Beruflich Dokumente

Kultur Dokumente

Selection Guide For Hot Mounting

Hochgeladen von

Can ERTANOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Selection Guide For Hot Mounting

Hochgeladen von

Can ERTANCopyright:

Verfügbare Formate

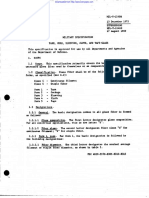

SELECTION GUIDE FOR HOT MOUNTING

Type ClaroFast CitoFast ConduFast DuroFast LevoFast PolyFast MultiFast

Melamine with

Acryl with aluminium Acryl with Epoxy with Bakelite with carbon Bakelite with

Material Acryl

filler iron filler mineral filler

mineral and

filler wood filler

glass filler

Type Thermoplastic Thermoplastic Thermoplastic Thermosetting Thermosetting Thermosetting Thermosetting

Clear, Metallic Dark grey Black Light beige Black Black, Green

Colour transparent (old mounts or Red

yellowish)

Shrinkage

From 1 -3 (1 is best)

Hardness

(1 is softes)

Removal rate High High High Low High High Medium

Process parameters*

Quantity ml 20 20 20 20 25 20 25

Heating min. 4 2.5 3.5 3.5 3.5 3.5 3

Heating pressure (bar) 350 300 250 325 250 250 250

Cooling min. 6.5 1 1.5 2 2 1.5 2

Cooling rate Low High High High High High High

Total process time* min. 10.5 3.5 5 5.5 5.5 5 5

Density of cured material

g/ml 1.15 1.9 2.45 2.05 1.8 1.6 1.45

Very fast mounting.

Clear mounts. Low process Routine

Excellent

Porous specimens. times also Excellent examination of

Electrolytic edge retention.

Application Surface electrical when it is used

polishing

edge retention.

For soft to medium

SEM examination. soft to medium hard

insulator for as backing For hard materials. materials.

hard materials.

ConduFast. for DuroFast Colour coding.

or LevoFast.

Most common Most common

Affected by Affected by

Chemical resistance acids and bases. acids and bases.

Affected by acetone and acetone and Most common Most common

Affected by Affected by

after curing acetone aluminium iron solving acids and bases. acids and bases.

liquids containing liquids containing

solving liquids liquids.

hydrofluoric acid. hydrofluoric acid.

*Process time at 180 C/356 F for a 30 mm dia. mount with 20 vol% 0.45 carbon steel specimen.

Das könnte Ihnen auch gefallen

- 2017-4.1 Columbia - HavelDokument19 Seiten2017-4.1 Columbia - HavelSandro FelixNoch keine Bewertungen

- Pressure Requirements: Flow LengthDokument43 SeitenPressure Requirements: Flow Lengthanirudha_jewalikar1100% (2)

- Newnes Engineering Materials Pocket BookVon EverandNewnes Engineering Materials Pocket BookBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Materials Processing and Manufacturing ScienceVon EverandMaterials Processing and Manufacturing ScienceBewertung: 5 von 5 Sternen5/5 (3)

- BS en Iso 13919-1-2019Dokument24 SeitenBS en Iso 13919-1-2019Can ERTAN100% (2)

- Eor Gas InjectionDokument45 SeitenEor Gas InjectionYustitiaNoch keine Bewertungen

- Rubber Compounds TableDokument2 SeitenRubber Compounds TableSrikanth Pothapragada100% (2)

- Galvanized Steel Vs Zinc Rich PaintDokument2 SeitenGalvanized Steel Vs Zinc Rich PaintImam SitumeangNoch keine Bewertungen

- Boronizing AVIONDokument37 SeitenBoronizing AVIONManwi Khandelwal100% (1)

- Heat Cure Vs Cold CureDokument1 SeiteHeat Cure Vs Cold CureMariam AdnanNoch keine Bewertungen

- Porosity Specific Surface Area Practice GuideDokument91 SeitenPorosity Specific Surface Area Practice Guidesilentpolter100% (2)

- Hot Water Supply ch.2 PDFDokument55 SeitenHot Water Supply ch.2 PDFasmaaasmaaa asmaa100% (1)

- Day 2 200 ItemsDokument25 SeitenDay 2 200 ItemsRobert DelfinNoch keine Bewertungen

- Fanuc Sensor65162e - 03Dokument659 SeitenFanuc Sensor65162e - 03sicstone100% (2)

- BurnerDokument33 SeitenBurnertoficNoch keine Bewertungen

- ASTM A903 - 12 Standard Specification For Steel Castings, Surface Acceptance Standards, Magnetic Particle and Liquid Penetrant InspectionDokument2 SeitenASTM A903 - 12 Standard Specification For Steel Castings, Surface Acceptance Standards, Magnetic Particle and Liquid Penetrant InspectionCan ERTANNoch keine Bewertungen

- High Rise Structural Systems: Presented byDokument35 SeitenHigh Rise Structural Systems: Presented byvidi herdianaNoch keine Bewertungen

- Metallographic Specimen Preparation Basics: by Donald C. Zipperian, Ph.D. Pace TechnologiesDokument14 SeitenMetallographic Specimen Preparation Basics: by Donald C. Zipperian, Ph.D. Pace Technologiesrazor75apNoch keine Bewertungen

- Weekly Report Part 222Dokument38 SeitenWeekly Report Part 222Julian Paul Villaruel QuerubinNoch keine Bewertungen

- Surface Finish Cross ReferenceDokument1 SeiteSurface Finish Cross ReferencemarcalpiNoch keine Bewertungen

- TPE-TPV Sarlink 4155 ProspectorDokument4 SeitenTPE-TPV Sarlink 4155 ProspectorcountzeroaslNoch keine Bewertungen

- Copper alloy data for valves and hardwareDokument12 SeitenCopper alloy data for valves and hardwareCristianoRoecherNoch keine Bewertungen

- Hoja-Tecnica-3m Scotch-Weld Epoxy Adhesive DP460 Off WhiteDokument15 SeitenHoja-Tecnica-3m Scotch-Weld Epoxy Adhesive DP460 Off WhiteJOEL EZEQUIEL PACHECO MENANoch keine Bewertungen

- 4 ProductDokument37 Seiten4 ProductDinesh TaragiNoch keine Bewertungen

- Compare HFW, SAWH and SAWL Welding MethodsDokument1 SeiteCompare HFW, SAWH and SAWL Welding MethodsWojciech SpychalskiNoch keine Bewertungen

- Chemical Composition: Copper Alloy DataDokument11 SeitenChemical Composition: Copper Alloy DataKen ChingNoch keine Bewertungen

- Copper Alloy C95200Dokument11 SeitenCopper Alloy C95200Lin DouaiNoch keine Bewertungen

- Kaowool Blanket: Thermal CeramicsDokument2 SeitenKaowool Blanket: Thermal CeramicsAlan GutierrezNoch keine Bewertungen

- Cargill Altor 205LV RDokument2 SeitenCargill Altor 205LV RHakan EKİNCİNoch keine Bewertungen

- The Importance of Machine Variables in Adhesion for Extrusion Coating & LaminatingDokument66 SeitenThe Importance of Machine Variables in Adhesion for Extrusion Coating & LaminatingHari Shanker MishraNoch keine Bewertungen

- AmberPress Users Manual 0606EN 170706Dokument18 SeitenAmberPress Users Manual 0606EN 170706mrahNoch keine Bewertungen

- PC-ABS Bayblend FR110Dokument3 SeitenPC-ABS Bayblend FR110countzeroaslNoch keine Bewertungen

- Array process overviewDokument8 SeitenArray process overviewJawahar DasNoch keine Bewertungen

- Powder Coating Technology P2 SheetDokument6 SeitenPowder Coating Technology P2 Sheetneeraj2184Noch keine Bewertungen

- Insulation Jacket PropertiesDokument1 SeiteInsulation Jacket PropertiesEasy Energy SACNoch keine Bewertungen

- Polytone: ABR Series/Thermoplastic Acrylic ResinsDokument7 SeitenPolytone: ABR Series/Thermoplastic Acrylic ResinsAdhvik PuriNoch keine Bewertungen

- Benzoic AcidDokument2 SeitenBenzoic AcidizzybjNoch keine Bewertungen

- PDF Elastomerguide PDFDokument1 SeitePDF Elastomerguide PDFCristhianVilchezNoch keine Bewertungen

- Selection Guide For Cold MountingDokument2 SeitenSelection Guide For Cold MountingSee Toh GeraldNoch keine Bewertungen

- Powder Metallurgy PDFDokument85 SeitenPowder Metallurgy PDFharsurajNoch keine Bewertungen

- Laser Comparison ChartDokument1 SeiteLaser Comparison ChartHung LeNoch keine Bewertungen

- Chapter 7 Others Construction MaterialsDokument61 SeitenChapter 7 Others Construction MaterialsNabil FarhanNoch keine Bewertungen

- Vistamaxx™ 6202: Performance PolymerDokument2 SeitenVistamaxx™ 6202: Performance PolymerJose Luis Arana AguilarNoch keine Bewertungen

- Copper Alloy C37700 PDFDokument10 SeitenCopper Alloy C37700 PDFMisaelNoch keine Bewertungen

- Technical Data of Adtech Fluoroplastic Polymers: Servicios E Importaciones Especializadas S.A. de C.VDokument1 SeiteTechnical Data of Adtech Fluoroplastic Polymers: Servicios E Importaciones Especializadas S.A. de C.VEdgar LucianoNoch keine Bewertungen

- 3m Adhesive Sealant BrochureDokument6 Seiten3m Adhesive Sealant BrochureJP anonymousNoch keine Bewertungen

- High-performance compression transducers for NDT applicationsDokument2 SeitenHigh-performance compression transducers for NDT applicationsRajaprasannakumarDPillaiNoch keine Bewertungen

- 4107Dokument49 Seiten4107Aaditya NaikNoch keine Bewertungen

- BESTARC The Most Power Efficient ElectrodeDokument1 SeiteBESTARC The Most Power Efficient Electrodesenthil4youNoch keine Bewertungen

- Chapter 7 Others Construction MaterialsDokument61 SeitenChapter 7 Others Construction Materialswan hazirahNoch keine Bewertungen

- Chemical Composition: Copper Alloy DataDokument11 SeitenChemical Composition: Copper Alloy DataLin DouaiNoch keine Bewertungen

- LOTHERME Ready Reckoner PDFDokument40 SeitenLOTHERME Ready Reckoner PDFAmit DuttaNoch keine Bewertungen

- TDS BorSafe ME3444 (E115026)Dokument2 SeitenTDS BorSafe ME3444 (E115026)charlesNoch keine Bewertungen

- Cutting Tool MaterialsDokument26 SeitenCutting Tool MaterialsMaheshwar DwivedyNoch keine Bewertungen

- POM Delrin 100Dokument5 SeitenPOM Delrin 100countzeroaslNoch keine Bewertungen

- Welcomes: Protecting The World From WearDokument30 SeitenWelcomes: Protecting The World From WearRodolfoMarínNoch keine Bewertungen

- 3m_lava_zirc_sci_facts_zirc_manufDokument2 Seiten3m_lava_zirc_sci_facts_zirc_manufwuhan lalalaNoch keine Bewertungen

- Comparison of PB PPR CPVC PeDokument7 SeitenComparison of PB PPR CPVC PePinyaporn VeerapraditNoch keine Bewertungen

- Electroplating: Northbrook, IL 847.528.3467Dokument14 SeitenElectroplating: Northbrook, IL 847.528.3467Halim BoucettaNoch keine Bewertungen

- Comparison Report of Packaging Films Ver-01 Dt. 30.04.2020 PDFDokument11 SeitenComparison Report of Packaging Films Ver-01 Dt. 30.04.2020 PDFSachin KothariNoch keine Bewertungen

- Ceramic wool mattress technical data sheetDokument1 SeiteCeramic wool mattress technical data sheetMohamed KhaledNoch keine Bewertungen

- Precision Ground 7075 Aluminum SheetDokument3 SeitenPrecision Ground 7075 Aluminum SheetHassan HelmyNoch keine Bewertungen

- Metallic Sample Preparation For EBSD by Mechanical Method and Argon Ion Beam MillingDokument5 SeitenMetallic Sample Preparation For EBSD by Mechanical Method and Argon Ion Beam MillingGee AbrahamNoch keine Bewertungen

- Poplar FBB - Shandong MillDokument1 SeitePoplar FBB - Shandong MillBill KingNoch keine Bewertungen

- Powders: Technical, Application & Safety DataDokument8 SeitenPowders: Technical, Application & Safety DataphuongNoch keine Bewertungen

- Ceramics and Ceramic Composites: Materialographic PreparationVon EverandCeramics and Ceramic Composites: Materialographic PreparationNoch keine Bewertungen

- Nozzle Clogging For Si' Killed Steel: Continuous Casting 32Dokument1 SeiteNozzle Clogging For Si' Killed Steel: Continuous Casting 32Can ERTANNoch keine Bewertungen

- ASTM E45-18 Standard Test Methods For Determining The Inclusion Content of SteelDokument19 SeitenASTM E45-18 Standard Test Methods For Determining The Inclusion Content of SteelCan ERTANNoch keine Bewertungen

- Post-Mortem Ladle Shroud Analysis From The Casting of Al-Killed Steel: Microstructures and Origin of Alumina Clogging DepositsDokument15 SeitenPost-Mortem Ladle Shroud Analysis From The Casting of Al-Killed Steel: Microstructures and Origin of Alumina Clogging DepositsCan ERTANNoch keine Bewertungen

- ASTM D4289-03 Standard Test Method For Elastomer Compatibility of Lubricating Greases and FluidsDokument8 SeitenASTM D4289-03 Standard Test Method For Elastomer Compatibility of Lubricating Greases and FluidsCan ERTANNoch keine Bewertungen

- A703 - A 703m - 04 Qtcwmy9bnzaztqDokument16 SeitenA703 - A 703m - 04 Qtcwmy9bnzaztqLemir LopezNoch keine Bewertungen

- Casting - Overhead - Nick MeyerDokument9 SeitenCasting - Overhead - Nick Meyerez2cdaveNoch keine Bewertungen

- Test Ink Blue 30-58 English FTTDokument11 SeitenTest Ink Blue 30-58 English FTTCan ERTANNoch keine Bewertungen

- General Presentation: Chemical Composition C Si MN Ni CR Cu Mo N P SDokument7 SeitenGeneral Presentation: Chemical Composition C Si MN Ni CR Cu Mo N P SCan ERTANNoch keine Bewertungen

- BS en 10222-1-2017Dokument28 SeitenBS en 10222-1-2017rahul mehta100% (2)

- MSF 730-732 733Dokument7 SeitenMSF 730-732 733Can ERTANNoch keine Bewertungen

- Fast Pulse Width Modulation (FPWM) Technology For DC-DC Converter, Featuring High-Speed Response With A Clock-Synchronized Comparator Control MethodDokument2 SeitenFast Pulse Width Modulation (FPWM) Technology For DC-DC Converter, Featuring High-Speed Response With A Clock-Synchronized Comparator Control MethodCan ERTANNoch keine Bewertungen

- 4 Principles To Make Sure The Beautiful Chords SOUND Beautiful IndeedDokument8 Seiten4 Principles To Make Sure The Beautiful Chords SOUND Beautiful IndeedCan ERTANNoch keine Bewertungen

- The Chord Reset (4 Variations)Dokument8 SeitenThe Chord Reset (4 Variations)Can ERTANNoch keine Bewertungen

- In and OutDokument1 SeiteIn and OutCan ERTANNoch keine Bewertungen

- The Foundation Finger - The Underlying Principle of Learning Chords FASTDokument5 SeitenThe Foundation Finger - The Underlying Principle of Learning Chords FASTCan ERTANNoch keine Bewertungen

- Steel-Purchasing 23.06.2004 PDFDokument25 SeitenSteel-Purchasing 23.06.2004 PDFCan ERTAN100% (1)

- FKM ChlorineDokument1 SeiteFKM ChlorineCan ERTANNoch keine Bewertungen

- Blank Guitar Neck Fretboard Charts 7 Diagrams Per Page by Jay Skyler 8 5X11 Paper Half Inch Margin PDFDokument1 SeiteBlank Guitar Neck Fretboard Charts 7 Diagrams Per Page by Jay Skyler 8 5X11 Paper Half Inch Margin PDFCan ERTANNoch keine Bewertungen

- Full Width Half MaximumDokument1 SeiteFull Width Half MaximumCan ERTANNoch keine Bewertungen

- Clone RecepieDokument1 SeiteClone RecepieCan ERTANNoch keine Bewertungen

- Tshirt War Is Peace Freedom Is Slavery and Ignorance Is Strength 1984 d0012828050Dokument2 SeitenTshirt War Is Peace Freedom Is Slavery and Ignorance Is Strength 1984 d0012828050Can ERTANNoch keine Bewertungen

- Cans LagerDokument1 SeiteCans LagerCan ERTANNoch keine Bewertungen

- How To GTA Way With MurderDokument1 SeiteHow To GTA Way With MurderCan ERTANNoch keine Bewertungen

- ASTM E6-09b Standard Terminology Relating To Methods of Mechanical TestingDokument27 SeitenASTM E6-09b Standard Terminology Relating To Methods of Mechanical TestingPacifier Nothingface0% (1)

- Hu 2014Dokument4 SeitenHu 2014Can ERTANNoch keine Bewertungen

- BainiteDokument5 SeitenBainiteCan ERTANNoch keine Bewertungen

- For The Upload PurposeDokument1 SeiteFor The Upload PurposeCan ERTANNoch keine Bewertungen

- Formula One - Technical Regulations - 2017Dokument91 SeitenFormula One - Technical Regulations - 2017antoniocdof1Noch keine Bewertungen

- Schneider Electric Staj DefteriDokument15 SeitenSchneider Electric Staj DefteriYavuz KaplanNoch keine Bewertungen

- WBS codes and activity tracking for electrical, BMS, mechanical and plumbing worksDokument8 SeitenWBS codes and activity tracking for electrical, BMS, mechanical and plumbing workskalyaniNoch keine Bewertungen

- Eclipse Airheat Burners: Ah-Ma SeriesDokument4 SeitenEclipse Airheat Burners: Ah-Ma Seriespanait trofinNoch keine Bewertungen

- NFPA Ratings / NFPA Diamond: (NFPA - National Fire Protection Association) Participant GuideDokument7 SeitenNFPA Ratings / NFPA Diamond: (NFPA - National Fire Protection Association) Participant GuideBenito.camelasNoch keine Bewertungen

- English For Industrial Machinery StudentsDokument4 SeitenEnglish For Industrial Machinery StudentsDíaz YvonneNoch keine Bewertungen

- Specification for glass fiber yarn, cordage, sleeving, cloth, and tapeDokument37 SeitenSpecification for glass fiber yarn, cordage, sleeving, cloth, and tapeMichael SkrableNoch keine Bewertungen

- Copper Alloy Guide EngDokument3 SeitenCopper Alloy Guide EngRishi SharmaNoch keine Bewertungen

- FM 200 Properties Uses Storage HandlingDokument16 SeitenFM 200 Properties Uses Storage HandlingAfsal NangathanNoch keine Bewertungen

- Social Icons: C-80 GradeDokument3 SeitenSocial Icons: C-80 GradeEdward OropezaNoch keine Bewertungen

- Simlpe Oscillating Steam MachineDokument2 SeitenSimlpe Oscillating Steam Machinehamzah40Noch keine Bewertungen

- Gate 1998 PDFDokument14 SeitenGate 1998 PDFVammsy Manikanta SaiNoch keine Bewertungen

- EDGE Wire Diagram R3 (FR)Dokument2 SeitenEDGE Wire Diagram R3 (FR)Peeyush AgarwalNoch keine Bewertungen

- PF Ds The Ultimate Technology in Separation and Washing 2020 05-27-608185Dokument40 SeitenPF Ds The Ultimate Technology in Separation and Washing 2020 05-27-608185Marcel MendivilNoch keine Bewertungen

- Vechi RWX62Dokument18 SeitenVechi RWX62Mihai ConstantinescuNoch keine Bewertungen

- Harmony Xb4 Xb4bd25Dokument4 SeitenHarmony Xb4 Xb4bd25Ismael AhmedNoch keine Bewertungen

- Inductive Proximity Sensors PDFDokument231 SeitenInductive Proximity Sensors PDFHassan AliNoch keine Bewertungen

- Volute Dwatering Press-Technical BrochureDokument19 SeitenVolute Dwatering Press-Technical BrochureGeorge CobraNoch keine Bewertungen

- Einhell BT-TB 13 e Manual ENDokument20 SeitenEinhell BT-TB 13 e Manual ENGustavs KrievkalnsNoch keine Bewertungen

- Turnbuckle AssembliesDokument4 SeitenTurnbuckle AssembliesarbiNoch keine Bewertungen

- Moisture Control Part 4Dokument36 SeitenMoisture Control Part 4Karthik RajendrenNoch keine Bewertungen

- Laboratory Experimental Testing and Development of An Efficient Low Pressure ES-SAGD ProcessDokument8 SeitenLaboratory Experimental Testing and Development of An Efficient Low Pressure ES-SAGD Processpedro aguilarNoch keine Bewertungen

- VIBRATORY ROLLER OPERATOR'S MANUALDokument43 SeitenVIBRATORY ROLLER OPERATOR'S MANUALkadaimamak100% (1)