Beruflich Dokumente

Kultur Dokumente

Diesel Hammer - Frank's International

Hochgeladen von

Miguelito Bernanet0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

96 Ansichten2 Seitendescripcion del martillo de franks international

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldendescripcion del martillo de franks international

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

96 Ansichten2 SeitenDiesel Hammer - Frank's International

Hochgeladen von

Miguelito Bernanetdescripcion del martillo de franks international

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

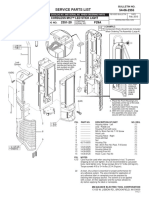

DIESEL HAMMER

Since the early 1960s, Franks has stocked a complete range of Delmag diesel hammers from D12

through D100. The Delmag hammer delivers superior engineering, efficiency, quality and performance

along with many other outstanding features:

- Self-contained mechanism requires no external

power supply

- Air-cooled

- Adaptable and efficient in all climates

- Highest energy/weight ratio of any hammer

available

- Adjustable energy controls

- Fuel efficient

- Easy to operate, usually requiring only two

operators

- Extremely mobile

Franks Engineering Division has further improved the

reliability and efficiency of its Hammer Operations by

custom designing several improvements to the

diesel hammer, including hydraulic/remotely

controlled fuel pumps and tripping devices.

The hydraulic/remotely controlled fuel pump gives

the operator maximum control over the amount of

energy actually delivered by the hammer and allows

instantaneous shut down of the hammer.

They hydraulic/remotely controlled tripping device

reduces damage to the pile often caused by

manually tripping the hammer, especially during

battered pile operations.

For more information call 1 -800-833-7265 or e-mail info@frankscasing.com

www.frankscasing.com

Copyright 2003 Franks Casing Crew & Rental Tools, Inc., Lafayette, LA

Diesel Hammer Operation:

Starting the Hammer (1)

The hammer's tripping device raises the ram weight (piston)

and automatically releases it at a given height.

Diesel Fuel Injection and Compression (2)

The ram weight's descent actuates the pump lever which

injects a specific quantity of diesel fuel onto the surface of

the impact block. Once past the exhaust ports, the piston will

begin compressing the air in the cylinder chamber. The

increasing compression presses the impact block and pile

helmet firmly onto the pile head.

Impact and Explosion (3)

The fuel is atomized by the force of the piston on the impact

block and ignites in the highly compressed air. The resulting

explosion forces the piston back up the cylinder.

Exhaust (4)

The exhaust gases escape through the ports which are exposed

on the piston's ascent. The pressure in the cylinder is

equalized by the exhaust.

Scavenging (5)

As the piston continues to ascend, fresh air is sucked in

through the exhaust ports, thoroughly scavenging the cylinder

and thereby releasing the pump lever. The pump lever return

to its original position sucking again diesel oil into the fuel

pump.

Diesel Hammer Specifications:

Das könnte Ihnen auch gefallen

- Diesel Common Rail Injection Electronic Components ExplainedVon EverandDiesel Common Rail Injection Electronic Components ExplainedBewertung: 3.5 von 5 Sternen3.5/5 (7)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiVon EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNoch keine Bewertungen

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- Diesel Engine Fundamentals and Servicing GuideDokument28 SeitenDiesel Engine Fundamentals and Servicing Guidefrankhil ramosNoch keine Bewertungen

- PV776 TSP23762 1Dokument70 SeitenPV776 TSP23762 1Benjamin Miranda FloresNoch keine Bewertungen

- Lecture 1 - Diesel Engine Power PlantDokument60 SeitenLecture 1 - Diesel Engine Power PlantbarryNoch keine Bewertungen

- Naval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyVon EverandNaval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyNoch keine Bewertungen

- Unit-I: TO Ic EnginesDokument43 SeitenUnit-I: TO Ic EnginesLeo Dev WinsNoch keine Bewertungen

- Turbo Charger - ProjectDokument36 SeitenTurbo Charger - ProjectSam Sams100% (2)

- REPORT of 4 Stroke EngineDokument8 SeitenREPORT of 4 Stroke Enginealibhalli4367% (3)

- Fujitsu M12 Server Installation Specialist Online AssessmentDokument60 SeitenFujitsu M12 Server Installation Specialist Online AssessmentTitus Kernel Maestria100% (1)

- 4 Stroke Petrol EngineDokument11 Seiten4 Stroke Petrol EngineAnkit Joshi50% (4)

- Comparison of Diesel and Petrol EnginesVon EverandComparison of Diesel and Petrol EnginesBewertung: 2.5 von 5 Sternen2.5/5 (3)

- Diesel Engine - FundamentalDokument20 SeitenDiesel Engine - FundamentalSoumen BhattaNoch keine Bewertungen

- Four-Stroke, Four Cylinder Diesel Engine: BY Shubham Kulshrestha Atul Yadav Irfan KhanDokument27 SeitenFour-Stroke, Four Cylinder Diesel Engine: BY Shubham Kulshrestha Atul Yadav Irfan KhanShubham Kulshrestha100% (1)

- V-I Curve TracerDokument3 SeitenV-I Curve TracerheidebrechtNoch keine Bewertungen

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsVon EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNoch keine Bewertungen

- Edexcel HNC/D Plant and Process Principles Outcome 4 - Power Supply Equipment Tutorial 1 - Diesel EnginesDokument9 SeitenEdexcel HNC/D Plant and Process Principles Outcome 4 - Power Supply Equipment Tutorial 1 - Diesel EnginescataiceNoch keine Bewertungen

- Nintendo Consumer BehaviourDokument18 SeitenNintendo Consumer BehaviourChu Yung-Lun100% (1)

- The 2 Stroke Diesel CycleDokument14 SeitenThe 2 Stroke Diesel CycleBharatiyulam100% (1)

- Diesel Engine Power Plant AuxiliariesDokument7 SeitenDiesel Engine Power Plant Auxiliariessivanu04032012100% (1)

- Marine Diesels Co UkDokument149 SeitenMarine Diesels Co Ukvmedica94% (32)

- Two Stroke Engine: 1. Swedish SaabDokument6 SeitenTwo Stroke Engine: 1. Swedish SaabGilbert Escolano AnchetaNoch keine Bewertungen

- Diesel Engine: Aguinaldo, Cellan, Gregorio, MedranoDokument33 SeitenDiesel Engine: Aguinaldo, Cellan, Gregorio, MedranoHannah AguinaldoNoch keine Bewertungen

- Unit 1 B Ic EnginesDokument47 SeitenUnit 1 B Ic Enginesoliyad teferiNoch keine Bewertungen

- Research PPDDokument9 SeitenResearch PPDRamil SalundagaNoch keine Bewertungen

- 38-character title for 2-stroke engine documentDokument5 Seiten38-character title for 2-stroke engine documentdwarika2006Noch keine Bewertungen

- Split-Cycle Engine RevolutionDokument14 SeitenSplit-Cycle Engine RevolutionSameer Patil0% (1)

- Final Project Mechanical PowerDokument163 SeitenFinal Project Mechanical PowerVikrant KumarNoch keine Bewertungen

- Team Nozzle Present .: Four Stroke Petrol EngineDokument33 SeitenTeam Nozzle Present .: Four Stroke Petrol EngineChamfreit AxereasNoch keine Bewertungen

- Mar Power Week 3Dokument15 SeitenMar Power Week 3DarkxeiDNoch keine Bewertungen

- KishoreDokument18 SeitenKishorenjaiguruNoch keine Bewertungen

- Comprssion EngineDokument11 SeitenComprssion EngineAyush HazarikaNoch keine Bewertungen

- 873 - Diesel Engine BasicsDokument10 Seiten873 - Diesel Engine BasicsanilNoch keine Bewertungen

- Ic Engines: Four Stroke Cycle Diesel EnginesDokument11 SeitenIc Engines: Four Stroke Cycle Diesel Enginesmechjobs4meNoch keine Bewertungen

- Everything You Need to Know About Two-Stroke EnginesDokument29 SeitenEverything You Need to Know About Two-Stroke EnginesShivam TripathiNoch keine Bewertungen

- List of Experiments: Lab In-Charge Hod MeDokument41 SeitenList of Experiments: Lab In-Charge Hod MeAshiq HussainNoch keine Bewertungen

- Petrol Engine: Working CyclesDokument7 SeitenPetrol Engine: Working CyclesBrijesh Patel100% (1)

- Thermo Ex.4Dokument5 SeitenThermo Ex.4Hafeez AliNoch keine Bewertungen

- I C Engines: Heat Engines and Engine ComponentsDokument42 SeitenI C Engines: Heat Engines and Engine ComponentsGeorgy KurienNoch keine Bewertungen

- Diesel Engine Fundamentals GuideDokument23 SeitenDiesel Engine Fundamentals GuideAjaykuamrNoch keine Bewertungen

- City and Guilds 9210 Level 6 Module - Unit 128 Applied Thermodynamics OUTCOME 4 - TUTORIAL 3Dokument13 SeitenCity and Guilds 9210 Level 6 Module - Unit 128 Applied Thermodynamics OUTCOME 4 - TUTORIAL 3khumisoNoch keine Bewertungen

- Diesel EngineDokument5 SeitenDiesel EnginejaftcolNoch keine Bewertungen

- Four Stroke EnginesDokument5 SeitenFour Stroke EnginesPacumio ClaretteNoch keine Bewertungen

- Air EngineDokument5 SeitenAir EngineVinay MohanNoch keine Bewertungen

- Me 56Dokument9 SeitenMe 56RhizhailNoch keine Bewertungen

- Basic automobile engineering assignmentDokument47 SeitenBasic automobile engineering assignmentGautam PrajapatNoch keine Bewertungen

- Maharashtra State Board of Technical Education Certificate: Mechanical Engineering of Marathwada Mitra Mandal'sDokument16 SeitenMaharashtra State Board of Technical Education Certificate: Mechanical Engineering of Marathwada Mitra Mandal's190 208 Rahul DhaneshwarNoch keine Bewertungen

- First Semester:-Course Title: Applied Thermodynamics TopicDokument8 SeitenFirst Semester:-Course Title: Applied Thermodynamics TopicHafeez AliNoch keine Bewertungen

- Basic Marine EngineeringDokument5 SeitenBasic Marine EngineeringCaryle GamboaNoch keine Bewertungen

- Four-Stroke Diesel Engine CyclesDokument10 SeitenFour-Stroke Diesel Engine Cyclesmechjobs4meNoch keine Bewertungen

- Diesel CycleDokument7 SeitenDiesel CycleRehman MansuriNoch keine Bewertungen

- Lecture 2Dokument29 SeitenLecture 2khalid mustafaNoch keine Bewertungen

- Diesel Engine Tune Up GuideDokument10 SeitenDiesel Engine Tune Up GuideMaher MarquezNoch keine Bewertungen

- AGR 318 Lec 3 - Engine Cons & CompDokument42 SeitenAGR 318 Lec 3 - Engine Cons & CompHaikal SapurataNoch keine Bewertungen

- Marine Diesel 2019 Week IDokument39 SeitenMarine Diesel 2019 Week IfaridNoch keine Bewertungen

- Types of EnginesDokument24 SeitenTypes of EnginesTimothy Del ValleNoch keine Bewertungen

- Diesel EngineDokument14 SeitenDiesel EngineAyşenur ÇetinNoch keine Bewertungen

- Lesson V Automobile Engine, and The Four-Stroke CycleDokument5 SeitenLesson V Automobile Engine, and The Four-Stroke CycleNicolas AntiguaNoch keine Bewertungen

- Marpower: Week No.1 Diesel Engine FundamentalsDokument6 SeitenMarpower: Week No.1 Diesel Engine FundamentalsDarkxeiDNoch keine Bewertungen

- M17-Gas and Diesel Enginesrev2 (Zadco-AHRT)Dokument41 SeitenM17-Gas and Diesel Enginesrev2 (Zadco-AHRT)VAN VIET NGONoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- MG HG ReplacementDokument16 SeitenMG HG ReplacementChrisBeller45Noch keine Bewertungen

- Microcontroller Applications Lab Course OutcomesDokument2 SeitenMicrocontroller Applications Lab Course OutcomesRishabh SoyamNoch keine Bewertungen

- Fundamental Algorithms: Chapter 3: Parallel Algorithms - The PRAM ModelDokument26 SeitenFundamental Algorithms: Chapter 3: Parallel Algorithms - The PRAM ModelHasnain RehmanNoch keine Bewertungen

- Analog Applications Journal Q2 2011 - Slyt409Dokument38 SeitenAnalog Applications Journal Q2 2011 - Slyt409marmotanNoch keine Bewertungen

- Astm A490Dokument20 SeitenAstm A490cesardario90Noch keine Bewertungen

- Watts Guia Usua Termost MiluxDokument2 SeitenWatts Guia Usua Termost MiluxFer NietoNoch keine Bewertungen

- ITT American Electric Package B Dusk-To-Dawn Series 11 Spec Sheet 8-80Dokument4 SeitenITT American Electric Package B Dusk-To-Dawn Series 11 Spec Sheet 8-80Alan MastersNoch keine Bewertungen

- Computer Awareness PDF by Recruitment - GuruDokument18 SeitenComputer Awareness PDF by Recruitment - GuruANNENoch keine Bewertungen

- File 1538 Service Parts List (54-06-2355)Dokument1 SeiteFile 1538 Service Parts List (54-06-2355)oscarzabala1311Noch keine Bewertungen

- BSNL 3G Data Card TrainingDokument47 SeitenBSNL 3G Data Card Trainingsandcauli1147Noch keine Bewertungen

- Technical Information ASSET DOC LOC 3008312 PDFDokument15 SeitenTechnical Information ASSET DOC LOC 3008312 PDFOusmane DiengNoch keine Bewertungen

- MSP CatalogDokument128 SeitenMSP CatalogsanthoshNoch keine Bewertungen

- Ug1209 Embedded Design TutorialDokument165 SeitenUg1209 Embedded Design TutorialFaizNoch keine Bewertungen

- Securedoc - Manual CleanupDokument14 SeitenSecuredoc - Manual Cleanuppablo gonzalesNoch keine Bewertungen

- Introduction to MS DOSDokument15 SeitenIntroduction to MS DOSSuresh Kumar MukhiyaNoch keine Bewertungen

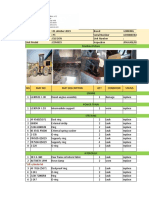

- PRS Lonking 833 CilegonDokument4 SeitenPRS Lonking 833 CilegonIrawan Budi SantosaNoch keine Bewertungen

- Data ExchangeDokument44 SeitenData Exchangepalaniappan_pandianNoch keine Bewertungen

- ZKTeco+Fingerprint+Scanner+SDK+Selection+Guide-Ver3 0 PDFDokument1 SeiteZKTeco+Fingerprint+Scanner+SDK+Selection+Guide-Ver3 0 PDFFaisal AminNoch keine Bewertungen

- E2505 p5vd2-mx Update PDFDokument108 SeitenE2505 p5vd2-mx Update PDFziskeNoch keine Bewertungen

- Parker - Triple-Lok - & - Triple-Lok - 2 - 37° - Flare - Tube - FittingsDokument36 SeitenParker - Triple-Lok - & - Triple-Lok - 2 - 37° - Flare - Tube - FittingsHemant RasamNoch keine Bewertungen

- Digital Rapids Studio Encoding ServersDokument4 SeitenDigital Rapids Studio Encoding ServersManuel AlvarezNoch keine Bewertungen

- GRADED LAB - INTRODUCTION TO COMPUTING TOPICS: IF-ELSE CONDITIONS, WHILE LOOPDokument5 SeitenGRADED LAB - INTRODUCTION TO COMPUTING TOPICS: IF-ELSE CONDITIONS, WHILE LOOPqwertyNoch keine Bewertungen

- Guidelines For The Use of Digital Content in Accreditation VisitsDokument13 SeitenGuidelines For The Use of Digital Content in Accreditation VisitsarchitectmagNoch keine Bewertungen

- QuickBooks 2019 DatasheetDokument5 SeitenQuickBooks 2019 Datasheetrtsarmiento014Noch keine Bewertungen

- HP Elitebook X360 1030 G2 Notebook PC: Seductive. Secure. Your New Favorite Carry-OnDokument4 SeitenHP Elitebook X360 1030 G2 Notebook PC: Seductive. Secure. Your New Favorite Carry-OntrinityNoch keine Bewertungen