Beruflich Dokumente

Kultur Dokumente

Abhimanyu 121416013

Hochgeladen von

patil_555Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Abhimanyu 121416013

Hochgeladen von

patil_555Copyright:

Verfügbare Formate

Implementation of S88 Model MIS No.

121416013

M.Tech (2nd Year)

for Batch Processing Pilot Process Instrumentation

College Of Engineering, Pune

Plant

Introduction / Project Overview / Project Idea: For Automation of Continuous, Batch and Discrete Pilot plants, We have three pilot plants that is

Boiler, Batch and Bottle Pilot Plant. Boiler pilot plant, which is the application of continuous process automation. Batch Process pilot plant, which is the

application of batch process automation system and Bottle Filling pilot plant is the application of discrete automation system. All the pilot plants will be

controlled by its own Local PLC's, Two Siemens S7-1200 PLC is used as controller for Batch and Bottle Filling Pilot Plant and Allen-Bradley 1400B is for

Boiler and these are also communicated with higher end controller Controllogix and DeltaV DCS and basic objectives are Implementation of S88 model for

batch processing pilot plant , Implementation of advance control strategies on boiler and heat exchanger and configuration of motion control using S7-1200

PLC.

Needs:

The increasing demands on flexibility and customer-driven production lead to an augmented interest in batch processes, which are more

economical for small-scale production. Furthermore, the growing demands on efficiency and reliability of industrial processes have increased the

importance of the implemented control systems and lead to an extension of their scope. In batch systems, the connection of the recipe and the mechanically

fixed equipment network represents a many-to-many relationship; this provides the flexibility of the batch systems, which leads to a multiproduct and

multipurpose plant. The technological operations follow one another in a predefined order. The equipment is designed not only for producing a single

product but also the same technological unit has to be capable for different operations or to produce different products. Consequently, significantly different

conditions might be necessary, which demand high flexibility from both equipment and control.

Block Diagrams & Results

Fig.2 Communication with higher end

controller

Fig. 3: Class Based Approach

Fig.1 P&ID of Batch Processing Plant

Fig.4 Arbitration for coordination between two phases Fig.5 SCADA of Batch Processing Pilot Plant

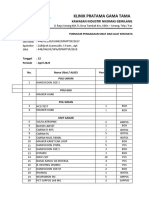

Hardware Used Software Used Benefits

Batch Pilot Plant (Siemens Step 7- TIA V11 (Siemens Step 7) It can reduce initial capital outlay (the cost of setting up the machines)

1200) RSLogix 500 and 5000 because a single production line can be used to produce several

Bottle Filling Pilot Plant (Siemens Factory Talk View Studio products.

Step 7-1200) RSLinx Enterprise Batch production can be useful for small businesses who cannot afford

Boiler & Heat exchanger Pilot Plant DeltaV Operator configure to run continuous production lines.

(Allen-bredaly micrologix 1400B) Control studio If a retailer buys a batch of a product that does not sell, then the

ControlLogix 5560 DeltaV Explore producer can cease production without having to sustain huge losses.

Emerson DeltaV S series DeltaV Recipe Studio Batch production is also useful for a factory that makes seasonal items,

Motors, Actuators, Transmitters, Batch Operator Interface products for which it is difficult to forecast demand, a trial run for

switches, etc Batch Executive production, or products that have a high profit margin.

IFIX 5.8 (Local SCADA) Reduce in risk

IGS & Kepware(OPC)

MATLAB

Name: Abhimanyu Kumar Guide: Prof. S. D. Agashe

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Niche PartitioningDokument3 SeitenNiche PartitioningKhang LqNoch keine Bewertungen

- Types of EvidenceDokument13 SeitenTypes of EvidenceSteven Jan Sab-itNoch keine Bewertungen

- Conflict MangementDokument35 SeitenConflict Mangementmadhuri_bind100% (1)

- Jet RevisedDokument8 SeitenJet RevisedDharavGosaliaNoch keine Bewertungen

- Gkenergy Quality ProcessDokument12 SeitenGkenergy Quality Processpatil_555Noch keine Bewertungen

- 3 DbscanDokument7 Seiten3 Dbscanpatil_555Noch keine Bewertungen

- (Ref. Page 10 Last Para.) (Ref. Page 10 Last Para.)Dokument1 Seite(Ref. Page 10 Last Para.) (Ref. Page 10 Last Para.)patil_555Noch keine Bewertungen

- 2 ClusteringDokument41 Seiten2 Clusteringpatil_555Noch keine Bewertungen

- Zomorrodi Shahrokhi PID Tunning Comparison PDFDokument12 SeitenZomorrodi Shahrokhi PID Tunning Comparison PDFpatil_555Noch keine Bewertungen

- Root FileDokument84 SeitenRoot Filepatil_555Noch keine Bewertungen

- Sensor CharacteristicDokument26 SeitenSensor CharacteristicLutfina PutriNoch keine Bewertungen

- Static Characteristics of MeasurementDokument17 SeitenStatic Characteristics of MeasurementdanielbhaskerNoch keine Bewertungen

- Shri NivasDokument6 SeitenShri Nivaspatil_555Noch keine Bewertungen

- 1000 IDokument1 Seite1000 Ipatil_555Noch keine Bewertungen

- Root FileDokument84 SeitenRoot Filepatil_555Noch keine Bewertungen

- Government of Maharashtra Directorate of Employment & Self-Employment Job Seeker Registration SlipDokument1 SeiteGovernment of Maharashtra Directorate of Employment & Self-Employment Job Seeker Registration SlipVineetVasuNoch keine Bewertungen

- Estimation of Optimum Range of Set-Points and Two Level & Four Level Control For A Closed Loop Quadruple Tank Pilot Plant Through PLCDokument9 SeitenEstimation of Optimum Range of Set-Points and Two Level & Four Level Control For A Closed Loop Quadruple Tank Pilot Plant Through PLCpatil_555Noch keine Bewertungen

- Commonlyused SentencesDokument1 SeiteCommonlyused Sentencespatil_555Noch keine Bewertungen

- To Design Fuzzy Model Based PID Controller For Level ProcessDokument2 SeitenTo Design Fuzzy Model Based PID Controller For Level Processpatil_555Noch keine Bewertungen

- Design, Development & Comparison of Various Control Strategies For Distillation Column Pilot PlantDokument2 SeitenDesign, Development & Comparison of Various Control Strategies For Distillation Column Pilot Plantpatil_555Noch keine Bewertungen

- Raewwwwwwwwwwwwwwwwwwwwwwwww: RUNG - A Section of The PLC Ladder Program That Terminates in An OutputDokument6 SeitenRaewwwwwwwwwwwwwwwwwwwwwwwww: RUNG - A Section of The PLC Ladder Program That Terminates in An Outputpatil_555Noch keine Bewertungen

- Design of PI/PID Controller For Coupled Tank SystemDokument3 SeitenDesign of PI/PID Controller For Coupled Tank Systempatil_555Noch keine Bewertungen

- WWW - Autho.dvat - Gov.in BankTest FrmPrintPayment - AspxDokument5 SeitenWWW - Autho.dvat - Gov.in BankTest FrmPrintPayment - Aspxpatil_555Noch keine Bewertungen

- Gkeapl Sugar PPT - CommonDokument42 SeitenGkeapl Sugar PPT - Commonpatil_555Noch keine Bewertungen

- Create Fault Logic Contact and CoilDokument27 SeitenCreate Fault Logic Contact and Coilpatil_555Noch keine Bewertungen

- Raewwwwwwwwwwwwwwwwwwwwwwwww: RUNG - A Section of The PLC Ladder Program That Terminates in An OutputDokument5 SeitenRaewwwwwwwwwwwwwwwwwwwwwwwww: RUNG - A Section of The PLC Ladder Program That Terminates in An Outputpatil_555Noch keine Bewertungen

- Raewwwwwwwwwwwwwwwwwwwwwwwww: RUNG - A Section of The PLC Ladder Program That Terminates in An OutputDokument6 SeitenRaewwwwwwwwwwwwwwwwwwwwwwwww: RUNG - A Section of The PLC Ladder Program That Terminates in An Outputpatil_555Noch keine Bewertungen

- (Ganesh Shete)Dokument18 Seiten(Ganesh Shete)patil_555Noch keine Bewertungen

- Icl-N2 Compressor Scada SnapshotDokument1 SeiteIcl-N2 Compressor Scada Snapshotpatil_555Noch keine Bewertungen

- Raewwwwwwwwwwwwwwwwwwwwwwwww: RUNG - A Section of The PLC Ladder Program That Terminates in An OutputDokument6 SeitenRaewwwwwwwwwwwwwwwwwwwwwwwww: RUNG - A Section of The PLC Ladder Program That Terminates in An Outputpatil_555Noch keine Bewertungen

- RaewwwwwwwwwwwwwwwwwwwwwwwwwDokument5 SeitenRaewwwwwwwwwwwwwwwwwwwwwwwwwpatil_555Noch keine Bewertungen

- Hber BernDokument6 SeitenHber Bernpatil_555Noch keine Bewertungen

- Raewwwwwwwwwwwwwwwwwwwwwwwww: RUNG - A Section of The PLC Ladder Program That Terminates in An OutputDokument2 SeitenRaewwwwwwwwwwwwwwwwwwwwwwwww: RUNG - A Section of The PLC Ladder Program That Terminates in An Outputpatil_555Noch keine Bewertungen

- TMJC - H2 - 2021 - Prelim P2Dokument9 SeitenTMJC - H2 - 2021 - Prelim P2猪猪侠Noch keine Bewertungen

- Update CV KhanDokument2 SeitenUpdate CV KhanqayyukhanNoch keine Bewertungen

- REV 0 Material Selection Diagram MSD Blueprint IncDokument5 SeitenREV 0 Material Selection Diagram MSD Blueprint IncJohn Patrick Sanay NunezNoch keine Bewertungen

- INCaDokument47 SeitenINCaMehdi SoltaniNoch keine Bewertungen

- Brochure GM IM Roller Mill Antares MDDR MDDT en LowDokument8 SeitenBrochure GM IM Roller Mill Antares MDDR MDDT en Lowahmed shomanNoch keine Bewertungen

- Sem2 NanoparticlesDokument35 SeitenSem2 NanoparticlesgujjugullygirlNoch keine Bewertungen

- Unit 4 Language Summary: VocabularyDokument1 SeiteUnit 4 Language Summary: VocabularyStephania GalindezNoch keine Bewertungen

- Three Theories of TruthDokument1 SeiteThree Theories of TruthDn AngelNoch keine Bewertungen

- ADokument3 SeitenAcristinandreeamNoch keine Bewertungen

- 4 Compass SurveyingDokument10 Seiten4 Compass SurveyingSuson DhitalNoch keine Bewertungen

- Sheet No. 1: Roop LalDokument6 SeitenSheet No. 1: Roop LalzzzNoch keine Bewertungen

- Single Core Bonding Cables Are Not in Scope of Supply.: LLC "RKS-Plast"Dokument1 SeiteSingle Core Bonding Cables Are Not in Scope of Supply.: LLC "RKS-Plast"Sunli Karla Sivincha RomeroNoch keine Bewertungen

- Order Details for Order #10105Dokument2 SeitenOrder Details for Order #10105Mohamed HarbNoch keine Bewertungen

- Updated Official All Campuses ON CAMPUS Final Exams Schedule Spring 2021-22 Plan BDokument11 SeitenUpdated Official All Campuses ON CAMPUS Final Exams Schedule Spring 2021-22 Plan BMohammad SafadiehNoch keine Bewertungen

- MAG Infinite S 10SC-017XIBDokument3 SeitenMAG Infinite S 10SC-017XIBPedro Garcia DiazNoch keine Bewertungen

- Pengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuDokument8 SeitenPengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuIsma Prasetya WardaniNoch keine Bewertungen

- X English QPDokument29 SeitenX English QPbadasserytechNoch keine Bewertungen

- What Is A BibliographyDokument7 SeitenWhat Is A BibliographyKaye Diamante ValleserNoch keine Bewertungen

- Tugas (UTS) ASPK - Andro Tri Julianda (95017019)Dokument4 SeitenTugas (UTS) ASPK - Andro Tri Julianda (95017019)محمد عزيرNoch keine Bewertungen

- Scheme of Examination For Master of Computer APPLICATIONS (M.C.A.) W.E.F. Academic Session 2014-15Dokument11 SeitenScheme of Examination For Master of Computer APPLICATIONS (M.C.A.) W.E.F. Academic Session 2014-15Siddharth JainNoch keine Bewertungen

- SampleDokument13 SeitenSamplemypermatakoe71Noch keine Bewertungen

- MFS 7104 Quantitative TechniquesDokument2 SeitenMFS 7104 Quantitative TechniquesDavid KNoch keine Bewertungen

- 3M Water Filtration Products - High Flow Series - HF40 and HF40 - S Performance Data SheetDokument2 Seiten3M Water Filtration Products - High Flow Series - HF40 and HF40 - S Performance Data SheetSergioNoch keine Bewertungen

- 1st Periodic Test - Math 9Dokument2 Seiten1st Periodic Test - Math 9Anna Rose Godes AntioquiaNoch keine Bewertungen

- Lecture 3Dokument16 SeitenLecture 3Awil MohamedNoch keine Bewertungen