Beruflich Dokumente

Kultur Dokumente

Chopped Strand Mat For Hand-Lay Up: Product Description

Hochgeladen von

abthakurOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chopped Strand Mat For Hand-Lay Up: Product Description

Hochgeladen von

abthakurCopyright:

Verfügbare Formate

M113

Chopped Strand Mat for Hand-Lay Up

PRODUCT DESCRIPTION

The M113 chopped strand mat is made with medium size strands of E-Glass,

held together by a powder binder which is extremely soluble in styrene.

The basic strand has a sizing system containing a silane coupling agent.

This multi-purpose mat is used in numerous applications; this explains the

extensive range of weights and widths available.

PRODUCT REFERENCE

Example : M113 300-130 1B

M113 : OCV Reinforcements code for this chopped strand mat

300 : roll weight (g/m2)

130 : roll width (cm)

1B : number of trimmed edges (zro, one or two)

PRODUCT APPLICATION

Good surface appearance

Continuous laminating (translucent panels, exterior

panels for truck trailers, sandwich panels, etc..)

Anti-corrosion applications.

FEATURES AND PRODUCT BENEFITS

Excellent compatibility with polyester resins, producing laminates

with very high clarity (without any appearance of the strand pattern) Approved by Lloyds Register.

Very high smoothness of the laminate surface with no visible strands Approved by Det Norske Veritas

Excellent compatibility with vinylester and epoxy resins.

TECHNICAL CHARACTERISTICS (nominal values)

Weight (g/m) Loss on Ignition (%) Moisture (Max value(%)

ISO 3374: 2000 ISO 1887: 1995 ISO 3344: 1997

100 16% 10.5 40%

150 16% 8 40%

300 16% 4.5 40% 0.2

450 16% 3.5 40%

600 16% 3.2 40%

VISUAL CHARACTERISTICS or POSSIBLE DEFECTS

Unbound edges

Holes (> 40mm) or tears

Dirt spots (greater than 5 mm)

Unopened strands

Accumulation of fibers (>40mm)

Each 100 m2 roll of chopped strand mat section may contain at most 6 of the defects listed above.

M113

Chopped Strand Mat for Hand-Lay Up

PRODUCT AVAILABILITY

All range of widths (between 10 and 320 cm) and weights are available. Most combinations of weights and

widths can be supplied (may be subject to minimum order quantities, extended lead times and

complementary widths).

Standard weight (g/m) Standard width (cm) Diameter (cm) Length Weight (kg)

300 220 86

450 130/125 40 150 88

600 110 86

A roll is considered to be complete if it measures more than 70% of the nominal length.

PACKAGING (standard ref.)

Each roll is wound up on a cardboard tube (internal diameter 101 mm) and packaged in an individual

cardboard box, 40 x 40 (L x W) ;the height is equal to the width of the mat.

9 standard rolls are packed vertically on a pallet, secured by shrink-wrap polythene. The pallet is

wrapped with polyamide straps.

Mat width Pallet dimensions Net pallet weight (kg)

(cm) L x W x H (cm) 300 g/ m2 450 g/m2 600 g/m2

130 120x120x147 702 738 702

Number of rolls per pallet = 9 vertical - Pallet height is equal I to mat width + 17 cm

The pallet is wrapped with polyamide straps.

Special packaging: strips are packed in cardboard boxes of palletized according to the quantity.

LABELLING

Each pallet has two identification labels detailing the product reference, the net and gross weights in Kg,

packaging and product code, identification code of the palletized unit, production date.

STORAGE

The M113 mat should be stored in its original packaging in a dry and cool place. Best conditions are at

temperature from 10 to 35C and humidity between 35 and 85 %. If you store the product at lower

temperatures, please move the soon to be processed pallets to the production area 24 hours ahead of

time; remove part of the protective cover of each roll to prevent condensation.

You can stock pallets one on one with a plywood plank in between the two.

OWENS CORNING OWENS CORNING Owens Corning

COMPOSITE MATERIALS, LLC FIBERGLAS, SPRL. OCV Asia Pacific

ONE OWENS CORNING PARKWAY 166, CHAUSSE DE LA HULPE Shanghai Regional Headquarters

2F Olive LVO Mansion 620 Hua Shan Road

TOLEDO, OHIO 43659 B-1170 BRUSSELS

SHANGHAI CHINA 200040

1.800.GET.PINK BELGIUM

+86.21.62489922

www.owenscorning.com +32.2.674.82.99

www.ocvreinforcements.com

Contact:

Contact: Contact:

ChoppedStrandMats.ocvap@owenscorning.com

ChoppedStrandMats.ocvamericas@owenscorning.com ChoppedStrandMats.ocvemea@owenscorning.com

This information and data contained herein is offered solely as a guide in the selection of a reinforcement. The information contained in this publication is based on actual laboratory

data and field test experience. We believe this information to be reliable, but do not guarantee its applicability to the user's process or assume any responsibility or liability arising out

of its use or performance. The user agrees to be responsible for thoroughly testing any application to determine its suitability before committing to production. It is important for the

user to determine the properties of its own commercial compounds when using this or any other reinforcement. Because of numerous factors affecting results, we make no warranty

of any kind, express or implied, including those of merchantability and fitness for a particular purpose. Statements in this publication shall not be construed as representations or

warranties or as inducements to infringe any patent or violate any law safety code or insurance regulation.

Owens Corning reserves the right to modify this document without prior notice. 2008 Owens Corning

ChoppedStrandMats_M113_ww_07-2008_Rev1

Das könnte Ihnen auch gefallen

- ASTM B 211 StandardDokument10 SeitenASTM B 211 StandardalbertNoch keine Bewertungen

- Proceedings 02 00425 v2Dokument7 SeitenProceedings 02 00425 v2abthakurNoch keine Bewertungen

- A5 Manual Welding Product Guide Feb 2016 Low Res Final 1379066 SnapshotDokument40 SeitenA5 Manual Welding Product Guide Feb 2016 Low Res Final 1379066 SnapshotRaron1Noch keine Bewertungen

- Application Note: Measurements On FM Transmitters For Acceptance, Commissioning and MaintenanceDokument89 SeitenApplication Note: Measurements On FM Transmitters For Acceptance, Commissioning and MaintenanceabthakurNoch keine Bewertungen

- Battery Bank App Note ADokument22 SeitenBattery Bank App Note Aamorosoy100% (3)

- ASTM B 211 StandardDokument10 SeitenASTM B 211 StandardalbertNoch keine Bewertungen

- Battery ReconditioningDokument26 SeitenBattery ReconditioningJamesTimNoch keine Bewertungen

- 230S 1 PDFDokument21 Seiten230S 1 PDFabthakurNoch keine Bewertungen

- Byv26a Byv26cDokument2 SeitenByv26a Byv26cabthakurNoch keine Bewertungen

- Lead Acid Battery Instruction Sheet (f5)Dokument4 SeitenLead Acid Battery Instruction Sheet (f5)FaycelmekadminiNoch keine Bewertungen

- Calibration WeightsDokument5 SeitenCalibration WeightsabthakurNoch keine Bewertungen

- Beamex White Paper - Weighing Scale Calibration ENGDokument8 SeitenBeamex White Paper - Weighing Scale Calibration ENGabthakurNoch keine Bewertungen

- Adhesion Test SpecDokument3 SeitenAdhesion Test SpecdcevipinNoch keine Bewertungen

- Sony BDP 1100Dokument36 SeitenSony BDP 1100abthakurNoch keine Bewertungen

- Aluminum Reference GuideDokument6 SeitenAluminum Reference GuideAravind BaskerNoch keine Bewertungen

- An 15Dokument2 SeitenAn 15abthakurNoch keine Bewertungen

- Data SheetDokument2 SeitenData SheetabthakurNoch keine Bewertungen

- An5030 PDFDokument20 SeitenAn5030 PDFCanh LuongtienNoch keine Bewertungen

- Byv26a Byv26cDokument2 SeitenByv26a Byv26cabthakurNoch keine Bewertungen

- Vernier CalipersDokument32 SeitenVernier CalipersabthakurNoch keine Bewertungen

- An 15Dokument2 SeitenAn 15abthakurNoch keine Bewertungen

- Icl7106 Icl7107Dokument14 SeitenIcl7106 Icl7107José AdelinoNoch keine Bewertungen

- Aluminium TemperDokument4 SeitenAluminium TemperSinan YıldızNoch keine Bewertungen

- Display Pixel Defect InformationDokument3 SeitenDisplay Pixel Defect InformationabthakurNoch keine Bewertungen

- Gap Analysis ChecklistDokument5 SeitenGap Analysis ChecklistabthakurNoch keine Bewertungen

- E4329 QuickGuideDokument52 SeitenE4329 QuickGuidelumasNoch keine Bewertungen

- Datasheet - HK Cxa1213bs 194518Dokument26 SeitenDatasheet - HK Cxa1213bs 194518abthakurNoch keine Bewertungen

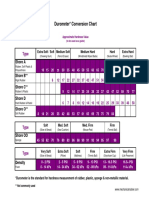

- Durometer Conversion Table PDFDokument1 SeiteDurometer Conversion Table PDFabthakurNoch keine Bewertungen

- Company Profile - Shubh CastingsDokument5 SeitenCompany Profile - Shubh CastingsabthakurNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Free Situational Judgement Test Questions FinalDokument6 SeitenFree Situational Judgement Test Questions FinalChristy Sanguyu100% (2)

- Type 4536 Oscillator-Divider ICDokument13 SeitenType 4536 Oscillator-Divider ICRoscoeDog718Noch keine Bewertungen

- Sicut CervusDokument4 SeitenSicut CervusMario SantiNoch keine Bewertungen

- Led 0608Dokument35 SeitenLed 0608Chris RogersNoch keine Bewertungen

- The Elements of Geology by Norton, William Harmon, 1856-1944Dokument221 SeitenThe Elements of Geology by Norton, William Harmon, 1856-1944Gutenberg.org100% (1)

- Ia Logo Guidelines 2015Dokument4 SeitenIa Logo Guidelines 2015Robert HopkinsNoch keine Bewertungen

- 2n6509 Data SheetDokument6 Seiten2n6509 Data SheetpapaskyNoch keine Bewertungen

- ASTM C942 - Compressive Strength of Grouts PDFDokument2 SeitenASTM C942 - Compressive Strength of Grouts PDFSrihariKyatamNoch keine Bewertungen

- B R 12345Dokument139 SeitenB R 12345rahmani bagherNoch keine Bewertungen

- IP ChecklistDokument4 SeitenIP ChecklistPraveen KumarNoch keine Bewertungen

- St. Croix County Property Transfers For Oct. 5-11, 2020Dokument31 SeitenSt. Croix County Property Transfers For Oct. 5-11, 2020Michael BrunNoch keine Bewertungen

- Official Solutions For CMO 2022: © 2022, Canadian Mathematical Society. All Rights ReservedDokument7 SeitenOfficial Solutions For CMO 2022: © 2022, Canadian Mathematical Society. All Rights ReservedCorneliaNoch keine Bewertungen

- Michael Veal Dub Starship Africa-1 PDFDokument24 SeitenMichael Veal Dub Starship Africa-1 PDFAlec MelosiniNoch keine Bewertungen

- E Awas Not AllotmentDokument2 SeitenE Awas Not AllotmentbittukumarpalNoch keine Bewertungen

- Just For Fun (Unit 1) : Beautiful Great Excellent Famous Handsome Wonderful Fantastic TerrificDokument1 SeiteJust For Fun (Unit 1) : Beautiful Great Excellent Famous Handsome Wonderful Fantastic TerrificAnonymous bjz5SOJmNoch keine Bewertungen

- Bread - If (Chords)Dokument2 SeitenBread - If (Chords)Tab HunterNoch keine Bewertungen

- We'Re Going On A Leaf Hunt - Metzger, Steve Sakamoto, Miki, Ill Miki Sakamoto - New York, 2005 - New York - Scholastic - 9780439773614 - Anna's ArchiveDokument36 SeitenWe'Re Going On A Leaf Hunt - Metzger, Steve Sakamoto, Miki, Ill Miki Sakamoto - New York, 2005 - New York - Scholastic - 9780439773614 - Anna's ArchiveChannah WenNoch keine Bewertungen

- Trade Surveillance and Monitoring Technology An Expanding LandscapeDokument19 SeitenTrade Surveillance and Monitoring Technology An Expanding LandscapezoombadosNoch keine Bewertungen

- Chap 03Dokument33 SeitenChap 03Gladys AnnNoch keine Bewertungen

- BMI V Davis (BMI MTD)Dokument21 SeitenBMI V Davis (BMI MTD)Christopher S. HarrisonNoch keine Bewertungen

- Èmoun Niuo KieDokument19 SeitenÈmoun Niuo Kiebill5Noch keine Bewertungen

- NEW VERSION1 1000ways PDFDokument223 SeitenNEW VERSION1 1000ways PDFRobert Glen Murrell JrNoch keine Bewertungen

- Shire Development Inc. v. Cadila Healthcare Limited (D/b/a Zydus Cadila), C.A. No. 10-581-KAJ (D. Del. Oct. 19, 2012)Dokument3 SeitenShire Development Inc. v. Cadila Healthcare Limited (D/b/a Zydus Cadila), C.A. No. 10-581-KAJ (D. Del. Oct. 19, 2012)YCSTBlogNoch keine Bewertungen

- Civil Procedure - Seminar SixDokument25 SeitenCivil Procedure - Seminar SixGrace YuNoch keine Bewertungen

- Documenting A Groundwater Sampling Event: Standard Guide ForDokument3 SeitenDocumenting A Groundwater Sampling Event: Standard Guide ForAntony Toranzo CamposNoch keine Bewertungen

- Law (Geographic Indications) SecG Group1Dokument16 SeitenLaw (Geographic Indications) SecG Group1Pyush GuptaNoch keine Bewertungen

- Appellant Memorial (Team-K)Dokument20 SeitenAppellant Memorial (Team-K)TanuNoch keine Bewertungen

- Ecograph Graphite CorpDokument25 SeitenEcograph Graphite CorpchinuasfaNoch keine Bewertungen

- 100 Years of Hollywood (Time-Life Art History Photo Ebook)Dokument194 Seiten100 Years of Hollywood (Time-Life Art History Photo Ebook)Alexandru Batu100% (1)

- VPA Trend Indicator - Pinescript R1Dokument4 SeitenVPA Trend Indicator - Pinescript R1SRIDHAR GOVARDHANANNoch keine Bewertungen