Beruflich Dokumente

Kultur Dokumente

Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)

Hochgeladen von

bey0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

37 Ansichten2 SeitenPRN001

Originaltitel

PRN001

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenPRN001

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

37 Ansichten2 SeitenBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)

Hochgeladen von

beyPRN001

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

PRN001

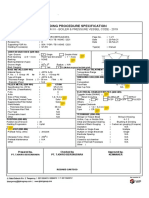

Company Name: The Shaw Group, Inc./ B. F. Shaw, Inc.

Procedure Qualification Record No.: 12,364 Date: June 15, 1990

WPS No.: 101, 103, 1.101

Welding Process(es) GTAW SMAW

Types (Manual, Automatic, Semi-Auto) Manual

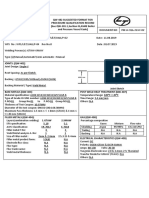

JOINTS (QW-402)

SINGLE VEE GROOVE

75 DEGREE INCLUDED ANGLE

1/8 GAP

3/32 LAND

Groove Design of Test Coupon

BASE METALS (QW-403) POSTWELD HEAT TREATMENT (QW-407)

Material Spec.: SA106 Temperature: None

Type or Grade: B Time:

P-No.: 1 to P-No.: 1 Other:

Thickness of test coupon: .375

Diameter of test coupon: 12 NPS

Other: The deposition of each pass did not exceed

3/16.

FILLER METALS (QW-404) GAS (QW-408)

Process: GTAW SMAW

SFA Specification: 5.18 5.1 GTAW ONLY Percent CFH

AWS Classification: ER70S-2 E7018 Gas(es) Composition Flow

Filler Metal F-No.: 6 4 (Mixture) Rate

Weld Metal A-No.: 1 1 Shielding Argon 99.99% 40-50

Size of Filler Metal: 1/8 3/32 Trailing None None None

Other: (Notes/Flux) Note 1 Backing None None None

Weld Metal Thickness: .125 .250

NOTES: ELECTRICAL CHARACTERISTICS (QW-409)

1. All passes were made with the addition of filler metal. Current: DC Polarity: GTAW: EN SMAW: EP

AMPS: GTAW: 105-140 SMAW: 65-140

Volts: GTAW: 11-20 SMAW: 22-27

Tungsten Electrode Size: 1/8 2% Thoriated

Transfer Mode: N/A

Other:

POSITION (QW-405) TECHNIQUE (QW-410)

Position of Groove: 6G Travel Speed: Manual

Weld Progression: Uphill String or Weave Bead: Weave

Other: Oscillation: Not applicable this WPS

PREHEAT (QW-406) Multipass/Single Pass (per side): Multipass

o o

Preheat Temp.: 85 F Interpass Temp: 375 F Single or Multiple Electrodes: Single

Other: Other:

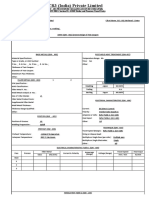

PQR No.: 12,364(PRN001)

QW-462.1(b)

Tensile Test (QW-150)

Ultimate Ultimate Type of Failure &

Specimen Width Thickness Total Load Unit Stress Location

No. (Inches) (Inches) Area lb psi

1 .742 .357 .265 20,500 77,358 Ductile-Weld

2 .749 .347 .260 19,800 76,154 Ductile-Weld

Guided-Bend Tests (QW-160)

Type and Figure No. Result

Side Bend No. 1 QW-462.2 Acceptable

Side Bend No. 2 QW-462.2 Acceptable

Side Bend No. 3 QW-462.2 Acceptable

Side Bend No. 4 QW-462.2 Acceptable

Toughness Tests (QW-170)

Specimen Notch Specimen Size Notch Test Impact Lateral Exp.

No. Location Type Temp. Values % Shear Mils

Fillet-Weld Test (QW-180)

Result Satisfactory: Yes ______ No _____ Penetration into Parent Metal: Yes _______ No _______

Macro-Results:

Other Tests

Type of Test: Brinell Hardness: Base Metal: 149, HAZ: 170, Weld: 159

Deposit Analysis:

Other:

Welders Name: James Horton Clock No.: Stamp No.: E9

Test Conducted By: Scientific Testing Laboratories, Inc. Laboratory Test No.: 12,364

We certify that the statements in this record are correct and that the test welds were prepared, welded, and

tested in accordance with the requirements of Section IX of the ASME Code.

Manufacturer: The Shaw Group, Inc./B.F. Shaw, Inc.

Date: April 7, 2000 By: ________________________________________

Das könnte Ihnen auch gefallen

- JOINTS (QW-402) : Groove Design of Test CouponDokument2 SeitenJOINTS (QW-402) : Groove Design of Test CouponbeyNoch keine Bewertungen

- JOINTS (QW-402) : Groove Design of Test CouponDokument2 SeitenJOINTS (QW-402) : Groove Design of Test CouponbeyNoch keine Bewertungen

- PRN005Dokument2 SeitenPRN005beyNoch keine Bewertungen

- PRN004Dokument2 SeitenPRN004beyNoch keine Bewertungen

- PQR With-PwhtDokument2 SeitenPQR With-PwhtKarthikNoch keine Bewertungen

- Procedure Qualification RecordDokument6 SeitenProcedure Qualification RecordGaurang PandyaNoch keine Bewertungen

- PQR FormatDokument2 SeitenPQR FormatBE GNoch keine Bewertungen

- QW483Dokument2 SeitenQW483Sc TanNoch keine Bewertungen

- LOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONDokument5 SeitenLOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONKAMALNoch keine Bewertungen

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDokument10 SeitenWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Dokument2 SeitenQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghNoch keine Bewertungen

- Gta+sma PQRDokument3 SeitenGta+sma PQRRahul MoottolikandyNoch keine Bewertungen

- Aic Asf PQR 133Dokument3 SeitenAic Asf PQR 133AHMED MEDANYNoch keine Bewertungen

- Qw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel CodeDokument4 SeitenQw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86Noch keine Bewertungen

- Mechanical Engineering M.Abdul GhoziDokument4 SeitenMechanical Engineering M.Abdul GhoziRizaldy PhoenksNoch keine Bewertungen

- Welding Procedure Specification for Stainless SteelDokument5 SeitenWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- SWATHI PQR Procedure QualificationDokument10 SeitenSWATHI PQR Procedure QualificationMustu AkolawalaNoch keine Bewertungen

- WPS for Manual SMAW Welding of 316L Stainless Steel Butt JointsDokument3 SeitenWPS for Manual SMAW Welding of 316L Stainless Steel Butt JointsAmjad PathanNoch keine Bewertungen

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDokument4 Seiten(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNoch keine Bewertungen

- 1 5 1Dokument5 Seiten1 5 1daemsalNoch keine Bewertungen

- Wps Format Asme Sec - IxDokument2 SeitenWps Format Asme Sec - IxDeepu ChandranNoch keine Bewertungen

- PQR ForDokument3 SeitenPQR ForAkash Singh TomarNoch keine Bewertungen

- PQR Welding Procedure RecordDokument2 SeitenPQR Welding Procedure RecordAtilio BarriosNoch keine Bewertungen

- 2005-05 - WPS & PQR C5Dokument6 Seiten2005-05 - WPS & PQR C5misthahNoch keine Bewertungen

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDokument5 SeitenWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNoch keine Bewertungen

- PQR GmawDokument4 SeitenPQR GmawEr Sumant Kumar Singh0% (1)

- ASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelDokument3 SeitenASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelBudi Setia RahmanNoch keine Bewertungen

- WPS CuNiDokument4 SeitenWPS CuNiSripathyNoch keine Bewertungen

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDokument5 SeitenWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNoch keine Bewertungen

- Welding Procedure SpecificationDokument27 SeitenWelding Procedure SpecificationGopakumar K100% (2)

- PQR Procedure Qualification RecordsDokument6 SeitenPQR Procedure Qualification RecordsDaniel CamposNoch keine Bewertungen

- Procedure Qualification Record (PQR)Dokument3 SeitenProcedure Qualification Record (PQR)surjithkocherilNoch keine Bewertungen

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Dokument20 SeitenWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- CALTECH ENGINEERING PQR PROCEDUREDokument8 SeitenCALTECH ENGINEERING PQR PROCEDURESrikant GanjiNoch keine Bewertungen

- WPS, PQR, WPQ PoojaDokument10 SeitenWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDokument6 SeitenWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNoch keine Bewertungen

- PQR 01 PDFDokument2 SeitenPQR 01 PDFVijay BhaleraoNoch keine Bewertungen

- QW-483 PQR PROCEDURE QUALIFICATION RECORDDokument6 SeitenQW-483 PQR PROCEDURE QUALIFICATION RECORDZam Zam NoorNoch keine Bewertungen

- METALS INSPECTION SERVICES WELDING PROCEDUREDokument6 SeitenMETALS INSPECTION SERVICES WELDING PROCEDURELuis MuñozNoch keine Bewertungen

- WPQ WeldCanada PDFDokument1 SeiteWPQ WeldCanada PDFAhmad DanielNoch keine Bewertungen

- WPS 8 To 1-3-1 Rev2 (10-1-13)Dokument5 SeitenWPS 8 To 1-3-1 Rev2 (10-1-13)ERA SSNoch keine Bewertungen

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Dokument2 SeitenWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- GTAW Welding Process ParametersDokument12 SeitenGTAW Welding Process Parametersmiteshpatel191Noch keine Bewertungen

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Dokument2 Seiten(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPS 6G CS Pipe CorrectDokument4 SeitenWPS 6G CS Pipe CorrectAla ReguiiNoch keine Bewertungen

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Dokument2 SeitenBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNoch keine Bewertungen

- Audco India Limited Welding Procedure Specification: LAB-005R1Dokument3 SeitenAudco India Limited Welding Procedure Specification: LAB-005R1sudeep_singh1Noch keine Bewertungen

- Procedure Qualification Record PQRDokument3 SeitenProcedure Qualification Record PQRNMBaihakiARNoch keine Bewertungen

- WPS Gtaw) - 47Dokument2 SeitenWPS Gtaw) - 47Dharmendra BhardwajNoch keine Bewertungen

- Nit 2019 20 56 Wps 1569579575Dokument16 SeitenNit 2019 20 56 Wps 1569579575vijayachiduNoch keine Bewertungen

- Aic Asf PQR 0122Dokument2 SeitenAic Asf PQR 0122AHMED MEDANYNoch keine Bewertungen

- WPS CuNiDokument1 SeiteWPS CuNiDieter Huaman ToscanoNoch keine Bewertungen

- WPS 01 WQT PDFDokument1 SeiteWPS 01 WQT PDFkiki270977Noch keine Bewertungen

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDokument2 SeitenWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNoch keine Bewertungen

- Qw-483 Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)Dokument3 SeitenQw-483 Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)Zam Zam NoorNoch keine Bewertungen

- PT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSDokument1 SeitePT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSBudi Setia RahmanNoch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Transducer Handbook: User's Directory of Electrical TransducersVon EverandTransducer Handbook: User's Directory of Electrical TransducersNoch keine Bewertungen

- Materials Data for Cyclic Loading: Low-Alloy SteelsVon EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsBewertung: 5 von 5 Sternen5/5 (2)

- Bilad 2018 01 21Dokument25 SeitenBilad 2018 01 21beyNoch keine Bewertungen

- 01 - Fluid FlowDokument76 Seiten01 - Fluid FlowMubarak AhmadNoch keine Bewertungen

- Pipeline & Piping ScheduleDokument12 SeitenPipeline & Piping SchedulebeyNoch keine Bewertungen

- 2 Wti FundamentalsDokument10 Seiten2 Wti FundamentalsgdchanesNoch keine Bewertungen

- 3 Wti Control of Downhole PDFDokument6 Seiten3 Wti Control of Downhole PDFAjendra SinghNoch keine Bewertungen

- CONOCOPHILLIPS 10-K (Annual Reports) 2009-02-25Dokument324 SeitenCONOCOPHILLIPS 10-K (Annual Reports) 2009-02-25http://secwatch.com100% (2)

- 4 Wti Wellsite ValidationDokument6 Seiten4 Wti Wellsite ValidationbeyNoch keine Bewertungen

- Well Test Interpreta TionDokument6 SeitenWell Test Interpreta TionbeyNoch keine Bewertungen

- Well Test Interpreta TionDokument6 SeitenWell Test Interpreta TionbeyNoch keine Bewertungen

- Lube Oil Function Test ProcedureDokument4 SeitenLube Oil Function Test ProcedurebeyNoch keine Bewertungen

- Pipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1Dokument1 SeitePipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1beyNoch keine Bewertungen

- 01 - Fluid FlowDokument76 Seiten01 - Fluid FlowMubarak AhmadNoch keine Bewertungen

- PRN List For Volume 1-113001Dokument1 SeitePRN List For Volume 1-113001beyNoch keine Bewertungen

- Algerian Petroleum Institute Drilling IntroductionDokument210 SeitenAlgerian Petroleum Institute Drilling IntroductionbeyNoch keine Bewertungen

- Three-View Drawings & Technical DiagramsDokument150 SeitenThree-View Drawings & Technical DiagramsMahesh KumarNoch keine Bewertungen

- API 14A UpdateDokument13 SeitenAPI 14A UpdateAnonymous 70lCzDJv100% (1)

- Engineering Data Book: Gas Processors Suppliers AssociationDokument30 SeitenEngineering Data Book: Gas Processors Suppliers Associationbey0% (1)

- Pipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1Dokument1 SeitePipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1beyNoch keine Bewertungen

- Section 17Dokument11 SeitenSection 17beyNoch keine Bewertungen

- 14A - E12 PADokument4 Seiten14A - E12 PAbeyNoch keine Bewertungen

- Piping Drawings Guide: PFDs, P&IDs, Isometrics & GADsDokument89 SeitenPiping Drawings Guide: PFDs, P&IDs, Isometrics & GADsbey100% (2)

- 2 Cyclonic LayoutDokument1 Seite2 Cyclonic LayoutbeyNoch keine Bewertungen

- Connector CatalogDokument60 SeitenConnector CatalogYadira De De Ciam100% (1)

- HTML DOM TutorialDokument11 SeitenHTML DOM Tutorialapi-3819971100% (1)

- SPECIFICATION WRITING MODULEDokument3 SeitenSPECIFICATION WRITING MODULEHana YeppeodaNoch keine Bewertungen

- Costiuc Silvia - Culas in Oltenia - CNHC 2011Dokument25 SeitenCostiuc Silvia - Culas in Oltenia - CNHC 2011trancalina100% (1)

- TumblerBook Web enDokument21 SeitenTumblerBook Web enbmj272Noch keine Bewertungen

- Database transactions, recovery, and concurrencyDokument30 SeitenDatabase transactions, recovery, and concurrencyIvan Jan AvigueteroNoch keine Bewertungen

- LDRDokument4 SeitenLDRRaymond ValdezNoch keine Bewertungen

- Household Electricity End-Use ConsumptionDokument22 SeitenHousehold Electricity End-Use ConsumptionEva ViskadourakiNoch keine Bewertungen

- Weigelt Experience With Stator End-Winding Vibrations Causes, Solutions and Monitoring EPRI 2011, AlbanyDokument53 SeitenWeigelt Experience With Stator End-Winding Vibrations Causes, Solutions and Monitoring EPRI 2011, AlbanyKevin Luis Perez QuirozNoch keine Bewertungen

- Durehete 1055Dokument5 SeitenDurehete 1055alextentwenty100% (1)

- Main Engine Fuel Pump Drive Roller Damage: Return To TOCDokument2 SeitenMain Engine Fuel Pump Drive Roller Damage: Return To TOCTunaNoch keine Bewertungen

- Acoples Lovejoy (Rejilla - Grid, 8 Pág.)Dokument8 SeitenAcoples Lovejoy (Rejilla - Grid, 8 Pág.)marcelo castilloNoch keine Bewertungen

- OpenDSS Level 1 TrainingDokument85 SeitenOpenDSS Level 1 Trainingraul_bsu100% (1)

- Semiconductive Shield Technologies in Power Distribution CablesDokument6 SeitenSemiconductive Shield Technologies in Power Distribution CablesA. HassanNoch keine Bewertungen

- Ce1a3q E1a3qDokument5 SeitenCe1a3q E1a3qapi-239041842Noch keine Bewertungen

- Company Profile Pt. DutaflowDokument62 SeitenCompany Profile Pt. DutaflowRizkiRamadhanNoch keine Bewertungen

- Absolute-Pressure Sensors: Micromechanics, Hybrid DesignDokument3 SeitenAbsolute-Pressure Sensors: Micromechanics, Hybrid Designc20get100% (2)

- Mastertop TC 458 PDFDokument3 SeitenMastertop TC 458 PDFFrancois-Noch keine Bewertungen

- Smart Test Series: 1-Circle The Correct Answer. (12x1 12)Dokument4 SeitenSmart Test Series: 1-Circle The Correct Answer. (12x1 12)Dr. AyshaNoch keine Bewertungen

- INA FAG Water Pump BearingsDokument31 SeitenINA FAG Water Pump Bearings2bjornNoch keine Bewertungen

- Last Name, First CHE426:: F C V C V C F + F F CDokument6 SeitenLast Name, First CHE426:: F C V C V C F + F F Clợi trầnNoch keine Bewertungen

- Damping FactorDokument2 SeitenDamping FactorAngel Morales MartínezNoch keine Bewertungen

- Problem Statement: Designing of Pump System For Multi Story Residential BuildingDokument23 SeitenProblem Statement: Designing of Pump System For Multi Story Residential Buildingmehtab ul hassanNoch keine Bewertungen

- LN Tutorial Services - Machine Design, Materials & Shop PracticesDokument4 SeitenLN Tutorial Services - Machine Design, Materials & Shop PracticesEngr Amethyst RiegoNoch keine Bewertungen

- Introduction LetterDokument4 SeitenIntroduction LetterKashifRaza0% (1)

- Simulation Instructor WB 2011 ENGDokument57 SeitenSimulation Instructor WB 2011 ENGjorgemariovega4910Noch keine Bewertungen

- Kitchen Equipment Dimensions and SpecsDokument25 SeitenKitchen Equipment Dimensions and SpecselektrikCi124Noch keine Bewertungen

- Centrifugal Aftermarket Solutions BrochureDokument8 SeitenCentrifugal Aftermarket Solutions BrochureJose Renato MendesNoch keine Bewertungen

- FV 623 CatalogDokument50 SeitenFV 623 CatalogOmar Coronado50% (2)

- Consolidation: Photocopiable © University of Dayton Publishing, 2012Dokument3 SeitenConsolidation: Photocopiable © University of Dayton Publishing, 2012borboleta_sNoch keine Bewertungen