Beruflich Dokumente

Kultur Dokumente

Kawa R670

Hochgeladen von

sanusi690 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

247 Ansichten6 SeitenRoof system

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenRoof system

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

247 Ansichten6 SeitenKawa R670

Hochgeladen von

sanusi69Roof system

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

1KeaWar R670

High Rib Roof Profile

THE MeaWer R670 IS A HIGH RIB ROOF PROFILE

ESPECIALLY IDEAL FOR HEAVY RAINFALL INTENSITY

AREAS. WITH ITS WIDE TRAY CONFIGURATIONS, WATER

IS SAFELY DISPERSED OF FROM THE ROOF SURFACE

AREA EVEN AT A MINIMUM ROOF PITCH OF 1°.

ADVANTAGES

* Itis a non-puncturing bolless roof. This unique fastening system greatly reduces the risk of leakage

at fasteners of conventional systems.

** High ribbed profile resulting in a stronger roof spanning wider purlin centres.

* A lower pitched roof, effectively reducing fascia usage.

* Wider profil, therefore increasing installation speed.

Kawa product manuel 31

Material STEEL

Base Steel Thickness (BST), (mm) 0.48 ‘E" "0.60 ‘E”

‘Overall Wit (mm) Nomina 705

Effective Cover Width (mm) Nominal 670,

Rib Height (mm) Nominal 41

Crimp Depth (mm) for Curvature Nominal 3.5

Mass per unit area (kt) 7

Mass per unit length (kg/m) 3.15 3.58 4.44

Area per Metric Tonne (m*/tonne) 212.66, 487.10, 160.83,

Pan eee eee eal

‘Span (rm)

12 ‘Safo Load kgit) 580 662 28

Dafiection for Above Load (mm) 4 4 4

18 ‘Safe Load gi") a7 226 520

Datistion for Above Lead (rm) 8 6 6

18 ‘Safe Load (kg/t') 258, 208 368

Detection for Above Load (rm) 2 3 9

2a ‘Safe Load kgitm) 185) 216 270

Deflection for Above Load mn) 2 2 12

24 ‘Safe Load git") 145; 166) 207

Defiection for Above Load (mm) 16 16 16

27 ‘Safo Load (kg/t") 14 131 164

Deticction for Above Lead (rm) 20 20 20

30 ‘Safe Load (kg/m) 9 106 132

Datisction for Above Load (mm) 25 25 25

35 Safe Load git") oa 78 97

Dafistion for Above Load im) a4 24 34

MIME ene mn een a a

Roof Application

‘Single Span (mm) 1800 1600 2000,

End Span (mm) 1650 1800 2800,

Internal Span (mmm) 2000 2200 2700

Free Cantilever (mm) 300 400 400

Wall Application

‘Single Span (rm) 1900 2200, 2300,

End Span (mm) 2200 2400 2600

Internal Soan (mm) 2400 2900 2000,

Free Cantilever (mm 300 400 400

On Application only

“Ez High Tensile Stool (550 MPa)

32. werwer product manval

INSTALLATION PROCEDURE

Eneure that the installation direction of the MteWeea! 670 roof

sheets opposes that of prevailing winds. Afgn the frst row of fixing

clips longtudinally using a wire as an alignment Ine. Fasten the

Kerwea’ F570 fixing clios onto the putins with four Wafar Head

DX 522 WO sel-diling sel-tanping screws.

STEP 2

Position tha ‘first shoot of KeeaWea' RS70 over the fxing clips,

fensuring that the overianping female rib of the roof sheel faces the

edge of the roof where installation is to commence. The sheets then

locked into position by applying foot pressure on the two centre ribs

‘and female rib of the sheet

STEP 3

‘Tho next row of Merwe’ 267

the purlns witht

fib ofthe roof sh

don

e male

‘xing clips are thon fastor

‘mall portion of the clips holding down

STEP 4

The next roof sheets then placed over the fing cins withthe female

rib of the roof sheet covering the male rib of the previous sheet, An

alignment wire is used to ensure that the roof sheets are aligned

laterally, parallel to the eave pur,

oe

STEP 5A

Popeat Step 3 and Step 4 unt the roof Is fully covered. Should the

space between the last sheet and the edge of the roof be more

than one third (1/8) the width of a sheet, then the final sheet shall

bbe cut along the pan longitudinally, positioned as close as possible

to the edge and installed as a full sheet, Finish root installation with

cessary flashing and capping,

STEP 5B

‘Should the space botwoon the last shaot and tho edgo of the ro0

bbe loss than one thre (1/2) the width of a sheet, then the last sheet

‘Would be the final sheet ancl secured down with a cut-off (1/3) fixing

lip. The remaining space is later flashed over for watertight

Fish roof installation with necessary flashing and capping.

product manual 33

TYPICAL ASSEMBLY DRAWING

Olmmiaae Cf: stevens Cae

FOR ROOF & WALL CLADDING

Kawer R670

WALL CLADDING

anwar R570 ROOF SHEET

FLASHING

RIDGE CAPPING

(OPTIONAL NOTCHING)

enw R670 FIXING CLIP

FLASHING.

ROOF PURLIN

FLASHING

Kawel R670

WALL CLADDING

ROOF PITCH

», the IKea Wea! R670 profile can be installed on @ roof pitch as low as 1°, Howey

red during designing to avoid sit accurnulation dus to reduced water velocity and

resul of uneven pur

END LAPS

Should endl:

pitch

3ve.a minimum of 250 mm end lap for a 5° root pitch and below, and a minimum 200 mm end lap fora root

tightness by aoplying & good sealant to the end lap,

PENDING OF ene 670

OF

34. mewer product manval

Kawa F670

ACCESSSORIES

ewer R670 FING CLP,

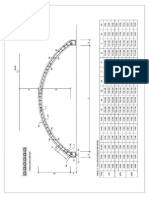

CRIMPED CURVED ROOF

Deh aa teria eke

functionality to the building envelop

Ree)

Seer eee ere

WAFER HEAD Dx 822 WO)

FOR FRING CLIP

fascias and roofs.

Ea Ee

eae

Creat)

eee ee ae)

DIAGRAM SHOWING THE RADIUS OF CURVATURE OF THE

Rea Wed 12670 CRIMPED CURVED PROHLE

Ens that the sheets ave Fted orto the roof te right way up withthe male

and female ribs in tho desired deostion, otherwise shoots vill nave to be

‘ofentatod during nsalstion,

\Whare a few sheets are reqited to cover the whole nath of the roof ue to

handling or transport considerations, installatn shal start ftom te bottom to

‘the top Bolero moving on to tho nex’ tun of ef. the end ps, @ minima

‘0250 ma ens lapis required for a5 oat eich and below, and a minimum

TYPICAL ASSEMBLY DRAWING OF THE

Mew 3670 CRIVPED CURVED PROFLE

‘0f 200 mm end laps requited fora oot pitch exceeding S.To enstre water

Lighiness, apply a good sealant to tne nd lp.

For tho KeeaWe" 670 Crimped Curved profile, val fixing ofthe shoes

recommended only on th fascia purl. For tho rst of the purlns, scrows

shouldbe ued on the crests of the sib when are supported by fing clos.

awe’ product marvel 35,

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Structural Design of Hangar For AirportDokument18 SeitenStructural Design of Hangar For Airportsanusi69100% (3)

- JKR Terms of ReferenceDokument12 SeitenJKR Terms of Referencesanusi69Noch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Terms of Reference For Geotechnical and Structural Independent CheckerDokument3 SeitenTerms of Reference For Geotechnical and Structural Independent Checkersanusi69Noch keine Bewertungen

- Macalloy Bars For Use in Post Tensioning ApplicationDokument21 SeitenMacalloy Bars For Use in Post Tensioning Applicationsanusi69Noch keine Bewertungen

- Determination of Mechanical Properties of Steel Fiber Reinforced Concrete With Mineral AdmixturesDokument3 SeitenDetermination of Mechanical Properties of Steel Fiber Reinforced Concrete With Mineral Admixturessanusi69Noch keine Bewertungen

- 2007-11-29 Bridge CE Findings PDFDokument19 Seiten2007-11-29 Bridge CE Findings PDFsanusi69Noch keine Bewertungen

- Volume 3 Chapter 11Dokument27 SeitenVolume 3 Chapter 11sanusi69Noch keine Bewertungen

- The Magazine of The Hilti GroupDokument36 SeitenThe Magazine of The Hilti Groupsanusi69Noch keine Bewertungen

- Seismic Soil-Structure Interaction: ECI 281A Adv. Soil Mechanics Term ProjectDokument18 SeitenSeismic Soil-Structure Interaction: ECI 281A Adv. Soil Mechanics Term Projectsanusi69Noch keine Bewertungen

- Tekla - Steel Detailing - Basic Training DrawingDokument160 SeitenTekla - Steel Detailing - Basic Training DrawingEileen Christopher100% (1)

- Design of A Bowstring Tied-Arch DeckDokument9 SeitenDesign of A Bowstring Tied-Arch Decksanusi69Noch keine Bewertungen

- Hydraulic Design of Culverts v2Dokument67 SeitenHydraulic Design of Culverts v2Rüştü Köseoğlu100% (1)

- Welcome: All Faculty Members & All Participants of Integrated Course-10109Dokument39 SeitenWelcome: All Faculty Members & All Participants of Integrated Course-10109structure12367% (3)

- Dam Breach ModellingDokument9 SeitenDam Breach Modellingsanusi69Noch keine Bewertungen

- Why Is Isra in Town?Dokument16 SeitenWhy Is Isra in Town?sanusi69Noch keine Bewertungen

- Pavement DesignDokument32 SeitenPavement Designsanusi69Noch keine Bewertungen

- Pengenalan JambatanDokument80 SeitenPengenalan Jambatansanusi69100% (1)

- First International Seminar On The Design & Construction of Second Penang BridgeDokument47 SeitenFirst International Seminar On The Design & Construction of Second Penang Bridgesanusi69Noch keine Bewertungen

- Construction ContractDokument192 SeitenConstruction Contractsanusi69100% (2)

- Bridge ManagementDokument53 SeitenBridge Managementsanusi69Noch keine Bewertungen

- Arch Bridge DetailDokument4 SeitenArch Bridge Detailsanusi69Noch keine Bewertungen