Beruflich Dokumente

Kultur Dokumente

STG CaseStudy 203

Hochgeladen von

FreshhhCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

STG CaseStudy 203

Hochgeladen von

FreshhhCopyright:

Verfügbare Formate

Stack Sizer Improves Jianshan Operation

at TISCO

Capacity Improves by 50%, from 6 Million tons/year to 9 Million tons/year

Circulation Load Decreases from 200-300% to 60%

Improves Tertiary Grinding Efficiency from 0.22 t/(m3.h) to 0.45 t/(m3.h)

Background

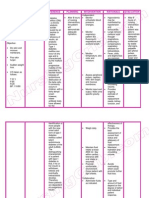

Jianshan Iron Ore Mine processes

Magnetic

6 million tons of iron ore yearly Separator

and supplies product to its mother

company Taiyuan Iron and Steel

(Group) Co. Ltd. (TISCO) via two Fine Screens

parallel 102km pipelines. With the

aim to increase production by 25

Magnetic

percent, Jianshan Iron Ore Mine was Separator

considering two options: purchase

a new mill or improve their current

operation, especially the grinding

circuits. Tertiary Mill

4 Stages of

Magnetic Sepatator

With the ore becoming finer

and harder, the grinding circuit,

especially tertiary grinding, had 2 Stages of 3 Stages of

Magnetic Sepatator Magnetic Sepatator

become less efficient due to poor

Product Tailings

classification operation. They were

using domestic fine screens with

either nylon surfaces or wire panels. Original Jianshan iron ore mine flow sheet.

The undersize efficiency was 28.09

percent for nylon surfaces and about Buying a new mill to produce the Derrick Stack Sizer. In June 2004,

60 percent for the wire panels. targeted additional 1.5 million tons/ Jianshan sent a sample to the Derrick

However, due to the blinding of those year appeared inevitable. testing lab at Buffalo, New York. The

panels, the efficiency continued testing was very successful, indicated

to degrade and, therefore, the Solution by high undersize efficiency of 78.42

liberated fine particles could not pass The process engineers in the percent, fine undersize product 93.79

through the panels. As a result, their Jianshan Iron Ore Mine were thinking percent passing 200 mesh, and high

circulation load was normally in the of achieving their objective by grade undersize product of 65.43

range of 200 to 300 percent, and they improving the classification efficiency percent at 40 percent feed solid

also were experiencing overgrinding of their closed grinding circuit. To content.

and low capacity in the closed explore this possibility, they decided

grinding circuit. to evaluate the performance of the (continued on opposite side)

Case Study | 203

Following the successful lab testing,

Jianshan purchased eight 2SG48- Magnetic

60W-5STK Stack Sizers to close Separator

their tertiary mill (see flowsheet).

In addition, they upgraded their

magnetic separation systems. Eight (8)

5-Deck Derrick

Stack Sizers

Conclusion

After installation of the Stack Sizers,

the process engineers conducted Magnetic

onsite evaluation, and the results Separator

showed that the Stack Sizer can

achieve high classification efficiency

(above 70 percent) consistently with

panel life exceeding domestic panels.

3 Stages of

The undersize recovery was improved Tertiary Mill Magnetic Sepatator

from 20 percent to 60 percent as a

result of reducing the circulating load

from 200-300 percent to 60 percent.

4 Stages of

The content of -325 mesh decreased Product Magnetic Sepatator Tailings

from 82 percent to 75 percent for the

same final product grade. In other New Jianshan iron ore mine flow sheet incorporating Derrick Equipment.

words, the overgrinding problem was

eliminated by the improvement in Today, the Jianshan Iron Ore Mine

classification performance. For the has 16 Stack Sizers4 in secondary

oversize product, the content of -200 grinding and 12 in tertiary grinding

mesh decreased from 82 percent and the total capacity of the plant is

to 55-60 percent, resulting in true now 9 million ton/year.

oversize regrinding. Additionally, the

oversize solid content increased from

60-63 percent to 67-70 percent due to

a reduction in fines.

The performance of the tertiary mill

is, therefore, significantly improved,

as indicated by an effective tonnage

improvement from 0.22 t/(m3.h) to

0.45 t/(m3.h). As a result, one of the

four mills in the tertiary grinding

circuit was removed from service.

The spare mill was then used for a

capacity expansion application.

For more information, please contact your local Derrick sales representative.

590 Duke Road Buffalo, New York 14225 T: (716) 683-9010 F: (716) 683-4991

info@derrick.com www.derrick.com

DC | CS_203 | 7/13 Copyright 2013 Derrick Corporation (All rights reserved)

All products indicated by trademark symbols are trademarked and/or registered by Derrick Corporation. Case Study | 203

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Nursing Care Plan Diabetes Mellitus Type 1Dokument2 SeitenNursing Care Plan Diabetes Mellitus Type 1deric85% (46)

- D90KSDokument1 SeiteD90KSAmilton filhoNoch keine Bewertungen

- Support of Roof and Side in Belowground Coal MinesDokument5 SeitenSupport of Roof and Side in Belowground Coal MinesNavdeep MandalNoch keine Bewertungen

- Comparison of The EC-GMP Guide Part I With The SFDA-GMP Guideline For Chinese CompaniesDokument7 SeitenComparison of The EC-GMP Guide Part I With The SFDA-GMP Guideline For Chinese Companiesrambabukomati472Noch keine Bewertungen

- FS1 Worksheet Topic 6Dokument2 SeitenFS1 Worksheet Topic 6ALMALYN ANDIHNoch keine Bewertungen

- Computer Forensics ReportDokument7 SeitenComputer Forensics ReportMatias IacobuzioNoch keine Bewertungen

- 33kV BS7835 LSZH 3core Armoured Power CableDokument2 Seiten33kV BS7835 LSZH 3core Armoured Power Cablelafarge lafargeNoch keine Bewertungen

- Warranties Liabilities Patents Bids and InsuranceDokument39 SeitenWarranties Liabilities Patents Bids and InsuranceIVAN JOHN BITONNoch keine Bewertungen

- KITZ - Cast Iron - 125FCL&125FCYDokument2 SeitenKITZ - Cast Iron - 125FCL&125FCYdanang hadi saputroNoch keine Bewertungen

- Lesson 2.4Dokument8 SeitenLesson 2.4Tobi TobiasNoch keine Bewertungen

- Algorithm Design TechniquesDokument24 SeitenAlgorithm Design TechniquespermasaNoch keine Bewertungen

- Pro Con ChartDokument3 SeitenPro Con Chartapi-461614875Noch keine Bewertungen

- Hitachi-HRL SeriesDokument13 SeitenHitachi-HRL SeriesJose LopezNoch keine Bewertungen

- Instrumentation Design BasicsDokument28 SeitenInstrumentation Design BasicsCharles ChettiarNoch keine Bewertungen

- Watt AC-DC Converters: FeaturesDokument3 SeitenWatt AC-DC Converters: FeatureskofidNoch keine Bewertungen

- 1600 Cal Meal Planning GuideDokument6 Seiten1600 Cal Meal Planning GuideAlyssa Jennings100% (2)

- Industrial Marketing Module 2Dokument32 SeitenIndustrial Marketing Module 2Raj Prixit RathoreNoch keine Bewertungen

- Resume Pet A Sol LanderDokument3 SeitenResume Pet A Sol LanderdreyesfinuliarNoch keine Bewertungen

- Year 10 English Unit Plan AdvertisingDokument5 SeitenYear 10 English Unit Plan Advertisingapi-333849174Noch keine Bewertungen

- Demystifying The Diagnosis and Classification of Lymphoma - Gabriel C. Caponetti, Adam BaggDokument6 SeitenDemystifying The Diagnosis and Classification of Lymphoma - Gabriel C. Caponetti, Adam BaggEddie CaptainNoch keine Bewertungen

- Interdisciplinary Project 1Dokument11 SeitenInterdisciplinary Project 1api-424250570Noch keine Bewertungen

- Media Analysis-GraphicDokument1 SeiteMedia Analysis-Graphicapi-262266786100% (1)

- Have Been Tried From Time To Time," As Churchill Famously Said (Third Paragraph) "?Dokument25 SeitenHave Been Tried From Time To Time," As Churchill Famously Said (Third Paragraph) "?Aditya ThakurNoch keine Bewertungen

- Lesson 3: Letters of RequestDokument4 SeitenLesson 3: Letters of RequestMinh HiếuNoch keine Bewertungen

- Concor PI CCDS 11 All StrengthsDokument10 SeitenConcor PI CCDS 11 All Strengthsgigid afandiNoch keine Bewertungen

- Perceptual Objective Listening Quality Assessment (POLQA), The Third Generation ITU-T Standard For End-to-End Speech Quality Measurement Part I-Temporal AlignmentDokument19 SeitenPerceptual Objective Listening Quality Assessment (POLQA), The Third Generation ITU-T Standard For End-to-End Speech Quality Measurement Part I-Temporal AlignmentmewarulesNoch keine Bewertungen

- POLAR BEARS-Biology ProjectDokument16 SeitenPOLAR BEARS-Biology Projectserwaa21Noch keine Bewertungen

- Report Palazzetto Croci SpreadsDokument73 SeitenReport Palazzetto Croci SpreadsUntaru EduardNoch keine Bewertungen

- SB Roadmap B1 1Dokument161 SeitenSB Roadmap B1 1Carmen Flores AloyNoch keine Bewertungen

- Water Quality MonitoringDokument3 SeitenWater Quality MonitoringJoa YupNoch keine Bewertungen