Beruflich Dokumente

Kultur Dokumente

Paper Cutting

Hochgeladen von

Hemant Sharma0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

11 Ansichten5 SeitenOriginaltitel

Paper cutting.docx

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

11 Ansichten5 SeitenPaper Cutting

Hochgeladen von

Hemant SharmaCopyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

Paper cutting & rewinding machine project report SREESANGH P GHOSH

1. 1. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13

ACKNOWLEDGEMENT I am very glad to represent project report on "PAPER CUTTING

ANDREWINDING MACHINE" fully designed, fabricated and tested in our polytechnicas part

of our curriculum is awarding the Diploma in Engineering. I have tried mylevel best to focus

upon each and every parameter. In concern with this topic thedetail, necessary figure,

definition, tabular analysis has been enumerated in veryeasy, simple, compact and lucid

manner. I have been able to achieve this task by the dynamic guidance ofhonorable

SIVARAMAN sir; I have no wards to express my gratitudetowards his kind, persistent

inspiration, parent advice and outstanding treatmentwhile clarifying my confusion. I also

extend my sincere thanks to our esteemed Head of MechanicalEngineering Department Mr.

M.R JAYACHANDRAN, whose guidance andconstant inspiration where a great use in

working of this project. We are alsograteful to our tutor MR. P.P. DEVADAS. I am also grateful

to our honorable work shop superintendentMr.N.M.SATHEESAN and members of staff of our

workshop for providingnumerous facilities and guidance due to which this difficult task turned

in aconvenient task. The permission granted to us by the honorable

principalMr.V.V.SADASIVAN, to do the project work in greatly acknowledged. Last but not

least, I am very thankful to my project partners without whosekind cooperation it was difficult

and impossible to go through the leaps andbounds while preparing this project. Also thanks

to them who directly or indirectlyco-operated and contributed during work. Page 1Department

of Mechanical Engg. S.R.G.P.T.C Triprayar

2. 2. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13 ABSTRACT Paper

Cutting & Rewinding Machine is one of the simplest machine which cutsrolled paper in

needed amount and re-winded form. The conventional paper rewindingmachine has complex

mechanism and bulk size. We made some modification to theconventional machine and

eliminating its defects. The main peculiarity of machine is itssimplicity, reduced size, weight.

And also reduces floor space. This project can bedirectly implemented to paper cutting and

rewinding machines in Paper mills. Thismachine can also use in textile mills, plastic and

rubber sheets cutting and rewindingprocess in various industries by changing its cutting

components. By applying these modifications to the conventional machine

reducemaintenance and servicing cost, floor area and overhead expenditures. It is well

suitedfor small scale industries. Page 2Department of Mechanical Engg. S.R.G.P.T.C

Triprayar

3. 3. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13 CONTENTSTOPIC

NO. TOPIC NAME PAGE-NO. 1. COMPONENTS OF MACHINE 4 2. MANUFACTURING

PROCESS 8 3. STRUCTURE FABRICATION PROCESS 8 4. ROLLER MACHING

PROCESS 10 5. CUTTER CLAMP MAKING PROCESS 12 6. DRIVING MECHANISM 13 7.

WORKING OF MACHINE 14 8. ADVANTAGES 15 9. SPECIFICATIONS OF MACHINE 15

10. MATERIAL REQUIREMENT & COST 16 11. BIBLIOGRAPHY 17 Page 3Department of

Mechanical Engg. S.R.G.P.T.C Triprayar

4. 4. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13 COMPONENTS

OF PAPER CUTTING & REWINDING MACHINE The main components of Paper Cutting &

Rewinding Machine are listed below. 1) BASIC FRAME The entire unit is mounted on a rigid

frame. The frame is made of mild steel C- Channels (75X40 mm) connected in rectangular

form and weld at their joints. 2) ROLLERS The paper rotating element in this device is the

89 mm outer diameter rollers with 40 mm outer diameter journals, which made up of three

components. 1) G. I Hollow Pipe of 89 mm outer Diameter. 2) M.S Rod of 40 mm

Diameter. 3) M.S Circular Plate of 81 mm Diameter. The rotation of motor is transferred to

the one of the four rollers on which cut paper is mounting in operation. The rotating roll

makes all other three rollers to rotate. The roller is supported at its two ends by Plummer

block with ball bearing blocks. The main functions of roller are to favor the cutting operation

by moving paper and rewind it to rolls. Page 4Department of Mechanical Engg. S.R.G.P.T.C

Triprayar

5. 5. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13 4) PLUMMER

BLOCK The roller is supported at the two ends with the help of Plummer block fitted with

40 mm diameter Ball bearings. The bearings are cleaned and greased for easy rotation of

roller. 5) BEARINGS Ball bearing is a type of rolling-element bearing that uses balls to

maintain the separation between the bearing races. The purpose of a ball bearing is to

reduce rotational friction and support radial and axial loads. It achieves this by using at least

two races to contain the balls and transmit the loads through the balls. In most applications,

one race is stationary in Plummer block and the other is attached to rollers journal. As one of

the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling

they have a much lower coefficient of friction than if two flat surfaces were sliding against

each other. Ball bearings tend to have lower load capacity for their size than other kinds of

rolling-element bearings due to the smaller contact area between the balls and races.

However, they can tolerate some misalignment of the inner and outer races. Page

5Department of Mechanical Engg. S.R.G.P.T.C Triprayar

6. 6. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13 6) INDUCTION

MOTOR An induction or asynchronous motor is an AC motor in which all electromagnetic

energy is transferred by inductive coupling from a primary winding to a secondary winding,

the two windings being separated by an air gap. The machine is powered by 1 Hp motor with

1440 rpm. This makes one roll rotates and rotating roll makes other rollers to rotate and not

only wound the paper but also pull the paper to make the operation going. 7) SINGLE V-

BELT AND PULLEY SYSTEM Vee belts (also known as V-belt or wedge rope) solved the

slippage and alignment problem. It is now the basic belt for power transmission. They

provide the best combination of traction, speed of movement, load of the bearings, and long

service life. They are generally endless, and their general cross-section shape is trapezoidal

(hence the name "V"). The "V" shape of the belt tracks in a mating groove in the pulley (or

sheave), with the result that the belt cannot slip off. The belt also tends to wedge into the

groove as the load increases-the greater the load, the greater the wedging action, V-belts

may be homogeneously rubber or polymer. Belts are looped over pulleys. The belt drives the

pulleys in the same direction. As a source of motion, the belt is one application where the

belt is adapted to continuously carry a load between the motor and pulley fitted on the roller.

Page 6Department of Mechanical Engg. S.R.G.P.T.C Triprayar

7. 7. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13 8) CUTTER CLAMP

(C-CLAMP) WITH BOLTS c-clamp with the two bolts are used to clamp the cutter to the

frame and one extended piece of flat for mounting of cutter. 9) NUT AND BOLTS Bolt, is a

type of fastener characterized by a helical ridge, known as an external thread or just thread,

wrapped around a cylinder. A nut is a type of fastener with a threaded hole. Nuts are almost

always used opposite a mating bolt to fasten a stack of parts together. They are made up of

Mild Steel. Nuts and Bolts of different size is used for fixing the Plummer block to the main

frame and to install the cutter clamp. Page 7Department of Mechanical Engg. S.R.G.P.T.C

Triprayar

8. 8. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13 MANUFACTURING

PROCESS I. STRUCTURE FABRICATING PROCESS :- For structure fabrication, the c-

channel of size 75 X 40 mm is used. Theapproximate wt. of it per meter is 6.8 kg. Steps in

fabrication of structure are givenbelow. Step One: First cut the c-channel in pieces of

length 71" (i.e. 6 feet [180 mm]- two pieces)and in 36" (i.e. 3 feet[91.5 mm] - three pieces).

Then Put the two lengths of 6 feetparallel to each other at a distance of 3 feet from each

other. Then put the lengths of 3feet on either end of two parallel lengths and weld them as

shown below. The twodiagonals must be same. Step Two: Then cut four pieces of c-

channel of length 24" (i.e. 2 feet[61 mm]) and weldtwo of them on one end of rectangular

structure vertically using engineers block. Thenweld remaining two pieces vertically at a

distance of 30" from previous pieces. Step Three: Then brought the two pieces of flat of

size 75 X 12 X 760 mm and weld them onthe top of four columns as shown. Page

8Department of Mechanical Engg. S.R.G.P.T.C Triprayar

9. 9. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13 Step Four: Then

cut another two pieces oflength 48" (i.e. 4 feet[122 mm]) andweld them vertically at a

distance of16" from previously welded columns.Afterwards weld the previously cutpiece of

36"[41 mm] on top and inbetween the upper ends of thesecolumns. Step Five: Then cut

two pieces of C-channel of length 15". And four pieces of 4" length.Then at a distance of 4.5"

from nearest end weld them to form a frame as shown below. Page 9Department of

Mechanical Engg. S.R.G.P.T.C Triprayar

10. 10. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13 II. ROLLER

MACHINING PROCESS Roll is mead up of hollow pipe, solid circular plates & solid shaft

journal. So we have to manufacture each part as per required size and then assemble it as a

roll. Steps in this task are:- Step one: First, brought the hollow pipe of required dimensions.

I.e. of required outer, inner and length. If it not available, then cut it on hacksaw machine.

Step two: Then brought two circular plates of 10 mm thickness, face them from bothsides by

holding them on lathe machine. And turn out to the diameter as equal toinner diameter of

hollow pipe so they can fit into pipe for welding purpose. Step three: Take solid bar of M.S.

of 50 mm diameter cut it to length 110 mm. Hold this bar on lathe chuck and turn it out up to

the diameter 38 mm so that it can be fit in pedestal self-aligning bearing block. Step four:

Now, weld the turned solid bar to each of two s o l i d circular plates axially. Page

10Department of Mechanical Engg. S.R.G.P.T.C Triprayar

11. 11. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13 GROOVE FOR

WELDING THE M.S ROD AT CENTRE- Step five: Now, weld these plates in the bore of

hollow pipe. Step six: The roll is completed, but because of welding different parts it need

to be turned again using lathe machine. Hold the journal on one side in chuck and turn the

other journal as well as hollow pipe part of roll. Do the same operation by holding other

journal in chuck so the roll will rotate along its axis accurately. Page 11Department of

Mechanical Engg. S.R.G.P.T.C Triprayar

12. 12. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13III. CUTTER

CLAMP MAKING PROCESS The c-clamp with the two bolts to clamp and one extended

piece of flat for mounting of cutter is welded. It is used to hold the cutter. Step One: First

take the flat of 25 X 10 and cut it by bend saw in size of 90 mm, 65mm, 60 mm and 40 mm.

Step Two: Weld the pieces of 90, 65, and 60 mm to form C. Then take the piece of 40

mmin length and weld it on the 65 mm side of clamp. Step Three: By using drilling

machine, make three holes of 10 mm at the points shown below in the complete assembly of

cutter. Afterwards perform the tapping operations using tap of inch. Page 12Department of

Mechanical Engg. S.R.G.P.T.C Triprayar

13. 13. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13IV. DRIVING

MECHANISM As our project as a demo and also designed for small weight we use the 1 Hp

A.C. motor. It is having the 1440 rpm speed. We use two pulleys of three [7.62 mm] & eight

[20.32] inch diameter respectively on motor and roller. One on the motor shaft and another is

on the shaft of roll. The numbers of belts required for given application is one. V-belt is used

for this purpose. Page 13Department of Mechanical Engg. S.R.G.P.T.C Triprayar

14. 14. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13V. WORKING OF

MACHINE As we give number of modifications it is necessary to briefly explain working

procedure of machine. When the paper being manufactured in paper mill it is not of standard

size an also get torn out at the edges. And here is the need of re-winding machine. The roll

of paper manufactured is mounted on the roll (A). In our machine we have given the self-

aligning bearing with inner extended ring for ease in mounting and urn- mounting. Then

paper is passed around roll (B) to ensure that paper remain straight and tight. Then it passed

through the cutter and grooved roll on top of machine, where it is cut. Because of our

modification to this cutter roll the wt. of machine is decreased. Then the paper which is cut is

come to the roll at bottom, The roll is powered by 1 Hp motor with 1440 rpm. This rotating roll

makes other roll (C) to rotate and not only wound the paper but also pull the paper to make

the operation going. Page 14Department of Mechanical Engg. S.R.G.P.T.C Triprayar

15. 15. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13 Advantages 1) It

is more compact as compared with conventional one. 2) Operation is simple Because of

eliminating complex mechanisms. 3) Saving of floor space as motor is adjusted inside the

structure. 4) New cutter clamping assembly given will eliminate the biggest disadvantage of

machine i.e. high weight. SPECIFICATIONS OF MACHINE 6 feet ( 152.4") Length =

387.096 mm Width 0.914 feet ( 36") = 91.44 mm Height 4 feet ( 48" ) = 121.92 mm 4 Hollow

rolls, 8 Plummer Components blocks,8 bearings 1 Hp, 3 phase, induction Motor motor Page

15Department of Mechanical Engg. S.R.G.P.T.C Triprayar

16. 16. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13 MATERIAL

REQUIREMENTS & COST SL DESCRIPTION QTY. RATE AMOUNT No. 760 X 89 mm

G.I 1 25 Kg. Rs. 81 per Kg. Rs. 2025.00 Pipe(4 Nos ) M.S. Rod 2 135 mm X 50 mm 24

Kg. Rs. 58 per Kg. Rs. 1392.00 M.S Circular Plate 3 12mm X 90 mm 7 Kg. Rs.58 per Kg.

Rs. 406.00 (8 No.) M. S. Flat 12 X 75 X 4 760 11 Kg. Rs. 58per kg. Rs. 638.00 (2 No C-

channel 5 76 Kg. Rs. 58 per kg. Rs.4400.00 75 X 40 ( 12.2 meter ) Plummer Blocks 6 8 No.

Rs.200 per block Rs.1600.00 No 208 i.e. 40 mm Bearings 40 mm 8 No. Rs.30 per

Bearing Rs. 240.00 7 Inner Pulleys 3" 1 No. Rs. 240 per Pulley Rs. 150.00 8 Pulley 8" 1 No.

Rs. 540 per Pulley Rs. 540.00 9 V- Belt of B-type 1 No. Rs.180 per Belt Rs.180.00 10 Paper

4.1 kg Rs. 35 per kg. Rs.131.00 Motor 1 Hp Induction 11 1 No. Rs. 2500 Rs. 2500 Motor

(2nd Hand) 12 Travelling Charge --- ------ Rs.1,160.00 Total Rs.14,962.00 Page

16Department of Mechanical Engg. S.R.G.P.T.C Triprayar

17. 17. PAPER CUTTING & REWINDING MACHINE Project Report 2012-13 BIBLIOGRAPHY

Forbes Marshall- Engineering Data Book Workshop Technology- B.S. Raghuwanshi (Vol. I

& II) Production Management- ICFAI University Elements of machine design- V. B.

Bhandari Strength of materials- R. K. Bansal Page 17Department of Mechanical Engg.

S.R.G.P.T.C Triprayar

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- MS For Site Mobilization Work Rev.0Dokument11 SeitenMS For Site Mobilization Work Rev.0nijasNoch keine Bewertungen

- 10.1201 9781003173434-214 ChapterpdfDokument7 Seiten10.1201 9781003173434-214 ChapterpdfSubha TrehanNoch keine Bewertungen

- Memorandum: Project: Library Archives Museum Project Date: 11 30 2010 Subject: Alternate Sites Feasibility StudyDokument7 SeitenMemorandum: Project: Library Archives Museum Project Date: 11 30 2010 Subject: Alternate Sites Feasibility StudyECI HyerNoch keine Bewertungen

- 1055 Attachment 9 - QP GRP Piping SpecifiDokument8 Seiten1055 Attachment 9 - QP GRP Piping SpecifikarunaNoch keine Bewertungen

- Manual For Hybrid StructureDokument102 SeitenManual For Hybrid StructureVirat KoiliNoch keine Bewertungen

- Technical ManagerDokument4 SeitenTechnical ManagerSrini vasanNoch keine Bewertungen

- 0160Dokument1 Seite0160kevinkaradaNoch keine Bewertungen

- CBX SeriesDokument22 SeitenCBX SeriesAtika AnjumNoch keine Bewertungen

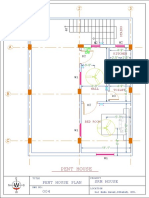

- House Plan - PENTHOUSEDokument1 SeiteHouse Plan - PENTHOUSEmuqtar4uNoch keine Bewertungen

- Through Hardening ProcessesDokument3 SeitenThrough Hardening ProcessesPurushothama Nanje Gowda100% (2)

- Geomembranes For Geofoam Applications PDFDokument22 SeitenGeomembranes For Geofoam Applications PDFΘανάσης ΓεωργακόπουλοςNoch keine Bewertungen

- Sample Architectural PlanDokument1 SeiteSample Architectural PlanAl DrinNoch keine Bewertungen

- Unit 12 (REINFORCED CONCRETE COLUMNS)Dokument30 SeitenUnit 12 (REINFORCED CONCRETE COLUMNS)Zara Nabilah100% (4)

- Development Authority: Bhubaneswar Development Authority RFP Document For EPC contractor-ISBT Baramunda, BhubaneshwarDokument8 SeitenDevelopment Authority: Bhubaneswar Development Authority RFP Document For EPC contractor-ISBT Baramunda, BhubaneshwarSARIT SEKHAR MUKHERJEENoch keine Bewertungen

- RULE7-8 ProblemAnalysis PDFDokument109 SeitenRULE7-8 ProblemAnalysis PDFMhae Torres100% (1)

- Fidic Letters by ContractorDokument78 SeitenFidic Letters by Contractormido75% (4)

- 30RB 21siDokument76 Seiten30RB 21sixavierxo50% (2)

- 01-Article - Per. STR. Gedung 5 LantaiDokument8 Seiten01-Article - Per. STR. Gedung 5 Lantaimuh khalifardiNoch keine Bewertungen

- Handbook On Vacuum Dewatering Concrete FlooringDokument18 SeitenHandbook On Vacuum Dewatering Concrete FlooringPrasanta Parida100% (1)

- Gabions - Matteres PVC Gabions - Mattress Malaysia, Johor, Batu Pahat Manufacturer, Supplier, Supplies, Supply - CHUN HOE TRADING SDN BHDDokument12 SeitenGabions - Matteres PVC Gabions - Mattress Malaysia, Johor, Batu Pahat Manufacturer, Supplier, Supplies, Supply - CHUN HOE TRADING SDN BHDSab RiNoch keine Bewertungen

- Statement of Position 81-1Dokument34 SeitenStatement of Position 81-1Vikas RalhanNoch keine Bewertungen

- BM Europe Stainless Steel Expansion JointsDokument67 SeitenBM Europe Stainless Steel Expansion JointsJacobo Becerra DiazNoch keine Bewertungen

- Chain Crosby® Grade 100Dokument1 SeiteChain Crosby® Grade 100CROSBYNoch keine Bewertungen

- Structural Engineer CVDokument2 SeitenStructural Engineer CVkarthikNoch keine Bewertungen

- Type 8 Railing (Full Panel) : Elevation End ViewDokument1 SeiteType 8 Railing (Full Panel) : Elevation End ViewTsui DanielNoch keine Bewertungen

- Insulation BOQ Area Wise (Square MTR.)Dokument11 SeitenInsulation BOQ Area Wise (Square MTR.)Atiq Ur RehmanNoch keine Bewertungen

- Zambia CoST Baseline Study FINAL REPORTDokument63 SeitenZambia CoST Baseline Study FINAL REPORTJanice Bana Chabota ChipoNoch keine Bewertungen

- PMGSY INspection FormatDokument15 SeitenPMGSY INspection FormatKrishan KumarNoch keine Bewertungen

- DBB Gate Valve CatalogDokument11 SeitenDBB Gate Valve CatalogVipul PanchalNoch keine Bewertungen

- Landscape Irrigation Products Catalog: The Intelligent Use of WaterDokument196 SeitenLandscape Irrigation Products Catalog: The Intelligent Use of WaterCosmin BonghezNoch keine Bewertungen