Beruflich Dokumente

Kultur Dokumente

Al Alloys Chemicals Mechanicals

Hochgeladen von

Factory FactoryCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Al Alloys Chemicals Mechanicals

Hochgeladen von

Factory FactoryCopyright:

Verfügbare Formate

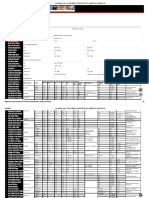

Aluminum Alloys

Refer to ASTM Specification B26/B26M-09

Chemical Compostion (%Max, unless range is stated )

Others

Former

ANSI Alloy # Designation

UNS Si Fe Cu Mn Mg Cr Ni Zn Sn Ti Each Total

319 319, Allcast A03190 5.5-6.5 1.0 3.0-4.0 0.50 0.10 - 0.35 1.0 - 0.25 - 0.50

356 356 A03560 6.5-7.5 0.60* 0.25 0.35* 0.20-0.45 - - 0.35 - 0.25 0.5 015

A356 (made from A356.2) A356 A13560 6.5-7.5 0.20 0.20 0.10 0.25-0.45 - - 0.10 - 0.20 0.05 0.15

535 Almag 35 A05350 0.15 0.15 0.05 0.10-0.25 6.2-7.5 - - - - 0.10-0.25 0.05 005

713 Tenzaloy A07130 0.25 1.1 0.40-1.0 0.6 0.20-0.50 035 0.15 7.0-8.0 - 0.25 010 0.25

* If iron exceeds 0.45, manganese content shall not be less than one-half the iron content

Mechanical Properties

Tensile Strength, Yield Strength, Elongation in 2 in. or 4 x diameter, Typical Brinell Typical Endurance Typical Charpy

Typical Shear Strength

AA Number min min min, % Hardnes, 500 kgf , limit Impact Notched

ksi (1000 psi) ksi (1000 psi) 10mm ksi (1000 psi) ksi (1000 psi) ft lbs

319.0-F 23 13 1.5 70 22 10 1

356.0-F 19 9.5 2.0 55 1 1/2

356.0-T51 23 16 not required 60 20 8

356.0-T6 30 20 3.0 70 26 8 2

A356.0-T6 34 24 3.5 80 26 8.5

535.0-F 35 18 9.0 70 34 8 10-12

713.0* 32 22 3.0 75 26 9 3

* After 21 days natural aging

F=as cast, T51=cooled from an elevated temperature and artificially aged, T6=solution heat treated and then artificially aged

Charasteristics- Aluminum Alloys

Solidification Normally Chemical Elevated Suitability

Resistance to Hot Pressure Corrosion Machin- Electro- Anodizing

ANSI Alloy # Cracking Tightness

Fluidity Shrinkage Heat

Resistance ability

Polishing

plating Quality

Oxide Temperature for

Tendency Treated Coating Strength Welding

319 2 2 2 2 Yes 3 3 4 2 4 3 3 2

356 1 1 1 1 Yes 2 4 5 2 4 2 3 2

A356 1 1 1 1 Yes 2 4 5 2 4 2 3 2

535 3 5 5 5 No 1 1 1 5 1 1 3 4

713 5 3 4 4 Aged only 2 1 1 2 2 3 5 4

Ratings: 1 =Excellent, 2 = Very Good, 3 = Good, 4 = Fair, 5 = Poor

Typical Physical Properties

Approx. Electrical Thermal

Pattern Shrinkage Coefficient of Thermal

ANSI Alloy # Allowance in/ft

Specific Gravity Density Melting Conduc- Conduc-

Expansion

Range tivity tivity

lb/cu in F % of A.I.C.S. CGS 68-212F 68-572F

319 5/32 2.79 0.101 90-1120 27 0.26 12.0 13.4

356 5/32 2.68 0.097 1035-1135 39 0.36 11.9 13.0

A356 5/32 2.68 0.097 1035-1135 39 0.36 11.9 13.0

535 5/32 2.62 0.095 1020-1150 23 0.24 13.1 14.8

713 3/16 2.81 0.102 1100-1180 35 0.35 13.1 14.2

Das könnte Ihnen auch gefallen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- 8620 Case Hardening Steel - Interlloy - Engineering Steels + AlloysDokument4 Seiten8620 Case Hardening Steel - Interlloy - Engineering Steels + Alloysankit7588Noch keine Bewertungen

- STANDARD - ASTM A653 - Brief DescriptionDokument7 SeitenSTANDARD - ASTM A653 - Brief DescriptionSeyong ParkNoch keine Bewertungen

- Alloy 6013 Tech Sheet 1Dokument4 SeitenAlloy 6013 Tech Sheet 1IlyasNoch keine Bewertungen

- Last Updated: Jan 27, 2006Dokument2 SeitenLast Updated: Jan 27, 2006박준용Noch keine Bewertungen

- CDA 84400 phosphor bronze alloy propertiesDokument4 SeitenCDA 84400 phosphor bronze alloy propertiesShariq KhanNoch keine Bewertungen

- Specifications and mechanical properties of steel platesDokument7 SeitenSpecifications and mechanical properties of steel platesprajakt_pieNoch keine Bewertungen

- Raffmetal: UNI EN 1676 and 1706Dokument2 SeitenRaffmetal: UNI EN 1676 and 1706Raj RajeshNoch keine Bewertungen

- Die Casting AlloysDokument6 SeitenDie Casting AlloyskeeblerkhanNoch keine Bewertungen

- 6063 VS 63400Dokument1 Seite6063 VS 63400siju1974Noch keine Bewertungen

- INDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Dokument6 SeitenINDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Roberto AlvarezNoch keine Bewertungen

- Spheroidal GraphiteDokument1 SeiteSpheroidal GraphiteS.Mohana sundaramNoch keine Bewertungen

- Applicable Standards: ASTM A792 ASTM A792 EN10215Dokument14 SeitenApplicable Standards: ASTM A792 ASTM A792 EN10215ersinNoch keine Bewertungen

- 6060 PropertiesDokument3 Seiten6060 Propertiesinterpon07Noch keine Bewertungen

- Adi 4 (2021 - 03 - 22 20 - 48 - 50 Utc)Dokument2 SeitenAdi 4 (2021 - 03 - 22 20 - 48 - 50 Utc)Milton Pereira JúniorNoch keine Bewertungen

- CuNi18Zn20 M18 CDokument3 SeitenCuNi18Zn20 M18 CJORDAN JUNOR ELLANoch keine Bewertungen

- Aisi 1010 Carbon Steel (Uns g10100)Dokument5 SeitenAisi 1010 Carbon Steel (Uns g10100)spiderblackNoch keine Bewertungen

- Cosmos Alminium-Technical - Specifications PDFDokument2 SeitenCosmos Alminium-Technical - Specifications PDFmindsopenNoch keine Bewertungen

- 34crnimo6: Steel GradeDokument6 Seiten34crnimo6: Steel GradeBiju KNoch keine Bewertungen

- 4.5.Material DescriptionDokument1 Seite4.5.Material DescriptionAhmed Hamdy WorkNoch keine Bewertungen

- Jis C3771Dokument2 SeitenJis C3771bkprodhNoch keine Bewertungen

- BOQ - Base Rate FileDokument3 SeitenBOQ - Base Rate FileSaleem khanNoch keine Bewertungen

- Raffmetal: UNI EN 1676 and 1706Dokument2 SeitenRaffmetal: UNI EN 1676 and 1706Martin DuarteNoch keine Bewertungen

- 38 MN VS6Dokument2 Seiten38 MN VS6Pramod NautiyalNoch keine Bewertungen

- Ok 83.28Dokument1 SeiteOk 83.28joe_frangiehNoch keine Bewertungen

- ALUMINIUM ALLOYS FOR EXTRUDED PROFILESDokument19 SeitenALUMINIUM ALLOYS FOR EXTRUDED PROFILESDon JonesNoch keine Bewertungen

- COVERED ELECTRODES FOR MILD STEEL WELDINGDokument1 SeiteCOVERED ELECTRODES FOR MILD STEEL WELDINGKannan MurugesanNoch keine Bewertungen

- Mechanical and chemical properties comparison of SA 516 Gr 60 and API 5L X70M PSL2 steel platesDokument4 SeitenMechanical and chemical properties comparison of SA 516 Gr 60 and API 5L X70M PSL2 steel platesEr Umesh RohitNoch keine Bewertungen

- Chinese Specification For Cast Iron and S. G. IronDokument1 SeiteChinese Specification For Cast Iron and S. G. IronRahul KhoslaNoch keine Bewertungen

- Interlloy Grade 8620 Case Hardening SteelDokument3 SeitenInterlloy Grade 8620 Case Hardening Steelajitchavan2150Noch keine Bewertungen

- CLC 18-12-4LN: A 3%mo Austenitic Stainless Steel With Nitrogen Addition (317LN Grade)Dokument4 SeitenCLC 18-12-4LN: A 3%mo Austenitic Stainless Steel With Nitrogen Addition (317LN Grade)PeterWayNoch keine Bewertungen

- Esab, Ok 309L (29.12.16)Dokument1 SeiteEsab, Ok 309L (29.12.16)RodrigoNoch keine Bewertungen

- En Aw 6082 Rev 2 Final PDFDokument3 SeitenEn Aw 6082 Rev 2 Final PDFtechspawNoch keine Bewertungen

- Technical Data 60 Oct20Dokument1 SeiteTechnical Data 60 Oct20ibrahim bohilalNoch keine Bewertungen

- Product Catalog AluminiuDokument32 SeitenProduct Catalog AluminiusnoofsnoofNoch keine Bewertungen

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDokument2 SeitenChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanNoch keine Bewertungen

- CuZn33 CatalogueDokument9 SeitenCuZn33 CataloguefedericoNoch keine Bewertungen

- 6005A Alloy SHTDokument2 Seiten6005A Alloy SHTgaju_scribdNoch keine Bewertungen

- WeldingDokument1 SeiteWeldingNNoch keine Bewertungen

- Aluminium 6082 Spec SheetDokument3 SeitenAluminium 6082 Spec SheetDeepak KumarNoch keine Bewertungen

- Metal Coated Structural Steels, EN10346:2015: General Product Description Mechanical PropertiesDokument3 SeitenMetal Coated Structural Steels, EN10346:2015: General Product Description Mechanical PropertiesSrikanth SrikantiNoch keine Bewertungen

- CLC 18.10LN: A Nitrogen Containing 18Cr-10Ni Austenitic Stainless Steel (304LN Grade)Dokument4 SeitenCLC 18.10LN: A Nitrogen Containing 18Cr-10Ni Austenitic Stainless Steel (304LN Grade)PeterWayNoch keine Bewertungen

- 20Mncr5: Steel GradeDokument4 Seiten20Mncr5: Steel GradeAhmad ShujaNoch keine Bewertungen

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Dokument1 SeiteTenalloy 125: LOW ALLOY STEEL (High Strength)satnamNoch keine Bewertungen

- Screw CharacteristicsDokument18 SeitenScrew CharacteristicsJaokNoch keine Bewertungen

- AS 3678 STEEL GRADE 350Dokument3 SeitenAS 3678 STEEL GRADE 350gsoaresrj80Noch keine Bewertungen

- Low alloy electrodes for welding high-strength steels with OK 75.75Dokument1 SeiteLow alloy electrodes for welding high-strength steels with OK 75.75corsini999Noch keine Bewertungen

- Alloy 6082 - Rev2012Dokument2 SeitenAlloy 6082 - Rev2012Ysraels Santisteban DurandNoch keine Bewertungen

- CM-9CB TG-S9Cb US-9CbDokument3 SeitenCM-9CB TG-S9Cb US-9Cbamit singhNoch keine Bewertungen

- CLC 17-13-5LN - High corrosion resistant austenitic stainless steelDokument4 SeitenCLC 17-13-5LN - High corrosion resistant austenitic stainless steelPeterWayNoch keine Bewertungen

- Alloy 6005A: We Are AluminumDokument2 SeitenAlloy 6005A: We Are AluminumLeo PardNoch keine Bewertungen

- SA/AS1548 - 7 - 460R: XlerplateDokument3 SeitenSA/AS1548 - 7 - 460R: XlerplatenavNoch keine Bewertungen

- SilcoTek Coatings For High Purity ApplicationsDokument30 SeitenSilcoTek Coatings For High Purity ApplicationsKommu RohithNoch keine Bewertungen

- Aisi 1010 Carbon Steel (Uns g10100)Dokument5 SeitenAisi 1010 Carbon Steel (Uns g10100)prasadjoshi781429Noch keine Bewertungen

- AISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionDokument3 SeitenAISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionGrimmo1979Noch keine Bewertungen

- Aisi 4130 PDFDokument2 SeitenAisi 4130 PDFEndru MeNoch keine Bewertungen

- Materials Data for Cyclic Loading: Low-Alloy SteelsVon EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsBewertung: 5 von 5 Sternen5/5 (2)

- Susin I Torq CatalogDokument12 SeitenSusin I Torq CatalogFactory FactoryNoch keine Bewertungen

- Nabl 122 12 PDFDokument21 SeitenNabl 122 12 PDFmaheshNoch keine Bewertungen

- API 510 Exam Publications Effectivity Sheet - : May and September 2016 and January 2017Dokument1 SeiteAPI 510 Exam Publications Effectivity Sheet - : May and September 2016 and January 2017mohamedeldeeb88Noch keine Bewertungen

- Pre Test QuestionsDokument2 SeitenPre Test QuestionsAndresNicolasBouvierNoch keine Bewertungen

- VERSATILE EXPROOF LIMIT SWITCHDokument2 SeitenVERSATILE EXPROOF LIMIT SWITCHFactory FactoryNoch keine Bewertungen

- Nabl 129 PDFDokument135 SeitenNabl 129 PDFDisha ShahNoch keine Bewertungen

- API Standards For Pipe Inspections PDFDokument38 SeitenAPI Standards For Pipe Inspections PDFajayghosh3140100% (8)

- ISO 9001-2015 General AwarenessDokument42 SeitenISO 9001-2015 General AwarenessJohnNoch keine Bewertungen

- PTFE Lip Seal Design Guide: Catalog EPS 5340/USADokument170 SeitenPTFE Lip Seal Design Guide: Catalog EPS 5340/USAdtr17Noch keine Bewertungen

- 4 Guidance On Valve Type SelectionDokument86 Seiten4 Guidance On Valve Type SelectionKrista OneillNoch keine Bewertungen

- Gearbox DrawingDokument1 SeiteGearbox DrawingFactory FactoryNoch keine Bewertungen

- Pneumatic Butterfly Valves Technical SpecificationDokument12 SeitenPneumatic Butterfly Valves Technical SpecificationFactory FactoryNoch keine Bewertungen

- Inspection - Spark-Testing PDFDokument3 SeitenInspection - Spark-Testing PDFanandtpe1Noch keine Bewertungen

- Environmental Pollution and DegradationDokument2 SeitenEnvironmental Pollution and DegradationCharLene MaRieNoch keine Bewertungen

- Maret 2021Dokument36 SeitenMaret 2021Muhammad Pahlan PiruzziNoch keine Bewertungen

- Electric Vehicle BatteryDokument15 SeitenElectric Vehicle BatteryTotal Acess100% (1)

- GP Series Portable Generator: Owner's ManualDokument48 SeitenGP Series Portable Generator: Owner's ManualWilliam Medina CondorNoch keine Bewertungen

- Photodegradation and Photoprotection of Wood SurfaceDokument14 SeitenPhotodegradation and Photoprotection of Wood Surfaceichsan hakimNoch keine Bewertungen

- P1007 PPPS For Raw Milk 1AR SD3 Cheese Risk AssessmentDokument304 SeitenP1007 PPPS For Raw Milk 1AR SD3 Cheese Risk AssessmentNicholasNoch keine Bewertungen

- One Page AdventuresDokument24 SeitenOne Page AdventuresPotato Knishes100% (1)

- Dimensions-Mm (Inch) : Valve Regulated Lead Acid Battery (VRLA)Dokument2 SeitenDimensions-Mm (Inch) : Valve Regulated Lead Acid Battery (VRLA)orunmila123Noch keine Bewertungen

- Escala de Violencia e Índice de SeveridadDokument11 SeitenEscala de Violencia e Índice de SeveridadpsiserviciosprofesioNoch keine Bewertungen

- Essay On Covid 19Dokument15 SeitenEssay On Covid 19Priyanka Dubey67% (3)

- Ageism PowerpointDokument11 SeitenAgeism Powerpointapi-254132646Noch keine Bewertungen

- KPI and Supplier Performance Scorecard ToolDokument7 SeitenKPI and Supplier Performance Scorecard ToolJayant Kumar JhaNoch keine Bewertungen

- ASP Quarterly Report FormsDokument16 SeitenASP Quarterly Report FormsMaria Rosario GeronimoNoch keine Bewertungen

- 16 Point Msds Format As Per ISO-DIS11014 PDFDokument8 Seiten16 Point Msds Format As Per ISO-DIS11014 PDFAntony JebarajNoch keine Bewertungen

- Laccase Mediator Pretreatment of Wheat StrawDokument15 SeitenLaccase Mediator Pretreatment of Wheat StrawMeyerling RandfordNoch keine Bewertungen

- Tabata Its A HIITDokument8 SeitenTabata Its A HIITbertabastionniNoch keine Bewertungen

- Certificate of Employment Document TitleDokument1 SeiteCertificate of Employment Document TitleAyni ReyesNoch keine Bewertungen

- Acute Atelectasis Prevention & TreatmentDokument9 SeitenAcute Atelectasis Prevention & TreatmentmetabolismeproteinNoch keine Bewertungen

- Food Regulations MalaysiaDokument4 SeitenFood Regulations MalaysiaSyafi'ie Syukri100% (1)

- Early Signs of AutismDokument27 SeitenEarly Signs of AutismErica Alejandra Schumacher100% (1)

- List of Personnel Benefits Granted by The SchoolDokument8 SeitenList of Personnel Benefits Granted by The SchoolAspci Assumption Passi100% (1)

- Assignment On Types of Retail Marketing: Submitted By: MR - Swapnil S. Ghag. Roll No.10 (A)Dokument9 SeitenAssignment On Types of Retail Marketing: Submitted By: MR - Swapnil S. Ghag. Roll No.10 (A)Swapnil Ghag100% (1)

- (Distracted Subjects) CHAPTER 2. Reading The Language of Distraction - Hamlet, Macbeth, King LearDokument23 Seiten(Distracted Subjects) CHAPTER 2. Reading The Language of Distraction - Hamlet, Macbeth, King LearLCAP ConsultingNoch keine Bewertungen

- Sodium Chloride MSDSDokument5 SeitenSodium Chloride MSDSIbaharmovic LpuNoch keine Bewertungen

- Annex C Olp On The RoadDokument7 SeitenAnnex C Olp On The RoadCabanglasanfs OLPNoch keine Bewertungen

- Calculate Size of Transformer / Fuse / Circuit Breaker: Connected Equipment To TransformerDokument16 SeitenCalculate Size of Transformer / Fuse / Circuit Breaker: Connected Equipment To TransformerHari OM MishraNoch keine Bewertungen

- Q 400 SYSTEM BestDokument9 SeitenQ 400 SYSTEM BestTeddy EshteNoch keine Bewertungen

- Sample MCQ Mec201Dokument10 SeitenSample MCQ Mec201UjjalKalitaNoch keine Bewertungen

- Frontier DL650 Maintenance Guide Ver 1.0Dokument25 SeitenFrontier DL650 Maintenance Guide Ver 1.0philippe raynalNoch keine Bewertungen

- Manual Murray 20Dokument28 SeitenManual Murray 20freebanker777741Noch keine Bewertungen