Beruflich Dokumente

Kultur Dokumente

MT6070iE Installation Manual

Hochgeladen von

kokabtCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MT6070iE Installation Manual

Hochgeladen von

kokabtCopyright:

Verfügbare Formate

MT8070/8100iE series 3 Installation Instructions

Secure the operator panel in position, using all the fastening holes and the provided brackets

Installation Instruction and screws: (A)

(B) Cutout

1 Installation and Startup Guide

This document covers the installation of MT8000iE Series HMI, for the detailed specifications and

operation, please refer to Datasheet and EasyBuilder Pro User Manual. Type A(mm) B(mm)

Install Environment: MT8070iE 192 138

NEMA Rating MT8000iE Series HMI is NEMA 4 rated (Indoor Only). MT8100iE 260 202

The MT8000iE Series has been tested to conform to European CE requirements.

Electrical This means that the circuitry is designed to resist the effects of electrical noise. 4 Power Connections NOTE:

Environment This does not guarantee noise immunity in severe cases. Proper wire routing and

1. Connect positive DC line to the + terminal

grounding will insure proper operation.

and the DC ground to the - terminal.

(1) Make sure that the displays are installed correctly and that the operating

limits are followed. Avoid installing units in environments where severe 2. Please do not connect HMI with PLC and PC

mechanical vibration or shocks are present. simultaneously to prevent potential difference

(2) Do not operate the unit in areas subject to explosion hazards due to from destroying USB ports of HMI and PC.

Environmental flammable gases, vapors or dusts.

Considerations (3) Do not install the unit where acid gas, such as SO2 exists. To make a connection, strip about 3/8 of

(4) This device should be mounted in the vertical position and for use on the flat insulation off the end of the wire, turn the

surface enclosure. connector screw counterclockwise until the gap

(5) Conform to UL508 (ISBN 0-7629-0404-6) machine safety for use in is wide open, insert the wire all the way in, and

Pollution Degree 2 Environment. turn the screw clockwise until its tight.

2 Unpacking the Unit NOTE:

Place the operator panel on a stable

Unpack and check the delivery. If damage is found, surface during installation. Dropping it or

notify the supplier. 5 System Settings

letting it fall may cause damage.

When HMI powered up and displays image, Go to the Network tab, you may choose

click the system setting button. to auto get DHCP IP, or designate your

(1) Installation Instruction, 2-sided A4 *1 (Default System Password: 111111) own IP.

(1) It is necessary to connect the HMI to

your network through a RJ-45 cable.

(2) Human Machine Interface *1

(2)

(3) Power Connector *1

(3)

(4) Brackets & Screws V3.0 *1 pack

(5) ( Note 1: For the details of HMI

(5) Fuse 1.25A/250V 5*20mm *1

(4) DIP SW function settings please

refer to Part 8 in this guide. )

NOTE: Make sure that all local and national electrical standards are met when

CAUTION

6 EasyBuilder Pro Software Settings installing the unit. Contact your local authorities to determine which codes apply.

Launch EasyBuilder Pro software, select your The HMI can be powered by DC power only, voltage range: 2420% Volts DC, compatible with

project file, press F7 shortcut key to open Power most controller DC systems. The power conditioning circuitry inside the unit is accomplished by a

the download dialog box: switching power supply. The peak starting current can be as high as 2A.

Select Ethernet > IP tab > Enter your HMI IP If the display does not come on within 5 seconds of power up, remove power. An internal fuse will

> Click Download to download this project Fusing

prevent damage if the polarity of the DC power is incorrect. Check wiring for proper connections

file to HMI. Require-

and try to power up again.

ments

( Please refer to EasyBuilder Pro User Manual

for software operation details ) An Internal fuse will prevent damage for over voltage condition however it isnt guaranteed. DC

High

voltage sources should provide proper isolation from main AC power and similar hazards.

Voltage

7 Communication Connections NOTE:

1. COM1 and COM3 [RS485] 2W support MPI 187.5K, A Hard-wired EMERGENCY STOP should be fitted in any system using HMI to comply with ICS

Emergency

please use one at one time. Safety Recommendations.

2. COM1 [RS485] / COM3 [RS485] with isolation protection. Stop

PIN# Symbol COM1 [RS232] Do not power the HMI and inductive DC loads, or input circuitry to the controller, with the same

COM1 [RS232] Supply

power supply. Note: The 24 VDC output from some controllers may not have enough current to

1 Not used Voltage

power the HMI.

Condition

2 RxD Received Data

a. Power wire length should be minimized (Max: 500m shielded, 300m unshielded).

3 TxD Transmitted Data Wire

b. Please use twisted pair cables for power wire and signal wire and conform to the impedance

4 Not used Routing

matching.

5 GND Signal Ground c. If wiring is to be exposed to lightning or surges, use appropriate surge suppression devices.

d. Keep AC, high energy, and rapidly switching DC power wiring separated from signal wires.

6 Not used e. Add a resistor and capacitor in the parallel connection between the ungrounded DC power

7 RTS Ready to send output supply and the frame ground. This provides a path for static and high frequency dissipation.

Typical values to use are 1M Ohm and 4700pF.

8 CTS Clear to send input DANGER

9 Not used

Com1 Com1 Com3 Hardware The system designer should be aware that devices in Controller systems could fail and thereby

COM1 / COM3 [RS485] PIN# Symbol Considerations create an unsafe condition. Furthermore, electrical interference in an operator interface can lead to

[RS485]2w [RS485]4w [RS485]

equipment start-up, which could result in property damage and/or physical injury to the operator.

1 Rx- Data- Rx-

If you use any programmable control systems that require an operator, be aware that this potential

2 Rx+ Data+ Rx+ safety hazard exists and take appropriate precautions. Although the specific design steps depend on

your particular application, the following precautions generally apply to installation of solid-state

3 Tx- Tx-

programmable control devices, and conform to the guidelines for installation of Controllers

4 Tx+ Tx+ recommended in NEMA ICS 3-304 Control Standards.

5 GND1 Ground1

To conform with ICS Safety Recommendations, checks should be placed in the controller to ensure

6 Not used Programming that all writable registers that control critical parts of plant or machinery have limit checks built into

7 Data- Data- Considerations the program, with an out-of-limit safe shut down procedure to ensure safety of personnel.

GME807810_MT8070_8100iE_Installation_130402

8 Data+ Data+

9 GND2 Ground2

8 DIP SW Settings Limited Warranty

SW1 SW2 SW3 SW4 Mode

ON OFF OFF OFF Touch Screen Calibration Mode This product is limited warranted against defects in design and manufacture.

The proven defective product will either be repaired or replaced, at Weinteks discretion.

OFF ON OFF OFF Hide HMI System Setting Bar This warranty shall not cover any product which is

OFF OFF ON Boot Loader Mode (a) Out of warranty period which is 1 year from the date of purchase.

OFF

(b) Damage caused by Force Majeure, accident, negligence, improper installation or misuse.

OFF OFF OFF ON Not supported (c) Product has been repaired or taken apart by unauthorized technicians.

OFF OFF OFF OFF Normal (d) Products whose identification markings have been removed or damaged.

Das könnte Ihnen auch gefallen

- Securebasebook PDFDokument184 SeitenSecurebasebook PDFMiyamoto MusashiNoch keine Bewertungen

- Cisco ASA Troubleshooting Commands - ItsecworksDokument37 SeitenCisco ASA Troubleshooting Commands - ItsecworksLinuxManCR100% (3)

- Grammar, Punctualization and CapitalizationDokument108 SeitenGrammar, Punctualization and CapitalizationFernando Ornelas100% (1)

- Connector Industry: A Profile of the European Connector Industry - Market Prospects to 1999Von EverandConnector Industry: A Profile of the European Connector Industry - Market Prospects to 1999Noch keine Bewertungen

- TK6070iQ Series: Installation InstructionDokument2 SeitenTK6070iQ Series: Installation InstructionAlbert Jiménez100% (1)

- D59999GC30 Sg2.unlocked PDFDokument230 SeitenD59999GC30 Sg2.unlocked PDFaeteromNoch keine Bewertungen

- FANUC-Fronius CommunicationDokument26 SeitenFANUC-Fronius CommunicationSreema Aruvi71% (7)

- Installation Instructions: Impulse Release Module (P/N 10 2748)Dokument4 SeitenInstallation Instructions: Impulse Release Module (P/N 10 2748)ZF Roberto100% (1)

- Installation Instructions For Flm-325-2I4 Dual Input Monitor ModuleDokument1 SeiteInstallation Instructions For Flm-325-2I4 Dual Input Monitor ModuleLuiyi Lazcano MontalvoNoch keine Bewertungen

- Contacts ExportDokument30 SeitenContacts Exportcityadvertisingsrl0% (1)

- MT6070/8070/6100/8100 I Series: Installation InstructionDokument2 SeitenMT6070/8070/6100/8100 I Series: Installation InstructionLuis Alberto PalaciosNoch keine Bewertungen

- Weintek Mt6071ip 8071ip InstallmanDokument2 SeitenWeintek Mt6071ip 8071ip InstallmanpiabNoch keine Bewertungen

- MT6071/8071/8101iE Series: Installation InstructionDokument2 SeitenMT6071/8071/8101iE Series: Installation InstructionAlbany PerezNoch keine Bewertungen

- MT6071/8071/8101iE Series: Installation InstructionDokument2 SeitenMT6071/8071/8101iE Series: Installation InstructionsaadNoch keine Bewertungen

- MT8103iE Series: Installation InstructionDokument2 SeitenMT8103iE Series: Installation InstructionLeonardo GonzálezNoch keine Bewertungen

- MT6071/8071/8101iE Series: Installation InstructionDokument2 SeitenMT6071/8071/8101iE Series: Installation InstructionĐào Mạnh LượngNoch keine Bewertungen

- Mt8102ip SeriesDokument2 SeitenMt8102ip SeriesHafiz AhmadNoch keine Bewertungen

- MT6000/8000iE Series: Installation InstructionDokument2 SeitenMT6000/8000iE Series: Installation InstructionsaadNoch keine Bewertungen

- MT8102iE Series: Installation InstructionDokument2 SeitenMT8102iE Series: Installation Instructionedi susantoNoch keine Bewertungen

- Manual Weintek Mt8051ipDokument2 SeitenManual Weintek Mt8051ipYgor EuripedesNoch keine Bewertungen

- CTP107-E Series 88 970 564: Installation InstructionDokument2 SeitenCTP107-E Series 88 970 564: Installation InstructionAlex RosaNoch keine Bewertungen

- MT607i MT610i: Installation InstructionDokument2 SeitenMT607i MT610i: Installation InstructionIvanNoch keine Bewertungen

- GME810XE0 MT8121 8150XE InstallationDokument2 SeitenGME810XE0 MT8121 8150XE Installationzaki abbasNoch keine Bewertungen

- MT6071iP MT8071iP Series: Installation InstructionDokument2 SeitenMT6071iP MT8071iP Series: Installation InstructionRuwaediEdiNoch keine Bewertungen

- WEG Guia de Instalacao Mt6050ip Mt8050ip Quick Guide EnglishDokument2 SeitenWEG Guia de Instalacao Mt6050ip Mt8050ip Quick Guide EnglishlucasmenegazzoNoch keine Bewertungen

- GME871P30 MT8072iP Installation 221019Dokument2 SeitenGME871P30 MT8072iP Installation 221019where moneyNoch keine Bewertungen

- WEG Guia de Instalacao mt6071 Mt8071ip enDokument2 SeitenWEG Guia de Instalacao mt6071 Mt8071ip enDiana Alejandra Aragon CeballosNoch keine Bewertungen

- WEG Guia de Instalacion Mt6070ip Mt8070ipDokument2 SeitenWEG Guia de Instalacion Mt6070ip Mt8070ipadalaviNoch keine Bewertungen

- GME8A23E1 MT8102iE1 8102iEU 8103ie1 InstallationDokument2 SeitenGME8A23E1 MT8102iE1 8102iEU 8103ie1 InstallationkamranNoch keine Bewertungen

- Instruction Sheet: A041J096 (Issue 3)Dokument12 SeitenInstruction Sheet: A041J096 (Issue 3)Stephane TronquetNoch keine Bewertungen

- MT6050i MT8050i: Installation InstructionDokument2 SeitenMT6050i MT8050i: Installation InstructionСања БанковићNoch keine Bewertungen

- Contador 542-072a-ManualDokument8 SeitenContador 542-072a-ManualRONALD ALFONSO PACHECO TORRESNoch keine Bewertungen

- Instruction Leaflet IL04802001E: Effective May 2010Dokument20 SeitenInstruction Leaflet IL04802001E: Effective May 2010Rubens PaivaNoch keine Bewertungen

- Gmecfhd00 CMT-FHD InstallationDokument2 SeitenGmecfhd00 CMT-FHD InstallationCokde IndraNoch keine Bewertungen

- Gmecfhd00 CMT-FHD InstallationDokument2 SeitenGmecfhd00 CMT-FHD InstallationCokde IndraNoch keine Bewertungen

- Hctx-Manual (Eng) - 10 05 25Dokument14 SeitenHctx-Manual (Eng) - 10 05 25onlylovetdNoch keine Bewertungen

- USB Application Interface Board-D1Dokument16 SeitenUSB Application Interface Board-D1Richard WilliamNoch keine Bewertungen

- Advanced PTZ/DVR Keyboard Controller: Right For BusinessDokument13 SeitenAdvanced PTZ/DVR Keyboard Controller: Right For Businessaasi121Noch keine Bewertungen

- Remote MicrophoneDokument8 SeitenRemote MicrophoneRavi100% (1)

- DPI External Comms Kit Installation Instructions - 20comm-In001 - En-PDokument4 SeitenDPI External Comms Kit Installation Instructions - 20comm-In001 - En-Pdenilson.rodr1357Noch keine Bewertungen

- Hig - Ie SW El10 8GT 2gesfp - V1.0 - 2020 10 29Dokument2 SeitenHig - Ie SW El10 8GT 2gesfp - V1.0 - 2020 10 29joaotgilNoch keine Bewertungen

- ST4012M-DG Control Panel: User's Installation TutorialDokument3 SeitenST4012M-DG Control Panel: User's Installation TutorialNguyên NguyênNoch keine Bewertungen

- Installation Manual: Remote User InterfaceDokument12 SeitenInstallation Manual: Remote User InterfaceALEKSANDARNoch keine Bewertungen

- EKRUMADokument12 SeitenEKRUMAALEKSANDARNoch keine Bewertungen

- GHW-LC InstrDokument12 SeitenGHW-LC InstrCostel GavrilasNoch keine Bewertungen

- Portero Electrico ManualDokument246 SeitenPortero Electrico ManualDavidde OBNoch keine Bewertungen

- MX430 101Dokument8 SeitenMX430 101Alberto LandaNoch keine Bewertungen

- HIG - IE SR 2TX WL Series - V1.3 - 2022 08 24Dokument2 SeitenHIG - IE SR 2TX WL Series - V1.3 - 2022 08 24Nitzan DaubeNoch keine Bewertungen

- CenRF DCS-LTE1800&WCDMA2100 Dualband Fiber Optical Repeater Brief Manual V3Dokument12 SeitenCenRF DCS-LTE1800&WCDMA2100 Dualband Fiber Optical Repeater Brief Manual V3cafe0sugarNoch keine Bewertungen

- TC 809 Ea 1035Dokument5 SeitenTC 809 Ea 1035pedrodany9098Noch keine Bewertungen

- Fingerprint Access Control Installation Manual (ZD2F20)Dokument20 SeitenFingerprint Access Control Installation Manual (ZD2F20)arnoldNoch keine Bewertungen

- Manual SMD JXCP1#Dokument2 SeitenManual SMD JXCP1#hamidreza.amiriNoch keine Bewertungen

- M90/91™ OPLC™: General DescriptionDokument8 SeitenM90/91™ OPLC™: General DescriptionDiego Alejandro Cetina MezaNoch keine Bewertungen

- V230 260 280 290 Instal-GuideDokument9 SeitenV230 260 280 290 Instal-Guideinven formNoch keine Bewertungen

- FLEX Ex NAMUR Input Module: Installation InstructionsDokument28 SeitenFLEX Ex NAMUR Input Module: Installation InstructionsRafa ANoch keine Bewertungen

- M750 Display UnitDokument32 SeitenM750 Display UnitjevalaNoch keine Bewertungen

- IOM3721 Input/Output Module: Installation InstructionsDokument11 SeitenIOM3721 Input/Output Module: Installation InstructionsAnderson Willian MendesNoch keine Bewertungen

- C627 PCC2100 PDFDokument5 SeitenC627 PCC2100 PDFmaurito1986Noch keine Bewertungen

- Feednet: ManualDokument56 SeitenFeednet: ManualRobot 3TNoch keine Bewertungen

- Installation Manual: 1. Mounting !Dokument2 SeitenInstallation Manual: 1. Mounting !Thukhoadaihocla TaNoch keine Bewertungen

- PROFIBUS-DP Interface Module: User's ManualDokument192 SeitenPROFIBUS-DP Interface Module: User's ManualNguyễnTuấnAnhNoch keine Bewertungen

- Installation Instructions For Series C F-Frame 310+ Electronic Circuit Breaker Types FDE, HFDE, FDCEDokument8 SeitenInstallation Instructions For Series C F-Frame 310+ Electronic Circuit Breaker Types FDE, HFDE, FDCEelechwNoch keine Bewertungen

- EZ9 Series HMI ManualDokument34 SeitenEZ9 Series HMI ManualDanielito AlvaracinNoch keine Bewertungen

- Wireless Video Door Phone: User ManualDokument6 SeitenWireless Video Door Phone: User ManualfabianoNoch keine Bewertungen

- U-V200-18-E4xb SpecDokument16 SeitenU-V200-18-E4xb SpeckokabtNoch keine Bewertungen

- RIA250数显仪Dokument9 SeitenRIA250数显仪kokabtNoch keine Bewertungen

- YDWI Project ParametersDokument42 SeitenYDWI Project ParameterskokabtNoch keine Bewertungen

- 41639ADokument418 Seiten41639AkokabtNoch keine Bewertungen

- AirLive AirMax5 ManualDokument146 SeitenAirLive AirMax5 ManualCarlos Garcia Jacome DarkerNoch keine Bewertungen

- Bacnet/Modbus Carrier Translator: Product DataDokument1 SeiteBacnet/Modbus Carrier Translator: Product DataTTIBCCANoch keine Bewertungen

- Manual - Acer Aspire U27-880Dokument63 SeitenManual - Acer Aspire U27-880edudajuNoch keine Bewertungen

- CDR Analysis Using Big Data TechnologyDokument5 SeitenCDR Analysis Using Big Data TechnologyJERSON FERNANDO PÉREZ CRISTANCHONoch keine Bewertungen

- WAF01 Barracuda Web Application Firewall - Foundation - TopologyDokument4 SeitenWAF01 Barracuda Web Application Firewall - Foundation - TopologyneoaltNoch keine Bewertungen

- DABEST - Abando - Full Paper - ENGINEERINGDokument7 SeitenDABEST - Abando - Full Paper - ENGINEERINGAnonymous PcPkRpAKD5Noch keine Bewertungen

- OneExpert 630 Extended QuickStart Guide V1aDokument153 SeitenOneExpert 630 Extended QuickStart Guide V1ajuan guillermo zapataNoch keine Bewertungen

- Cloud Computing Technology A Technical SDokument30 SeitenCloud Computing Technology A Technical SKalyan Reddy AnuguNoch keine Bewertungen

- GED125Dokument141 SeitenGED125Srinivasan Senthamarai KannanNoch keine Bewertungen

- Rigol 2016 Full Product CatalogDokument52 SeitenRigol 2016 Full Product Cataloghindukusc80Noch keine Bewertungen

- PlateSpin Migrate 12 Administration-Workbook - NewDokument41 SeitenPlateSpin Migrate 12 Administration-Workbook - NewVishal MulikNoch keine Bewertungen

- Final Project1Dokument44 SeitenFinal Project1dawit muluNoch keine Bewertungen

- MDaemon Pro Vs Zimbra ServerDokument2 SeitenMDaemon Pro Vs Zimbra ServerbooimNoch keine Bewertungen

- RTN 905 S Product Description (V100R020C10 - 02) (PDF) - ENDokument90 SeitenRTN 905 S Product Description (V100R020C10 - 02) (PDF) - ENJuanNoch keine Bewertungen

- ExoMars Rover VehicleDokument26 SeitenExoMars Rover VehicleDavid KenyoNoch keine Bewertungen

- Ltrsec 1000 LGDokument394 SeitenLtrsec 1000 LGВладимир ЗайнулинNoch keine Bewertungen

- IPT T4 Trading Datasheet Linx NetworksDokument4 SeitenIPT T4 Trading Datasheet Linx NetworksBanjac BojanNoch keine Bewertungen

- Nextcloud Ubuntu 20.04 LTSDokument16 SeitenNextcloud Ubuntu 20.04 LTSNanoSys StuffNoch keine Bewertungen

- Sesi 3 Managing Digital Business InfrastructureDokument14 SeitenSesi 3 Managing Digital Business InfrastructureSavitri Nurul KhikmahNoch keine Bewertungen

- Kona MacroDokument2 SeitenKona MacroLandmine MapperNoch keine Bewertungen

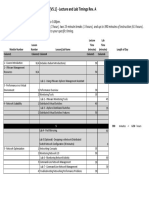

- Vmware Vsphere: Optimize and Scale (V5.1) - Lecture and Lab Timings Rev. ADokument1 SeiteVmware Vsphere: Optimize and Scale (V5.1) - Lecture and Lab Timings Rev. Au9yNoch keine Bewertungen

- Dos Command1Dokument5 SeitenDos Command1Vinoth MechNoch keine Bewertungen

- It2353 Web Technology Question Bank Unit I: 40. HTML Is Case Sensitive or Not?Dokument4 SeitenIt2353 Web Technology Question Bank Unit I: 40. HTML Is Case Sensitive or Not?Baran Mahamood MNoch keine Bewertungen

- List of Nursing Organization SpecializationDokument3 SeitenList of Nursing Organization SpecializationAnthonyBernardoAbustanNoch keine Bewertungen

- Devise Multiple Resources, Registrations, STI and Single Sign Sign OnDokument3 SeitenDevise Multiple Resources, Registrations, STI and Single Sign Sign OnSandip RansingNoch keine Bewertungen

- Address Resolution Protocol (ARP)Dokument11 SeitenAddress Resolution Protocol (ARP)fortunatesanjibNoch keine Bewertungen