of ends affects Site, Parking Structure, MOB Shell and Core, and MOB

means, and available means affects ends. Interiors

Collaborative design and planning maximizes positive Coordinate in 3 and 4D as design evolves

iterations and reduces negative iterations.

7 8

Parking Structure & Medical Office Building The Camino Medical Center

For the Camino Medical Group (CMG)

In Mountain View, California

Site & Infrastructure development (420,790sf)

Parking structure (1,110 stalls, 420,000sf)

Medical Office Building (110 Providers,

250,000sf)

Urgent Care Center (6,000sf)

Outpatient Surgery Center (5 Suites, 20,000sf)

Pharmacy (6,000sf)

Laboratory and Diagnostics Radiology Center

(30,000sf)

$100 million in construction costs

9 10

Virtual Building is an enabling

Lean Project Delivery & Virtual Building

technology for Lean Project Delivery

Lean Project Delivery

A process

Lean Project Delivery System

Eliminate waste by designing product (the

building) and process (building the building) Purposes

Design

Concepts

Product

Design

Fabrication

& Logistics

Testing &

Turnover

simultaneously

Design Process Detailed

Installation

Virtual Building

Criteria Design Engineering

A technology and process

Virtual Building

3D object model of the product

Clash detection of multiple 3D object models Project

Definition

Lean

Design

Lean

Supply

Lean

Assembly

4D visualization of construction Production Control

Work Structuring

Post-Occupancy

Evaluation

11 12

Dean Reed, DPR Construction, Inc.

2005 2

Delivering Lean Results for Healthcare 18 July 2005

Using Virtual Building & the Last

Planner System

Why & How Does Virtual Building 3D Solids / Parametric Objects

Enable Lean on the Camino Project? Not CAD Drafting - Not Surfaces

Design Concepts Product Design Object Model

3D visualization has allowed stakeholders to understand design 3D solid / parametric

Process Design objects with attributes

Construction sequence animated in 4D

Detailed Engineering

HVAC, plumbing, fire protection and electrical coordination and

shop drawings in 3D

Fabrication

HVAC will fabricate from 3D shop drawings

Plumbing and electrical will pre-fab from 3D shops

Logistics and Sequence

Trade installations within areas will be sequenced in 3/4D Surface Model

2D polygons into 3D

object with limited

attributes

13 14

Modeling Raises Questions about How Multiple 3D Object Models Created

Things Fit Together (Much Earlier) by AE & Specialty Contractors

Objects from libraries Architectural Model

of predefined parts

Objects assembled

just like the real thing

15 16

Multiple 3D Object Models Created Multiple 3D Object Models Created

by AE & Specialty Contractors by AE & Specialty Contractors

HVAC Model

Electrical Model

17 18

Dean Reed, DPR Construction, Inc.

2005 3

Delivering Lean Results for Healthcare 18 July 2005

Using Virtual Building & the Last

Planner System

3D Process Lessons Learned from Previous

Integration of Multiple Models in 3 & 4D Projects

Modeling is early learning

Model incomplete work early

Integrated Model Start with blocks in schematics and develop

detail as design progresses

Model to shop drawing level and below

Integrate models created with different tools

Model in field to solve coordination problems

Surround team with 3D images

Structure work in 4D with subcontractors

Progress 4D models to use in lookahead

planning

DPR Portland Office

19 20

Sutter Healths Expectation The Vision

Facility Assembled in Computer Before Its Built Onsite

Sutter Health agreed to invest money in early All important design decisions are made during

collaboration and virtual building design phase:

DRR hired during Conceptual Design

MEP/FP, Skin and Steel subcontractors brought on in No misunderstanding

Schematic Design No conflict of systems

Architectural and construction budgets increased to No change orders

pay for additional expense of 3 / 4D modeling and

coordination

Construction costs will be reduced overall

Changes take

RFIs will be significantly reduced place during the

Change orders due to coordination conflicts will be design phase

eliminated not during

construction

21 22

Lean Virtual Building Guidelines

Lean Virtual Building Guidelines 1. Architects & Structural Engineer

Created 3D Object Models

1. Determine authors of architectural and structural 3D

object models

2. Define the Virtual - Lean Design Collaboration process

3. Pre-qualify A/Es and subcontractors for Virtual Building

capability

4. Determine collaboration and modeling responsibilities

5. Agree on protocol for sharing drawings and models

6. Agree on coordination and conflict resolution process

7. Pull design coordination from construction

8. Sequence trades through interactive construction of 4D

models

23 24

Dean Reed, DPR Construction, Inc.

2005 4

Delivering Lean Results for Healthcare 18 July 2005

Using Virtual Building & the Last

Planner System

Lean Virtual Building Guidelines

Lean Virtual Building Guidelines

2. Camino Design Collaboration Process 3. Subcontractors Pre-qualified for

Contractor

Input to Design

Criteria & Equip

Virtual Building Capability

Contractor Selection, Sizing,

Input to Design Routing &

Alternatives Coordination

SD SD DD

50% Collaboration 100% 50% Collaboration

Engineer Object Modeling

Engineering & Engineer

Design in 2D Design in 2D Detailed design will be done in CAD 3D object modeling software,

which can create objects having the following characteristics:

Each object in the model has a unique name or object identifier, and

Contractor

can have attributes attached to it, i.e., geometry info, weight, cost,

Detailed Design & schedule, procurement info, etc.

Coordination in 3D

These objects are either 3D solids or true parametric objects. They

Engr

DD Bldg CD are not 2D polygons that are combined to create a 3D object, as is the

Collaboration Stamps Permit

100% Drwgs Dept Set 100% case in a surface model.

The object model is assembled from libraries of predefined parts

Engineer

Design Review & representing a constructible component or assembly of components.

RFIs = Drawing Author

Documentaion in Build

2D

25 26

Lean Virtual Building Guidelines

Lean Virtual Building Guidelines

4. Modeling Responsibilities 5. Protocols Agreed for Sharing

Drawings & Models

Scope Design Phase 3D File naming conventions

Model Created Reference point for 3D models

Architect Schematic Design

Protocol for sharing files using FTP site

Structural Engineer Design Development

Protocol for updating the drawing files

Mechanical Engineer No 3D

Electrical Engineer No 3D CAD backgrounds, colors and layer

HVAC Contractor Construction Documents

management for the drawings / models

Plumbing Contractor Construction Documents Protocol for combining drawings in a

Electrical Contractor Construction Documents single NavisWorks model for coordination

Fire Protection Contractor Construction Documents

27 28

Lean Virtual Building Guidelines Lean Virtual Building Guidelines

6. Coordination & Conflict Resolution 7. 3D Coordination Drawings Pulled

Process Established from Construction Schedule

29 30

Dean Reed, DPR Construction, Inc.

2005 5

Delivering Lean Results for Healthcare 18 July 2005

Using Virtual Building & the Last

Planner System

Lean Virtual Building Guidelines

8. Trades Will Be Sequenced through The Five Big Ideas of Lean Project Delivery

Interactive Development of 4D Models #3 Projects are networks of commitments

Projects are not processes. They are not value

streams. The work of management in project

environments is the ongoing articulation and

activation of unique networks of commitment.

The work of leaders is bringing coherence to

the network of commitments in the face of the

uncertain future and co-creating the future with

project participants. This contrasts with the

commonsense understanding that planning is

predicting, managing is controlling, and

leadership is setting direction.

31 32

Translating into Action on Camino

Projects as Networks of Commitments Camino Organization Was Typical

Negotiate deliverables rather than issuing commands

Be willing to say and hear No

Ask for and make honest commitments

Declare complete when youre done to release work to the

next performer

33 34

Silos & Big Batches The Black Box of Design

Architects and engineers worked and Architects developed a summary level

communicated in their own silos, apart work plan to deliver the big batches

from builders

Customer inputs and deliverables within

A/Es used to working in large batches the design team and to contractors not

Schematic Design

planned

Design Development

Construction Documents Difficult to get architect to agree to delivery

A/Es traditional practice was to throw the dates for design packages

batches over the wall for cost and No Success in pulling a design phase

construct-ability review schedule from deliverable dates

35 36

Dean Reed, DPR Construction, Inc.

2005 6

Delivering Lean Results for Healthcare 18 July 2005

Using Virtual Building & the Last

Planner System

Seeing Inside the Black Box Commitment Manager

Project team came to understand Tracks commitments and related actions

importance of making requests and between people

keeping promises Maintains status of commitment

Commitment Manager software reviewed Manages commitments reminds and escalates

and selected by project team as a tool for Provides visualization of commitment status

strengthen the network of commitments Provides metrics as a byproduct of tracking the

Team members could make requests and actions

respond from their workplaces Runs on a Web or Microsoft Outlook server

Requesters, performers and observers

could see status of requested actions

37 38

Commitment Manager in Place of RFIs

During Design

Commitment Manager should be used for the following:

Documenting all design collaboration queries between the

project team prior to the permit being issued for the

particular scope of work.

Documenting of all cost impact issues shall be entered by

the subcontractors in the Commitment Manager as a

request of Scott Sass. The requests will then be committed

by Scott Sass and the DPR team in the cost impact log.

39 40

Making a Request Commitment Status Report

41 42

Dean Reed, DPR Construction, Inc.

2005 7

Delivering Lean Results for Healthcare 18 July 2005

Using Virtual Building & the Last

Planner System

Applying the Last Planner System in

Using the Weekly Work Plan

Design

Not able to create a pull Design Phase Requests for information and offers to

schedule provide answers are recorded in a MEP

Not able to look ahead and do constraints Weekly Work Plan

analysis WWP developed on screen in the meeting

DPR worked with Sutter Health to make Commitments by A/Es, the GC and

the Weekly Work Plan the focus of the subcontractors are scored and charted

weekly project meeting each week

Meeting minutes are kept to record WWP is distributed to all participants after

discussion, not used to run the meeting the meeting

43 44

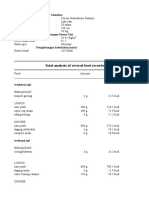

Mechanical & Electrical Weekly Work Cost Benefits Study

Plan & Pareto Charts Collaboration Results So Far

Cost Avoidance: $5,356,980

45 50

Presentation to

Australian Construction

Creating value

Industry Conference

Eliminating waste Sydney, Australia

18 July 2005

Questions & Answers

Dean Reed, DPR Construction, Inc.

2005 8

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Quant Job Application ChecklistDokument4 SeitenQuant Job Application Checklistmetametax22100% (1)

- B028-Sayli Kapse B029-Surya Teja B030-Taranum Kaur B032-Yashesh Kothari B034-Sathish Kumar B035-ManeeshDokument24 SeitenB028-Sayli Kapse B029-Surya Teja B030-Taranum Kaur B032-Yashesh Kothari B034-Sathish Kumar B035-ManeeshTaranum RandhawaNoch keine Bewertungen

- Question Bank Chemistry (B.Tech.) : Solid StateDokument10 SeitenQuestion Bank Chemistry (B.Tech.) : Solid StatenraiinNoch keine Bewertungen

- (PDF) Books Toxic Parents Epub Popular Download - by Susan ForwardDokument1 Seite(PDF) Books Toxic Parents Epub Popular Download - by Susan Forwardmartagonzalezbordonaba0% (3)

- Zemoso - PM AssignmentDokument3 SeitenZemoso - PM AssignmentTushar Basakhtre (HBK)Noch keine Bewertungen

- All Vaccinees Are Requested To Bring Certificate of Dose-II From COWIN Portal Alongwith Registered Mobile Number Before Proceeding For VaccinationDokument7 SeitenAll Vaccinees Are Requested To Bring Certificate of Dose-II From COWIN Portal Alongwith Registered Mobile Number Before Proceeding For VaccinationRakesh KumarNoch keine Bewertungen

- Primary Tooth Pulp Therapy - Dr. Elizabeth BerryDokument52 SeitenPrimary Tooth Pulp Therapy - Dr. Elizabeth BerryMihaela TuculinaNoch keine Bewertungen

- 15-Statutory Report Statutory Define Law (Legal Protection) Statutory MeetingDokument2 Seiten15-Statutory Report Statutory Define Law (Legal Protection) Statutory MeetingRaima DollNoch keine Bewertungen

- Tugas Gizi Caesar Nurhadiono RDokument2 SeitenTugas Gizi Caesar Nurhadiono RCaesar 'nche' NurhadionoNoch keine Bewertungen

- Stas Final ReviewerDokument8 SeitenStas Final ReviewerShane SaynoNoch keine Bewertungen

- CW Catalogue Cables and Wires A4 En-2Dokument1.156 SeitenCW Catalogue Cables and Wires A4 En-2Ovidiu PuieNoch keine Bewertungen

- Industrial SpecialtiesDokument103 SeitenIndustrial SpecialtiesRahul ThekkiniakathNoch keine Bewertungen

- Ulangan Tengah Semester: Mata Pelajaran Kelas: Bahasa Inggris: X Ak 1 / X Ak 2 Hari/ Tanggal: Waktu: 50 MenitDokument4 SeitenUlangan Tengah Semester: Mata Pelajaran Kelas: Bahasa Inggris: X Ak 1 / X Ak 2 Hari/ Tanggal: Waktu: 50 Menitmirah yuliarsianitaNoch keine Bewertungen

- Amniotic Fluid DisordersDokument16 SeitenAmniotic Fluid DisordersLytiana Williams100% (2)

- 13 Ed Gulski PraesentationDokument45 Seiten13 Ed Gulski Praesentationcarlos vidalNoch keine Bewertungen

- 742210V01Dokument2 Seiten742210V01hakim_zadehNoch keine Bewertungen

- ICT ContactCenterServices 9 Q1 LAS3 FINALDokument10 SeitenICT ContactCenterServices 9 Q1 LAS3 FINALRomnia Grace DivinagraciaNoch keine Bewertungen

- Catalogo StafsjoDokument12 SeitenCatalogo StafsjoBruno Bassotti SilveiraNoch keine Bewertungen

- Listes de Produits GAURAPADDokument1 SeiteListes de Produits GAURAPADBertrand KouamNoch keine Bewertungen

- MCQSDokument25 SeitenMCQSAsifa Liaqat0% (1)

- MODEL 1332 MODEL 1432: Slide LengthDokument8 SeitenMODEL 1332 MODEL 1432: Slide LengthFabian FragosoNoch keine Bewertungen

- PL 806aDokument45 SeitenPL 806acesar luis gonzalez rodriguezNoch keine Bewertungen

- Esomeprazol Vs RabeprazolDokument7 SeitenEsomeprazol Vs RabeprazolpabloNoch keine Bewertungen

- Lecture 8: Separation DesignDokument45 SeitenLecture 8: Separation DesignRavi Kiran MNoch keine Bewertungen

- EMC Design GuideDokument42 SeitenEMC Design GuideDe Raghu Veer KNoch keine Bewertungen

- Excerpts From Roe v. Wade Majority OpinionDokument2 SeitenExcerpts From Roe v. Wade Majority OpinioncatherinewangcNoch keine Bewertungen

- Vinegar Intake Reduces Body Weight Body Fat Mass and Serum Triglyceride Levels in Obese Japanese SubjectsDokument8 SeitenVinegar Intake Reduces Body Weight Body Fat Mass and Serum Triglyceride Levels in Obese Japanese SubjectsZaphan ZaphanNoch keine Bewertungen

- Ens TecDokument28 SeitenEns TecBorja CanalsNoch keine Bewertungen

- Reading Test - 3 Clinical Depression Text ADokument17 SeitenReading Test - 3 Clinical Depression Text AJisha JanardhanNoch keine Bewertungen

- FRMUnit IDokument17 SeitenFRMUnit IAnonNoch keine Bewertungen