Beruflich Dokumente

Kultur Dokumente

Power Station 2013

Hochgeladen von

Ayman EsaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Power Station 2013

Hochgeladen von

Ayman EsaCopyright:

Verfügbare Formate

1

Final Term Exam (13/5/2013)

Benha University/Faculty of Engineering Conventional Power Stations

Mechanical Engineering Department Time Allowed: 4 hours

Fourth Year, Power Section Max. Marks=100

Please Answer All Questions

Steam Chart is allowed only

1. It is required to design the main parts of a vertical steam boiler of capacity 40 t/h with outlet state

at 50 bars and 550oC working with heavy fuel oil having the composition percentage:

C=80%, H2=11.8%, S=2.1% and O2 =6.1%.

Take =1.3, ambient air =25oC and inlet air to furnace is at 250oC. The heat loss from furnace due

to radiation and unburnt fuel is 13% and excess air coefficient is 21%. See Figure (1).

i. Calculate lower and higher calorific value for the fuel.

ii. Calculate theoretical air required for the combustion per kg fuel.

iii. Find fuel quantity required in kg/s for boiler efficiency 80%.

iv.Find a/f ratio, air quantity required in kg/s and gas specific heat, Cpg.

v. If furnace heating factor=1.2MW/m3, design furnace height for a square surface area of 5x5 m2.

vi. Calculate temperature distribution of flue gases through the furnace, evaporator, superheater,

economizer and air preheater parts.

vii. Find the stack height and nominal diameter if p=22mm of water at gas velocity=8m/s.

2

viii. If an evaporative heating factor = 100 kgs/m h, design the evaporative water tube-wall area.

ix. If a superheating overall heat transfer coefficient Ush=30W/m2oC, design superheater heating area

due convection and conduction heat transfer.

x.If an air preheater overall heat transfer coefficient Uah=12W/m2oC, design air preheater heating

area for gas and air velocities 8 and 9 m/s respectively.

xi. If water economizer overall heat transfer coefficient UEc=12W/m2oC, design water economizer

heating area using ribbed Cast Iron tubes type.

------------------------------

2. The daily load curve for a power station is given by the following correlation:

L= -0.4 t2 +10 t + 6, where t is the time in hours from 0 to 24 hours and L is in MW.

a) Draw the daily load curve and daily duration curve.

b) Calculate peak load and its time.

c) Calculate average load.

d) Calculate load factor.

e) If four equal units are used to supply this load curve; each equals 20 MW, calculate the

reserve factor of that station.

----------------------------------

3. Design condenser number of tubes that would handle 40t/h of 90% percent quality at 0.07 bars, as

well as 4t /h of 75oC drain water from the low pressure feed water heater, and 1.2t/h of 225 oC

drains saturated from the steam-jet air ejector. Fresh cooling water is available at 25oC. C1=2582

for one inch outer tube diameter, C2 =1.003 at Twi=25oC, C3=0.54 and C4=0.85 and a velocity of 1.8

m/s can be assumed. Assume tube-sheet pitching =7.5 tubes/m2/pass. See Figure (2).

Part I With Great Success, Dr Atef A Aly

2

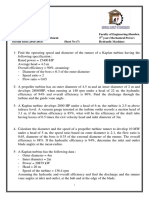

Flue gas

o

Super-heated Steam (output) of 550 C, 50 bars

Superheater

Water inlet

Boiler Part

o

Water Heater 230 C

(Economizer)

o

Air Preheater Air input 25 C

Evaporator

Exhaust of combustion Gases to smoke stack

F

Furnace part

Fuel o

Input

Secondary Air, 250 C

o

Primary Air, 250 C

5m

5m

Figure (1)

Dshell

10 m

Tube-sheet pitching/pass

Figure (2)

Part I With Great Success, Dr Atef A Aly

3

1)

I) Calculate lower and higher calorific value for the fuel:

CVH = (4.18/100)[8080*(%C)+34500*((%H2)-(%O2)/8))+2220*(%S)]

= 4.18*(8080*0.8+34500*(0.11-0.061/8) + 2220*0.029) =43206 kJ/kg

CVL = 43206-588.76*4.18 *(9x0.118/100) = 40592kJ/kg.

ii) Find fuel quantity required in kg/s for boiler efficiency 80%:

B= [ms(hs-hfb)]/[mf*CVL] AND mf=(ms(hs-hfb))/(BCVL)

mf = 40(3550-4.18x230)/(0.8x40592) = 3.1947t/h = 1 kg/s

iii) Calculate theoretical air required for the combustion per kg fuel:

Substance Kgsub/kgf KgO2/kgf

C 0.8 2.133

H2 0.118 0.944

S 0.029 0.021

O2 0.061 -0.061

Sum 1 3.037

Theoretical air required for the combustion per kg fuel = 3.037x100/23 =13.206 kgair/kgf

iv) Find a/f ratio, air quantity required in kg/s and gas specific heat, Cpg:

(a/f)theoretical = 13.206

(a/f)actual = 13.206 x1.21 =15.979

mair = (a/f)actualx mf = 15.979 x 1 = 15.979

Excess air = 21 %

(A/F)= 1.20(A/F)th = 1.21x13.206= 15.684= kgair/kgf

mair = mf * (A/F)= 15.979x3.194= 51.243= t/h= 14 kg/s

mg= mair + mf = 51.243+ 3.194= 54.510= t/h= 15 kg/s

Flue gas (i) mi (kgi/kgf) Mi ni=(mi/Mi) xi=(ni/nt) xiMi

CO2 2.933 44 0.067 0.116 5.115

SO2 0.058 64 0.001 0.002 0.101

H2O 0.990 18 0.055 0.096 1.726

O2 0.626 32 0.020 0.034 1.092

N2 12.077 28 0.431 0.752 21.060

Sum 16.684 0.573 1 29.094

Mm=xiMi 29.094 kgg/kgf

Rg=(Ru/Mm) = 0.286 kJ/kgoC

Cp,g = 1.238 kJ/kgoC

Part I With Great Success, Dr Atef A Aly

4

(v)

Furnace

Furnace loss 13 %

Hv= 1.20 MW/m3

A=5*5= 25 m2

H=(1-(%loss/100)) * (mf * CVL)/(Hv*A)

H= 1.0 M

(vi)

Furnace

(1-(%loss/100)) * mfCVL = mgCp,gTfg - maCp,aTa2

Tfg={(1-(%loss/100)) * mfCVL + maCp,aTa2} / mgCp,g

Tfg= 1859.0 o

C

Evaporator

mshfg=mgCp,g(Tfg-Tg1)

Tg1=Tfg- (mshfg)/(mgCp,g)

Tg1= 887.0 o

C

Superheater

ms(h1-hg)=mgCp,g(Tg1-Tg2)

Tg2=Tg1- (ms(h1-hg))/(mgCp,g)

Tg2= 439.2 o

C

Economizer

msCwater(Tsat-Tfb)=mgCp,g(Tg2-Tg3)

Tg3=Tg2- (msCwater(Tsat-Tfb))/(mgCp,g)

Tg3= 352.5 o

C

Air Preheater

maCp,a(Ta2-Ta1)=mgCp,g(Tg3-Tg4)

Tg4=Tg3- (maCp,a(Ta2-Ta1))/(mgCp,g)

Tg4= 180.9 o

C

(vii)

Stack

P = 22.0 mm H2O

Vg= 8.0 m/s

P = Hch(air-g) air =(Patm/RaTa1)= 1.18 kg/m3

Part I With Great Success, Dr Atef A Aly

5

Hch= P/(air-g) g =(Patm/RgTg4)= 0.78 kg/m3

Hch= 54.5 m

mg=gVgAg

Ag=mg/gVg

Ag= 2.42 m2

D= (4Ag/) 1.76 M

(viii)

Design of Evaporator Water Tube-Wall Area

Evaporative heating factor = 100.0 kg/m2.h

A=ms/Evap.heating factor = 400.0 m2

(ix)

Design of Superheater Heating

Area

Ush= 108.0 kJ/h m2 oC

Qsh=ms(h1-hg)=AUshTlm,sh

A=ms(h1-hg)/UshTlm,sh

A= 1134.4 m2

Tgas,in=Tg1 Ts,out=T1 Tgas,out=Tg2 Ts,in=Tsat T1 T2 Tlm,sh

887.0 550 439.2 265 337.0 174.2 246.7

(x)

Design of Air Preheater Heating Area

Uah= 43.2 kJ/h m2 oC

Qpreheater=maCp,a(Ta2-Ta1)=AUahTlm,ah

A=maCp,a(Ta2-Ta1)/UahTlm,ah

A= 2106.5 m2

Tgas,in=Tg3 Tair,out=Ta,2 Tgas,out=Tg4 Tair,out=Ta,1 T1 T2 Tlm,ah

352.5 250 180.9 25 102.5 155.9 127.3

(xi)

Design of Water Economizer Heating Area

UEc= 43.2 kJ/h m2 oC

Part I With Great Success, Dr Atef A Aly

6

QEconomizer=msCwTEco=AUEcTlm,Ec

A=msCwTEco/UEcTlm,Ec

A= 922.4 m2

Tgas,in=Tg2 Tw,out=Tsat Tgas,out=Tg3 Tw,in=Tfb T1 T2 Tlm,Ec

439.2 265 352.5 230 174.2 122.5 146.9

2) L= -0.4t2+10t+6

Daily load curve Daily Duration Curve

L,MW

L,MW

100 100

50 50

0 0

0 4 8 12 16 20 24 0 4 8 12 16 20 24

t,hr t,hr

dL/dt =-0.8t*+10 =0

t* = 12.5 hours

Lp= -0.4t2+10t+6 =-0.4x(12.5)2+10x12.5+6 = 68.5 MW

Lav =Eday/24

Eday = -0.4t2+10t+6)dt =(( ) ( ) ) = 1180.8MWh

Lav =1180.8/24 =49.2 MW

L.f = Lav/Lp = 49.2/68.5 = 0.718

R.f = LR/Lp = (20x4)/68.5 = 1.167

Part I With Great Success, Dr Atef A Aly

7

3) Q = ms(hf+xhfg)+mwcwTw +mjhg - mthf

= (1000/3600)[40 (163+0.9x2409)+4x4.18x75 + 1.2x2803.3 45.2x163]=25137.3 kW

U= c1xc2xc3xc4 (v)0.5 = 2582x1.003x0.54x0.85(1.8)0.5/1000 =1.5947kW/m2oC

Tlm =[ (39-35)-(39-25)]/ln[(39-35)/ (39-25)] =7.98 oC

A = Q/UTlm =25137.3/(1.5947x7.98) = 1975.32 m2 = 2dNL=2x(22/7)x0.0254xNx10

N= 1237.23=1238 tubes

Area of tube plate section=2.5p x 3p sin 60 =7.5p2/2

Assume tube sheet pitching =7.5 tubes/m2/pass

Then area = 1238/7.5 = 165.067 m2 = DshellL=(22/7)x10Dshell

Dshell=5.25m

2.5p

1.25 p

p p

p p p

p p

p 2.5 p

3p sin60

p p p

p

p p

2.5 p

p p p

p p

1.25 p

o

60

Part I With Great Success, Dr Atef A Aly

Das könnte Ihnen auch gefallen

- TA1 Test For Electrical System: Status Description CommentsDokument6 SeitenTA1 Test For Electrical System: Status Description CommentsAyman EsaNoch keine Bewertungen

- TA1 Test For Steering SystemDokument6 SeitenTA1 Test For Steering SystemAyman EsaNoch keine Bewertungen

- Section 3 Hydraulic SystemDokument3 SeitenSection 3 Hydraulic SystemAyman EsaNoch keine Bewertungen

- BobcatTroubleshooting Method 2018Dokument17 SeitenBobcatTroubleshooting Method 2018Ayman Esa100% (1)

- 220 ElectricalDokument17 Seiten220 ElectricalAyman EsaNoch keine Bewertungen

- TA1 Test For Engine: Status Description CommentsDokument3 SeitenTA1 Test For Engine: Status Description CommentsAyman EsaNoch keine Bewertungen

- TA1 Test For Hydraulic System: Status Description CommentsDokument6 SeitenTA1 Test For Hydraulic System: Status Description CommentsAyman EsaNoch keine Bewertungen

- TA1 Test For Fuel SystemDokument6 SeitenTA1 Test For Fuel SystemAyman EsaNoch keine Bewertungen

- TA2test For S-O-S: Status Description CommentsDokument3 SeitenTA2test For S-O-S: Status Description CommentsAyman EsaNoch keine Bewertungen

- TA1 Test For Frame and Body: Status Description CommentsDokument6 SeitenTA1 Test For Frame and Body: Status Description CommentsAyman EsaNoch keine Bewertungen

- TA1 Test For Power TrainDokument6 SeitenTA1 Test For Power TrainAyman EsaNoch keine Bewertungen

- TA1 Test For Air Inlet and Exhaust: Status Description CommentsDokument6 SeitenTA1 Test For Air Inlet and Exhaust: Status Description CommentsAyman EsaNoch keine Bewertungen

- TA1 Test For Operator StationDokument6 SeitenTA1 Test For Operator StationAyman EsaNoch keine Bewertungen

- Design of Internal Combustion EngineDokument17 SeitenDesign of Internal Combustion EngineAyman EsaNoch keine Bewertungen

- Sheet 6 Francis TurbineDokument2 SeitenSheet 6 Francis TurbineAyman EsaNoch keine Bewertungen

- 2.3 Components ValveDokument25 Seiten2.3 Components ValveAyman Esa50% (2)

- What Is Comparative Politics?: Theory of Comparative Political SystemsDokument47 SeitenWhat Is Comparative Politics?: Theory of Comparative Political SystemsAyman EsaNoch keine Bewertungen

- Done By: Moustafa Ibrahim Sec.: 8Dokument2 SeitenDone By: Moustafa Ibrahim Sec.: 8Ayman EsaNoch keine Bewertungen

- Hands-On Training: Power of ColorsDokument18 SeitenHands-On Training: Power of ColorsAyman EsaNoch keine Bewertungen

- 3.1 Components ActuatorDokument10 Seiten3.1 Components ActuatorAyman EsaNoch keine Bewertungen

- FluidPower Chapters1-4Dokument61 SeitenFluidPower Chapters1-4Ayman EsaNoch keine Bewertungen

- Sheet (3) - Numerical Solutions For Differential EquationsDokument4 SeitenSheet (3) - Numerical Solutions For Differential EquationsAyman EsaNoch keine Bewertungen

- Sheet 1 SolvedDokument2 SeitenSheet 1 SolvedAyman Esa50% (2)

- Benha University Final Examination2009 SolutionDokument13 SeitenBenha University Final Examination2009 SolutionAyman Esa100% (1)

- 3rd Power Semester Work-Final-2015Dokument10 Seiten3rd Power Semester Work-Final-2015Ayman EsaNoch keine Bewertungen

- Sheet 7 Kaplan TurbineDokument1 SeiteSheet 7 Kaplan TurbineAyman EsaNoch keine Bewertungen

- Power Plant EconomicsDokument27 SeitenPower Plant EconomicsAyman Esa0% (1)

- Examples Electron Volt Calculation For Panel Power OutputDokument10 SeitenExamples Electron Volt Calculation For Panel Power OutputAyman EsaNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Physics Today: Solar Energy ConversionDokument7 SeitenPhysics Today: Solar Energy ConversionLy Que UyenNoch keine Bewertungen

- Energy N Power SpellsDokument17 SeitenEnergy N Power SpellsSelenio Emilio100% (1)

- Cable SelectionDokument1 SeiteCable SelectionMAYUR GENSETNoch keine Bewertungen

- 7XG3120 - ReyArc Catalogue SheetDokument16 Seiten7XG3120 - ReyArc Catalogue Sheetsameer233100% (1)

- 19 PDFDokument1 Seite19 PDFRaj KumarNoch keine Bewertungen

- Medium Voltage Potential Transformer Ptg5: Features 15Kv ClassDokument2 SeitenMedium Voltage Potential Transformer Ptg5: Features 15Kv ClassalejandrozabalaNoch keine Bewertungen

- 3244cr Four Stroke Diesel Engine - 3 PDFDokument9 Seiten3244cr Four Stroke Diesel Engine - 3 PDFalulgameNoch keine Bewertungen

- Studies in Occult Chemistry and PhysicsDokument117 SeitenStudies in Occult Chemistry and PhysicsNerv RulzNoch keine Bewertungen

- Electrical SubstationsDokument16 SeitenElectrical SubstationsEngr Syed Numan ShahNoch keine Bewertungen

- SF10A300HPR: 300V, 10A Ultrafast Dual RectifiersDokument5 SeitenSF10A300HPR: 300V, 10A Ultrafast Dual RectifiersImãos SilvaNoch keine Bewertungen

- Cyber CafeDokument1 SeiteCyber Cafeindia4gNoch keine Bewertungen

- Resume 4may2022Dokument7 SeitenResume 4may2022raghvendraprasadNoch keine Bewertungen

- ABB Capability Guide - LRDokument60 SeitenABB Capability Guide - LRtobyNoch keine Bewertungen

- AllreligionsareoneDokument234 SeitenAllreligionsareoneEugene100% (4)

- Carlo F. Barenghi - Is The Reynolds Number Infinite in Superfluid Turbulence?Dokument8 SeitenCarlo F. Barenghi - Is The Reynolds Number Infinite in Superfluid Turbulence?JuaxmawNoch keine Bewertungen

- 2017 Directory of China's Natural Gas Pipelines PDFDokument12 Seiten2017 Directory of China's Natural Gas Pipelines PDFarapublicationNoch keine Bewertungen

- Combined Cycle GTW Specs - Rule of Thumb EstimationsDokument4 SeitenCombined Cycle GTW Specs - Rule of Thumb EstimationsvankayalasuryaNoch keine Bewertungen

- Steam Turbines Mechanical Drive Applications 1 160 MWDokument8 SeitenSteam Turbines Mechanical Drive Applications 1 160 MWKalai SelvanNoch keine Bewertungen

- Huawei Solar Hybrid Technical - Proposal (Pure Solar)Dokument23 SeitenHuawei Solar Hybrid Technical - Proposal (Pure Solar)Nuru J. Haule100% (1)

- EE 2019 2022 Past Board Exam Questions in Electrical Engineering Professional Subjects PDFDokument46 SeitenEE 2019 2022 Past Board Exam Questions in Electrical Engineering Professional Subjects PDFlexfred55Noch keine Bewertungen

- Tidal Energy Final ReportDokument19 SeitenTidal Energy Final Reportkavya kruthiNoch keine Bewertungen

- Deye Catalogue-2022Dokument42 SeitenDeye Catalogue-2022M Khalif WinaryaNoch keine Bewertungen

- EarthingDokument8 SeitenEarthingSatyender Kumar Jain100% (1)

- Cable Solution EnertechDokument1 SeiteCable Solution EnertechAlvaro Bartolome GarciaNoch keine Bewertungen

- Slide UCG HayDokument23 SeitenSlide UCG HayVăn Đại - BKHNNoch keine Bewertungen

- Gujarat Technological University: Introduction To Electric VehicleDokument3 SeitenGujarat Technological University: Introduction To Electric VehicleKRISHNANoch keine Bewertungen

- 1 s2.0 S2211467X17300512 MainDokument15 Seiten1 s2.0 S2211467X17300512 MaingfiygNoch keine Bewertungen

- Contactor Selection and Data: LS22K, LS30K, LS37KDokument1 SeiteContactor Selection and Data: LS22K, LS30K, LS37KGerman J'IngNoch keine Bewertungen

- Metrosil IntroductionDokument2 SeitenMetrosil Introductionian.rowley4051Noch keine Bewertungen

- EcoEnergy Catalogue 081110 PDFDokument68 SeitenEcoEnergy Catalogue 081110 PDFkawsayaNoch keine Bewertungen