Beruflich Dokumente

Kultur Dokumente

Qatar Rail Fencing Specification

Hochgeladen von

Mikku KattaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Qatar Rail Fencing Specification

Hochgeladen von

Mikku KattaCopyright:

Verfügbare Formate

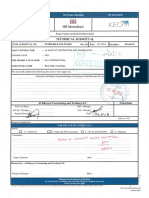

EMPLOYER:

QATAR RAILWAYS COMPANY

P.O. BOX 29988

Doha State of Qatar

CONTRACTOR:

P.O. Box 31412

Doha State of Qatar

LEAD DESIGNER: ARCHITECTURAL

DESIGNER:

P.O. Box 24656 P.O. Box 31412

Doha State of Qatar Doha, Qatar

0.1 2016-09-09 MAM VAN YRE Issued for Review

Date Issue Review Approval

Rev. (YYYY-MM-DD) Designer Contractor Contractor Description

PROJECT:

RED LINE SOUTH UNDERGROUND

ARCHITECTURAL PROVISIONAL SUM WORKS

TITLE:

ARCHITECTURAL FINISHES - TECHNICAL SPECIFICATION

Q40 FENCING

M 0 0 3 Q G D A R C S P E 6 9 4 6 5 0.1

Project Code Organization Code Discipline Code Document Type Sequence No. Rev.

M003-QGD-QMS-FRM-00034 Rev. 8 Date of Form: 2015-12-08

ARCHITECTURAL FINISHES - TECHNICAL SPECIFICATION

Q40 FENCING

RED LINE SOUTH UNDERGROUND

Date: 2016-09-09 Codification: M003-QGD-ARC-SPE-69465 Rev: 0.1 Page 2 of 11

DESIGN REVIEW AND APPROVAL:

0.1 2016-09-09 SVI FBE MAM KDI Issued for Review

Date Issue Review Approval Approval

Rev. (YYYY-MM-DD) Designer Designer Designer Arcadis Description

DOCUMENT INFORMATION (TO BE FILLED BY ISSUER)

WBS SECTION OF WORKS RSSTNNN

WBS MAJOR WORKS ARCHITECTURAL FINISHES

PROJECT STAGE Detailed Design

DESIGN STAGE M4

SUMMARY OF DOCUMENT CHANGES

Page Chapter Modifications

M003-QGD-QMS-FRM-00034 Rev. 8 Date of Form: 2015-12-08

ARCHITECTURAL FINISHES - TECHNICAL SPECIFICATION

Q40 FENCING

RED LINE SOUTH UNDERGROUND

Date: 2016-09-09 Codification: M003-QGD-ARC-SPE-69465 Rev: 0.1 Page 3 of 11

Table of Contents

Q40 FENCING ......................................................................................................................4

GENERAL NOTES..................................................................................................................... 4

SECTION INCLUDES................................................................................................................. 4

SCOPE OF SECTION ................................................................................................................. 5

GSAS GLOBAL SUSTAINABILITY ASSESSMENT SYSTEM .......................................................... 5

SPECIFIC REQUIREMENTS ....................................................................................................... 5

000/FIR FIRE PROTECTION ..............................................................................................................................5

000/TOL TOLERANCES ......................................................................................................................................6

000/SPA SPARES ...............................................................................................................................................6

000/SUB DOCUMENTS TO BE SUBMITTED .......................................................................................................6

FENCING SYSTEMS ................................................................................................................. 8

Q40/126A OPEN MESH STEEL PANEL SECURITY FENCING..................................................................................8

Q40/126B OPEN MESH STEEL PANEL SECURITY FENCING - standard fence ......................................................8

Q40/126C OPEN MESH STEEL PANEL SECURITY FENCING - future development design/ advertisement fence

...........................................................................................................................................................8

Q40/126D OPEN MESH STEEL PANEL SECURITY FENCING - station identity fence ............................................8

Q40/126E OPEN MESH STEEL PANEL SECURITY FENCING - landscape fence ....................................................9

Q40/340 STEEL VERTICAL BAR FENCING ..........................................................................................................9

EXECUTION ............................................................................................................................ 9

Q40/710 INSTALLATION GENERALLY ................................................................................................................9

Q40/720 SETTING POSTS IN CONCRETE ...........................................................................................................9

Q40/780 MAKING GOOD GALVANIZED SURFACES........................................................................................ 10

Q40/790 SITE PAINTING ................................................................................................................................ 10

COMPLETION ....................................................................................................................... 10

Q40/910 CLEANING ....................................................................................................................................... 10

Q40/920 FIXINGS ........................................................................................................................................... 10

Q40/930 GATES ............................................................................................................................................. 10

ANNEX: SUSTAINABILITY/GSAS MATERIAL ASSESSMENT FORM ............................................. 11

M003-QGD-QMS-FRM-00034 Rev. 8 Date of Form: 2015-12-08

ARCHITECTURAL FINISHES - TECHNICAL SPECIFICATION

Q40 FENCING

RED LINE SOUTH UNDERGROUND

Date: 2016-09-09 Codification: M003-QGD-ARC-SPE-69465 Rev: 0.1 Page 4 of 11

Q40 FENCING

To be read with Preliminaries/ General conditions.

GENERAL NOTES

- Terms and abbreviations:

- RLS-JV Red Line South Underground JV

- ABM Architectural Branding Manual

- ER Employers Requirements

- GSAS Global Sustainability Assessment System

- NBS National Building Specification

- FOH Front of House

- BOH Back of House

- Material codes:

- The base Material Code (i.e. A01) is the base material from the Architectural Branding Manual

and is reflected on the finishes drawings.

- The material code with suffix is used in Finishes Specifications where additional information

are required, based on different finishing technical system or location.

- Some of the Material Codes have alternative material options (described as option A, option

B, etc.)

- Related documents:

- The present document shall be read in conjunction with the contract design documents.

- For full material list, refer to the specific documents and schedules within the contract design

documents.

- For full list of material specifications refer to the dedicated Codes Reference Schedule For

Specifications

SECTION INCLUDES

The present section relates to:

- the following ABM codes:

- none

- general specification (refer to table of contents)

- all the contents specified in the SCOPE OF SECTION.

M003-QGD-QMS-FRM-00034 Rev. 8 Date of Form: 2015-12-08

ARCHITECTURAL FINISHES - TECHNICAL SPECIFICATION

Q40 FENCING

RED LINE SOUTH UNDERGROUND

Date: 2016-09-09 Codification: M003-QGD-ARC-SPE-69465 Rev: 0.1 Page 5 of 11

SCOPE OF SECTION

This section deals with wood, metal, plastics and concrete fencing, railings and screens to control

access or provide visual or noise screening, with associated gates.

This section does not include:

- Hoardings and site fencing erected by the contractor these should not be specified. For special

requirements such as signing, corporate colours, vision panels, etc., see Preliminaries section

A36.

- Temporary protection to existing trees and vegetation erected by the contractor - see

Preliminaries section A36.

- Handrailings and balustrades - see section L30.

- Painting and clear finishing - see section M60.

- Barriers and guardrails, including sports ground barriers - see section Q41.

- Gates not part of a fence - see section Q50.

- Access control systems - see section W90 or Engineering services section W40.

GSAS GLOBAL SUSTAINABILITY ASSESSMENT SYSTEM

Materials used in the project should originate from sources with a documented Environmental

Management System (EMS). The EMS should adhere to the principles covered in ISO 14001.

As per GSAS Railways Design Assessment Manual v2.1 requirements for the following criteria:

- M.1: to consider locally sourced/locally assembled materials

- M.2: BS8902:2009; ISO26000; ISO14001; ISO9001

- M.3: consider materials made with recycled content or % recycled content

- M.7: consider materials with Environmental Product Declaration Study (EPD)

- IE.9: consider low emitting materials with VOC those specified in the attached GSAS Material

Form

NOTE: Attached Sustainability/GSAS Material Assessment form to be completed for any material

provided by other proposed suppliers/manufacturers.

SPECIFIC REQUIREMENTS

The finishing materials shall comply with the following requirements, included in Volume 6 -

Employers Requirements - Design Specifications, unless otherwise herein specified.

000/FIR FIRE PROTECTION

- Architectural/Interior finishes shall comply with the related requirements of NFPA 130 (2010

edition) and Qatar Civil Defence Department (QCDD).

- Specific certificate of finishes material compliance shall be provided.

M003-QGD-QMS-FRM-00034 Rev. 8 Date of Form: 2015-12-08

ARCHITECTURAL FINISHES - TECHNICAL SPECIFICATION

Q40 FENCING

RED LINE SOUTH UNDERGROUND

Date: 2016-09-09 Codification: M003-QGD-ARC-SPE-69465 Rev: 0.1 Page 6 of 11

000/TOL TOLERANCES

- Tolerances and dimensional accuracy of materials and elements shall comply to British Standard

BS ISO 1803:1997 "Building Construction, Tolerances". Only most restrictive tolerances will be

accepted.

- More restrictive values included herein (if any) shall prevail over the above mentioned British

Standard.

000/SPA SPARES

- At completion the sufficient quantities of items and accessories for spare and maintenance work

shall be supplied.

- Items and quantities to be proposed by the Sub-Contractor for RLS-JV approval.

000/SUB DOCUMENTS TO BE SUBMITTED

- Submit the following documents:

- Technical information and certification demonstrating compliance with specification of

proposed incorporated products and finishes, including fixings and fasteners.

- Certification, reports, test results and calculations demonstrating compliance with specification

of proposed system.

- GSAS Assessment Sheet and supporting documents as evidence.

- Solar Reflectance (SR) value and test results, for external materials (including roof cladding).

- Structural, when applicable, and performance calculations.

- Manufacturers data sheets and technical documentation.

- Shop drawings showing all detailed connections between the different components of the

system and with adjacent components/ materials, including associated bracketry and fixing

requirements.

- Proposals for connections to and support from the main structure.

- Proposals for replacing damages or failed products.

- Schedule of builders work, special provisions and special attendance by others.

- Fabrication and installation method statements for carrying out the works specified in this

section.

- Standard product samples to be proposed by the Sub-Contractor for Engineers approval.

- Specific Project Quality Plan in accordance with the general Project Quality plan of the Client.

- Areas of non-compliance with specification.

- BIM models.

- Panel component reference codes.

- Material and systems technical submittals (MAR) shall also include the following information to

demonstrate compliance with Employers Requirements:

- Look and feel accepted

- DVE verification document

M003-QGD-QMS-FRM-00034 Rev. 8 Date of Form: 2015-12-08

ARCHITECTURAL FINISHES - TECHNICAL SPECIFICATION

Q40 FENCING

RED LINE SOUTH UNDERGROUND

Date: 2016-09-09 Codification: M003-QGD-ARC-SPE-69465 Rev: 0.1 Page 7 of 11

- Reference to Specification (intended use/ location/ application)

- Material data sheet - list of component data/ system information

- Material safety data sheet

- Demonstrate properties compliance

- H&S and environmental implications/ references

- Warranty and associated implications

- Durability; expected life (BS7543)

- Maintenance and cleaning implications (BS7543)

- Method of replacement (BS7543)

- Demonstrate Code compliance and test applicable to Standards and requirements:

- NFPA

- QCD FSS (Civil Defense Department - Fire Safety Standards)

- QCS (Qatar National Construction Standards)

- Testing labs on GDCD (General Directorate of Civil Defense) list

- Other certification required

- GDCD (General Directorate of Civil Defense) certification as applicable

- Other test required: i.e. slip resistance, VOC rating

- Method statement and ITP (inspection and test plan) documents referenced in the material

technical submittal including requirements for:

- Quality reference for benchmarking

- 2 Nr. control samples

M003-QGD-QMS-FRM-00034 Rev. 8 Date of Form: 2015-12-08

ARCHITECTURAL FINISHES - TECHNICAL SPECIFICATION

Q40 FENCING

RED LINE SOUTH UNDERGROUND

Date: 2016-09-09 Codification: M003-QGD-ARC-SPE-69465 Rev: 0.1 Page 8 of 11

FENCING SYSTEMS

Q40/126A OPEN MESH STEEL PANEL SECURITY FENCING

- Manufacturer: To be proposed by the Sub-Contractor for RLS-JV approval.

- Product reference: To RLS-JVs selection from the manufacturer's standard range.

- Standard: To BS 1722-14, category 1, 2, 3, 4, according to fence height.

- Height: as per contract design documents.

- Mesh and wire: Heavy wire mesh in zinc-coated steel, dimensions and spacing as per contract

design documents.

- Posts: Galvanized steel with polyester covering.

- Maximum centres of posts: as per contract design documents.

- Method of setting posts: In concrete foundations to comply with the design loading requirements

specified by BS 1722-14 for this category of fence.

- Bottom of fencing: Posts anchored to concrete base through plate and bolts.

- Accessories: Gates to match fence; dimensions as per contract design documents.

- Conformity: Submit manufacturer's and installer's certificates, to BS 1722-14.

Q40/126B OPEN MESH STEEL PANEL SECURITY FENCING - STANDARD FENCE

- Fence system as per clause 126A.

- Other requirements: Qatar Rail logo (high adhesive sticker on white board) on each panel as per

contract desing documents.

Q40/126C OPEN MESH STEEL PANEL SECURITY FENCING - FUTURE DEVELOPMENT DESIGN/

ADVERTISEMENT FENCE

- Fence system as per clause 126A.

- Other requirements:

- OPTION A: High Adhesive stickers on transparent support (e.g. polycarbonate panels) or

printed transparent textile with future development design or advertisement images

- OPTION B: Printed transparent textile with future development design or advertisement images

Q40/126D OPEN MESH STEEL PANEL SECURITY FENCING - STATION IDENTITY FENCE

- Fence system as per clause 126A.

- Other requirements:

- OPTION A: High Adhesive stickers on transparent support (e.g. polycarbonate panels) or

printed transparent textile with station identity images

- OPTION B: Printed transparent textile with station identity images

- OPTION C: 3D elements fixed on the fence (wooden board, sail, )

M003-QGD-QMS-FRM-00034 Rev. 8 Date of Form: 2015-12-08

ARCHITECTURAL FINISHES - TECHNICAL SPECIFICATION

Q40 FENCING

RED LINE SOUTH UNDERGROUND

Date: 2016-09-09 Codification: M003-QGD-ARC-SPE-69465 Rev: 0.1 Page 9 of 11

Q40/126E OPEN MESH STEEL PANEL SECURITY FENCING - LANDSCAPE FENCE

- Fence system as per clause 126A.

- Other requirements: Front climbing plants

Q40/340 STEEL VERTICAL BAR FENCING

- Manufacturer: To be proposed by the Sub-Contractor for RLS-JV approval.

- Product reference: To RLS-JVs selection from the manufacturer's standard range.

- Standard: To BS 1722-9.

- Height: as per contract design documents.

- Verticals: Round bars, as per contract design documents.

- Centres of verticals: as per contract design documents.

- Posts: RHS, dimension as per contract design documents.

- Finish: To be proposed by the Sub-Contractor for RLS-JV approval.

Colour: To be proposed by the Sub-Contractor for RLS-JV approval.

- Centres of posts (maximum): as recommended by approved manufacturer.

- Method of setting posts/ stays/ legs: as recommended by approved manufacturer.

- Accessories: Single leaf pedestrian gate.

- Conformity: Submit manufacturer's and installer's certificates, to BS 1722-9.

EXECUTION

Q40/710 INSTALLATION GENERALLY

- Set out and erect:

- Alignment: Straight lines or smoothly flowing curves.

- Tops of posts: Following profile of the ground.

- Setting posts: Rigid, plumb and to specified depth, or greater where necessary to ensure

adequate support.

- Fixings: All components securely fixed.

Q40/720 SETTING POSTS IN CONCRETE

- Standard: To BS 8500-2.

- Mix: Designated concrete not less than GEN1 or Standard prescribed concrete not less than

ST2.

- Alternative mix for small quantities: 50 kg Portland cement to 150 kg fine aggregate to 250 kg 20

mm nominal maximum size coarse aggregate, medium workability.

- Admixtures: Do not use.

- Holes: Excavate neatly and with vertical sides.

M003-QGD-QMS-FRM-00034 Rev. 8 Date of Form: 2015-12-08

ARCHITECTURAL FINISHES - TECHNICAL SPECIFICATION

Q40 FENCING

RED LINE SOUTH UNDERGROUND

Date: 2016-09-09 Codification: M003-QGD-ARC-SPE-69465 Rev: 0.1 Page 10 of 11

- Filling: Position post/ strut and fill hole with concrete to not less than the specified depth, well

rammed as filling proceeds and consolidated.

- Backfilling of holes not completely filled with concrete: Excavated material, well rammed and

consolidated.

Q40/780 MAKING GOOD GALVANIZED SURFACES

- Treatment of minor damage (including on fasteners and fittings): Low melting point zinc alloy

repair rods or powders made for this purpose, or at least two coats of zinc-rich paint to BS 4652.

- Thickness: Apply sufficient material to provide a zinc coating at least equal in thickness to the

original layer.

Q40/790 SITE PAINTING

- Timing: Prepare surfaces and apply finishes as soon as possible after fixing.

COMPLETION

Q40/910 CLEANING

- General: Leave the works in a clean, tidy condition.

- Surfaces: Clean immediately before handover.

Q40/920 FIXINGS

- All components: Tighten.

- Timing: Before handover.

Q40/930 GATES

- Hinges, latches and closers: Adjust to provide smooth operation. Lubricate where necessary.

- Timing: Before handover.

M003-QGD-QMS-FRM-00034 Rev. 8 Date of Form: 2015-12-08

ARCHITECTURAL FINISHES - TECHNICAL SPECIFICATION

Q40 FENCING

RED LINE SOUTH UNDERGROUND

Date: 2016-09-09 Codification: M003-QGD-ARC-SPE-69465 Rev: 0.1 Page 11 of 11

ANNEX: SUSTAINABILITY/GSAS MATERIAL ASSESSMENT FORM

(To be completed for any material provided by other proposed suppliers/manufacturers)

M003-QGD-QMS-FRM-00034 Rev. 8 Date of Form: 2015-12-08

MATERIAL SUSTAINABILITY ASSESSMENT SHEET

ABM

Material's Name: Supplier's Name:

Code

Contact Person:

E-Mail:

Telephone:

S.07 Heat Island Effect Answer Material Information Evidence

Solar Reflectance SR

YES Solar Heat Gain Coefficient

Is the material used on the building envelope, roof, or Value/Albedo factor Provide material data sheets

a.

landscape/hardscape areas? for evidence

NO

W.01 Water Consumption Answer Material Information Evidence

YES

Flush rate (L/flush) Flow rate (L/min) Provide material data sheets

a. Does the material refer to a toilet fixture/fitting?

for evidence

NO

E.01 Energy Demand Answer Material Information Evidence

YES U-value (W/m2/K) Provide material data sheets

a. Is the material used on the building envelope or roof?

for evidence

NO

YES Assembly U-value (W/m2/K)

b. Is the material made up of more than one element. Provide U-Value Calculations

NO

M.01 Regional Materials Answer Material Information Evidence

Distance in km to each RLSU

YES Country/City of Origin

GSAS certified station

to (i) ----------- Km Provide chain of custody or

a. Is the material manufactured or assembled in Qatar?

to (ii) ---------- Km other proof of origin

NO

YES Percentage by weight of each element

Provide material composition

b. Is the material made up of more than one element.

data sheet

NO

M.02 Responsible Sourcing of Materials Answer Material Information Evidence

Do the Supplier and/or the Manufacturer have a valid ISO YES

14000/14001 certification? NO

Do the Supplier and/or the Manufacturer have a valid ISO YES

9000/9001 certification? NO

If the product is a wood/timber material: do you have Forest YES

Provide copy of valid

a. Stewardship Council (FSC) certification? NO

certification

YES

Other valid qualifications (environmental quality or sustainability)?

NO

Do the Supplier and/or the Manufacturer have a valid BS8902:2009 YES

certificate or equivalent for sustainable sourcing? NO

M.03 Recycled Material Answer Material Information Evidence

YES Percentage of recycled content(%) Provide material composition

a. Is the material made up of recycled content data sheet and a certified

NO letter by the company

M.06 Design for Disassembly Answer Material Information Evidence

YES

Can the product be disassembled & reused without Provide evidence

a.

compromising its quality/integrity? (data sheets, manual, etc.)

NO

IE.09 Indoor Environmental Quality Answer Material Information Evidence

VOC content of adhesive,

YES VOC Content of material (g/L)

Does the material contain Volatile Organic Compounds (VOC) or sealant, paint, etc. (g/L) Provide material safety data

a.

requires the of an adhesive, paint, polish coat, sealant? sheet

NO

General Information Answer

a. What is the average weight of the material (Kg)

b. What is the average cost of material (QR)

Architect .SUS. Mgr. Comments

Approved by

RLSU-JV SUS. Mgr. Comments

Notes:

1. Only include materials and finishes permanently installed, and required for the construction of the project. Exclude all mechanical, electrical, and plumbing assemblies, as well as

specialist items and equipment.

2. Name of product/material supply company

3. Indicative Cost of material, as documented in Bill of Quantities (BOQ). Cost per quantity unit. List the currency and the quantity unit required

4. VOC=Volatile Organic Compound, please list VOCs present in the material or finish by unit weight per volume for i.e. 100g/Litre and consider the maximam VOC limits for paints,Coating,

Sealants and other Finishes (copy attached to this application).

5. Total weight in Kg as appropriate

6. Materials or products that use recycled content that reduce the need for virgin materials (i.e. mined, harvested or extracted content from the Earth or Sea), the % in the material + cost

of recycled material

7. Distance in km to each RLSU GSAS certified station: (i) AL Doha Al Jadeda station (ii) Umm Ghuwailina Station.

8. Manufacturers of materials that have the following certification standards to be attached: ISO 26000, ISO 9001, ISO 14001, FSC (C.O.C verification), Environmental Product Declaration

(EPD) with % of material + cost

Certification:

I, ---------------------------------------, an authorized representative of------------------------------------------ hereby certify that the information contained herein is accurate to the best of my

knowledge.

SIGNATURE: ------------------------------------------------DATE:---------------------------------------- Company Stamp:

Das könnte Ihnen auch gefallen

- M007-OnW-ARC-SPE-11303-V1.0 - (Msheireb Station, Finishes Materials and Structural Works Specifications, P1.2 Secondary Shelters De)Dokument318 SeitenM007-OnW-ARC-SPE-11303-V1.0 - (Msheireb Station, Finishes Materials and Structural Works Specifications, P1.2 Secondary Shelters De)Mikku KattaNoch keine Bewertungen

- 001 - Vendor & MnufctrDokument22 Seiten001 - Vendor & Mnufctrmogbel1Noch keine Bewertungen

- FDOT General Aviation Airport Construction (2015) PDFDokument667 SeitenFDOT General Aviation Airport Construction (2015) PDFSinan İcik100% (1)

- EXW P006 0000 MQ SHC MS 00014 SubmittalDokument216 SeitenEXW P006 0000 MQ SHC MS 00014 SubmittalRaheelHashmiNoch keine Bewertungen

- Crane SpecificationDokument17 SeitenCrane Specificationrasiuom100% (1)

- د أ ر 21 - المواصفات الإنشائية القياسية - الجزء الثاني PDFDokument711 Seitenد أ ر 21 - المواصفات الإنشائية القياسية - الجزء الثاني PDFpeterNoch keine Bewertungen

- Download Aci 309r 05 Concrete Specification PDFDokument3 SeitenDownload Aci 309r 05 Concrete Specification PDFShokhieb Showbad CarriebNoch keine Bewertungen

- Business Planning Model (ASTC Asphalt Plant Qatar)Dokument1 SeiteBusiness Planning Model (ASTC Asphalt Plant Qatar)VhirMabansagNoch keine Bewertungen

- TI 801-02 Volume 2 - Statement of WorkDokument81 SeitenTI 801-02 Volume 2 - Statement of WorkMohamed FathiNoch keine Bewertungen

- QHDM - Vol. 03 Part 18 PDFDokument4 SeitenQHDM - Vol. 03 Part 18 PDFAbdul RahmanNoch keine Bewertungen

- V361 - Standard.05 Con & Ren LOW RESDokument34 SeitenV361 - Standard.05 Con & Ren LOW RESMike Harper100% (1)

- Water Works RTADokument15 SeitenWater Works RTAalfaza3Noch keine Bewertungen

- Australian Manufactured Sand GuidelineDokument2 SeitenAustralian Manufactured Sand GuidelineahmadiahreadymixlabNoch keine Bewertungen

- Rheobuild 561: A Superplasticising Admixture To Produce Low Slump Loss Rheoplastic ConcreteDokument2 SeitenRheobuild 561: A Superplasticising Admixture To Produce Low Slump Loss Rheoplastic Concreteiker88100% (1)

- Housing Estate Road Construction Specification Updated May 2014Dokument112 SeitenHousing Estate Road Construction Specification Updated May 2014Chris FindlayNoch keine Bewertungen

- Asphalt Materials and Uses: Section 1. NomenclatureDokument9 SeitenAsphalt Materials and Uses: Section 1. Nomenclaturephoenix_12_Noch keine Bewertungen

- Reinstatement of Trenches Along Local Asphalt Roads A101.01Dokument2 SeitenReinstatement of Trenches Along Local Asphalt Roads A101.01Nicholas VineyNoch keine Bewertungen

- Company Profile 2018Dokument163 SeitenCompany Profile 2018Alam Junaid100% (1)

- Concrete Curing Compound GuideDokument2 SeitenConcrete Curing Compound GuideMaki Salim HussainNoch keine Bewertungen

- Ashghal Approved Material List (Taheel) CPVC Pipes and Fittings PDFDokument1 SeiteAshghal Approved Material List (Taheel) CPVC Pipes and Fittings PDFNaveen DiggaiNoch keine Bewertungen

- Egypt Construction Cost 8-2023Dokument3 SeitenEgypt Construction Cost 8-2023Ahmed Saber Nassar100% (1)

- Differential Qty Item Mort&H Spec Ref Description Unit As Per Aggt. Quantity As Per Site. Quantity Bill No. 1Dokument40 SeitenDifferential Qty Item Mort&H Spec Ref Description Unit As Per Aggt. Quantity As Per Site. Quantity Bill No. 1Sharat SahaNoch keine Bewertungen

- Department of Public Works and HighwaysDokument17 SeitenDepartment of Public Works and HighwaysRolly Marc G. SoteloNoch keine Bewertungen

- 20Dokument1 Seite20Khizer IslamNoch keine Bewertungen

- Letter To KSEBDokument1 SeiteLetter To KSEBSujithNoch keine Bewertungen

- Raknor - BrochureDokument33 SeitenRaknor - Brochureeromax1Noch keine Bewertungen

- Methodology For Stone Pitching Revetment On SlopesDokument3 SeitenMethodology For Stone Pitching Revetment On SlopesRSBIPL NH17 LABNoch keine Bewertungen

- BS standards for construction materialsDokument11 SeitenBS standards for construction materialsShirleyLiuNoch keine Bewertungen

- Certificate of Compliance: Att: Dorat Al TameerDokument1 SeiteCertificate of Compliance: Att: Dorat Al TameerMohammad ArslanNoch keine Bewertungen

- Tender Submission: Tender Evaluation: G Force Client: S&S Sdn. Bhd. Project:Mars Lander/Rover Date:17/09/2017 RevisionDokument49 SeitenTender Submission: Tender Evaluation: G Force Client: S&S Sdn. Bhd. Project:Mars Lander/Rover Date:17/09/2017 Revisionapi-372696692Noch keine Bewertungen

- Qatar Highway Design Manual - 1997 PDFDokument258 SeitenQatar Highway Design Manual - 1997 PDFska100% (2)

- HSBEI-1294-0314 Piling Rigs Overturning On Construction SitesDokument4 SeitenHSBEI-1294-0314 Piling Rigs Overturning On Construction SitestsuakNoch keine Bewertungen

- Technical Datasheet for MoyaProof CWP Cementitious WaterproofingDokument4 SeitenTechnical Datasheet for MoyaProof CWP Cementitious Waterproofingcmtheboss100% (1)

- Work Method Statement: ActivityDokument5 SeitenWork Method Statement: ActivityamolNoch keine Bewertungen

- F ST 53 PDFDokument1 SeiteF ST 53 PDFMohammed YacobNoch keine Bewertungen

- M007-CCC-STR-MES-00005 Rev. 2.0Dokument102 SeitenM007-CCC-STR-MES-00005 Rev. 2.0Mikku KattaNoch keine Bewertungen

- Vol 1Dokument60 SeitenVol 1Faseen ibnu Ameer AhasenNoch keine Bewertungen

- Concrete Sheet Pile Construction MethodologyDokument15 SeitenConcrete Sheet Pile Construction MethodologyRolly Marc G. Sotelo100% (1)

- Bid Response Document PDFDokument99 SeitenBid Response Document PDFSudip PudasainiNoch keine Bewertungen

- EAPA Bat Update Version2007Dokument55 SeitenEAPA Bat Update Version2007Spiros LicoudisNoch keine Bewertungen

- Daily construction site reportDokument2 SeitenDaily construction site reportMohamed Sanoos100% (1)

- Letter of UndertakingDokument1 SeiteLetter of UndertakingAnonymous tBLJaNu100% (1)

- NOC Submission Guidelines Version 3 2015Dokument143 SeitenNOC Submission Guidelines Version 3 2015Ahmed KassemNoch keine Bewertungen

- Which Is The Best Excavator?: 7 AnswersDokument4 SeitenWhich Is The Best Excavator?: 7 AnswersMuhammad IqbalNoch keine Bewertungen

- Al-Jazeera Green Semi GlossDokument1 SeiteAl-Jazeera Green Semi GlossmctmcNoch keine Bewertungen

- Installing GeotextilesDokument2 SeitenInstalling GeotextilesAbdullah MofarrahNoch keine Bewertungen

- Volume1 PDFDokument164 SeitenVolume1 PDFVarun GuggilamNoch keine Bewertungen

- CTP ConcretePavingManual Nov2011Dokument109 SeitenCTP ConcretePavingManual Nov2011spaw0202Noch keine Bewertungen

- Quality Control Requirements For Using Crumb Rubber Modified Bitumen (CRMB) in Bituminous Mixtures PDFDokument6 SeitenQuality Control Requirements For Using Crumb Rubber Modified Bitumen (CRMB) in Bituminous Mixtures PDFAkhilesh DwivediNoch keine Bewertungen

- Final Estimates Level 1 ManualDokument114 SeitenFinal Estimates Level 1 ManualenesNoch keine Bewertungen

- Material Submittal of Robson PaintDokument147 SeitenMaterial Submittal of Robson PaintJason RazatlabNoch keine Bewertungen

- Preparation Schedule for Nghi Son 2 BOT Thermal Power Plant Dredging ProjectDokument1 SeitePreparation Schedule for Nghi Son 2 BOT Thermal Power Plant Dredging ProjectjeorgeNoch keine Bewertungen

- ICTS Civil Tender Contract Conditions PDFDokument180 SeitenICTS Civil Tender Contract Conditions PDFKusuma gowdaNoch keine Bewertungen

- Danco Aquaflex PE100 Installation Specification & Good Practices GuideDokument34 SeitenDanco Aquaflex PE100 Installation Specification & Good Practices GuideJavan OmitiNoch keine Bewertungen

- Construction Traffic Management Officer (CTMO)Dokument66 SeitenConstruction Traffic Management Officer (CTMO)Tun afiq0% (1)

- NHA CSR 2014 Rates for Sindh ProjectsDokument262 SeitenNHA CSR 2014 Rates for Sindh ProjectsSohail Ahmed Khilji100% (1)

- 245 20 Pi DTS 00002Dokument12 Seiten245 20 Pi DTS 00002ritesh142Noch keine Bewertungen

- Fuel Gas Skid Technical SpecificationDokument32 SeitenFuel Gas Skid Technical Specificationsumit kumarNoch keine Bewertungen

- 26070-203-3PS-CG00-I1002 - Spec Road - Rev00A (Reviewed)Dokument52 Seiten26070-203-3PS-CG00-I1002 - Spec Road - Rev00A (Reviewed)Andrew LimbongNoch keine Bewertungen

- S-0100-1520-104 - 1 - Manuf Data Record PDFDokument13 SeitenS-0100-1520-104 - 1 - Manuf Data Record PDFAliZenati100% (1)

- P1m-Mts-Ar-087 Rev.01Dokument30 SeitenP1m-Mts-Ar-087 Rev.01Mikku KattaNoch keine Bewertungen

- Jotun Zinc Primer GuideDokument35 SeitenJotun Zinc Primer GuideMikku KattaNoch keine Bewertungen

- Quality Policy WLLDokument1 SeiteQuality Policy WLLMikku KattaNoch keine Bewertungen

- Cert PDB en Iso 9001Dokument2 SeitenCert PDB en Iso 9001Mikku KattaNoch keine Bewertungen

- m007 MML Arc DWG Ucstmus PL 00501 Rev10.0Dokument1 Seitem007 MML Arc DWG Ucstmus PL 00501 Rev10.0Mikku KattaNoch keine Bewertungen

- Design Calculation For Wall Mount HandrailDokument28 SeitenDesign Calculation For Wall Mount HandrailMikku Katta0% (1)

- 8mm THK Plate SsDokument1 Seite8mm THK Plate SsMikku KattaNoch keine Bewertungen

- M007-CCC-STR-MES-00005 Rev. 2.0Dokument102 SeitenM007-CCC-STR-MES-00005 Rev. 2.0Mikku KattaNoch keine Bewertungen

- E CatalogueDokument12 SeitenE CatalogueMikku KattaNoch keine Bewertungen

- Special Stainless Steel Grades For Forgings PDFDokument4 SeitenSpecial Stainless Steel Grades For Forgings PDFMikku KattaNoch keine Bewertungen

- A500 Spec SheetDokument2 SeitenA500 Spec SheetMikku KattaNoch keine Bewertungen

- Atlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFDokument57 SeitenAtlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFMikku KattaNoch keine Bewertungen

- Integrated Management System ManualDokument41 SeitenIntegrated Management System ManualMikku Katta100% (2)

- Section 24 Finishes To BuildingDokument83 SeitenSection 24 Finishes To BuildingMikku KattaNoch keine Bewertungen

- Mes List 2Dokument3 SeitenMes List 2Mikku KattaNoch keine Bewertungen

- SeismologyDokument2 SeitenSeismologyMikku KattaNoch keine Bewertungen

- M007-Ccc-Str-Mes-00005 Rev1.0Dokument58 SeitenM007-Ccc-Str-Mes-00005 Rev1.0Mikku KattaNoch keine Bewertungen

- Mall of Qatar Trolley Corral Installation Method StatementDokument63 SeitenMall of Qatar Trolley Corral Installation Method StatementMikku Katta67% (3)

- Clay ShonkwilerDokument9 SeitenClay ShonkwilerJeoff Libo-onNoch keine Bewertungen

- 5.case Study: Effects of Homeopathic Medicines in AdultsDokument2 Seiten5.case Study: Effects of Homeopathic Medicines in AdultsAMEEN ARTSNoch keine Bewertungen

- Chemistry How To Make Stuff PDFDokument184 SeitenChemistry How To Make Stuff PDF2967449CEENoch keine Bewertungen

- Classification of Placenta PDFDokument5 SeitenClassification of Placenta PDFAdarsh jainNoch keine Bewertungen

- VCDS Scan Reveals Faults in HVAC, ABS and Transmission SystemsDokument4 SeitenVCDS Scan Reveals Faults in HVAC, ABS and Transmission SystemsDan MirceaNoch keine Bewertungen

- Artikel Ilmiah FikriDokument6 SeitenArtikel Ilmiah FikriViola Mei DamayantiNoch keine Bewertungen

- English Qualification TestDokument5 SeitenEnglish Qualification TestMoh FaisolNoch keine Bewertungen

- MACRO-ETCHING SOLUTIONS FOR ALUMINIUM ALLOYSDokument1 SeiteMACRO-ETCHING SOLUTIONS FOR ALUMINIUM ALLOYSsensoham03Noch keine Bewertungen

- Reference Design Hardware Guide for EVM CE-2Dokument7 SeitenReference Design Hardware Guide for EVM CE-2Angie FoleyNoch keine Bewertungen

- Refraction Through Lenses & Optical Instruments5Dokument144 SeitenRefraction Through Lenses & Optical Instruments5geniusamahNoch keine Bewertungen

- Synopsis THESIS 2022: Aiswarya Vs Tqarebc005 S10Dokument5 SeitenSynopsis THESIS 2022: Aiswarya Vs Tqarebc005 S10Asna DTNoch keine Bewertungen

- Eng ThreePDokument192 SeitenEng ThreePMr Ahmed AbdallahNoch keine Bewertungen

- Purification of Morphologically and Functionally Intact Human Basophils To Near HomogeneityDokument9 SeitenPurification of Morphologically and Functionally Intact Human Basophils To Near HomogeneitySinaí GutierrezNoch keine Bewertungen

- Soal ReadingDokument3 SeitenSoal ReadingSendi PuspaNoch keine Bewertungen

- Abbey Pain Scale assessment toolDokument2 SeitenAbbey Pain Scale assessment toolMuhammad RezgiaNoch keine Bewertungen

- Mahindra Powertrain - Market StrategyDokument4 SeitenMahindra Powertrain - Market StrategyEshan KapoorNoch keine Bewertungen

- Steel StaircaseDokument17 SeitenSteel StaircaseKarthick CrazeiNoch keine Bewertungen

- 7H17-28 Clearances and Wear Limits PDFDokument3 Seiten7H17-28 Clearances and Wear Limits PDFDimitris K100% (1)

- Classified Advertisements from Gulf Times NewspaperDokument6 SeitenClassified Advertisements from Gulf Times NewspaperAli Naveed FarookiNoch keine Bewertungen

- The Karnataka Maternity Benefit (Amendment) Rules 2019Dokument30 SeitenThe Karnataka Maternity Benefit (Amendment) Rules 2019Manisha SNoch keine Bewertungen

- Procedure - AC Circuits and Signal Modulation - W20Dokument6 SeitenProcedure - AC Circuits and Signal Modulation - W20ChocoNoch keine Bewertungen

- MICROPAR PPT Group ADokument43 SeitenMICROPAR PPT Group AEben Alameda-PalapuzNoch keine Bewertungen

- @MedicalBooksStore 2016 AntibioticDokument349 Seiten@MedicalBooksStore 2016 Antibioticant bee100% (1)

- Civil Engineering Subjects (1st - 5th Year) - 1Dokument5 SeitenCivil Engineering Subjects (1st - 5th Year) - 1Vincent TayagNoch keine Bewertungen

- Perioperative HypothermiaDokument4 SeitenPerioperative Hypothermiasri utari masyitahNoch keine Bewertungen

- BBO 2011 ROUND 2 QUESTIONSDokument16 SeitenBBO 2011 ROUND 2 QUESTIONSMalvina YuanNoch keine Bewertungen

- Monsterology Activity KitDokument2 SeitenMonsterology Activity KitCandlewick PressNoch keine Bewertungen

- Dental Radiographs and Photographs in Human Forensic IdentificationDokument8 SeitenDental Radiographs and Photographs in Human Forensic IdentificationBudi PurnomoNoch keine Bewertungen

- Fundamentals of VolleyballDokument2 SeitenFundamentals of VolleyballLawrence CezarNoch keine Bewertungen

- Type 2 Diabetes MellitusDokument6 SeitenType 2 Diabetes MellitusJoy NisoladaNoch keine Bewertungen