Beruflich Dokumente

Kultur Dokumente

Exp 5 Result Dis TQ

Hochgeladen von

Malek Marry AnneOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Exp 5 Result Dis TQ

Hochgeladen von

Malek Marry AnneCopyright:

Verfügbare Formate

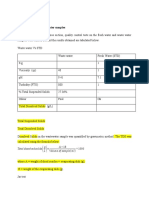

Heavy Phase flow rate : Extract Composition (g/l) Time (min)

10 L/min 0.6 mL 5

0.8 mL 10

Light Phase flow rate : 0.9 mL 15

1.0 mL 20

15 L/min

1.0 mL 25

Raffinate Composition (g/l) Time (min)

48.2 mL 25

Heavy Phase flow rate : Extract Composition (g/l) Time (min)

15 L/min 1.5 mL 5

1.8 mL 10

Light Phase flow rate : 2.8 mL 15

2.8 mL 20

15 L/min

Raffinate Composition (g/l) Time (min)

53.9 mL 15

Heavy Phase flow rate : Extract Composition (g/l) Time (min)

20 L/min 2.2 mL 5

2.8 mL 10

Light Phase flow rate : 2.8 mL 15

Raffinate Composition (g/l) Time (min)

15 L/min

85.6 mL 15

4.0 Results and Discussions

Experimental Data :

Data Analysis and Discussion

The data collected from the experiment show that as the flow rate of the heavy phase

is increased while keeping the light phase flow rate constant, the number of time interval

taken for the extract composition to near constant becomes less. As the flow rate of the heavy

phase increases, a higher volume of the particular phase is brought into contact with the

opposite phase thus increasing the residence time of the two phases together within a certain

time interval. This allows the steady state to be reached much faster, thus giving constant

extract composition data.

The composition of the extract is observed to be increasing with increasing time

intervals of 5 minutes. This shows that the system is moving towards a steady state within the

time interval and once the steady state has been reached, the extract composition remains

constant.

The heavy phase, light phase, solvent, solute and diluents.

Heavy phase Water

Light phase Iodine and hexane

Solvent Water

Solute Iodine

Diluents Hexane

Table 1:Heavy phase, light phase, solvent, solute and diluent components identified from the experiment.

The dispersed phase and the continuous phase.

Dispersed phase Continuous phase

Iodine and hexane Water

Table 2: Dispersed and continuous phase components identified from the experiment.

Equilibrium contact.

Equilibrium contact is an equilibrium separation process which is usually operated in

a counter current configuration in which the heavy phase and light phase are made to flow

opposite to each other is a closed vessel. The contact process can be viewed as a stage wise

process in which the two layers of heavy phase and the light phase are contacted thoroughly

in each stage and leaves at equilibrium.

Effect of flow rate towards the extraction performance.

Theoretically, steady state can be achieved faster when the flow rate of the heavy

phase increases. When the flow rate of heavy phase increase , the concentration of extract

composition will also be higher. Thus can improve the extraction performance.

Ways to increase the performance of extraction process.

First of all, solvent selection is most important. The desired properties of solvents

should be high distribution coefficient, good selectivity towards solute and little or no

miscibility with feed solution. Also, the solvent should be easily recoverable for recycle.

Temperature can also be used as a variable to alter selectivity. Elevated temperatures

are sometimes used in order to keep viscosity low and thereby minimizing mass-transfer

resistance. Other parameters to be considered are selectivity, mutual solubility, precipitation

of solids and vapor pressure.

The pH becomes significant in metal and bio-extractions. In bio-extractions (e.g.,

Penicillin) and some agrochemicals (e.g. Orthene), pH is maintained to improve distribution

coefficient and minimize degradation of product. In metal extractions, kinetic considerations

govern the pH. In dissociation-based extraction of organic molecules, pH can play a

significant role (e.g., cresols separation).

Residence time is an important parameter in reactive extraction processes (e.g., metals

separations, formaldehyde extraction from aqueous streams) and in processes involving

short-life components (e.g., antibiotics & vitamins)

Importance of liquid-liquid extraction process in chemical engineering.

Liquid-liquid extraction is a type of separation process that allows different

compounds to be separated based on their solubilities. This involves the usage of different

immiscible liquids. The liquids used in this process are usually water and a solvent. This is a

common chemical process and there are several pieces of equipment that perform this task.

In addition to helping in studying certain solutions, liquid-liquid extraction also has

industrial applications. This type of extraction is often used in biotechnological settings.

Biologically produced chemicals and fuels, like algae, often required liquid-liquid extraction.

This allows engineers to separate the different components of these fuels. Not all of the

fermented and biologically formed components are usable, so they must be extracted while

keeping the rest of the useful solution intact. Liquid-liquid extraction is used to lower the

required energy levels for the distillation of these solutions.

Conclusion

From the experiment, the relationship between the change of flow rate and the

extraction efficiency is obtained. In this experiment, it is observed that the change of flow

rate for the heavy phase liquid in the liquid-liquid extraction will increase the extraction

efficiency as the time taken to achieve extraction equilibrium will be shorter. On the other

hand, the decrease in the heavy phase flow rate will decrease the extraction effiency as the

time taken to achieve extraction equilibrium will be longer.

Das könnte Ihnen auch gefallen

- CMT267 - Liquid - Liquid ExtractionDokument10 SeitenCMT267 - Liquid - Liquid ExtractionNUR AINUL MARDHIAH FAZLISYAMNoch keine Bewertungen

- Laboratory Report #1 - Basic Principles in BiochemistryDokument8 SeitenLaboratory Report #1 - Basic Principles in BiochemistryLala HalaNoch keine Bewertungen

- Jar Test Lab Report Environmental EngineeringDokument7 SeitenJar Test Lab Report Environmental EngineeringNur Hazimah100% (1)

- Catalase LabDokument6 SeitenCatalase Laboofnivlak5100% (11)

- WEEK 2 - Level 0 - Jar TestDokument2 SeitenWEEK 2 - Level 0 - Jar TestWHfamilyNoch keine Bewertungen

- ANSASOL-Water Quality Analysis Report-25.5.23Dokument4 SeitenANSASOL-Water Quality Analysis Report-25.5.23farhaNoch keine Bewertungen

- Liquid Liquid Extraction ExperimentDokument22 SeitenLiquid Liquid Extraction ExperimentMohd Sharu Mamat69% (13)

- Lab (2) PHT514Dokument6 SeitenLab (2) PHT514Mohamed GamalNoch keine Bewertungen

- Enzyme Catalysis Lab Hypothesis: Exercise 2A: Test of Catalase ActivityDokument6 SeitenEnzyme Catalysis Lab Hypothesis: Exercise 2A: Test of Catalase ActivityMarques LoveNoch keine Bewertungen

- Iquisa CorridaDokument6 SeitenIquisa CorridapipaNoch keine Bewertungen

- Liquid Liquid ExtractionDokument40 SeitenLiquid Liquid ExtractionApurba Sarker Apu93% (29)

- Exp 4Dokument14 SeitenExp 4Farhatul Abrar AnandaNoch keine Bewertungen

- Water Jar Test DoneDokument8 SeitenWater Jar Test DoneNasEvan'sNoch keine Bewertungen

- Lab Report LLE LatestDokument7 SeitenLab Report LLE Latestnajihah50% (2)

- Liquid-Liquid ExtractionDokument8 SeitenLiquid-Liquid Extractionrr1819Noch keine Bewertungen

- Lab Report TPP Experiment 3Dokument10 SeitenLab Report TPP Experiment 3Nurul Najwa100% (1)

- Chemistry Investigatory ProjectDokument7 SeitenChemistry Investigatory ProjectAditya PandeyNoch keine Bewertungen

- 3-SCH 403 Colagative PropertiesDokument25 Seiten3-SCH 403 Colagative PropertiesAnn KiamaNoch keine Bewertungen

- Org Exp 45 PDFDokument15 SeitenOrg Exp 45 PDFMardhia AtiqahNoch keine Bewertungen

- Lab LleDokument20 SeitenLab LleMuhamad Baihakhi Shamsudin100% (1)

- Chapter 1Dokument90 SeitenChapter 1PMNoch keine Bewertungen

- Lec 10Dokument14 SeitenLec 10Anugrah SyaifullahNoch keine Bewertungen

- Gen. Chem Colligative PropertiesDokument50 SeitenGen. Chem Colligative PropertiesKath Del CastilloNoch keine Bewertungen

- Chapter 7Dokument5 SeitenChapter 7Earl averzosaNoch keine Bewertungen

- Results and DiscussionDokument9 SeitenResults and Discussionbridget mutsutsururuNoch keine Bewertungen

- Experiment 2 HPLC chm510Dokument9 SeitenExperiment 2 HPLC chm510Amar Safwan75% (12)

- Liquid Liquid ExtractionDokument16 SeitenLiquid Liquid ExtractionShahrizatSmailKassimNoch keine Bewertungen

- Corrosion Control Treatment: Answer KeyDokument66 SeitenCorrosion Control Treatment: Answer KeyEscobar ValderramaNoch keine Bewertungen

- Chapter3B DiscussionDokument18 SeitenChapter3B DiscussionirfanNoch keine Bewertungen

- DesignDokument3 SeitenDesigntata_77Noch keine Bewertungen

- Imene Djedid Coagulation-FloculationDokument3 SeitenImene Djedid Coagulation-Floculationmanel KaddourNoch keine Bewertungen

- Trial Wave-UF - RO - IXMBDokument38 SeitenTrial Wave-UF - RO - IXMBmufti chemiNoch keine Bewertungen

- Learning Objectives: Colligative PropertiesDokument9 SeitenLearning Objectives: Colligative PropertiesBea Dacillo Bautista100% (3)

- Physic Pharmacy Module 2 - PrelimDokument7 SeitenPhysic Pharmacy Module 2 - PrelimRegine PeñarandaNoch keine Bewertungen

- AcidityDokument3 SeitenAcidityJoash SalamancaNoch keine Bewertungen

- Lab Report Exp 1 Aishah Nazirah Ed260Dokument8 SeitenLab Report Exp 1 Aishah Nazirah Ed260nuraishahnazirahzNoch keine Bewertungen

- L-1 Water TreatmentDokument11 SeitenL-1 Water TreatmentSambhav ShrivastavaNoch keine Bewertungen

- EXTRACTIONDokument6 SeitenEXTRACTIONSu KelesogluNoch keine Bewertungen

- Chemistry-Dr Hanaa-Lec3, gp3,4Dokument25 SeitenChemistry-Dr Hanaa-Lec3, gp3,4Mohamed Abd Elnabi ElnagarNoch keine Bewertungen

- Liquid - Liquid ExtractionDokument15 SeitenLiquid - Liquid ExtractionDeepChacNoch keine Bewertungen

- Lab Report RecrystallizationDokument5 SeitenLab Report RecrystallizationBerdigylychNoch keine Bewertungen

- Liquid Liquid ExtractionDokument6 SeitenLiquid Liquid ExtractionCâmeraNoch keine Bewertungen

- Supercritical Fluid Extraction, Chromatography and Other ApplicationsDokument50 SeitenSupercritical Fluid Extraction, Chromatography and Other ApplicationsJalil LaadimiNoch keine Bewertungen

- Distribution of Acetic Acid Between Two Immiscible Solution by Simple Simple Methods PapooDokument11 SeitenDistribution of Acetic Acid Between Two Immiscible Solution by Simple Simple Methods PapooHasnain SaifiNoch keine Bewertungen

- Cascara Sagrada Bark Rhamnus PurshianaDokument2 SeitenCascara Sagrada Bark Rhamnus PurshianaFernando AlexanderNoch keine Bewertungen

- Distillation: by Assistant Professor Jntua-Otpri AnantapurDokument39 SeitenDistillation: by Assistant Professor Jntua-Otpri AnantapurRAJESHPAVANNoch keine Bewertungen

- Lab #1 Report Harry, Aikumis, Islam ..Dokument24 SeitenLab #1 Report Harry, Aikumis, Islam ..hussainNoch keine Bewertungen

- Experiment 4 UODokument10 SeitenExperiment 4 UONajmin RoslanNoch keine Bewertungen

- Protein Purificiation Formal Lab Write UpDokument12 SeitenProtein Purificiation Formal Lab Write Upgraum1090% (20)

- Chemistry Project DivyanshDokument17 SeitenChemistry Project DivyanshDivyansh kumarNoch keine Bewertungen

- THE ACTION OF ENZYMES IN LAUNDRY DETERGENTS-Group N6Dokument16 SeitenTHE ACTION OF ENZYMES IN LAUNDRY DETERGENTS-Group N6Sebastian VillacresNoch keine Bewertungen

- Physiology - Darah & Cairan TubuhDokument90 SeitenPhysiology - Darah & Cairan TubuhMuhammad RanggaNoch keine Bewertungen

- Drinking and Non-Potable 3rd Party WAJuly.2022 Pk2Dokument11 SeitenDrinking and Non-Potable 3rd Party WAJuly.2022 Pk2khrayzie bhoneNoch keine Bewertungen

- EDTADokument12 SeitenEDTAPrabhatNoch keine Bewertungen

- Project Report - Hardness of Water r2 FinalDokument10 SeitenProject Report - Hardness of Water r2 FinalS Balagopal SivaprakasamNoch keine Bewertungen

- Wave RO 66 m3 Per Jam Sei MengkeiDokument3 SeitenWave RO 66 m3 Per Jam Sei MengkeiAhmad JundullahNoch keine Bewertungen

- L.O. (2) Part-2Dokument15 SeitenL.O. (2) Part-2nohaNoch keine Bewertungen

- Environment Biotechnology JOURNAL 2Dokument2 SeitenEnvironment Biotechnology JOURNAL 2Malek Marry AnneNoch keine Bewertungen

- Proposal Water PurifierDokument4 SeitenProposal Water PurifierMalek Marry Anne0% (1)

- 3.0 Literature Review 3.1 P ControllerDokument12 Seiten3.0 Literature Review 3.1 P ControllerMalek Marry AnneNoch keine Bewertungen

- Example Project Plan Proposal SKKK4173 - 2017 PDFDokument17 SeitenExample Project Plan Proposal SKKK4173 - 2017 PDFMalek Marry AnneNoch keine Bewertungen

- Industrial Training/ Practice (It/Ip)Dokument11 SeitenIndustrial Training/ Practice (It/Ip)Malek Marry AnneNoch keine Bewertungen

- Cell Disruption MethodsDokument19 SeitenCell Disruption MethodsMalek Marry AnneNoch keine Bewertungen

- Result Time Turbidity (600nm) Glucose (540nm) Mass Before After Mass of Dry CellDokument3 SeitenResult Time Turbidity (600nm) Glucose (540nm) Mass Before After Mass of Dry CellMalek Marry AnneNoch keine Bewertungen

- Rate of Return One ProjectDokument18 SeitenRate of Return One ProjectMalek Marry Anne100% (1)

- Radiation 1Dokument26 SeitenRadiation 1Malek Marry AnneNoch keine Bewertungen

- Molecular DiffusionDokument26 SeitenMolecular DiffusionMalek Marry AnneNoch keine Bewertungen

- 1 SynopsisDokument11 Seiten1 SynopsisMalek Marry AnneNoch keine Bewertungen

- Absolute Amounts of Glucose Vs A540: DiscussionDokument3 SeitenAbsolute Amounts of Glucose Vs A540: DiscussionMalek Marry AnneNoch keine Bewertungen

- Heat ExchangerDokument12 SeitenHeat ExchangerMalek Marry AnneNoch keine Bewertungen

- Chapter 9: Instrumentation On BioreactorDokument34 SeitenChapter 9: Instrumentation On BioreactorMalek Marry AnneNoch keine Bewertungen

- Chapter 3 Rates Law and StoichiometryDokument60 SeitenChapter 3 Rates Law and StoichiometryMalek Marry AnneNoch keine Bewertungen

- Cultures of The West A History, Volume 1 To 1750 3rd PDFDokument720 SeitenCultures of The West A History, Volume 1 To 1750 3rd PDFtonnyNoch keine Bewertungen

- Lorenzo JDokument2 SeitenLorenzo Japi-528402595Noch keine Bewertungen

- AS Film Production Lesson.Dokument13 SeitenAS Film Production Lesson.MsCowanNoch keine Bewertungen

- A-Health Advance - Application Form With InstructionsDokument14 SeitenA-Health Advance - Application Form With InstructionsExsan OthmanNoch keine Bewertungen

- Performance Task 1st Quarter Poetry Writing WorkshopDokument3 SeitenPerformance Task 1st Quarter Poetry Writing WorkshopNicole john ZuluetaNoch keine Bewertungen

- Acid Bases and Salts Previous Year Questiosn Class 10 ScienceDokument5 SeitenAcid Bases and Salts Previous Year Questiosn Class 10 Scienceclashhunting123123Noch keine Bewertungen

- BagbagtoDokument3 SeitenBagbagtoJayson Valentin EscobarNoch keine Bewertungen

- CV (Martin A Johnson)Dokument7 SeitenCV (Martin A Johnson)kganesanNoch keine Bewertungen

- American J Political Sci - 2023 - Eggers - Placebo Tests For Causal InferenceDokument16 SeitenAmerican J Political Sci - 2023 - Eggers - Placebo Tests For Causal Inferencemarta bernardiNoch keine Bewertungen

- Manufacturing Finance With SAP ERP Financials: Subbu RamakrishnanDokument33 SeitenManufacturing Finance With SAP ERP Financials: Subbu RamakrishnanKhalifa Hassan100% (1)

- 2022+ACCF+111+Class+test+2 Moderated+versionDokument8 Seiten2022+ACCF+111+Class+test+2 Moderated+versionLucas LuluNoch keine Bewertungen

- Seinfelt - The CheesecakeDokument31 SeitenSeinfelt - The Cheesecakeseinfelt100% (2)

- UX-driven Heuristics For Every Designer: OutlineDokument7 SeitenUX-driven Heuristics For Every Designer: OutlinemuhammadsabirinhadisNoch keine Bewertungen

- Specification For Neoprene Coating On The Riser CasingDokument17 SeitenSpecification For Neoprene Coating On The Riser CasingLambang AsmaraNoch keine Bewertungen

- Tes - 29 October 2021 UserUploadNetDokument120 SeitenTes - 29 October 2021 UserUploadNetTran Nhat QuangNoch keine Bewertungen

- WRhine-Main-Danube CanalDokument6 SeitenWRhine-Main-Danube CanalbillNoch keine Bewertungen

- Chen Probable Cause Affidavit 050714Dokument7 SeitenChen Probable Cause Affidavit 050714USA TODAYNoch keine Bewertungen

- Determination of Iron in Water - SpectrophotometryDokument4 SeitenDetermination of Iron in Water - Spectrophotometryhanif ahmadNoch keine Bewertungen

- PapernathazDokument26 SeitenPapernathazAbelardo LapathaNoch keine Bewertungen

- Modal Verbs EjercicioDokument2 SeitenModal Verbs EjercicioAngel sosaNoch keine Bewertungen

- ToobaKhawar 6733 VPL Lab Sat 12 3 All TasksDokument38 SeitenToobaKhawar 6733 VPL Lab Sat 12 3 All TasksTooba KhawarNoch keine Bewertungen

- AWP 4A Syllabus Fall 2021 (Misinformation)Dokument11 SeitenAWP 4A Syllabus Fall 2021 (Misinformation)camNoch keine Bewertungen

- Chemical Recycling of Textile PolymersDokument8 SeitenChemical Recycling of Textile PolymersVaishali RaneNoch keine Bewertungen

- Issues in Corporate GovernanceDokument15 SeitenIssues in Corporate GovernanceVandana ŘwţNoch keine Bewertungen

- Engineering Data: Wireway SelectionDokument3 SeitenEngineering Data: Wireway SelectionFidel Castrzzo BaeNoch keine Bewertungen

- Fulltext PDFDokument454 SeitenFulltext PDFVirmantas JuoceviciusNoch keine Bewertungen

- Character AnalysisDokument3 SeitenCharacter AnalysisjefncomoraNoch keine Bewertungen

- International Standard: Iso/Iec 7816-2Dokument16 SeitenInternational Standard: Iso/Iec 7816-2Anwar MohamedNoch keine Bewertungen

- A Hack For The Yoga PoseDokument3 SeitenA Hack For The Yoga PoseAlex NNoch keine Bewertungen

- DSE4610 DSE4620 Operators ManualDokument86 SeitenDSE4610 DSE4620 Operators ManualJorge Carrasco100% (6)