Beruflich Dokumente

Kultur Dokumente

Boost Power Plant Efficiency with Overlooked Hydrodynamic Speed Control

Hochgeladen von

mfhaleem@pgesco.comOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Boost Power Plant Efficiency with Overlooked Hydrodynamic Speed Control

Hochgeladen von

mfhaleem@pgesco.comCopyright:

Verfügbare Formate

An overlooked asset

Hydrodynamic speed control in Combined Cycle

Power Plants

Dip.-Ing. (FH) Bernd Harnisch, Voith Turbo Pte. Ltd., Singapore

Special Print from Power Engineering International, November issue 2003

Combined Cycle Technology Bernd Harnisch, Voith Turbo Pte Ltd., Singapore

In competitive power markets, the focus is on plant efficiency and cost control. This often means that developers

overlook devices that can reduce plant operation and maintenance costs as well as increase efficiency.

An overlooked asset

E nergy generation in todays market is

becoming more and more efficient,

with combined cycle power stations

on the rise with net efficiencies reaching

130

120

110

almost 60 per cent. While there is much 100

Throttle Control

focus on efficiency at full load, little or no 90

attention is paid to the impact of part-load

Power (%)

80

(cycling) operation on a plants efficiency.

This article tries to shed some light on the 70

design of the boiler feedwater system and 60 Power Savings Variable Speed

some common misconceptions or myths 50 Coupling

regarding the use of variable speed drives 40

for the high pressure boiler feed pumps. 30

20

Part-load vs base-load

10

Myth No. 1: Combined cycle power sta-

tions can be operated as base-load power 0

plants to best utilize the higher efficiencies 0 10 20 30 40 50 60 70 80 90 100 110

provided by this technology. Flow (%)

The idea of operating combined cycle Figure 1. Absorbed power of high-pressure boiler feed pumps (throttle vs. speed control)

power stations at base-load throughout

their service life is very appealing. In prac- mainly on the following factors: bined cycle plant in Singapore supports the

tice however, gas turbine powered stations Load pattern: The load pattern has a sig- above arguments fully. The study based

are much more suitable than e.g. coal-fired nificant impact on the potential savings in on exclusive base-load operation shows

plants to cover peak capacities. auxiliary energy as shown in Figure 1. a power saving of 180 kW per 50 per cent

Furthermore, there is no guarantee for Test point of heat recovery boiler: boiler feed pump. As a result an energy

base-load operation over the lifetime of 25 Depending on regulations, steam genera- saving of some 3 million kWh can be

years. Government regulations and PPAs tors have to withstand an excess steam achieved during one year. The theoretical

may change and electricity pool systems flow of up to 105 per cent, an excess feed- values have been verified and confirmed in

might be established obliging operators to water flow of up to 125 per cent and an real life operation. At 100 per cent MCR

bid for every kWh to sell. In times of reces- excess feedwater pressure of up to 110 per the pumps are running at 2580 r/min com-

sion, decreasing or stagnant electricity cent of design capacity. This leads to a pared to a design speed of 2877 r/min.

demand will ultimately result in excess design of a high-pressure boiler feed pump When related to the total plant output,

capacities installed thus forcing power

plants into part-load operation. If the plant has to go into part-load operation, the original

If after five or even ten years the plant has

to go into part-load operation, the original

design, i.e. as a base-load plant, may not be suitable for the more

design, i.e. as a base-load plant, may not be demanding requirements of a cycling plant

suitable for the more demanding require-

ments of a cycling plant. Assuming that no that largely exceeds the requirements of the plants net efficiency at full load can be

provisions were made to operate the high- the 100 per cent MCR (maximum contin- increased by 0.1 per cent compared to a

pressure boiler feed pumps at variable uous rating) operating point. In addition, design using fixed speed pumps. In view of

speed, the operator may face increasing contract guarantees from the boiler and the very moderate capital expenditure for

maintenance cost due to higher pressure the pump manufacturer further widen the the inclusion of variable speed couplings

levels and increased wear and tear. gap between design and nominal operating the cost for other efficiency enhancing

Frequent start-ups may cause problems conditions. The use of fixed speed pumps measures to achieve the same goal may be

with the minimum flow control valves inevitably results in high losses in the feed- far higher. The efficiency advantage

while the feedwater control valves have to water control valve even if the plant is remains throughout the plants lifetime

cope with higher differential pressures due exclusively operated at base-load. and can increase to as much as 0.5 per cent

to reduced plant output. Fixed pressure versus sliding pressure if the plant goes into cycling operation.

characteristic: If the boiler is operated in

Energy savings sliding pressure mode, the pressure differ- Operating experience

Myth No. 2: If combined cycle power sta- ence between pump characteristic and Myth No. 3: Additional installation of

tions are operated as base-load power boiler resistance line increases dramati- hydrodynamic variable speed couplings

plants the use of variable speed boiler feed cally towards lower flow rates and with it reduces reliability and increases mainte-

pumps has no economical advantage. the power losses of a fixed speed pump nance cost.

The potential of auxiliary energy savings compared to a variable speed pump. The operating experience of customers

in a combined cycle power station depends A study carried out for a 425 MW com- worldwide is in strong contrast to the

November 2003 PEi

Combined Cycle Technology

common opinion that an additional device Project cost control valves to balance any operational

will result in lower reliability or higher Myth No. 4: Hydrodynamic variable variation between two or three boilers.

maintenance cost of the overall system. To speed couplings increase the project cost The integrated oil system of the variable

understand the supposed contradiction, significantly. speed coupling can also supply lube oil to

one needs to look closer into the charac- The cost for hydrodynamic variable speed motor and pump bearings, whereas a sep-

teristic of a hydrodynamic coupling. couplings are not very high compared to the arate lube oil supply unit is needed in case

Contrary to a fixed gear box, the hydro- overall project cost. Typically, a coupling of fixed speed pumps.

dynamic variable speed coupling changes for a 500 MW combined cycle power sta-

the operating characteristic of the boiler tion costs some $50 000. At the contractors First choice

feed pump. Torque is transmitted by using side cost for modified foundations and Myth No. 5: Hydrodynamic variable speed

the kinetic energy of hydraulic oil flowing implementation into the control system has couplings are not cost-efficient.

from the primary wheel (pump impeller) to to be considered. Despite the tremendous development of

the secondary wheel (turbine). A mechani- On the other hand, some of the addi- frequency converters and improved filter

cally driven pump maintains the oil flow tional cost may be saved when designing systems to handle the harmonics feeding

needed to dissipate the hydraulic losses an optimized system making full use of the back into the mains, the demand for

while the moveable scoop tube adjusts the benefits of the latest design of hydrody- hydrodynamic variable speed drives has

oil level in the coupling according to the namic variable speed couplings. The con- not changed over the years. The absorbed

required output speed. A 4-20 mA signal ventional start-up and feedwater valves power of centrifugal machines decreases

from the control room is all that is needed

to control the speed. 160

The discharge pressure of a speed-con- 2 x 50%

140

trolled pump is lower than that of a fixed- 1 x 50%

speed pump. Thus the pump can be oper- Pump Characteristic Test Point

120

ated at its optimum operating point and

Pressure (bar)

internal efficiency. Controlling the feedwa- 100% MCR

100

ter flow by valves only (throttle control)

BFP

causes the internal pump efficiency to drop. 80

Feedback from power plant operators with Boiler Characteristic

fixed-speed pumps indicates that wear and 60

tear of the feedwater control valves results

in increased maintenance cost and even in 40

replacements of complete valves every year.

This is even more valid in case of the start- 20

up (minimum flow) valves that have to

0

compensate a differential pressure between 0 10 20 30 40 50 60 70 80 90 100 110 120 130

boiler (approximately 10 bar) and the boil-

Flow (%)

er feed pump (80-180 bar) during cold

Figure 2. Boiler feedwater pump and boiler characteristics

start. Wear and tear on these systems is

minimal in speed-controlled systems may be replaced with less sophisticated with the 3rd power of speed. Thus, the

because the lower pressures can be directly designs as the operating requirements are efficiency advantage of electrical systems

provided by the pumps. Besides, the whole less severe. Recently, Voith developed a combined with their usually higher invest-

starting process becomes easier to manage new, hydraulically supported design for ment cost does not result in shorter pay-

and problems such as water hammer or the scoop tube control. This control pro- back terms. Because of the utmost impor-

cavitation can be easily avoided. vides extremely fast reaction times (mini- tance of reliability and availability in a

Hydrodynamic variable speed couplings mum to maximum flow within 5 s) and power plant, the hydrodynamic variable

help protect the valves of the feedwater sys- high accuracy thus allowing designing speed coupling will remain first choice for

tem and provide reliability and availability feedwater systems without feedwater con- many operators worldwide.

that is unmatched by any other means of trol valves in the future. Common header

variable speed control. systems would still require feedwater A valuable asset

While suppliers spare no efforts to further

3000 8000

improve todays efficiencies of combined

100% Flow cycle power stations by increasing gas tur-

Load Pattern Throttle Control 2276 kW

Throttle Control

Speed Control 1916 kW 7000 bine temperatures and selecting ever more

2500 Savings 2 x 180 = 360 kW

Variable Speed Coupling exotic turbine materials, the use of hydro-

Theoretical Pump Power 6000 dynamic variable speed couplings for the

360 kW

high-pressure boiler feed pumps is still

Test Point

2000

Motor Power (kW)

Hours per year

5000

considered a luxury. The concentration on

760 kW

1500

70% Flow

Throttle Control 1880 kW 4000 lowest capital expenditures for the power

Speed Control 1220 kW

Savings 2 x 380 = 760 kW

plant makes investors and contractors fail

3000 to notice a device which not only is able to

1000

increase the plants net efficiency by anoth-

2000

er 0.1-0.5 per cent, but also to protect

500 their capital investment by reducing main-

1000

tenance and wear and tear of the complete

0 0 feedwater system. When looking for alter-

0 10 20 30 40 50 60 70 80 90 100 110 120 130 natives at comparable price levels one will

Flow (%) easily find out that the hydrodynamic vari-

able speed coupling is an asset all too often

Figure 3. Load pattern and boiler feedwater pump power consumption

wrongly overlooked. PEi

PEi November 2003

Voith Turbo GmbH & Co. KG

Variable speed drives

Voithstrae 1

D-74564 Crailsheim/Germany

Tel.: +49 (0) 79 51 32-0

Fax: +49 (0) 79 51 32-6 50

vs.drives@voith.com

www.variable-speed.com

www.voithturbo.com

Cr 598 e 08/ 2004 1.000 Pennwell Technial data and illustrations subject to change.

Das könnte Ihnen auch gefallen

- Steam Turbine Drives for Rotating EquipmentDokument2 SeitenSteam Turbine Drives for Rotating EquipmentAnonymous dqbb02DUhNoch keine Bewertungen

- Energy Efficient PumpDokument5 SeitenEnergy Efficient PumpDhananjay SinghNoch keine Bewertungen

- X Ahorro Energetico Con Variadores de FrecuenciaDokument7 SeitenX Ahorro Energetico Con Variadores de FrecuenciaJayson TeoNoch keine Bewertungen

- Centrifugal - Pump DOE USADokument4 SeitenCentrifugal - Pump DOE USAGopal KrishnaNoch keine Bewertungen

- Design and Analysis of Centrifugal PumpsDokument2 SeitenDesign and Analysis of Centrifugal PumpsMTOLNoch keine Bewertungen

- Steam Turbine Replacement by High Speed Electric System Driven CompressorsDokument9 SeitenSteam Turbine Replacement by High Speed Electric System Driven CompressorsJoffre BourgeoisNoch keine Bewertungen

- Optimization of Distillation ProcessDokument8 SeitenOptimization of Distillation ProcessAhmed AldubaiNoch keine Bewertungen

- Variable Speed OperationDokument10 SeitenVariable Speed Operationmunagala balasubramanyamNoch keine Bewertungen

- Energy Tips - Steam: Consider Steam Turbine Drives For Rotating EquipmentDokument2 SeitenEnergy Tips - Steam: Consider Steam Turbine Drives For Rotating EquipmentMohammedBujairNoch keine Bewertungen

- Optimization Tests Improve Kaplan Turbine EfficiencyDokument10 SeitenOptimization Tests Improve Kaplan Turbine EfficiencyAdam Saeed FNoch keine Bewertungen

- Converting To Variable Speed at A Pumped-Storage PlantDokument9 SeitenConverting To Variable Speed at A Pumped-Storage Plantle hoai NamNoch keine Bewertungen

- Sugar Mill DrivesDokument8 SeitenSugar Mill Drivessayyadmannan67% (3)

- Consider Steam Turbine Drives for Rotating EquipmentDokument2 SeitenConsider Steam Turbine Drives for Rotating EquipmentHatem Abdelrahman100% (1)

- Management System For Drilling Rig Power Supply and Storage SystemDokument12 SeitenManagement System For Drilling Rig Power Supply and Storage SystemGustaNoch keine Bewertungen

- Steam16 Cycling LossesDokument2 SeitenSteam16 Cycling LossesShahid AliNoch keine Bewertungen

- 1 s2.0 S1474667017447458 Main PDFDokument6 Seiten1 s2.0 S1474667017447458 Main PDFDebraj DattaNoch keine Bewertungen

- Affinity Laws For Variable Speed Centrifugal PumpsDokument4 SeitenAffinity Laws For Variable Speed Centrifugal PumpsSwapnil KadamNoch keine Bewertungen

- NIKKISO Speed ControlDokument14 SeitenNIKKISO Speed ControlsajidkaleemNoch keine Bewertungen

- Permanent Magnet Direct-Drive Shaft Generators in Marine ApplicationsDokument6 SeitenPermanent Magnet Direct-Drive Shaft Generators in Marine ApplicationsringarosesNoch keine Bewertungen

- Power Abb DrivesDokument16 SeitenPower Abb Drivessf111Noch keine Bewertungen

- To VFD or To FCVDokument7 SeitenTo VFD or To FCVAmit SarkarNoch keine Bewertungen

- Benefits of Variable Speed Drives in Sugar Production: White PaperDokument12 SeitenBenefits of Variable Speed Drives in Sugar Production: White PaperMashudi FikriNoch keine Bewertungen

- Steam: Turbine ControlDokument4 SeitenSteam: Turbine ControlEliyanto E BudiartoNoch keine Bewertungen

- Turbomach New Compressor Lube Oil SystemDokument4 SeitenTurbomach New Compressor Lube Oil SystemK T SinghNoch keine Bewertungen

- Main Steam Turbine Controls Retrofit ISA FinalDokument13 SeitenMain Steam Turbine Controls Retrofit ISA Finalvankayalasurya100% (1)

- Powerplant PerformanceDokument161 SeitenPowerplant PerformancePhanindra Kumar J100% (1)

- Power Palnt Performance PDFDokument161 SeitenPower Palnt Performance PDFrafik1995100% (1)

- Replace Pressure-Reducing Valves With Backpressure TurbogeneratorsDokument2 SeitenReplace Pressure-Reducing Valves With Backpressure TurbogeneratorsEmerson RwkNoch keine Bewertungen

- Variable Frequency Drives (Primary+Condense Pump)Dokument90 SeitenVariable Frequency Drives (Primary+Condense Pump)Trần Khắc ĐộNoch keine Bewertungen

- Integrated Variable Speed DrivesDokument14 SeitenIntegrated Variable Speed DrivesulatbookNoch keine Bewertungen

- A New Coordinated Control Strategy For Boiler-Turbine System of Coal-Fired Power PlantDokument12 SeitenA New Coordinated Control Strategy For Boiler-Turbine System of Coal-Fired Power Plantmuhammad aliNoch keine Bewertungen

- Kapco PDFDokument12 SeitenKapco PDFmuhammad aliNoch keine Bewertungen

- Epe 2013043010100419Dokument7 SeitenEpe 2013043010100419le hoai NamNoch keine Bewertungen

- Power Palnt PerformanceDokument0 SeitenPower Palnt PerformanceSHIVAJI CHOUDHURY100% (2)

- 5 May 2018 - High or Medium Speed Generator Sets - Which Is Right For Your Application PDFDokument5 Seiten5 May 2018 - High or Medium Speed Generator Sets - Which Is Right For Your Application PDFamin aliNoch keine Bewertungen

- Trim Replace Impellers7 PDFDokument2 SeitenTrim Replace Impellers7 PDFhachanNoch keine Bewertungen

- Selection of Diesel GeneratorDokument3 SeitenSelection of Diesel GeneratordankorankoNoch keine Bewertungen

- Conduct An In-Plant Pumping System Survey PDFDokument2 SeitenConduct An In-Plant Pumping System Survey PDFsuilanroNoch keine Bewertungen

- Irrigation PumpsDokument4 SeitenIrrigation PumpsNogaraNoch keine Bewertungen

- LEXE1561-01 Issues With Peak DemandDokument4 SeitenLEXE1561-01 Issues With Peak DemandDave HeardNoch keine Bewertungen

- ExcavatorEnergy savingEfficiencyBasedonDieselEngineDokument9 SeitenExcavatorEnergy savingEfficiencyBasedonDieselEngineyusufNoch keine Bewertungen

- Benefits and costs of improving pumping efficiencyDokument2 SeitenBenefits and costs of improving pumping efficiencyJhon Albert RobledoNoch keine Bewertungen

- Analysis and Investigation of The Cause of Increased Energy Consumption in A Centrifugal Dewatering PlantDokument5 SeitenAnalysis and Investigation of The Cause of Increased Energy Consumption in A Centrifugal Dewatering PlantResearch ParkNoch keine Bewertungen

- 364 Parallel Operation: Compressor Manual 300 Reciprocating CompressorsDokument1 Seite364 Parallel Operation: Compressor Manual 300 Reciprocating CompressorsBaoLCNoch keine Bewertungen

- Driving Towards A Better FutureDokument5 SeitenDriving Towards A Better FuturePravit MartroNoch keine Bewertungen

- MARLO Activity 1 FINALDokument16 SeitenMARLO Activity 1 FINALJesther Marlou C. OrongNoch keine Bewertungen

- Application Note - Cement KilnsDokument2 SeitenApplication Note - Cement KilnsMarcNoch keine Bewertungen

- Power Consumption Optimization For Multiple Parallel Centrifugal PumpsDokument6 SeitenPower Consumption Optimization For Multiple Parallel Centrifugal PumpshachanNoch keine Bewertungen

- Power Plant Performance PDFDokument161 SeitenPower Plant Performance PDFvamsikl100% (2)

- Using Pumps As Power Recovery TurbinesDokument4 SeitenUsing Pumps As Power Recovery TurbinesKali CharanNoch keine Bewertungen

- Simplify Your Pump Connections With Fluid Coupling ControlDokument5 SeitenSimplify Your Pump Connections With Fluid Coupling Controlcjp6124Noch keine Bewertungen

- Steam Turbine Power Plant DesignDokument52 SeitenSteam Turbine Power Plant DesignykeinNoch keine Bewertungen

- Process System Value and Exergoeconomic Performance of Captive Power PlantsVon EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsNoch keine Bewertungen

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceVon EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceNoch keine Bewertungen

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideVon EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideBewertung: 4 von 5 Sternen4/5 (8)

- Sewage Pumping HandbookDokument12 SeitenSewage Pumping Handbookmfhaleem@pgesco.comNoch keine Bewertungen

- Api682 Iso21049 John Crane General CommentsDokument62 SeitenApi682 Iso21049 John Crane General CommentsMixtli Garcia100% (4)

- Cooling Tower Fundamentals PDFDokument117 SeitenCooling Tower Fundamentals PDFsoumenhazraNoch keine Bewertungen

- ReviewofWearandGallingCharacteristicsofStainlessSteel 9006Dokument0 SeitenReviewofWearandGallingCharacteristicsofStainlessSteel 9006fahreezNoch keine Bewertungen

- Sump Pump Manual (6!15!2016)Dokument14 SeitenSump Pump Manual (6!15!2016)mfhaleem@pgesco.comNoch keine Bewertungen

- Fire Pump Testing E211 0Dokument9 SeitenFire Pump Testing E211 0mfhaleem@pgesco.comNoch keine Bewertungen

- Oil and Gas Production Handbook Ed3x0 - WebDokument2 SeitenOil and Gas Production Handbook Ed3x0 - Webmfhaleem@pgesco.comNoch keine Bewertungen

- GRUNDFOS - Sewage Handbook - LowDokument118 SeitenGRUNDFOS - Sewage Handbook - Lowrdavid@hotmail.it100% (1)

- Turbine Overspeed Systems and Required Response Times Rev B.01Dokument30 SeitenTurbine Overspeed Systems and Required Response Times Rev B.01mfhaleem@pgesco.comNoch keine Bewertungen

- Hayward Tyler AR2015Dokument96 SeitenHayward Tyler AR2015mfhaleem@pgesco.comNoch keine Bewertungen

- Compressor Tech June 2014 PDFDokument89 SeitenCompressor Tech June 2014 PDFmfhaleem@pgesco.comNoch keine Bewertungen

- 3B 1fox PDFDokument27 Seiten3B 1fox PDFmfhaleem@pgesco.comNoch keine Bewertungen

- Product-Lubricated Pump Bearings: Erwin LeibundgutDokument4 SeitenProduct-Lubricated Pump Bearings: Erwin Leibundgutmfhaleem@pgesco.comNoch keine Bewertungen

- API 610 Pump Selection and Curve EvaluationDokument4 SeitenAPI 610 Pump Selection and Curve EvaluationbbmokshNoch keine Bewertungen

- Design of Centrifugal Pump For Produced Water: Sverre Stefanussen FoslieDokument155 SeitenDesign of Centrifugal Pump For Produced Water: Sverre Stefanussen Fosliemfhaleem@pgesco.comNoch keine Bewertungen

- Thordon PropShaftBrochure Int PDFDokument8 SeitenThordon PropShaftBrochure Int PDFmfhaleem@pgesco.comNoch keine Bewertungen

- Fire Pump PropertiesDokument62 SeitenFire Pump Propertiesyamaha100% (2)

- Fire Pump Essentials - Derek ThompsonDokument24 SeitenFire Pump Essentials - Derek Thompsonmfhaleem@pgesco.comNoch keine Bewertungen

- Orifice KsoDokument2 SeitenOrifice Ksomfhaleem@pgesco.comNoch keine Bewertungen

- 10 1115@power2015-49551Dokument8 Seiten10 1115@power2015-49551mfhaleem@pgesco.comNoch keine Bewertungen

- Wang LigangDokument198 SeitenWang Ligangmfhaleem@pgesco.comNoch keine Bewertungen

- Ccc221coalpowerR MDokument58 SeitenCcc221coalpowerR Mmfhaleem@pgesco.comNoch keine Bewertungen

- Discover The Power Within:: LUV Boiler Recirculation PumpsDokument8 SeitenDiscover The Power Within:: LUV Boiler Recirculation Pumpsmfhaleem@pgesco.comNoch keine Bewertungen

- HELE coal-fired power generation: current technology and future prospectsDokument24 SeitenHELE coal-fired power generation: current technology and future prospectsmfhaleem@pgesco.comNoch keine Bewertungen

- Disk CouplingDokument36 SeitenDisk Couplingmfhaleem@pgesco.comNoch keine Bewertungen

- HLVDokument7 SeitenHLVmfhaleem@pgesco.comNoch keine Bewertungen

- 2 Pga 2008Dokument30 Seiten2 Pga 2008mfhaleem@pgesco.comNoch keine Bewertungen

- External hydraulic balance line reduces pump wearDokument1 SeiteExternal hydraulic balance line reduces pump wearmfhaleem@pgesco.comNoch keine Bewertungen

- Mesh To Micron ConverterDokument1 SeiteMesh To Micron ConverterAniket royNoch keine Bewertungen

- Flare Gas Ignition System: For Oil and Gas Producing Facilities and Petrochemical PlantsDokument2 SeitenFlare Gas Ignition System: For Oil and Gas Producing Facilities and Petrochemical Plantsdebasish bhowmickNoch keine Bewertungen

- Uop Benfield Datasheet PDFDokument2 SeitenUop Benfield Datasheet PDFArya YudistiraNoch keine Bewertungen

- Here UN Eets Ater: W S M WDokument37 SeitenHere UN Eets Ater: W S M Wsandeep devabhaktuniNoch keine Bewertungen

- FFC TestDokument16 SeitenFFC TestArslan Arshad100% (1)

- Analysis of Power Plant Deaerator Under Transient Turbine LoadsDokument9 SeitenAnalysis of Power Plant Deaerator Under Transient Turbine LoadsTanju OralNoch keine Bewertungen

- 60 TPH Technical SheduleDokument32 Seiten60 TPH Technical SheduleSeenu HassanNoch keine Bewertungen

- Remark SN Particulars: Left TOP Front Left TOP FrontDokument6 SeitenRemark SN Particulars: Left TOP Front Left TOP FrontPankaj PandeyNoch keine Bewertungen

- Ventilation in Hospital ProjectsDokument18 SeitenVentilation in Hospital ProjectsMAGDY KAMELNoch keine Bewertungen

- CPV10 14 PSI US Valve ManifoldDokument2 SeitenCPV10 14 PSI US Valve ManifoldAmir AlibegovićNoch keine Bewertungen

- DLN Combustion Systems ExplainedDokument49 SeitenDLN Combustion Systems ExplainedSahariar Bin Shafique100% (1)

- Performance Review of Thermal Power Stations 2011-12: Sl. No Name of Station Unit No Organisation CapacityDokument4 SeitenPerformance Review of Thermal Power Stations 2011-12: Sl. No Name of Station Unit No Organisation Capacitys_banerjeeNoch keine Bewertungen

- 400 KVA Data SheetDokument3 Seiten400 KVA Data SheetYasirSwatiNoch keine Bewertungen

- Gas CompressionDokument10 SeitenGas Compressionmelannie adanteNoch keine Bewertungen

- Pressure Relief Valves HenryDokument7 SeitenPressure Relief Valves HenryOSCAR ASIAINNoch keine Bewertungen

- Condensate Pot Hook UpDokument3 SeitenCondensate Pot Hook UpGoogool YNoch keine Bewertungen

- SOM Lab EXP8Dokument9 SeitenSOM Lab EXP8Amisha SharonNoch keine Bewertungen

- Topic: Reheat, Regenerative & Other Steam Power CycleDokument17 SeitenTopic: Reheat, Regenerative & Other Steam Power CycleMurvin VillarosaNoch keine Bewertungen

- Auha 36 LatnDokument28 SeitenAuha 36 LatnJuan Antonio Martinez MarinNoch keine Bewertungen

- Ras Al Khaimah Cement CompanyDokument351 SeitenRas Al Khaimah Cement CompanyHerwin NavarreteNoch keine Bewertungen

- Thermal Engineering I MANUALDokument35 SeitenThermal Engineering I MANUALKalpit KauraseNoch keine Bewertungen

- IC Engines (Asst 2)Dokument2 SeitenIC Engines (Asst 2)narasimha raoNoch keine Bewertungen

- BS5440 Quick GuideDokument4 SeitenBS5440 Quick Guidenyj martin100% (2)

- Previous ResearchDokument2 SeitenPrevious ResearchsudhakarNoch keine Bewertungen

- Cold Start UpDokument31 SeitenCold Start UpJijo JoseNoch keine Bewertungen

- Brochure AC FIREDokument8 SeitenBrochure AC FIREPablo Martin Ruiz VirruetaNoch keine Bewertungen

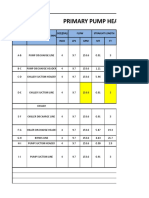

- 12.primary Pump Head CalculationDokument4 Seiten12.primary Pump Head CalculationZain ShariffNoch keine Bewertungen

- How To Size A PumpDokument90 SeitenHow To Size A PumpDaani Olora100% (5)

- Fundamentals of Combustions and Combustion EquipmentDokument18 SeitenFundamentals of Combustions and Combustion EquipmentEngr Mujahid MehdiNoch keine Bewertungen

- Motorpal Despiece InyeccionDokument25 SeitenMotorpal Despiece InyeccionЕкатерина Калашникова0% (1)

- Mitsubishi Diesel Engine Technical Information: Specification Sheets of S16R-PTA2 EngineDokument4 SeitenMitsubishi Diesel Engine Technical Information: Specification Sheets of S16R-PTA2 EnginefendynovapamelaNoch keine Bewertungen