Beruflich Dokumente

Kultur Dokumente

ASME VIII-1 Lethal Service Requirements

Hochgeladen von

israr khan0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

431 Ansichten4 SeitenWhen determining if a vessel is in lethal service, the user must decide if the vessel contents are poisonous or dangerous when inhaled in small amounts. If deemed lethal, additional code requirements apply such as 100% radiography of all butt welds, prohibiting certain materials, and special restrictions on joint designs like prohibiting slip-on flanges or partial penetration nozzles. The main source of lethal service rules is ASME VIII-1 section UW-2, which imposes further restrictions on welding and heat treatment depending on the category of joint.

Originalbeschreibung:

lethal service requirement

Originaltitel

Lethal Service

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenWhen determining if a vessel is in lethal service, the user must decide if the vessel contents are poisonous or dangerous when inhaled in small amounts. If deemed lethal, additional code requirements apply such as 100% radiography of all butt welds, prohibiting certain materials, and special restrictions on joint designs like prohibiting slip-on flanges or partial penetration nozzles. The main source of lethal service rules is ASME VIII-1 section UW-2, which imposes further restrictions on welding and heat treatment depending on the category of joint.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

431 Ansichten4 SeitenASME VIII-1 Lethal Service Requirements

Hochgeladen von

israr khanWhen determining if a vessel is in lethal service, the user must decide if the vessel contents are poisonous or dangerous when inhaled in small amounts. If deemed lethal, additional code requirements apply such as 100% radiography of all butt welds, prohibiting certain materials, and special restrictions on joint designs like prohibiting slip-on flanges or partial penetration nozzles. The main source of lethal service rules is ASME VIII-1 section UW-2, which imposes further restrictions on welding and heat treatment depending on the category of joint.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

Lethal Service - Quick Guide

File:PVE-3856, Date:Oct 7, 2011, By:LB

Requirements for lethal service are scattered through VIII-1, the code cases and the interpretations.

ASME VIII-1 section UW-2 (2007 edition) has most of the requirements for lethal service. Two

definitions of lethal service are provided in UW-2:

[A] vessel is to contain fluids of such a nature that a very small amount mixed or unmixed with air is

dangerous to life when inhaled[.]

By "lethal substances" are meant poisonous gases or liquids of such a nature that a very small amount

of the gas or of the vapour of the liquid mixed or unmixed with air is dangerous to-life when inhaled.

For purposes of this Division, this class includes substances of this nature which are stored under

pressure or may generate a pressure if stored in a closed vessel.

It is up to the user to determine if a service is lethal. We at Pressure Vessel Engineering do not

determine if the vessel service is lethal (but we might have opinions based on previous jobs).

When it has been determined that a vessel is in Lethal Service, some of the following code sections will

apply. Other code sections might also be required.

UG-16(5)(a) - Air cooled and cooling tower heat exchanger tube walls to be

1/16" min.

UG-24(b)(5)(a)- Casting RT requirements. UCI-2, UCD-2 Cast iron and ductile

cast iron vessels are not allowed.

UG-99(g),(k) - Hydro test visual leak inspection cannot be waived. Do not paint

prior to the hydro test.

UG-100(d)(4) - Pneumatic tests cannot be used for lethal service vessels, but

also see code cases 2046-2, 2055-2, 2407 regarding pneumatic instead of

hydrostatic testing

UG-116(c) - "L" stamping must be added to the nameplate. UG-120(d)(1) -

"lethal service" is added to the data report

UW-2 - Service Restrictions - main source of info on Lethal Service (see lots more

from UW-2 below)

UW-11(a)(1) - All shell and head butt welds to be 100% RT

UB-3 - Brazed vessels shall not be used

UCS-6 - Do not use SA-36, 38W or SA-283

UCS-79 - PWHT and extreme fiber elongation - read for rules when heat

treatment is required

ULW-1 & ULW-26(b)(4) - Layered vessels lethal restrictions apply to the inner

shell and heads only

UHX-19.1(b)- Heat exchanger markings

Appendix 2-5(d) - Maximum Flange Bolt Spacing

Appendix 2-6 - Bolt Spacing Correction

Appendix 7-1, 7-5 - Steel casting examination for 100% quality factor

Appendix 9-8 - if the jacket does not carry lethal substances, lethal service

restrictions do not apply to it

Appendix 17-2(a) - Dimple jackets will not contain lethal substances

Appendix W Table W-3 - Filing out the U forms

More from UW-2:

UW-2(a) and UW-11(a)(1) - All butt welds shall be 100% radiographed

UW-2(a) - ERW pipe (like some grades of SA-53) is not permitted but

interpretation VIII-1-01-118 says it is acceptable if the long seam is fully

radiographed

UW-2(a) - Post weld heat treatment is required for CS and Low Alloy

UW-2(a)(1)(a) - Category A welds shall be type 1 only (butt welded with no

permanent backing strip)

UW-2(a)(1)(b&c) &Interpretation VIII-1 92-211 - Category B & C welds

shall be type 1 or 2 only (butt welded). No slip on flanges! No Figure UW-13.2

Flange or Head to Shell attachments

Interpretation VIII-I-98-23 - Category D welds (typically nozzles) shall be full

penetration.

UW-2(a)(1)(c) - Category C joints for stub ends have a long list of requirements

UW-2(a)(2 and 3) - Heat exchangers have a long list of requirements

Read all of UW-2 for more restrictions...

The following Code Cases refer to lethal service for VIII-1 vessels (2007)

1750-20(g) - A126 not to be used for prvs, or rupture disks.

2249 - Furnace Brazing

2318 - slip on flanges in lethal service

2321-1 PWHT of P4 and P5A materials

2324 - Ultrasonic inspection

2334 - single fillet lap joint tubesheet to shell connection

2346-1 & 2537 - Alternative rules for SE and F&D head to shell attachment

2369 - Testing of covers separate from vessels

2377 - RT of SA-612 steel

2421 - Single fillet joints in Heat exchanger tubes

2437 - Diffusion bonded heat exchangers

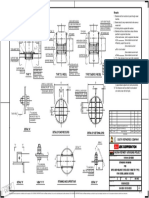

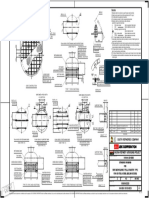

Weld restrictions

Special lap joint stub end for lethal service All partial penetration nozzles are prohibited

All figure UW-13.2 corner welds are prohibited No slip on flanges

Disclaimer: This material is provided for educational uses only. Only ASME can make code

interpretations.

Das könnte Ihnen auch gefallen

- Lethal ServiceDokument6 SeitenLethal ServiceNilabhNoch keine Bewertungen

- ASME VIII Lethal Service Requirements GuideDokument3 SeitenASME VIII Lethal Service Requirements GuideNasir Khan Jadoon0% (1)

- Lethal Service GuideDokument5 SeitenLethal Service GuidekingstonNoch keine Bewertungen

- Lethal Service - Quick Guide - Pressure Vessel EngineeringDokument8 SeitenLethal Service - Quick Guide - Pressure Vessel EngineeringIara NascimentoNoch keine Bewertungen

- Lethal Service - Quick Guide - Pressure Vessel EngineeringDokument4 SeitenLethal Service - Quick Guide - Pressure Vessel EngineeringVilas AndhaleNoch keine Bewertungen

- Code Requirement For Lethal ServiceDokument5 SeitenCode Requirement For Lethal Servicesajalkk25Noch keine Bewertungen

- Lethal Service Quick GuideDokument5 SeitenLethal Service Quick GuideMuhammadShabbirNoch keine Bewertungen

- Lethal ServiceDokument4 SeitenLethal Servicesajalkk25Noch keine Bewertungen

- Quick Guides - Pressure Vessel EngineeringDokument7 SeitenQuick Guides - Pressure Vessel EngineeringWaqas WaqasNoch keine Bewertungen

- Pressure Vessel - For LETHAL ServiceDokument3 SeitenPressure Vessel - For LETHAL ServiceGene Andrew OnaNoch keine Bewertungen

- important code diagram asmeDokument3 Seitenimportant code diagram asmesajalkk25Noch keine Bewertungen

- Asme Seccion Viii Div 1 - Apartado Uw-2 Restricciones de ServicioDokument3 SeitenAsme Seccion Viii Div 1 - Apartado Uw-2 Restricciones de ServicioAlexander CorvinNoch keine Bewertungen

- Vacuum buffer tank equipment RT requirementsDokument1 SeiteVacuum buffer tank equipment RT requirementsmiteshpatel191Noch keine Bewertungen

- PP 2001 11Dokument4 SeitenPP 2001 11Ashish YadavNoch keine Bewertungen

- ASME VIII-2-Service Restrictions, Joint Efficiencies, RadiographyDokument34 SeitenASME VIII-2-Service Restrictions, Joint Efficiencies, RadiographyMohammed AnshafNoch keine Bewertungen

- Technical Bulletin 21 PDFDokument7 SeitenTechnical Bulletin 21 PDFAgustin ParadisoNoch keine Bewertungen

- 1876 3Dokument4 Seiten1876 3hogoyoNoch keine Bewertungen

- MIL-W-8604A WeldingDokument20 SeitenMIL-W-8604A Weldingbob_rocksNoch keine Bewertungen

- Welding Inspection Pressure VesselDokument37 SeitenWelding Inspection Pressure Vesselken100% (3)

- Category of RadiographyDokument9 SeitenCategory of RadiographySAGARNoch keine Bewertungen

- MIL DTL 23971C Grall Spec Power Dividers Power CombinersDokument21 SeitenMIL DTL 23971C Grall Spec Power Dividers Power CombinersRamiro ArtazaNoch keine Bewertungen

- ASME Pressure Vessel JointDokument8 SeitenASME Pressure Vessel Jointf4CHNoch keine Bewertungen

- Study Material FlagesDokument4 SeitenStudy Material FlagesAnoop JobanputraNoch keine Bewertungen

- Inspection Requirements ASME VIII DIV 1 1673549276Dokument39 SeitenInspection Requirements ASME VIII DIV 1 1673549276Mat Pustjens100% (1)

- ASME Section VIII Div. 1 Pressure Vessel Inspection GuideDokument47 SeitenASME Section VIII Div. 1 Pressure Vessel Inspection GuideTayfunwNoch keine Bewertungen

- WS-302 Ab 11302021Dokument7 SeitenWS-302 Ab 11302021quality cncNoch keine Bewertungen

- MIL-W-8604 - A (Welding, Fusion Aluminum Alloys Process and Performance Of)Dokument20 SeitenMIL-W-8604 - A (Welding, Fusion Aluminum Alloys Process and Performance Of)ccorp0089Noch keine Bewertungen

- RTDokument7 SeitenRTSUDARSAN SNoch keine Bewertungen

- Asme Section Viii Div 1 2 3Dokument73 SeitenAsme Section Viii Div 1 2 3Sakthi Pk100% (3)

- ASME Code News (Questions and Answers)Dokument4 SeitenASME Code News (Questions and Answers)dj22500Noch keine Bewertungen

- MIL-C-23233A_1992Dokument62 SeitenMIL-C-23233A_1992Martin JensenNoch keine Bewertungen

- Asco Direct Acting Solenoid Valve - 320Dokument6 SeitenAsco Direct Acting Solenoid Valve - 320SatyamEng100% (1)

- Asme Section Viii Div-1,2,3Dokument73 SeitenAsme Section Viii Div-1,2,3me2437090% (39)

- Pressure Points: New Rules For The Use of Rod & Bar in ASME Section VIIIDokument6 SeitenPressure Points: New Rules For The Use of Rod & Bar in ASME Section VIIImohdfirdausNoch keine Bewertungen

- Asme Standards Specifications-1Dokument72 SeitenAsme Standards Specifications-1DHAVAL PANCHAL100% (1)

- Asme Viii - QDokument431 SeitenAsme Viii - Qmajdi jerbiNoch keine Bewertungen

- Forged Valve and Fittings For Sour ServiceDokument1 SeiteForged Valve and Fittings For Sour ServiceVijay AcharyaNoch keine Bewertungen

- Anixter Wire&Cable CatalogDokument698 SeitenAnixter Wire&Cable CatalogNelson GarvizuNoch keine Bewertungen

- Review of Current Practice for Welding of Grade 92Dokument13 SeitenReview of Current Practice for Welding of Grade 92pipedown456100% (1)

- Overhead Electric Distribution ManualDokument636 SeitenOverhead Electric Distribution ManualAlvaro DiazNoch keine Bewertungen

- BRIDGE Steel Welding GuideDokument2 SeitenBRIDGE Steel Welding GuideANTONYLEONoch keine Bewertungen

- Asme Sect. Viii Div-I Codes, Standards & SpecificationsDokument72 SeitenAsme Sect. Viii Div-I Codes, Standards & SpecificationsrodrigoperezsimoneNoch keine Bewertungen

- Mil DTL 26482HDokument86 SeitenMil DTL 26482HImran HashmiNoch keine Bewertungen

- ASME Sec VIII - AwarenessDokument33 SeitenASME Sec VIII - AwarenessNirmal100% (4)

- C Pipe SupportDokument25 SeitenC Pipe Supportsanjay421100% (2)

- Mil V 1189DDokument19 SeitenMil V 1189DSharad KokateNoch keine Bewertungen

- ASME Pressure Vessel Joint Efficiencies and RT Test RequirementsDokument5 SeitenASME Pressure Vessel Joint Efficiencies and RT Test RequirementsEqubal KhanNoch keine Bewertungen

- TABLE-3 LIST OF ATTACHMENTS - Rev 0Dokument5 SeitenTABLE-3 LIST OF ATTACHMENTS - Rev 0Anonymous AyDvqgNoch keine Bewertungen

- Extracto de Seccion 8 Div 1Dokument22 SeitenExtracto de Seccion 8 Div 1Jorge DiazNoch keine Bewertungen

- Asme Q&aDokument57 SeitenAsme Q&amsraja7767% (3)

- Guide for ASME Audit SectionsDokument1 SeiteGuide for ASME Audit Sectionsanon_673643629Noch keine Bewertungen

- Technical Specification for Dual Plate Check ValvesDokument12 SeitenTechnical Specification for Dual Plate Check ValvesShivashankar Durga MedisettiNoch keine Bewertungen

- Marine Electrical Practice: Marine Engineering SeriesVon EverandMarine Electrical Practice: Marine Engineering SeriesBewertung: 4 von 5 Sternen4/5 (8)

- Coastal Engineering Manual: Overview And Coastal HydrodynamicsVon EverandCoastal Engineering Manual: Overview And Coastal HydrodynamicsNoch keine Bewertungen

- Cathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesVon EverandCathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantVon EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantBewertung: 3.5 von 5 Sternen3.5/5 (3)

- DD 011 13513 0007 - 01Dokument1 SeiteDD 011 13513 0007 - 01israr khanNoch keine Bewertungen

- DB 000 13510 0025 - 01Dokument1 SeiteDB 000 13510 0025 - 01israr khanNoch keine Bewertungen

- Cooling Water Treatment PDFDokument56 SeitenCooling Water Treatment PDFwaheed22860% (1)

- PPR 4 1stDokument10 SeitenPPR 4 1stisrar khanNoch keine Bewertungen

- 03 V 003 Depresurring Case 2Dokument364 Seiten03 V 003 Depresurring Case 2israr khanNoch keine Bewertungen

- ENPPI Pressure VesselsDokument47 SeitenENPPI Pressure Vesselsisrar khan100% (2)

- Tag No Nozzle Mark Nozzle Size Part No Reason For ChangeDokument1 SeiteTag No Nozzle Mark Nozzle Size Part No Reason For Changeisrar khanNoch keine Bewertungen

- DB 000 13510 0023 - 01Dokument1 SeiteDB 000 13510 0023 - 01israr khanNoch keine Bewertungen

- DB 000 13510 0021 - 01Dokument1 SeiteDB 000 13510 0021 - 01israr khanNoch keine Bewertungen

- The Weld Type For Nozzle To WN Falnge For CS Material Page 2 To 6Dokument18 SeitenThe Weld Type For Nozzle To WN Falnge For CS Material Page 2 To 6israr khanNoch keine Bewertungen

- Still Column With Reflux - sht.01 To 02 PDFDokument2 SeitenStill Column With Reflux - sht.01 To 02 PDFisrar khanNoch keine Bewertungen

- HVAC Cooling Load Procedure Guideline Lo0Dokument62 SeitenHVAC Cooling Load Procedure Guideline Lo0api-385802594% (36)

- Asme Section I & Section Viii Fundamentals: Pdhonline Course M398 (3 PDH)Dokument59 SeitenAsme Section I & Section Viii Fundamentals: Pdhonline Course M398 (3 PDH)vuchinhNoch keine Bewertungen

- Eds A 9Dokument30 SeitenEds A 9israr khanNoch keine Bewertungen

- Mean Metal Temperature For Fixed Heat Exchanger - Intergraph CADWorx & AnalysisDokument3 SeitenMean Metal Temperature For Fixed Heat Exchanger - Intergraph CADWorx & Analysisisrar khanNoch keine Bewertungen

- Design of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-TipsDokument2 SeitenDesign of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-Tipsisrar khanNoch keine Bewertungen

- Nozzle Reinforcement in Elliptical Head - Intergraph CADWorx & AnalysisDokument4 SeitenNozzle Reinforcement in Elliptical Head - Intergraph CADWorx & Analysisisrar khanNoch keine Bewertungen

- Design of Tail LugDokument34 SeitenDesign of Tail LugPrajwal Shetty100% (1)

- VIII 59 85 - UW 11a5bDokument2 SeitenVIII 59 85 - UW 11a5bisrar khanNoch keine Bewertungen

- CR4 - Thread - What Hydrostatic Test Pressure May Be Used To Test A 2000bar Pressure VesselDokument5 SeitenCR4 - Thread - What Hydrostatic Test Pressure May Be Used To Test A 2000bar Pressure Vesselisrar khanNoch keine Bewertungen

- CR4 - Thread - What Hydrostatic Test Pressure May Be Used To Test A 2000bar Pressure VesselDokument5 SeitenCR4 - Thread - What Hydrostatic Test Pressure May Be Used To Test A 2000bar Pressure Vesselisrar khanNoch keine Bewertungen

- Qa VS QCDokument4 SeitenQa VS QCisrar khanNoch keine Bewertungen

- Durlon Gasketing Technical HandbookDokument15 SeitenDurlon Gasketing Technical Handbookisrar khanNoch keine Bewertungen

- Nozzle Reinforcement in Elliptical Head - Intergraph CADWorx & AnalysisDokument4 SeitenNozzle Reinforcement in Elliptical Head - Intergraph CADWorx & Analysisisrar khanNoch keine Bewertungen

- MATERIAL SA36 - ASME (Mechanical) Code Issues - Eng-TipsDokument2 SeitenMATERIAL SA36 - ASME (Mechanical) Code Issues - Eng-Tipsisrar khanNoch keine Bewertungen

- Tube Expansion Issues & MethodsDokument4 SeitenTube Expansion Issues & MethodsSuleyman HaliciogluNoch keine Bewertungen

- A694 F65 Flanges Manufactured To ASME B16Dokument2 SeitenA694 F65 Flanges Manufactured To ASME B16israr khanNoch keine Bewertungen

- CR4 - Thread - Heat Exchanger DesignDokument4 SeitenCR4 - Thread - Heat Exchanger Designisrar khanNoch keine Bewertungen

- ML040150682 PDFDokument406 SeitenML040150682 PDFjimmy_bikerNoch keine Bewertungen

- BIS 4503 1967 Shell and Tube Type Heat Exchangers PDFDokument72 SeitenBIS 4503 1967 Shell and Tube Type Heat Exchangers PDFmahaveenNoch keine Bewertungen

- Troubleshooting Hydraulic Circuits: Fluid PowerDokument32 SeitenTroubleshooting Hydraulic Circuits: Fluid PowerMi LuanaNoch keine Bewertungen

- Oecumenius’ Exegetical Method in His Commentary on the RevelationDokument10 SeitenOecumenius’ Exegetical Method in His Commentary on the RevelationMichał WojciechowskiNoch keine Bewertungen

- Gautam Samhita CHP 1 CHP 2 CHP 3 ColorDokument22 SeitenGautam Samhita CHP 1 CHP 2 CHP 3 ColorSaptarishisAstrology100% (1)

- Canon imageFORMULA DR-X10CDokument208 SeitenCanon imageFORMULA DR-X10CYury KobzarNoch keine Bewertungen

- Madu Rash Tak AmDokument4 SeitenMadu Rash Tak AmAdv. Govind S. TehareNoch keine Bewertungen

- HSC 405 Grant ProposalDokument23 SeitenHSC 405 Grant Proposalapi-355220460100% (2)

- Conjoint Analysis Basic PrincipleDokument16 SeitenConjoint Analysis Basic PrinciplePAglu JohnNoch keine Bewertungen

- WOOD Investor Presentation 3Q21Dokument65 SeitenWOOD Investor Presentation 3Q21Koko HadiwanaNoch keine Bewertungen

- Discuss The Challenges For Firms To Operate in The Hard-Boiled Confectionery Market in India?Dokument4 SeitenDiscuss The Challenges For Firms To Operate in The Hard-Boiled Confectionery Market in India?harryNoch keine Bewertungen

- Certificate Testing ResultsDokument1 SeiteCertificate Testing ResultsNisarg PandyaNoch keine Bewertungen

- The Impact of Employees' Commitment Towards Food Safety at Ayana Resort, BaliDokument58 SeitenThe Impact of Employees' Commitment Towards Food Safety at Ayana Resort, Balirachelle agathaNoch keine Bewertungen

- Aleister Crowley and the SiriansDokument4 SeitenAleister Crowley and the SiriansJCMNoch keine Bewertungen

- Patent for Fired Heater with Radiant and Convection SectionsDokument11 SeitenPatent for Fired Heater with Radiant and Convection Sectionsxyz7890Noch keine Bewertungen

- Sattvik Brochure - Web VersionDokument4 SeitenSattvik Brochure - Web Versionudiptya_papai2007Noch keine Bewertungen

- Chemistry of FormazanDokument36 SeitenChemistry of FormazanEsteban ArayaNoch keine Bewertungen

- VT6050 VT6010 QuickGuide ENDokument19 SeitenVT6050 VT6010 QuickGuide ENPriyank KumarNoch keine Bewertungen

- Naukri LalitaSharma (3y 4m)Dokument2 SeitenNaukri LalitaSharma (3y 4m)rashika asraniNoch keine Bewertungen

- Xii Neet Chemistry Mcqs PDFDokument30 SeitenXii Neet Chemistry Mcqs PDFMarcus Rashford100% (3)

- Ultrasonic Weld Examination ProcedureDokument16 SeitenUltrasonic Weld Examination ProcedureramalingamNoch keine Bewertungen

- DK Children Nature S Deadliest Creatures Visual Encyclopedia PDFDokument210 SeitenDK Children Nature S Deadliest Creatures Visual Encyclopedia PDFThu Hà100% (6)

- PC3 The Sea PeopleDokument100 SeitenPC3 The Sea PeoplePJ100% (4)

- Update On The Management of Acute Pancreatitis.52Dokument7 SeitenUpdate On The Management of Acute Pancreatitis.52Sebastian DeMarinoNoch keine Bewertungen

- Daftar Spesifikasi Teknis Pembangunan Gedung Kantor BPN BojonegoroDokument6 SeitenDaftar Spesifikasi Teknis Pembangunan Gedung Kantor BPN BojonegoroIrwin DarmansyahNoch keine Bewertungen

- Home Brewing Log Sheet PDFDokument2 SeitenHome Brewing Log Sheet PDFStefanita0% (1)

- MS For Brick WorkDokument7 SeitenMS For Brick WorkSumit OmarNoch keine Bewertungen

- JK Paper Q4FY11 Earnings Call TranscriptDokument10 SeitenJK Paper Q4FY11 Earnings Call TranscriptkallllllooooNoch keine Bewertungen

- ADDRESSABLE 51.HI 60854 G Contoller GuideDokument76 SeitenADDRESSABLE 51.HI 60854 G Contoller Guidemohinfo88Noch keine Bewertungen

- Gauss Contest: Grade 8Dokument4 SeitenGauss Contest: Grade 8peter100% (1)

- Thermal BurnsDokument50 SeitenThermal BurnsPooya WindyNoch keine Bewertungen

- Quaternary Protoberberine Alkaloids (Must Read)Dokument26 SeitenQuaternary Protoberberine Alkaloids (Must Read)Akshay AgnihotriNoch keine Bewertungen