Beruflich Dokumente

Kultur Dokumente

PCR049 MGDS 2 17 0001

Hochgeladen von

DharmenderSinghChoudharyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PCR049 MGDS 2 17 0001

Hochgeladen von

DharmenderSinghChoudharyCopyright:

Verfügbare Formate

`

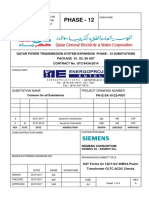

CONTRACT NO : LC16104300 PROJECT NO: PCR049

PROJECT TITLE:-

EPIC FOR UPGRADING 500KVA EMERGENCY DG SET AT GD

STATION 'S', MESAIEED

DOCUMENT TITLE:

ADEQUACY REPORT FOR LV BREAKER SIZING

MAIN CONTRACTOR: DESIGN CONSULTANT:

P.O. Box: 22006

AlWaab City | Salwa Road | Doha | Qatar

0 10-03-2017 ISSUED FOR COMMENTS DS BR HT

Rev Date Description Prepared Checked Approved Approved

by by by by QP

Document No. PCR049-MGDS-2-12-0001 01 of 11 Rev.0

ADEQUACY REPORT FOR LV

BREAKER SIZING

REVISION RECORD

REV DATE DESCRIPTION

0 10-03-2017 ISSUED FOR COMMENTS

Doc No: PCR049-MGDS-2-12-0001 Rev.0 Page 2 of 11

ADEQUACY REPORT FOR LV

BREAKER SIZING

CONTENTS Pag

DEFINITIONS.......................................................................................................................4

ABBREVIATION...................................................................................................................5

1 INTRODUCTION.....................................................................................................6

2 OBJECTIVE.............................................................................................................6

3 SCOPE DEFINITION...............................................................................................6

3.1 BACKGROUND......................................................................................................6

3.2 SCOPE....................................................................................................................7

4 BASIC DATA...........................................................................................................7

4.1 ENVIRONMENTAL CONDITIONS..........................................................................7

4.2 TAGGING SYSTEM................................................................................................8

5 CODES AND STANDARDS....................................................................................8

5.1 QP STANDARDS/SPECIFICATIONS.....................................................................8

6 DEFINATIONS.........................................................................................................9

6.1 CONSUMED LOAD (in KW)...................................................................................9

6.2 RATED POWER (in KW)........................................................................................9

6.3 CONTINUOUS LOADS.........................................................................................10

6.4 INTERMITTENT LOADS.......................................................................................10

6.5 STANDBY LOADS................................................................................................10

7 METHODOLOGY OF CALCULATION.................................................................10

1.1 SITE CONDITION..................................................................................................10

1.2 SELECTION CRITERIA........................................................................................10

8 ADEQUACY OF EXISTING DG INCOMER BREAKER.......................................11

1.3 BREAKER SIZING................................................................................................11

9 SUMMARY.............................................................................................................11

Doc No: PCR049-MGDS-2-12-0001 Rev.0 Page 3 of 11

ADEQUACY REPORT FOR LV

BREAKER SIZING

DEFINITIONS

For the purposes of this report, the following definitions of terms and interpretations shall

apply regardless of and other meaning the words may have in other respects:

Shall The word "shall" is to be understood as mandatory.

Should The word "should" is to be understood as being strongly

Recommended

May The word "may" is used where alternatives are equally

acceptable

Must The word "must" is used where a provision is a statutory

Requirement

Client / Company Qatar Petroleum

Contractor Company / Firm or Party appointed by QP to perform the

works in accordance with this specification

Manufacturer The Party that manufactures, fabricates or produces

materials or products covered by this specification

Supplier Company / Firm or Party appointed by QP to supply

material, equipment or other products in accordance with

this specification

Doc No: PCR049-MGDS-2-12-0001 Rev.0 Page 4 of 11

ADEQUACY REPORT FOR LV

BREAKER SIZING

ABBREVIATION

AC - Alternating Current

ACB - Air Circuit breaker

AWA - Aluminum Wire Armour

BP RP - British Petroleum Recommended Practices

BS - British Standard

CT - Current Transformer

CU - Copper

DEPM - Diesel Engine Prime Mover

DG - Diesel Generator

ES - Engineering Standard

EPIC - Engineering Procurement Installation and Commissioning

ESD - Emergency Shutdown System

FAT - Factory Acceptance Test

GCP - Generator Control Panel

IEC - International Electro-technical Commission

IET - Institute of Environmental Technology

IEEE - International Electrical Electronics Engineers

ISO - International Organization for Standardization

kVA - kilo Volt Ampere

LV - Low Voltage

OEM - Original Equipment Manufacturer

PLC - Programmable Logic Controller

PVC - Poly Vinyl Chloride

QDC - Qatar Design Consortium

QP - Qatar Petroleum

RMS - Root Mean Square

SB - Switchboard

TEFC - Totally Enclosed Fan Cooled

XLPE - Cross Linked Poly Ethylene

Doc No: PCR049-MGDS-2-12-0001 Rev.0 Page 5 of 11

ADEQUACY REPORT FOR LV

BREAKER SIZING

1 INTRODUCTION

QATAR PETROLEUM (QP) has awarded contract to Petroserv Controls &

Communication for the project (Engineering Consultancy Services for Upgrading of

500kVA Emergency DG set at GD station S) under the contract no. LC16104300. Qatar

Design Consortium (QDC) is engineering design consultant to perform the detailed

design and engineering services for the contract.

2 OBJECTIVE

The main objective of this document is to check adequacy of LV Breaker Sizing for

DG Incomer Breaker.

3 SCOPE DEFINITION

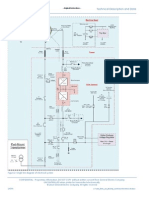

3.1 BACKGROUND

The Emergency switch board SSB-104 is now in excess of load, it would be more than

500kVA. Therefore, the existing 500kVA DG set needs to be upgraded to higher range of

DG capacity. Power supply to the existing switch board (S-SB-104) is fed from 500KVA

DG set in case of emergency power required. The existing DG set is skid mounting type;

Make: FG Wilson (Engineering) Ltd, the rating of the DG set is 500KVA or rated standby

power capacity of DG is 548 kVA (438kW).

Controller ACESS 4000 is provided for the protection of DG set. ACCESS 4000 controller

has a facility to operate the DG set in both Auto & Manual mode. The existing batteries:

2nos of 12V of capacity 200AH (Make: CAT; model: 1400 CCA) maintenance free with

auxiliary charger used for charging of batteries during DG off condition.

The power cables laid in existing cable trench from generator power panel to switch

board SWB-104. Adequacy of existing power cable needs to be checked for new

proposed DG set and the higher range of cable shall be replaced suitably, if the existing

cables are found inadequate.

The existing cable shall be 2Rx1Cx 630 Sq.mm per phase; Cu/XLPE/AWA/PVC cables

per phase & 1Rx1Cx 630Sq.mm for neutral; Cu/XLPE/AWA/PVC laid and these are

connected from DG power panel to the DG incomer ACB in the existing emergency

switch board SB-104.

Doc No: PCR049-MGDS-2-12-0001 Rev.0 Page 6 of 11

ADEQUACY REPORT FOR LV

BREAKER SIZING

3.2 SCOPE

This document specification detailed about requirements for industrial type self-excited

power generators driven by diesel engine abbreviated DEPM (Diesel engine prime mover)

along with brushless excitation system, automatic voltage regulator, generator control panel,

generator breaker and associated accessories.

4 BASIC DATA

4.1 ENVIRONMENTAL CONDITIONS

A typical sulphurous coastal environment prevails with frequent sandstorms. The

atmosphere can be both salt and sand laden. Hydrogen sulphide (H2S) at corrosive

levels can be present in the atmosphere. The environmental data to be used is as follows:

4.1.1 Temperature & Pressure

Average Maximum Shade Temperature: 49 Deg C

Maximum Recorded Shade Temperature: 52 Deg C

Average Minimum Shade Temperature: 20 Deg C

Normal Winter Minimum Temperature: 12 Deg C

Minimum Winter Temperature 0 Deg C

Maximum Sun Radiation Temperature 84 Deg C

Average Barometric Pressure 0.98 / 1.01 Bar A

4.1.2 Relative Humidity

Absolute Maximum Humidity 100%

Absolute Minimum Humidity 0%

The highest average humidity occurs during the months of December and January. At the

time of maximum temperature the maximum relative humidity is 46%. Humidity in the

range of 100% at 27C is recorded previously. Moisture in the atmosphere occasionally

holds salts.

4.1.3 Rainfall

Average annual rainfall 80 mm

Maximum recorded annual rainfall 175 mm

Minimum recorded annual rainfall 13 mm

Doc No: PCR049-MGDS-2-12-0001 Rev.0 Page 7 of 11

ADEQUACY REPORT FOR LV

BREAKER SIZING

4.1.4 Winds

Prevailing wind direction is from the North-West to North-North-West

Basic Wind Speed for Civil/ Structural 45m/Sec to BS CP3

for Design purpose wind direction shall be any direction.

4.1.5 Lightning

Thunderstorms and lighting occur at infrequent periods

4.1.6 Sandstorm

Severe sandstorms are common.

4.1.7 Earthquakes

Earthquakes do not occur and an earthquake zone rating is not applicable.

4.2 TAGGING SYSTEM

Dummy tags shall be used for the proposed equipment. A request for actual tags shall be

generated by EPIC contractor to QP during detail design phase as per QP

Engineering Standard QPR-DKN-05_Rev.02 (2012).

5 CODES AND STANDARDS

Reference has also been made in this specification to the latest edition of the following

codes standards and specifications.

5.1 QP STANDARDS/SPECIFICATIONS

QP STANDARDS

ES.2.03.0001 Electrical Engineering Philosophy, Rev B

ES.2.06.0001 Electrical Installation Recommended Practices, Rev A

ES.2.14.0002 Diesel Engine Driven Generator, Rev A

E.S.2.14.0098 Electrical Requirement for package equipment

E.S.2.14.0015 Low Voltage Switchgear and Control gear for use indoor

E.S.2.14.0035 Low Voltage cage induction Motors.

ES.2.14.0070 Electrical Power Control Cables and Cable glands, Rev A

ES.2.14.0074 Electrical Bulk Materials

ES.2.18.0001 Safety Instructions Electrical General, Rev 1

Doc No: PCR049-MGDS-2-12-0001 Rev.0 Page 8 of 11

ADEQUACY REPORT FOR LV

BREAKER SIZING

ES.2.03.0001 Electrical Engineering Philosophy, Rev B

INTERNATIONAL STANDARDS

IEC 60034 Rotating Electrical Machines

IEEE 141 Electrical power distribution for Industrial plants.

Low-voltage electrical installations - Part 5-52: Selection and

IEC 60364

erection of electrical equipment - Wiring systems

IEC 60439 Low Voltage switchgear and control Assemblies.

IEC-60947 LV Motor Starters

IEC-60227 PVC cables of rated voltages up to including 450/750V.

BS 7671 Requirements for Electrical Installations, IET Wiring Regulations

BS 6883 Cable selection and sizing

BS 6121 Cable Glands.

Guide for measuring earth resistivity, ground impedance and

IEEE 81

earth surface potentials for ground system.

IEC 60529/ BS 60592 Degrees of protection provided by enclosures (IP Code)

IEC 60079 Electrical Apparatus for Explosive Gas Atmospheres.

IEC-60885 Electric test methods for Electric cables.

6 DEFINATIONS

The following items defined below are for general information and better understanding of Load

Schedule

6.1 CONSUMED LOAD (in KW)

This is the design power requirement of the driven equipment at design point, in kilowatt. The

design power requirement is the power drawn by the equipment when the plant is operating at the

design capacity under normal operating condition.

6.2 RATED POWER (in KW)

The rated power is the rated kilowatt indicated on the name plate of the equipment.

Doc No: PCR049-MGDS-2-12-0001 Rev.0 Page 9 of 11

ADEQUACY REPORT FOR LV

BREAKER SIZING

6.3 CONTINUOUS LOADS

All the loads, which may be running continuously in normal operating conditions like motors,

lighting loads, UPS and battery charger loads etc.

6.4 INTERMITTENT LOADS

All the loads which are required for intermediate operations like Hoist, Motor operated Valves etc.

6.5 STANDBY LOADS

All loads which are required to be operated only in the event of failure of normal operating loads

and during shutdown of plant like spare motors, receptacle outlets, welding outlets etc.

7 METHODOLOGY OF CALCULATION

1.1 SITE CONDITION

Facility Location GD STATION 'S', MESAIEED

Temperature (Ambient) 45 C

Max. Temperature (Ambient) 52 C

Humidity 65-100%

Rainfall 175mm(max)-13mm(min)/annum

Wind & Storms 45 m/s

1.2 SELECTION CRITERIA

Breaker sizing is based on the following criteria:

Continuous Current Rating

Maximum interrupting capacity

In regards to continuous current rating, ACB are rated in amperes at a specific

ambient temperature. The interrupting rating is generally accepted as the highest

amount of fault current. The breaker can interrupt without causing system failure to it.

The calculation for breaker sizing is given in Section 5.3.

Doc No: PCR049-MGDS-2-12-0001 Rev.0 Page 10 of 11

ADEQUACY REPORT FOR LV

BREAKER SIZING

8 ADEQUACY OF EXISTING DG INCOMER BREAKER

Rating of existing DG incomer ACB : 1600 Amps

Peak Load of emergency switch board : 511KVA

Rated current of the System = 711 A

Considering 25% Margin on System :711* 1.25

(Refer QP Electrical Engineering Philosophy- Rev-B)

Full Load Current after 25% Margin = 888A

Conclusion:

Looking into the above, the existing DG incomer ACB (1600A) is adequate to carry

the rated full load current of 1000KVA DG set.

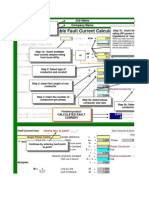

1.3 BREAKER SIZING

Calculations are carried out using the formulae as:

Load details:

Peak Load of Emergency switch board : 511KVA

Determine current rating:

IfL : kVA / (1.732 x Supply voltage)

: (511) / (1.732 x 0.415)

= 711 A

Full Load current after considering 25% Margin= 711 x 1.25

= 888A

9 SUMMARY

Referring to the above sizing calculation result, selection of breaker size (1600A) is

adequate for 1000kVA DG set.

Doc No: PCR049-MGDS-2-12-0001 Rev.0 Page 11 of 11

Das könnte Ihnen auch gefallen

- Pre-Trip Inspection PowerpointDokument71 SeitenPre-Trip Inspection Powerpointapi-272112942100% (4)

- Computer System Validation Master PlanDokument54 SeitenComputer System Validation Master Plancpkakope86% (7)

- CT Sizing For MalawiDokument2 SeitenCT Sizing For MalawiDharmenderSinghChoudhary100% (1)

- ASME IX Interpretation Part1 PDFDokument51 SeitenASME IX Interpretation Part1 PDFalisyalala100% (3)

- Auto Sync & Load ShareDokument24 SeitenAuto Sync & Load Shareravi_kumar_100% (1)

- Emergency Diesel Generator Sizing for Power PlantDokument5 SeitenEmergency Diesel Generator Sizing for Power PlantflyzalNoch keine Bewertungen

- 132-33kv, Schneider Electric 31.5mva Power Transformer-1 Control & ProtectioDokument90 Seiten132-33kv, Schneider Electric 31.5mva Power Transformer-1 Control & ProtectioVeera ChaitanyaNoch keine Bewertungen

- Review On Four Standard Tests On Flame SpreadingDokument20 SeitenReview On Four Standard Tests On Flame SpreadingMarija MilenkovicNoch keine Bewertungen

- Sony KDL-32BX320 - 32BX321 - 32BX420 - 32BX421 - 40BX421 - 46BX420 - 46BX421... AZ2-UK ChassisDokument74 SeitenSony KDL-32BX320 - 32BX321 - 32BX420 - 32BX421 - 40BX421 - 46BX420 - 46BX421... AZ2-UK Chassismartijn16340% (1)

- DGFDokument25 SeitenDGFarshadbayaNoch keine Bewertungen

- Fault Ride ThroughDokument9 SeitenFault Ride ThroughKishore KrishnaNoch keine Bewertungen

- Item 06a p1916 0657 4004 Calculation Note Short Circuit Currents - C IfaDokument42 SeitenItem 06a p1916 0657 4004 Calculation Note Short Circuit Currents - C Ifaapi-3704641100% (2)

- Prefabricated Substation SolutionsDokument5 SeitenPrefabricated Substation Solutionssankuma100% (2)

- Advance Ese Lightning Protection System For 130m RadiusDokument16 SeitenAdvance Ese Lightning Protection System For 130m Radiusflngoff6419Noch keine Bewertungen

- LV Capacitor Sizing:: Thus APFC Capacitor Bank Size Selected As 925 KVARDokument10 SeitenLV Capacitor Sizing:: Thus APFC Capacitor Bank Size Selected As 925 KVARSonu DesaiNoch keine Bewertungen

- How To Select Genset PDFDokument25 SeitenHow To Select Genset PDFSaraswatapalit100% (1)

- Technical Manual LSC Alternators PDFDokument51 SeitenTechnical Manual LSC Alternators PDFMarcello RosiniNoch keine Bewertungen

- 20 Mvar Capacitor BankDokument9 Seiten20 Mvar Capacitor BankTejaswi ShuklaNoch keine Bewertungen

- Fault Current CalculationDokument11 SeitenFault Current CalculationSaroj Kumar MallickNoch keine Bewertungen

- Installation ManualDokument60 SeitenInstallation ManualmaituanNoch keine Bewertungen

- Lecture 4 - Generator Set SizingDokument40 SeitenLecture 4 - Generator Set Sizingjimmy_barredoNoch keine Bewertungen

- Booster Pump Motor Technical Data Sheet ReviewedDokument7 SeitenBooster Pump Motor Technical Data Sheet ReviewedSantoshkumar GuptaNoch keine Bewertungen

- Electrical System Earthing Design Philosophy: Prelude Floating LNG PROJECTDokument28 SeitenElectrical System Earthing Design Philosophy: Prelude Floating LNG PROJECTStefano FavaroNoch keine Bewertungen

- SLD of WTGDokument1 SeiteSLD of WTGbhargavram1987Noch keine Bewertungen

- BS7671 2008Dokument11 SeitenBS7671 2008Vijai Prasath100% (1)

- 1.6 MVA Oil Type Transformer GTP - Mar22-2011Dokument15 Seiten1.6 MVA Oil Type Transformer GTP - Mar22-2011Ramesh Cuppu0% (1)

- NGR Technical InformationDokument6 SeitenNGR Technical InformationPrabakar PNoch keine Bewertungen

- Grouding System Field Test ProcedureDokument9 SeitenGrouding System Field Test Proceduremilton1987Noch keine Bewertungen

- 7-AZN-PDS-3501 - (20kV Switchgear (PDS) ) GA & SLD 24kV Switchgear SM6 - As BuiltDokument40 Seiten7-AZN-PDS-3501 - (20kV Switchgear (PDS) ) GA & SLD 24kV Switchgear SM6 - As BuiltRingoNoch keine Bewertungen

- CBFDokument17 SeitenCBFPhilip D'cruzNoch keine Bewertungen

- UPS Guide SpecsDokument13 SeitenUPS Guide SpecsONILEDA1970100% (1)

- SVC Abb Case StudyDokument2 SeitenSVC Abb Case StudybhsujanNoch keine Bewertungen

- Fichtner ElectricalDokument51 SeitenFichtner ElectricalMathivanan AnbazhaganNoch keine Bewertungen

- Upgrade Electrical Systems at Abqaiq Plants: Plan Elevation and General Arrangement Drawing For 111-091-MCC-002Dokument6 SeitenUpgrade Electrical Systems at Abqaiq Plants: Plan Elevation and General Arrangement Drawing For 111-091-MCC-002Asad MaherNoch keine Bewertungen

- General notes and details for substation constructionDokument1 SeiteGeneral notes and details for substation constructionA.K.M Shafiq MondolNoch keine Bewertungen

- Power GenerationDokument16 SeitenPower GenerationBert De BorjaNoch keine Bewertungen

- Relay Settings TablesDokument29 SeitenRelay Settings Tablesgirishprabhu1984Noch keine Bewertungen

- ABB Modular eHouse Solutions CatalogueDokument12 SeitenABB Modular eHouse Solutions CatalogueSuneelKumarNoch keine Bewertungen

- 199 GST 0104 RevA - Power Control Center SpecificationDokument16 Seiten199 GST 0104 RevA - Power Control Center Specificationdhanny maNoch keine Bewertungen

- Alternator Protection For Emergency StandbyEngine GeneratorsDokument30 SeitenAlternator Protection For Emergency StandbyEngine GeneratorsAdrian BrokmanNoch keine Bewertungen

- Calculating Motor Starting Times Using Torque and Current Exponent RatiosDokument0 SeitenCalculating Motor Starting Times Using Torque and Current Exponent RatiosmicrefeeNoch keine Bewertungen

- Persian Gulf Bid Boland Gas Treating Project Earth Resistance CalculationDokument24 SeitenPersian Gulf Bid Boland Gas Treating Project Earth Resistance Calculationsivasan10006098Noch keine Bewertungen

- Large Motor Starting CalculationDokument5 SeitenLarge Motor Starting CalculationBert De Borja100% (1)

- Instalasi Fire Gas Detector System (FGDS) Tanki Floating Roof Refinery Unit Ii DumaiDokument3 SeitenInstalasi Fire Gas Detector System (FGDS) Tanki Floating Roof Refinery Unit Ii DumaiAji Abi-nya FathanNoch keine Bewertungen

- Gen Protection 077625-B41-SR-4122-0001-A4105-002 - 3-CDokument14 SeitenGen Protection 077625-B41-SR-4122-0001-A4105-002 - 3-CRabindra SutradharNoch keine Bewertungen

- Indoor + Outdoor Substation With Generator RoomDokument1 SeiteIndoor + Outdoor Substation With Generator RoomMukterNoch keine Bewertungen

- Motor StartingDokument16 SeitenMotor StartingBabar SaleemNoch keine Bewertungen

- Power Transformer - 1M - CDokument3 SeitenPower Transformer - 1M - CahmedelgharibNoch keine Bewertungen

- Nema Ab 1-1986Dokument45 SeitenNema Ab 1-1986Ulysses OreiroNoch keine Bewertungen

- Genset Sizing GuideDokument27 SeitenGenset Sizing GuidekhudoNoch keine Bewertungen

- Site As Built: General ArrangementDokument152 SeitenSite As Built: General ArrangementSATHISKUMARNoch keine Bewertungen

- Theni GIS FT 10 MWDokument3 SeitenTheni GIS FT 10 MWgohilnarendra100% (1)

- Item200 500kVA 6xDokument55 SeitenItem200 500kVA 6xscribd_raja100% (1)

- Motor Protection Application GuideDokument28 SeitenMotor Protection Application Guidemersium100% (1)

- Dse Training Parts ListDokument24 SeitenDse Training Parts ListNaveed AhmadNoch keine Bewertungen

- Auxiliary Main Transformer 3011Dokument48 SeitenAuxiliary Main Transformer 3011Dileep DudiNoch keine Bewertungen

- 1.list of Drawings For Cable Sealing System KHONSA SubstationDokument5 Seiten1.list of Drawings For Cable Sealing System KHONSA SubstationmanishNoch keine Bewertungen

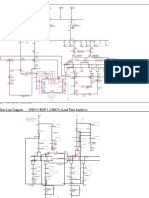

- One-Line Diagram - SFNY (Load Flow Analysis) : CB15-4 CB20-2 CB18-2Dokument19 SeitenOne-Line Diagram - SFNY (Load Flow Analysis) : CB15-4 CB20-2 CB18-2Geetha BirudalaNoch keine Bewertungen

- Technical Complementary Guide 2013Dokument256 SeitenTechnical Complementary Guide 2013brightstardustNoch keine Bewertungen

- PCR049 MGDS 2 30 0001Dokument19 SeitenPCR049 MGDS 2 30 0001DharmenderSinghChoudhary0% (1)

- BLOWDOWN AND VENT STUDYDokument238 SeitenBLOWDOWN AND VENT STUDYUmair A. KhanNoch keine Bewertungen

- Ph12-3a-10-22-P007 - Rev - A - 40mva Oltc Ac and DC ChecksDokument5 SeitenPh12-3a-10-22-P007 - Rev - A - 40mva Oltc Ac and DC Checksaravindhana1a1Noch keine Bewertungen

- SSP-CRCO-SS05-SYSW-PRO-00119 - 04 - PAT Procedure For 750V DC Earth SwitchDokument31 SeitenSSP-CRCO-SS05-SYSW-PRO-00119 - 04 - PAT Procedure For 750V DC Earth Switchabu bakarNoch keine Bewertungen

- BST Gen Cns Mos Aip 10003 10002 00 Pin BrazingDokument67 SeitenBST Gen Cns Mos Aip 10003 10002 00 Pin BrazingRao DharmaNoch keine Bewertungen

- 400-Eng-9336-003 Rev 00 (Technical Specification For 220KV Switchyard) PDFDokument69 Seiten400-Eng-9336-003 Rev 00 (Technical Specification For 220KV Switchyard) PDFSridhar Reddy Gandra100% (1)

- 216kV Surge Arrester Technical SpecificationDokument16 Seiten216kV Surge Arrester Technical SpecificationSolar PowerNoch keine Bewertungen

- S&B Engineers and Constructors, Ltd. Texas Registration Number F-1581Dokument1 SeiteS&B Engineers and Constructors, Ltd. Texas Registration Number F-1581DharmenderSinghChoudharyNoch keine Bewertungen

- Application of Undervoltage Protection To Critical Motors PDFDokument6 SeitenApplication of Undervoltage Protection To Critical Motors PDFarisNoch keine Bewertungen

- CT Sizing For MalawiDokument2 SeitenCT Sizing For MalawiDharmenderSinghChoudharyNoch keine Bewertungen

- Iec 60865 & Ieee 605Dokument13 SeitenIec 60865 & Ieee 605DharmenderSinghChoudhary100% (2)

- Battery Sizing 110VDokument17 SeitenBattery Sizing 110VDharmenderSinghChoudhary100% (1)

- Cable Sizing For Main Cable - DBDokument8 SeitenCable Sizing For Main Cable - DBDharmenderSinghChoudharyNoch keine Bewertungen

- PCR049 MGDS 2 30 0001Dokument19 SeitenPCR049 MGDS 2 30 0001DharmenderSinghChoudhary0% (1)

- SIP5 7UT82-85-86-87 V07.00 Manual C016-6 En2Dokument3 SeitenSIP5 7UT82-85-86-87 V07.00 Manual C016-6 En2DharmenderSinghChoudharyNoch keine Bewertungen

- SIP5 7UT82-85-86-87 V07.00 Manual C016-6 En2Dokument3 SeitenSIP5 7UT82-85-86-87 V07.00 Manual C016-6 En2DharmenderSinghChoudharyNoch keine Bewertungen

- ETAP Installation ProcedureDokument1 SeiteETAP Installation ProcedureDharmenderSinghChoudharyNoch keine Bewertungen

- DMES0025Dokument14 SeitenDMES0025Jothimanikkam SomasundaramNoch keine Bewertungen

- ETAP700 SysreqDokument1 SeiteETAP700 SysreqMohammed Shareef ShaikhNoch keine Bewertungen

- Iocl SLDDokument11 SeitenIocl SLDDharmenderSinghChoudharyNoch keine Bewertungen

- Data Sheet of Local Control StationsDokument4 SeitenData Sheet of Local Control StationsDharmenderSinghChoudharyNoch keine Bewertungen

- DMES0025Dokument14 SeitenDMES0025Jothimanikkam SomasundaramNoch keine Bewertungen

- Comments Resolution Sheet (CRS) : No. QP Comments Contractor ResponseDokument2 SeitenComments Resolution Sheet (CRS) : No. QP Comments Contractor ResponseDharmenderSinghChoudharyNoch keine Bewertungen

- ETAP Installation ProcedureDokument1 SeiteETAP Installation ProcedureDharmenderSinghChoudharyNoch keine Bewertungen

- Qatar Design Consortium, W.L.L: Weekly Time SheetDokument1 SeiteQatar Design Consortium, W.L.L: Weekly Time SheetDharmenderSinghChoudharyNoch keine Bewertungen

- WWW TenderwizardDokument1 SeiteWWW TenderwizardDharmenderSinghChoudharyNoch keine Bewertungen

- Providing Manpower Assistance for Instrumentation DepartmentDokument5 SeitenProviding Manpower Assistance for Instrumentation DepartmentDharmenderSinghChoudharyNoch keine Bewertungen

- TNDokument1.744 SeitenTNDharmenderSinghChoudharyNoch keine Bewertungen

- Tender Acceptance FormatDokument1 SeiteTender Acceptance FormatDharmenderSinghChoudharyNoch keine Bewertungen

- Indian Oil Corporation Limited Guwahati Refinery: NIT NO: GC16ITT093Dokument2 SeitenIndian Oil Corporation Limited Guwahati Refinery: NIT NO: GC16ITT093DharmenderSinghChoudharyNoch keine Bewertungen

- Cover Page Tender 1631Dokument244 SeitenCover Page Tender 1631DharmenderSinghChoudharyNoch keine Bewertungen

- Risk ScreeingDokument4 SeitenRisk ScreeingDharmenderSinghChoudharyNoch keine Bewertungen

- Indian Oil Corporation Limited Guwahati Refinery: NIT NO: GC16ITT093Dokument1 SeiteIndian Oil Corporation Limited Guwahati Refinery: NIT NO: GC16ITT093DharmenderSinghChoudharyNoch keine Bewertungen

- Boq 44049Dokument8 SeitenBoq 44049DharmenderSinghChoudharyNoch keine Bewertungen

- Tender Acceptance FormatDokument1 SeiteTender Acceptance FormatDharmenderSinghChoudharyNoch keine Bewertungen

- AWC-DCA1-Flame Spread Performance of Wood Products Used For Interior Finish-201906Dokument7 SeitenAWC-DCA1-Flame Spread Performance of Wood Products Used For Interior Finish-201906LarryHNoch keine Bewertungen

- Allowable Number of Students in A ClassroomDokument5 SeitenAllowable Number of Students in A ClassroomCentaur ArcherNoch keine Bewertungen

- Arcal-21 Welding GasDokument7 SeitenArcal-21 Welding GasManoj Kumar BarikNoch keine Bewertungen

- Lap Splices and DowelsDokument4 SeitenLap Splices and DowelsJaewoo ParkNoch keine Bewertungen

- (D-101) Pressure Vessels - Rev2 PDFDokument30 Seiten(D-101) Pressure Vessels - Rev2 PDFmihir_jha2Noch keine Bewertungen

- Key Factors in Acheiving Education QualityDokument9 SeitenKey Factors in Acheiving Education QualityAshraf S. Youssef50% (2)

- Predictability & Measurement With KanbanDokument32 SeitenPredictability & Measurement With Kanbandigz6666Noch keine Bewertungen

- YD Series Three Phase Asynchro Conveyor MotorDokument18 SeitenYD Series Three Phase Asynchro Conveyor MotorAditya SafarudinNoch keine Bewertungen

- Genius Power j9940 200w SCHDokument1 SeiteGenius Power j9940 200w SCHsmokefieldNoch keine Bewertungen

- LPS Earth Test Report of Liberty Knitwear LTD 30.10.2022.docx222Dokument22 SeitenLPS Earth Test Report of Liberty Knitwear LTD 30.10.2022.docx222roniNoch keine Bewertungen

- Emotron FDU2-0 - Manual - 01-5325-01r1 - ENDokument226 SeitenEmotron FDU2-0 - Manual - 01-5325-01r1 - ENLingaraj Suresh Lingaian100% (1)

- Certified Sustainability Reporting Assurance TrainingDokument3 SeitenCertified Sustainability Reporting Assurance TrainingAli FarhanNoch keine Bewertungen

- ElectromagneticShakersF3 F4 F5B F10Dokument16 SeitenElectromagneticShakersF3 F4 F5B F10Valentin PredaNoch keine Bewertungen

- Citizen Watch Repair 1198-101Dokument5 SeitenCitizen Watch Repair 1198-101David McFaddenNoch keine Bewertungen

- Data Entry Methods CDokument28 SeitenData Entry Methods Capi-381097667% (3)

- Sell Sheet Optal XP en FinalDokument2 SeitenSell Sheet Optal XP en Finalalguna54Noch keine Bewertungen

- Understanding Wired and Wireless Networks: Lesson 3Dokument32 SeitenUnderstanding Wired and Wireless Networks: Lesson 3Guadalupe SantiagoNoch keine Bewertungen

- Autodesk Revit 2010 Exam-Guide 0709 Env3Dokument7 SeitenAutodesk Revit 2010 Exam-Guide 0709 Env3oksbgtNoch keine Bewertungen

- PLC PPU-3 Data Sheet 4921240354 UKDokument23 SeitenPLC PPU-3 Data Sheet 4921240354 UKOswerd coronadoNoch keine Bewertungen

- Little Book BimDokument36 SeitenLittle Book BimTimNoch keine Bewertungen

- Introduction To Pipe SupportDokument63 SeitenIntroduction To Pipe SupportAkhil Joseph100% (4)

- Aker Solutions LNGDokument27 SeitenAker Solutions LNGruov100% (1)

- INFO6030 - T3 Assignment 2 (Callaghan)Dokument3 SeitenINFO6030 - T3 Assignment 2 (Callaghan)Muna DiNoch keine Bewertungen

- 821F - 921F Catalogo de PartesDokument912 Seiten821F - 921F Catalogo de Partesjose juan100% (12)

- Stratix 2000 SwitchesDokument2 SeitenStratix 2000 SwitchesMarisurNoch keine Bewertungen