Beruflich Dokumente

Kultur Dokumente

Vidya Vikas Institute of Engineering & Technology: PO:1-9 (CO1, CO2) PO:1-9 (CO1, CO2)

Hochgeladen von

Arun NesamOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Vidya Vikas Institute of Engineering & Technology: PO:1-9 (CO1, CO2) PO:1-9 (CO1, CO2)

Hochgeladen von

Arun NesamCopyright:

Verfügbare Formate

VIDYA VIKAS INSTITUTE OF ENGINEERING &

TECHNOLOGY

MYSURU

DEPARTMENT OF CIVILENGINEERING

SECOND INTERNALTEST, MAY2015

Subject: Advanced Concrete Subject Code: 10CV81 Branch & Semester : 8th

Technology Sem, CIVIL

Max. Marks : 50 Date: 15-05-2015. Ti Time: 11.00 AM to 12.30

PM

Answer Any FIVE Question, Each question carries 10 Marks

10 PO:1-9(CO1,

1 What are Requirements of concrete mix design Marks CO2)

What are the Factors affecting the choice of mix 10 PO:1-9(CO1,

2 Marks CO2)

proportions

Design a concrete mix proportioning [M40 pump

able concrete with fly ash

a) Grade designation: M40

b) Type of cement: OPC 43 grade confirming to IS 8112

c) Type of mineral admixture: Fly ash confirming to IS

3812 (Part-1)

d) Maximum nominal size of aggregates: 20 mm

e) Minimum cement content: 320 kg/m3 PO:1-9(CO1,

3 f) Maximum water cement ratio : 0.45 20

CO2)

g) Workability: 100 mm (slump) Marks

h) Exposure condition: Severe (for reinforced concrete)

i) Method of concrete placing: Pumping

j) Degree of supervision: Good

k) Maximum cement content: 450 kg/m3

l) Chemical admixture type : Superplasticiser

m) Sp of cement=3.15,Sp of FA=2.65(zone-II),Sp of

CA=2.60,Sp of fly ash=2.15

Define Durability of Concrete. What are the 10 PO:1-9(CO1,

Marks CO2)

4 Environmental Related Causes of Concrete

Durability Problems?

5 Design a concrete mix proportioning M20 grade 20 PO:1-9(CO1,

concrete without using any Admixtures Marks CO2)

a) Grade designation: M20

VIDYA VIKAS INSTITUTE OF ENGINEERING &

TECHNOLOGY

MYSURU

DEPARTMENT OF CIVILENGINEERING

b) Type of cement: OPC 43 grade confirming to IS 8112

c) Maximum nominal size of aggregates: 20 mm

d) Minimum cement content: 300 kg/m3

e) Maximum water cement ratio : 0.55

f) Workability: 75 mm (slump)

g) Exposure condition: Mild (for reinforced concrete)

h) Method of concrete placing: Pumping

i) Degree of supervision: Good

j) Maximum cement content: 450 kg/m3

Sp of cement=3.15,Sp of FA=2.65(zone-II),Sp of CA=2.60,Sp of fly

ash=2.15

10 PO:1-9(CO1,

Explain a Typical Mix Proportioning of Self

6 Marks CO2)

Compacting Concrete.

10 PO:1-9(CO1,

8 Explain a typical mix of light weight concrete Marks CO2)

Course outcomes

Students will be able to

Understand the Designing and proportioning of Concrete Mix as per IS 10262-2009,by considering

the properties of the materials for different Applications

Das könnte Ihnen auch gefallen

- Mix Design M60Dokument3 SeitenMix Design M60Jocular Jaghan100% (6)

- Assignment ECS338 OCT2020-FEB2021 (Latest)Dokument5 SeitenAssignment ECS338 OCT2020-FEB2021 (Latest)Muhamad IzzanNoch keine Bewertungen

- Estimation Quantities and EsmationDokument5 SeitenEstimation Quantities and EsmationNURUL MAISARAH MOHD YUSSOFNoch keine Bewertungen

- Guru Nanak Dev Engineering College Bidar, KarnatakaDokument12 SeitenGuru Nanak Dev Engineering College Bidar, KarnatakaVEERKUMARNoch keine Bewertungen

- BCP&CT - Assignment - 1Dokument1 SeiteBCP&CT - Assignment - 1T Chaitanya Srikrishna Asst. ProfessorNoch keine Bewertungen

- Surprise Test1Dokument1 SeiteSurprise Test1pratishtha vermaNoch keine Bewertungen

- Concrete TechnologyDokument5 SeitenConcrete TechnologyAh RashedNoch keine Bewertungen

- 9th Region X PICE TC Sustainable ConcreteDokument68 Seiten9th Region X PICE TC Sustainable ConcreteIskolarAko Engineer-PlannerNoch keine Bewertungen

- ASSIGNMENTDokument3 SeitenASSIGNMENTSami BoyNoch keine Bewertungen

- Act PDFDokument61 SeitenAct PDFBindu SrirangamNoch keine Bewertungen

- Effectof Waterand Admixtureon Foam Concrete PropertiesDokument12 SeitenEffectof Waterand Admixtureon Foam Concrete PropertiesRakha AdinataNoch keine Bewertungen

- ECS246 Test 1 Sarawak MAC - JUL2022 EndorsedDokument2 SeitenECS246 Test 1 Sarawak MAC - JUL2022 EndorsedDEBRA DEIRDRE S. ONONG DEBRA DEIRDRE S. ONONGNoch keine Bewertungen

- Reg No:: Ce8020 - Maintenance, Repair and Rehabilitation of StructuresDokument2 SeitenReg No:: Ce8020 - Maintenance, Repair and Rehabilitation of StructuresAvinash KumarNoch keine Bewertungen

- Mix Proportion of Cementitious Material in Pervious ConcreteDokument13 SeitenMix Proportion of Cementitious Material in Pervious ConcreteMadhu Krishna0% (1)

- Time: 20 Minutes Date: 16-7-2022 FN Max Marks:10 Name: H.T. No: Sign. of An InvigilatorDokument4 SeitenTime: 20 Minutes Date: 16-7-2022 FN Max Marks:10 Name: H.T. No: Sign. of An InvigilatorHOD CIVILNoch keine Bewertungen

- Screenshot 2023-11-21 at 7.21.02 PMDokument1 SeiteScreenshot 2023-11-21 at 7.21.02 PMbibekbasnet7800Noch keine Bewertungen

- CE512 Exam PaperDokument22 SeitenCE512 Exam Paperedmond nyakundiNoch keine Bewertungen

- May 2018Dokument2 SeitenMay 2018Mohammed FurqanNoch keine Bewertungen

- UNIT-3: SP - GR Water Absorption Free (Surface-Moisture)Dokument2 SeitenUNIT-3: SP - GR Water Absorption Free (Surface-Moisture)NmNoch keine Bewertungen

- Sample Courses - Co Po MappingDokument6 SeitenSample Courses - Co Po MappingJayaguru CNoch keine Bewertungen

- International Conference On Recent Innovation in Civil Engineering For Sustainable DevelopmentDokument6 SeitenInternational Conference On Recent Innovation in Civil Engineering For Sustainable DevelopmentToufik AhmedNoch keine Bewertungen

- 1 ST Test 20cse31Dokument2 Seiten1 ST Test 20cse31RameshBMNoch keine Bewertungen

- Article 2Dokument14 SeitenArticle 2Imed Said atmaniNoch keine Bewertungen

- TestDokument8 SeitenTestMayank GuptaNoch keine Bewertungen

- Master of Civil Engg. Examination, 2006Dokument2 SeitenMaster of Civil Engg. Examination, 2006shaswataaNoch keine Bewertungen

- BSR 560 Jan 2022 Test (w6 Exercise)Dokument3 SeitenBSR 560 Jan 2022 Test (w6 Exercise)Muhammad SahrizatNoch keine Bewertungen

- Universiti Teknologi Mara: Kampus Kota Samarahan 2Dokument2 SeitenUniversiti Teknologi Mara: Kampus Kota Samarahan 2DEBRA DEIRDRE S. ONONG DEBRA DEIRDRE S. ONONGNoch keine Bewertungen

- An Introduction To Concrete Technology (Civl 4126) - 2021Dokument4 SeitenAn Introduction To Concrete Technology (Civl 4126) - 2021132 Arindam DattaNoch keine Bewertungen

- CEMB1013 Final Exam S1 2021Dokument8 SeitenCEMB1013 Final Exam S1 2021alolqigoNoch keine Bewertungen

- Effect of Cement Types On Carbonation Depth of ConcreteDokument8 SeitenEffect of Cement Types On Carbonation Depth of ConcreteEliott ThommesNoch keine Bewertungen

- Pa&d JalanDokument9 SeitenPa&d JalanIkram MuzhaffarNoch keine Bewertungen

- 17cv81 - Online Internal Assessment Test - 2Dokument2 Seiten17cv81 - Online Internal Assessment Test - 2Basavaraj HsNoch keine Bewertungen

- Part - A Questions: What Are The Effects of Fly Ash and GGBS On Concrete?Dokument2 SeitenPart - A Questions: What Are The Effects of Fly Ash and GGBS On Concrete?Sivakumar SelvarajNoch keine Bewertungen

- 9A01502 Concrete TechnologyDokument4 Seiten9A01502 Concrete TechnologysietkcivilNoch keine Bewertungen

- Design and Durability Analysis of Marine ConcreteDokument8 SeitenDesign and Durability Analysis of Marine Concretemarlon lumanogNoch keine Bewertungen

- Concrete Mix Design G20Dokument4 SeitenConcrete Mix Design G20Syerifaizal Hj. MustaphaNoch keine Bewertungen

- The Effect of Ground Limestone Addition On Carbonation and Chloride Resistance of ConcreteDokument8 SeitenThe Effect of Ground Limestone Addition On Carbonation and Chloride Resistance of ConcreteNuno FerreiraNoch keine Bewertungen

- BMC (3rd) May2018Dokument2 SeitenBMC (3rd) May2018Rajdev RaushanNoch keine Bewertungen

- 0421 - 16 MS PT Meindo Elang EndahDokument1 Seite0421 - 16 MS PT Meindo Elang EndahJoel Alfonso ManurungNoch keine Bewertungen

- B.tech III-II All Branch Regular and Supple Previous Question Papers May 2018Dokument28 SeitenB.tech III-II All Branch Regular and Supple Previous Question Papers May 2018bhanuprakeshNoch keine Bewertungen

- Influence of Waste Brick Powder On Properties of MDokument14 SeitenInfluence of Waste Brick Powder On Properties of MMd. Mominul IslamNoch keine Bewertungen

- CIE 2 CTP Set 1 Civil Engg Oct 2023Dokument2 SeitenCIE 2 CTP Set 1 Civil Engg Oct 2023Rajha RajeswaranNoch keine Bewertungen

- 9A01502 Concrete TechnologyDokument1 Seite9A01502 Concrete TechnologysivabharathamurthyNoch keine Bewertungen

- ITP 4 NOV PresentationR1-Dr. ArvindDokument17 SeitenITP 4 NOV PresentationR1-Dr. ArvindAfuriata ZebuaNoch keine Bewertungen

- Cet402 Quantity Surveying and ValuationDokument13 SeitenCet402 Quantity Surveying and ValuationdipinnediyaparambathNoch keine Bewertungen

- Concrete TechnologyDokument3 SeitenConcrete Technologyusama elalaouiNoch keine Bewertungen

- 456 CodeDokument66 Seiten456 CodeDebesh KuanrNoch keine Bewertungen

- Topics: A Glimpse Into Sustainable Ternary-Blended Cements of The FutureDokument19 SeitenTopics: A Glimpse Into Sustainable Ternary-Blended Cements of The FutureEmilioLimberArredondoOyolaNoch keine Bewertungen

- PSK GroupDokument1 SeitePSK GroupThe JdNoch keine Bewertungen

- Newcastle University: (Turn Over..Dokument9 SeitenNewcastle University: (Turn Over..mastergeo35Noch keine Bewertungen

- Calcinated Bentonite As Supplementary Cementitious Materials in CementBased MortarDokument10 SeitenCalcinated Bentonite As Supplementary Cementitious Materials in CementBased MortarAli RazaNoch keine Bewertungen

- Experimental Study On Concrete Mix Design by Replacing Fine Aggregate by Crushed Tiles & Cement With Marble PowderDokument8 SeitenExperimental Study On Concrete Mix Design by Replacing Fine Aggregate by Crushed Tiles & Cement With Marble PowderIJRASETPublicationsNoch keine Bewertungen

- To Study Comparison Between Conventional Slab and Bubble Deck SlabDokument7 SeitenTo Study Comparison Between Conventional Slab and Bubble Deck SlabNoor KhreisatNoch keine Bewertungen

- ADDMIX 109 PCCI-v1Dokument2 SeitenADDMIX 109 PCCI-v1Ankita Baban GavadeNoch keine Bewertungen

- Assessment of Potential of Marble Slurry As A Mineral Admixture in ConcreteDokument14 SeitenAssessment of Potential of Marble Slurry As A Mineral Admixture in ConcreteEditor IJTSRDNoch keine Bewertungen

- Act NotesDokument2 SeitenAct NotesMohan SubramaniNoch keine Bewertungen

- Priliminary Exam Paper CTDokument3 SeitenPriliminary Exam Paper CTspatil1472Noch keine Bewertungen

- CE680 - Internals1Dokument1 SeiteCE680 - Internals1santoshNoch keine Bewertungen

- Anna University:: Chennai: Roll NoDokument3 SeitenAnna University:: Chennai: Roll Nomdusman2010Noch keine Bewertungen

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeVon EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNoch keine Bewertungen

- Vidya Vikas Institute of Engineering and TechnologyDokument2 SeitenVidya Vikas Institute of Engineering and TechnologyArun NesamNoch keine Bewertungen

- Projection and Transformation CalculationsDokument38 SeitenProjection and Transformation CalculationsArun NesamNoch keine Bewertungen

- 2022 Drik Panchang Tamil Calendar v1.0.1Dokument25 Seiten2022 Drik Panchang Tamil Calendar v1.0.1Arun NesamNoch keine Bewertungen

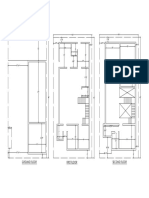

- Plan Model PDFDokument1 SeitePlan Model PDFArun NesamNoch keine Bewertungen

- Unit - 2 UTPDokument11 SeitenUnit - 2 UTPArun NesamNoch keine Bewertungen

- First Ia 17ccs23 QPDokument1 SeiteFirst Ia 17ccs23 QPArun NesamNoch keine Bewertungen

- Reinforced Concrete Slab PDFDokument8 SeitenReinforced Concrete Slab PDFArun NesamNoch keine Bewertungen

- Using Sitiffness Method of Analysis, Find The Moments and Reactions of The Frames ShownDokument9 SeitenUsing Sitiffness Method of Analysis, Find The Moments and Reactions of The Frames ShownArun NesamNoch keine Bewertungen

- SL - No. USN Name of The Candidate Sgpa %ge GradeDokument2 SeitenSL - No. USN Name of The Candidate Sgpa %ge GradeArun NesamNoch keine Bewertungen

- Plan Model PDFDokument1 SeitePlan Model PDFArun NesamNoch keine Bewertungen

- 01.MBT-RCC OHT-5 Lakh-DK-Model PDFDokument1 Seite01.MBT-RCC OHT-5 Lakh-DK-Model PDFArun NesamNoch keine Bewertungen

- Vidya Vikas Institute of Engineering & Technology: Answer Any FIVE Question, Each Question Carries 10 MarksDokument1 SeiteVidya Vikas Institute of Engineering & Technology: Answer Any FIVE Question, Each Question Carries 10 MarksArun NesamNoch keine Bewertungen

- M&E Question BankDokument7 SeitenM&E Question BankArun NesamNoch keine Bewertungen

- Library Details NAACDokument9 SeitenLibrary Details NAACArun NesamNoch keine Bewertungen

- Chapter 1Dokument92 SeitenChapter 1Arun NesamNoch keine Bewertungen

- Experimental Studies On Cement Stabilized Masonry Blocks Prepared From Brick Powder and Fine Recycled Concrete AggregateDokument2 SeitenExperimental Studies On Cement Stabilized Masonry Blocks Prepared From Brick Powder and Fine Recycled Concrete AggregateArun NesamNoch keine Bewertungen

- Site Layout Planning: Helpdesk@construction-Productivity - Co.ukDokument25 SeitenSite Layout Planning: Helpdesk@construction-Productivity - Co.ukArun NesamNoch keine Bewertungen

- Chapter 1Dokument23 SeitenChapter 1Arun NesamNoch keine Bewertungen

- BE Books 5Dokument2.928 SeitenBE Books 5Arun NesamNoch keine Bewertungen

- Chapter 8Dokument68 SeitenChapter 8Arun Nesam100% (1)

- Vinay Kumar: Supporting Agencies and Institutional SupportDokument20 SeitenVinay Kumar: Supporting Agencies and Institutional SupportArun NesamNoch keine Bewertungen

- Chapter 5Dokument48 SeitenChapter 5Arun NesamNoch keine Bewertungen

- Jurnal International AmilumDokument17 SeitenJurnal International AmilumGhiyatsKalukuNoch keine Bewertungen

- M Pharm Sem IIDokument25 SeitenM Pharm Sem IIBhaven PatelNoch keine Bewertungen

- Eiffic/Efuf (T:, RFRDT (FrrtfuDokument17 SeitenEiffic/Efuf (T:, RFRDT (FrrtfuRamasubba RajuNoch keine Bewertungen

- AMINE UNIT EVALUATION FORM Metric UnitDokument4 SeitenAMINE UNIT EVALUATION FORM Metric Unitandrey.glinskyNoch keine Bewertungen

- Viking Sprinkler Shield & GuardDokument4 SeitenViking Sprinkler Shield & Guardshankar_04Noch keine Bewertungen

- HTT 45 CableDokument1 SeiteHTT 45 CableKoel DeyNoch keine Bewertungen

- 1st Yr Lec3Dokument16 Seiten1st Yr Lec3abhijeetnarkhede69198Noch keine Bewertungen

- 5MF 10MFDokument8 Seiten5MF 10MFRodrigo Pessoa VespaNoch keine Bewertungen

- 3075-Article Text-9088-1-10-20201218Dokument11 Seiten3075-Article Text-9088-1-10-20201218Rasdawati RasulNoch keine Bewertungen

- ENVIROMENTAL Civic Education 10 To 12 PDF - RepairedDokument9 SeitenENVIROMENTAL Civic Education 10 To 12 PDF - RepairedRichard シNoch keine Bewertungen

- ColaMulse EZDokument2 SeitenColaMulse EZmndmattNoch keine Bewertungen

- NESC Diploma - MillwrightDokument2 SeitenNESC Diploma - MillwrightjamesNoch keine Bewertungen

- Rework Procedure For Bga ModulesDokument8 SeitenRework Procedure For Bga ModulesexwilliamNoch keine Bewertungen

- Description and Solubility - MTZDokument6 SeitenDescription and Solubility - MTZPityu PíNoch keine Bewertungen

- Solutios, Solutions of Non Electrolyte - 2019-2020 v2Dokument80 SeitenSolutios, Solutions of Non Electrolyte - 2019-2020 v2hazo hazNoch keine Bewertungen

- Casting in AviationDokument32 SeitenCasting in AviationJCNoch keine Bewertungen

- Praxis GuideDokument43 SeitenPraxis GuideRyan NegadNoch keine Bewertungen

- GPRSDokument6 SeitenGPRSRoberto CapchaNoch keine Bewertungen

- Isensee Robert W1943Dokument17 SeitenIsensee Robert W1943DŨNG VŨ NGUYỄN TUẤNNoch keine Bewertungen

- 2018 10 08 ICSG Factbook Copper 2018Dokument66 Seiten2018 10 08 ICSG Factbook Copper 2018treNoch keine Bewertungen

- 006-MS For Purging of Stainless Steel PDFDokument18 Seiten006-MS For Purging of Stainless Steel PDFKöksal PatanNoch keine Bewertungen

- Samsung Electric Dryer Dve54r7600 Dve54r7200 Manual OptimizedDokument124 SeitenSamsung Electric Dryer Dve54r7600 Dve54r7200 Manual OptimizedArgus JazminNoch keine Bewertungen

- USP Monographs - Miconazole NitrateDokument2 SeitenUSP Monographs - Miconazole NitrateMukarram MudjahidNoch keine Bewertungen

- Determination of Contents in Cold DrinksDokument12 SeitenDetermination of Contents in Cold DrinksMayank AggarwalNoch keine Bewertungen

- Chemistry For Engineers Assignment 2: Part I: Multiple Choice Questions (5Pts)Dokument2 SeitenChemistry For Engineers Assignment 2: Part I: Multiple Choice Questions (5Pts)Đạt Trương MinhNoch keine Bewertungen

- Dielectric Strength of Transformer OilDokument2 SeitenDielectric Strength of Transformer OilAnil VarriNoch keine Bewertungen

- Experiments 11 15 NotesDokument16 SeitenExperiments 11 15 Notesforisko05Noch keine Bewertungen

- Project Report Final-1Dokument33 SeitenProject Report Final-1Sahil ChelatNoch keine Bewertungen

- TIAC TechnologyDokument13 SeitenTIAC TechnologyPaul SunnyNoch keine Bewertungen

- Lin Jingwei - A Nomadic Furniture For College StudentsDokument129 SeitenLin Jingwei - A Nomadic Furniture For College StudentsAarish Netarwala100% (2)