Beruflich Dokumente

Kultur Dokumente

Effect of Latex Conversion On Glass Transition Temperature: Shao-Xiang Li, Ying-Dong Guan, Lu-Mei Liu

Hochgeladen von

CublktigressOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Effect of Latex Conversion On Glass Transition Temperature: Shao-Xiang Li, Ying-Dong Guan, Lu-Mei Liu

Hochgeladen von

CublktigressCopyright:

Verfügbare Formate

Vol.2, No.

5, 515-518 (2010) Natural Science

http://dx.doi.org/10.4236/ns.2010.25064

Effect of latex conversion on glass transition temperature

Shao-Xiang Li1, Ying-Dong Guan1*, Lu-Mei Liu2

1

Department of Micropolymer Materials of Science and Engineering, Qingdao University of Science & Technology, Qingdao, China;

*

Corresponding Author: gyd821123@126.com

2

Department of Materials Science and Engineering, Qingdao University of Science & Technology, Qingdao, China

Received 29 January 2010; revised 1 March 2010; accepted 25 March 2010.

ABSTRACT zation but ignored the investigation of minimum film-

forming temperature. In fact, there is a big difference

We have synthesized styrene-acrylic latex and between actual minimum film-forming temperature

investigated the effect of such reaction condi- and theoretical minimum film-forming temperature,

tions as the dosage of initiator, surfactant and which brings polymer designers difficulties in pre-

stirring speed on monomer conversion and dicting glass transition temperature and designing the

glass transition temperature (Tg) of polymer by hardness of the polymer, at the same time, brings users

means of orthogonal experiment, then we get a lot of inconvenience in use. There are many reasons

the best reaction conditions. Test results prove for the difference between actual minimum film-

that the glass transition temperature of the forming temperature and theoretical minimum film-

polymer is directly related to the monomer con- forming temperature, one of the most important is the

version. The improvement of monomer conver- monomer conversion. Due to the minimum film-

sion can make the glass transition temperature forming temperature has a good corresponding relation

close to the theoretical value. In the case of high with the glass-transition temperature [6], so this paper

final conversion, we can predict the glass tran- mainly investigates the glass-transition temperature by

sition temperature of the polymers of different means of optimizing the latexs polymerization condi-

composition according to the theoretical rela- tions. We obtain latex with high conversion, thus we

tion effectively. can solve the above problems in polymerization tech-

nology aspect and obtain the latex recipe of different

Keywords: Monomer Conversion; Orthogonal glass transition temperature under the guidance of the

Experiment; Glass Transition Temperature theoretical relation.

1. INTRODUCTION 2. EXPERIMENTAL

2.1. Materials

Styrene-acrylic latex is made of styrene and acrylate

monomers, which has many advantages. For example, Butyl acrylate (BA, 96%), Styrene (St, 97%), Methyl

it has wide source of raw materials, high function/price Methacrylate (MAA, 96%) and Diacetone acryl amide

ratio, simple synthetic process and the latex has out- (DAAM) were purchased from Qingdao Reagent Com-

standing water resistance, alkali resistance, scrub re- pany. The anionic surfactant sodium dodecyl sulfate

sistance and also the paint film has good outdoor du- (SDS), nonionic surfactant nonylphenol polyoxyethyl-

rable, adhesive attraction. So the styrene-acrylic latex ene ether (OP-10) and ammonium persulfate (APS)

has been widely used in building coating, metal sur- were purchased from Qingdao Chemistry Reagent

face coating and so on. Many researchers [1-5] have Company. All materials were used without further puri-

studied styrene-acrylic latex. Climates are usually di- fication.

verse across countries, even in one country. Therefore, 2.2. Preparation of Styrene-Acrylic Latex

a single recipe cannot satisfy different needs in the

different climate. In order to adapt to different envi- All emulsifier and deionized water were feeded into

ronment, especially the temperature environment, it four-necked flask and stirred at high speed first, then

requires the minimum film-forming temperature can feed monomer mixtures slowly to obtain the before-

not only has an unchangeable temperature. Scholars in hand latex. Take part of beforehand latex for seed latex,

this area had focused mostly on performance optimi- when temperature was wormed up to 75 1, feed

Copyright 2010 SciRes. OPEN ACCESS

516 S.-X. Li et al. / Natural Science 2 (2010) 515-518

part of initiator solution. After the blue seed latex After analysis, the author believes that the main reason

formed, the remaining latex was fed gradually, and par- of this phenomenon is due to a lower conversion of po-

tially drop initiator, beforehand latex and initiator were lymerization, the system was not polymerized according

added respectively in 3.5 h and 4 h. Then the tempera- to the expectable proportion, so we do the experiment to

ture was heated to 85 1 and kept this temperature optimize the process parameters of polymerization by

for 1 h, then cooled, adjusted PH = 7-8, Filtered and orthogonal experimental firstly in order to obtain the

Collected latex at last. latex with high monomer conversion.

Based on a large number of references and many re-

2.3. Characterization peated experiments, we consider that the dosage of ini-

The test of solid content: tiator (A), Emulsifier (B) and stirring speed (C) are the

main factors of polymerization, and have designed L9

m1 (33) orthogonal table (three variables, three levels Or-

s 100%

m0 thogonal design), the results are shown in Table 1.

where s is the solid content of latex, m1 is the weight of 3.2. The Analysis of Orthogonal Experiment

the latex after dried at 80 in vacuum drying oven, m0 Results

is the weight of the latex.

The test of monomer conversion: The weighted average (K) and range (R) are given in

We calculate the conversion by below relation Table 2.

Table 2 shows that the sequence of the effect of vari-

W1 S W 2 W 3 W 4

C (%) 100 % ous factors on conversion is emulsifier > initiator > stir-

W0 ring speed, the best condition is A3B2C2: initiator: 0.8%,

where W1 is the whole output of latex, W2 is the amount emulsifier: 4%, stirring speed: 180 rpm. But we can see

of gel, W3 is the amount of initiator, W4 is the amount of that the difference between k2 (88.033) and k3 (89.000) is

emulsifier, W0 is the amount of whole monomers, S is very small, and as we know the conversion increase with

the solid content of latex. the increase of the initiator, but the gel will increase ob-

The theoretical value of copolymers glass transition viously and the polymerization will become unstable at

temperature: the same time, so we choose A2B2C2: initiator: 0.6%,

Using the following FOX relation, we can get the emulsifier: 4%, stirring speed: 180 rpm at last.

composition of copolymers which have an expectable

Tg. Table 1. Test results.

1 W W W W Test A B C Conversion

1 2 3 ...... n NO % % rpm %

Tg Tg1 Tg 2 Tg3 Tg n 1 1(0.4) 1(2) 1(140) 82.6

where Tg is the glass transition temperature of co- 2 1 2(4) 2(180) 90.0

polymers, Tgl, Tg2, Tg3, Tgn are the glass transition 3 1 3(6) 3(240) 78.3

temperature of the respective homopolymers and Wl, 4 2(0.6) 1 2 87.6

W2, W3, Wn are the weight fraction of the respective 5 2 2 3 92.5

groups. 6 2 3 1 84.0

2.4. Differential Scanning Calorimeter (DSC) 7 3(0.8) 1 3 90.0

Analysis 8 3 2 1 91.0

9 3 3 2 86.0

Tg was measured by the DSC method in a NEYZSCH

204F1 type differential scanning calorimeter for polymer Table 2. The analysis of experiment results.

samples of ~20 mg. DSC condition measurement: hold for

1.0 min at 100, heat from 80 to 100 at 10 min1 Test Indicators A B C

and with nitrogen protection. k1 83.633 86.733 85.867

conversion k2 88.033 91.167 87.867

3. RESULTS AND DISCUSSION k3 89.000 82.767 86.933

R 5.367 8.400 2.000

3.1. Choice of Variables and Level of the

Orthogonal Experiment and its Results Table 3. Properties of the latex under the condition of A2B2C2.

During the experiment we found that there is a big dif- solid content (%) gel (%) water absorption(%) Conversion(%)

ference between measured value and theoretical value of

Tg (the theoretical value is calculated by FOX relation). 48.6 3.5 7 94

Copyright 2010 SciRes. OPEN ACCESS

S.-X. Li et al. / Natural Science 2 (2010) 515-518 517

As shown in Tables 1 and 2, the final conversion can see from it that with the increase of the monomer con-

reach 94% under the condition of A2B2C2 and it is higher version, the glass transition temperature of the latex de-

than the others, in addition, some other properties are crease gradually, when the final conversion is over 90%,

ideal too. Tg reaches a plateau and the value is about 10.0. The

mainly reason is that during the radical copolymerization,

3.3. DSC Test Analysis when the final conversion is low, the monomer with a

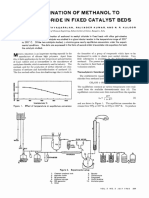

In this paper, the initial composition of monomer is BA: strong conjugacy is easier to polymerize than the others,

MMA:St = 33:19:18, the theoretical value of Tg which is styrene is such a hard monomer and the glass transition

calculated by FOX relation is 8. But when we adopt the temperature of its homopolymer is 105, so the Tg of

flowing factor: initiator: 0.6%, emulsifier: 4%, speed: copolymer will be a little higher than usual; on the con-

180 rpm, the final conversion reaches 94% and the meas- trary, when the final conversion is high, the system is

ured value of Tg achieved by DSC test is 9.8 (Figure 1), able to polymerize according to the expectable propor-

the difference between them is small. That is to say at the tion, the measured value and theoretical value of Tg

condition of high conversion, the measured value of Tg is match very well. However, the conversion of polymeri-

very close to its theoretical value and so we can design the zation can not reach 100%. In addition, Tg will increase

hardness of copolymers according FOX relation. because of the hydrogen bonds formed between the

Components [7]. Some references [8-11] introduce that

3.4. The Relationship of Monomer some additives and functional monomers will have a

Conversion and Glass Transition certain impact on glass transition temperature, therefore,

Temperature there will be a difference between measured and ex-

pected value of Tg inevitably.

Figure 2 shows us the relation between Tg and mono-

mer conversion (BA:MMA:St = 33:19:18) and we can 3.5. The Latex Recipe of Different Tg

In this paper, the total mass of the monomer is fixed at

0.30

70 g and the ratio of two hard monomer (St and MMA)

0.25

will not change at about 1:1, we changes the proportion

of soft and hard monomer only. Table 4 shows the latex

0.20 recipe with different Tg which are obtained at the condi-

DSC /(mW/mg)

Glass Transition: tion of A2B2C2.

Mid: 9.8

0.15

Table 4 shows that when the final conversion is at a

0.10

high level, the measured value and theoretical value of

Tg matches very well, thus researcher can be able to

0.05 forecast the Tg of polymer according to the proportion

monomers.

0.00

-80 -60 -40 -20 0 20 40 60 80 100 120

4. CONCLUSIONS

Temperature /

Figure 1. DSC curve of Styrene-acrylic latex (BA:MMA:St = 1) The results of the orthogonal experimental shows that

33:19:18). emulsifier > initiator > stirring speed in terms of their

effects on conversion. And we get the best condition:

20 emulsifier 4%, initiator 0.6%, stirring speed 180 rpm.

18

Table 4. Latex recipe with different Tg.

16 theoretical measured

BA(g) MMA(g) St(g)

value of Tg value of Tg

14

1# 48 11 11 20.0 18.3

Tg /

2# 43 14 13 10.0 9.3

12

3# 38 16 16 3.0 2.2

10 4# 33 19 18 7.8 9.8

5# 28 21 21 20.0 20.4

8

6# 26 22 22 24.0 25.2

82 84 86 88 90 92 94 7# 24 23 23 30.0 32.7

Monomer conversion /% 8# 20 25 25 40.0 42.7

Figure 2. The relation between Tg and monomer conversion. 9# 17 27 26 45.0 46.9

Copyright 2010 SciRes. OPEN ACCESS

518 S.-X. Li et al. / Natural Science 2 (2010) 515-518

2) There is a direct relationship between conversion [5] Joensson, J.L., Hassander, H. and Jansson, L.H. (1991)

and glass transition temperature, the improvement of the Morphology of two-phase polystyrene/poly (methyl

final conversion has made the measured value close to methacrylate) latex particles prepared under different

the theoretical value. polymerization conditions [J]. Macromolecules, 24(1),

126-131.

3) At the condition of high conversion, the measured

value and theoretical value of Tg matches very well. [6] Chen, R. (2007) Minimum temperature and polymer

glass-transition temperatures [J]. Chemical Industry of

Acrylic and Application, 20(1), 17-19.

REFERENCES [7] Gmez-Carracedo, A. and Alvarez-Lorenzo, C. (2003)

Chemical structure and glass transition temperature of

[1] Yu, Y.B. and Zhang, Y.H. (1996) Studying progress on non-ionic cellulose ethers DSC, TMDSC [J]. Journal of

styrene-acrylate emulsion polymerization[J]. Chemical Thermal Analysis and Calorimetry, 73(2), 587-596.

Industry and Engineering Progress, 2, 36-39. [8] Luo, H. and Wei, Z.G. (1997) Study on Tg of acrylic

[2] Wang, W.F., Li, S.X. and Liu, L.M. (2007) Preparation of emulsion copolymer [J]. Fine Chemicals, 69, 42-45.

low VOC waterborne epoxy-acrylate hybrid emulsion for [9] Xu, J. and Chen, B. (2005) Prediction of glass transition

wood coating [J]. Coating Industry, 37(11), 30-33. temperatures of OLED materials using topological indi-

[3] Pan, G.R., Wu, L.M. and Zhang, Z.Q. (2002) Synthesis ces [J]. Journal of Molecular Modeling, 12(1), 24-33.

and characterization of epoxy-acrylate composite latex [10] An, J., Li, X.Y. and Zhu, X.W. (2007) Segment distribut-

[J]. Journal of Applied Polymer Science, 83(8), 1736-1743. ing of copolymer form microemulsion copolymerization

[4] Chen, C.F., Lee, K.H. and Chiu, W.Y. (2007) Synthesis of styrene and butyl acrylate [J]. Chinese Journal of

and characterization of poly (butyl acrylate-methyl me- Colloid & Polymer, 25 (1), 1-2.

thacrylate)/polyaniline core-shell latexes [J]. Journal of [11] Wang, C.C. and Bao, Q.Y. (2005) Acrylate coatings [M].

Applied Polymer Science, 104(2), 823-830. Chemical and Industry Publishing Company, Beijing.

Copyright 2010 SciRes. OPEN ACCESS

Das könnte Ihnen auch gefallen

- Bercic-1993-Catalytic Dehydration of MethanolDokument7 SeitenBercic-1993-Catalytic Dehydration of MethanolIonut BanuNoch keine Bewertungen

- Synthesis of Diethylacetal: Thermodynamic and Kinetic StudiesDokument9 SeitenSynthesis of Diethylacetal: Thermodynamic and Kinetic StudiesrukwavuNoch keine Bewertungen

- Curing of Highly Loaded Ceramics Suspensions in AcrylatesDokument33 SeitenCuring of Highly Loaded Ceramics Suspensions in AcrylatesEllen Kay CacatianNoch keine Bewertungen

- CAPACCIODokument6 SeitenCAPACCIOapi-3733260Noch keine Bewertungen

- Catalytic Dehydration of Methanol To DimDokument8 SeitenCatalytic Dehydration of Methanol To DimNorma JenarezNoch keine Bewertungen

- Microwave Curing Reduces Voids in Thermoset CompositesDokument5 SeitenMicrowave Curing Reduces Voids in Thermoset CompositesAbd BaghadNoch keine Bewertungen

- Catalytic Decomposition of PolyethyleneDokument7 SeitenCatalytic Decomposition of PolyethyleneEvans KasondeNoch keine Bewertungen

- Catalytic Dehydration of Methanol To Dimethyl Ether. Kinetic Investigation and Reactor SimulationDokument8 SeitenCatalytic Dehydration of Methanol To Dimethyl Ether. Kinetic Investigation and Reactor SimulationLuiz Rodrigo AssisNoch keine Bewertungen

- Courtois 2018Dokument17 SeitenCourtois 2018chopin.wlive.cnNoch keine Bewertungen

- Hello HelloDokument15 SeitenHello Hellomanimaran_ratnamNoch keine Bewertungen

- RRRRRR Chido ReactHetExamenOrdinarioJunio2020aDokument4 SeitenRRRRRR Chido ReactHetExamenOrdinarioJunio2020aDaniel Moreno CabreraNoch keine Bewertungen

- Ziegler-Natta Catalyst PropertiesDokument7 SeitenZiegler-Natta Catalyst PropertiesParom WaikasikarnNoch keine Bewertungen

- Characterization of Sludge From The Wastewater-Treatment Plant of A RefineryDokument9 SeitenCharacterization of Sludge From The Wastewater-Treatment Plant of A Refinerythehoang12310Noch keine Bewertungen

- Isothermal Sorption Characteristics of T PDFDokument8 SeitenIsothermal Sorption Characteristics of T PDFDestria FiryalNoch keine Bewertungen

- Low Coefficient of Thermal ExpansionDokument13 SeitenLow Coefficient of Thermal ExpansionnileshsawNoch keine Bewertungen

- Hidratación de Oxido de Etileno Cinética PDFDokument5 SeitenHidratación de Oxido de Etileno Cinética PDFangieNoch keine Bewertungen

- Synthesis of renewable bio-based functional polymers from carbohydratesDokument49 SeitenSynthesis of renewable bio-based functional polymers from carbohydratesMohamed MehawedNoch keine Bewertungen

- Thermal and catalytic pyrolysis of polyethyleneDokument9 SeitenThermal and catalytic pyrolysis of polyethyleneKatiane MesquitaNoch keine Bewertungen

- Aging of HTPB Al AP Rocket Propellant Formulations by DMA MeasuremnetsDokument9 SeitenAging of HTPB Al AP Rocket Propellant Formulations by DMA MeasuremnetsAmmineni Syam PrasadNoch keine Bewertungen

- Morphology and Dynamic Mechanical Properties Nylon 66/poly (Ether Imide) BlendsDokument9 SeitenMorphology and Dynamic Mechanical Properties Nylon 66/poly (Ether Imide) Blendsapi-3733260Noch keine Bewertungen

- Cohn1987 PDFDokument5 SeitenCohn1987 PDFJuan Pablo BulaciosNoch keine Bewertungen

- Combustion of Spanish Coals Under Simulated Pressurized - Uidized-Bed-Combustion ConditionsDokument6 SeitenCombustion of Spanish Coals Under Simulated Pressurized - Uidized-Bed-Combustion Conditionsphemt84Noch keine Bewertungen

- Thermochimica Acta: Meriem Fertani-Gmati, Khemaies Brahim, Ismail Khattech, Mohamed JemalDokument10 SeitenThermochimica Acta: Meriem Fertani-Gmati, Khemaies Brahim, Ismail Khattech, Mohamed JemalwandaNoch keine Bewertungen

- 10.1007 - s13202 013 0051 4Dokument4 Seiten10.1007 - s13202 013 0051 4Luis FloresNoch keine Bewertungen

- Enthalpy Relaxation of Non-Stoichiometric Epoxy-Amine ResinsDokument13 SeitenEnthalpy Relaxation of Non-Stoichiometric Epoxy-Amine ResinsOussama El BouadiNoch keine Bewertungen

- DilatometryDokument4 SeitenDilatometryAttila MalinikNoch keine Bewertungen

- Synthesis of Tert-Amyl Ethyl Ether For Gasoline Additive: SciencedirectDokument6 SeitenSynthesis of Tert-Amyl Ethyl Ether For Gasoline Additive: SciencedirectElena Raluca DraguNoch keine Bewertungen

- 2013.06 LIST Modeling and Simulation of Polymerization of Lactide To Polylactic Acid EnglDokument7 Seiten2013.06 LIST Modeling and Simulation of Polymerization of Lactide To Polylactic Acid Englrusheekesh3497Noch keine Bewertungen

- Natural Mineral Fire Retardant Fillers For PolyethyleneDokument10 SeitenNatural Mineral Fire Retardant Fillers For Polyethylenegusanito09Noch keine Bewertungen

- Heat Transfer Analysis of Dilute Magnetorheological Fluid in Turbulator Assisted Concentric Tube Heat Exchanger AbstractDokument12 SeitenHeat Transfer Analysis of Dilute Magnetorheological Fluid in Turbulator Assisted Concentric Tube Heat Exchanger AbstractAshish KNoch keine Bewertungen

- Hydro ChlorinationDokument5 SeitenHydro ChlorinationIqbal Muhamad IrfanNoch keine Bewertungen

- Control of Gel Time UprDokument6 SeitenControl of Gel Time UprFredy HernándezNoch keine Bewertungen

- The Transport Process in The Catalytic Dehydrogenation of Ethyl AlcoholDokument23 SeitenThe Transport Process in The Catalytic Dehydrogenation of Ethyl AlcoholFiqkyAkbarNoch keine Bewertungen

- Vernikovskaya2011 BanyakDokument7 SeitenVernikovskaya2011 BanyakAisah Cory PrasonoNoch keine Bewertungen

- J of Applied Polymer Sci - 1998 - Cook - Curing Kinetics and Thermal Properties of Vinyl Ester ResinsDokument13 SeitenJ of Applied Polymer Sci - 1998 - Cook - Curing Kinetics and Thermal Properties of Vinyl Ester Resinsasaad biqaiNoch keine Bewertungen

- Lab ManualDokument17 SeitenLab ManualDaniel WigginsNoch keine Bewertungen

- Radical Coupling ReactionDokument7 SeitenRadical Coupling ReactionGobe JamNoch keine Bewertungen

- Ethylene Epoxidation in A Catalytic Packed-Bed Membrane ReactorDokument14 SeitenEthylene Epoxidation in A Catalytic Packed-Bed Membrane ReactorLim Xiu XianNoch keine Bewertungen

- Thermal analysis of polymers using TGA and DSCDokument17 SeitenThermal analysis of polymers using TGA and DSChyebibieNoch keine Bewertungen

- Molecules: Liquid-Phase Synthesis of Cyanuric Acid From UreaDokument5 SeitenMolecules: Liquid-Phase Synthesis of Cyanuric Acid From UreaSrujana BudheNoch keine Bewertungen

- BME 245/445L Mechanical Properties LabDokument6 SeitenBME 245/445L Mechanical Properties LabSrividyaNoch keine Bewertungen

- IYOHA COLLINS 16CF020531 Batch Reactor ReportDokument19 SeitenIYOHA COLLINS 16CF020531 Batch Reactor ReportDavid OvieNoch keine Bewertungen

- Modeling and Simulation of Polymerization of Lactide To PolylacticDokument7 SeitenModeling and Simulation of Polymerization of Lactide To Polylactickeyur1109Noch keine Bewertungen

- Pembuatan Etil AsetatDokument4 SeitenPembuatan Etil AsetatFenny Tri AriyaniNoch keine Bewertungen

- Polymers 07 01379 PDFDokument10 SeitenPolymers 07 01379 PDFKristineNoch keine Bewertungen

- Catalytic Degradation of Plastic Waste To Liquid Fuel Over Commercial Cracking Catalysts Effect of Polymer To Catalyst Ratio/acidity ContentDokument7 SeitenCatalytic Degradation of Plastic Waste To Liquid Fuel Over Commercial Cracking Catalysts Effect of Polymer To Catalyst Ratio/acidity ContentZahid FarooqNoch keine Bewertungen

- Paper CompositesWorld Evonik Oct2017Dokument12 SeitenPaper CompositesWorld Evonik Oct2017uzzy2Noch keine Bewertungen

- Chemical EngineeringDokument6 SeitenChemical EngineeringSriArthiNoch keine Bewertungen

- Epoxy Urethane OligomersDokument8 SeitenEpoxy Urethane Oligomersganeshdombe1980Noch keine Bewertungen

- Kuliah Teknik Reaksi Kimia HomogenDokument19 SeitenKuliah Teknik Reaksi Kimia HomogenThe Golden PieNoch keine Bewertungen

- The MICROREACTOR A Systematic and Efficient ToolDokument7 SeitenThe MICROREACTOR A Systematic and Efficient Tooljulianque81574Noch keine Bewertungen

- Crystallization of Paracetamolin Acetone-Water MixturesDokument7 SeitenCrystallization of Paracetamolin Acetone-Water Mixturesishwarya rNoch keine Bewertungen

- A Mathematical Model For The Production of Low Density Polyethylene in A Tubular ReactorDokument8 SeitenA Mathematical Model For The Production of Low Density Polyethylene in A Tubular ReactorAlfredo IllescasNoch keine Bewertungen

- 2017 AdvancesDokument8 Seiten2017 AdvancesAkshai Ashok KumarNoch keine Bewertungen

- Steam Cracking of Naphtha in Packed Bed ReactorsDokument6 SeitenSteam Cracking of Naphtha in Packed Bed Reactorscandidater100% (1)

- Polyester-Based Coil CoatingsDokument7 SeitenPolyester-Based Coil CoatingsRodolvano EmilianoNoch keine Bewertungen

- Studi Kinerja Katalisator Lewatit Monoplus s-100 pada Reaksi Esterifikasi antara Etanol dan Asam AsetatDokument4 SeitenStudi Kinerja Katalisator Lewatit Monoplus s-100 pada Reaksi Esterifikasi antara Etanol dan Asam AsetatRisantiSimatupangNoch keine Bewertungen

- Materials: Cure Cycle Optimization of Rapidly Cured Out-Of-Autoclave CompositesDokument15 SeitenMaterials: Cure Cycle Optimization of Rapidly Cured Out-Of-Autoclave CompositesAbd BaghadNoch keine Bewertungen

- NFR1-Ref 17Dokument28 SeitenNFR1-Ref 17LAURA KATHERINE CENTENO JAIMESNoch keine Bewertungen

- Things You Will Need:: How To Lighten Dark Lips in 1 Week? DIY Lip Scrub + Lip MaskDokument5 SeitenThings You Will Need:: How To Lighten Dark Lips in 1 Week? DIY Lip Scrub + Lip MaskCublktigressNoch keine Bewertungen

- Supplementary Material for Chemical CommunicationsDokument6 SeitenSupplementary Material for Chemical CommunicationsCublktigressNoch keine Bewertungen

- Creating A Family Mission Statement: Getting StartedDokument4 SeitenCreating A Family Mission Statement: Getting StartedCublktigressNoch keine Bewertungen

- The-Silent-Salesman - Anik SengalDokument68 SeitenThe-Silent-Salesman - Anik SengalCublktigress67% (3)

- Antiburnish Dead Matted GMADokument8 SeitenAntiburnish Dead Matted GMACublktigressNoch keine Bewertungen

- AR PaintMeasurementDokument3 SeitenAR PaintMeasurementCublktigressNoch keine Bewertungen

- Solar EnergyDokument183 SeitenSolar Energyghpeterkid100% (11)

- Stress Skin201909 DLDokument30 SeitenStress Skin201909 DLCublktigressNoch keine Bewertungen

- An Overview of The Use of Rheology For Adhesive ManufacturersDokument8 SeitenAn Overview of The Use of Rheology For Adhesive ManufacturersCublktigressNoch keine Bewertungen

- Slip and Leveling Agent Mar 2010Dokument33 SeitenSlip and Leveling Agent Mar 2010vasudevanrv9405Noch keine Bewertungen

- Barthelmes Particle Size Distributions and Viscosity of Suspensions Undergoing Shear-Induced Coagulation and Fragmentation CES03Dokument10 SeitenBarthelmes Particle Size Distributions and Viscosity of Suspensions Undergoing Shear-Induced Coagulation and Fragmentation CES03CublktigressNoch keine Bewertungen

- Publishing Guide 2015Dokument42 SeitenPublishing Guide 2015CublktigressNoch keine Bewertungen

- History of Paint SGCDokument19 SeitenHistory of Paint SGCHugo WizenbergNoch keine Bewertungen

- Antiburnish Dead Matted GMADokument8 SeitenAntiburnish Dead Matted GMACublktigressNoch keine Bewertungen

- Luna PresentationDokument16 SeitenLuna PresentationCublktigressNoch keine Bewertungen

- TheFreeReport PDFDokument52 SeitenTheFreeReport PDFCublktigressNoch keine Bewertungen

- Cocoa Buds TastebudsDokument27 SeitenCocoa Buds TastebudsCublktigressNoch keine Bewertungen

- SC Business License Handbook Guide for OfficialsDokument102 SeitenSC Business License Handbook Guide for OfficialsCublktigressNoch keine Bewertungen

- HomeostasisDokument12 SeitenHomeostasisaries-eiydaNoch keine Bewertungen

- Us 20100016430Dokument7 SeitenUs 20100016430CublktigressNoch keine Bewertungen

- Cocoa Buds TastebudsDokument27 SeitenCocoa Buds TastebudsCublktigressNoch keine Bewertungen

- Water Soluble Polymers For Industrial Water Treatment ApplicationsDokument38 SeitenWater Soluble Polymers For Industrial Water Treatment ApplicationsSong Nguyen NguyenNoch keine Bewertungen

- Pellegrino Nanoletters 2004Dokument5 SeitenPellegrino Nanoletters 2004Mirko AlloriNoch keine Bewertungen

- Acrylic Acid Vinyl Acetate CopolymersDokument5 SeitenAcrylic Acid Vinyl Acetate CopolymersKaveti VenuNoch keine Bewertungen

- Lecture 7 Application DTA & DSC01Dokument34 SeitenLecture 7 Application DTA & DSC01ZUL KAMARUDDINNoch keine Bewertungen

- Conducting Polymers: A New Class of MaterialsDokument7 SeitenConducting Polymers: A New Class of MaterialsscribdprateekNoch keine Bewertungen

- MOWIOL - Alcoholes Polivinilicos de Clariant - TdsDokument5 SeitenMOWIOL - Alcoholes Polivinilicos de Clariant - TdskbezalpNoch keine Bewertungen

- Effect of Microcrystalline Cellulose From Banana Stem Fiber On Mechanical Properties and Cystallinity of PLA Composite FilmsDokument5 SeitenEffect of Microcrystalline Cellulose From Banana Stem Fiber On Mechanical Properties and Cystallinity of PLA Composite FilmsHubby Mukaffa Al-JauzyNoch keine Bewertungen

- Juliana Dos Santos Carneiro Da CunhaDokument9 SeitenJuliana Dos Santos Carneiro Da CunhaClaudia MunizNoch keine Bewertungen

- Chemmatters April2010 Bioplastics PDFDokument3 SeitenChemmatters April2010 Bioplastics PDFMarilyn Mishell GarciaNoch keine Bewertungen

- B-Cycle Recycling PortfolioDokument30 SeitenB-Cycle Recycling PortfolioJose Victoriano MontielNoch keine Bewertungen

- Edible Water PodsDokument2 SeitenEdible Water PodsDivyashini MohanNoch keine Bewertungen

- Ma. Teresa U. Ocular Bsce-Structural 1 YearDokument4 SeitenMa. Teresa U. Ocular Bsce-Structural 1 YearMa. Teresa OcularNoch keine Bewertungen

- Technical Information and Applications For PEEK Fabrics: Customer Info NR 2Dokument8 SeitenTechnical Information and Applications For PEEK Fabrics: Customer Info NR 2Bernardo RodriguesNoch keine Bewertungen

- Polymers Control Drug DeliveryDokument8 SeitenPolymers Control Drug DeliveryUma DeviNoch keine Bewertungen

- The Mechanical Loss Coefficient (Tan Delta)Dokument2 SeitenThe Mechanical Loss Coefficient (Tan Delta)gego2100% (1)

- Fiber-Reinforced Asphalt-Concrete - A ReviewDokument7 SeitenFiber-Reinforced Asphalt-Concrete - A ReviewAlberto GaxiolaNoch keine Bewertungen

- Introduction To The Structure and The Structural Role of Elements in GlassesDokument84 SeitenIntroduction To The Structure and The Structural Role of Elements in GlassesBiswanath senNoch keine Bewertungen

- PTFE Tribology and The Role of Mechanochemistry in The Development of Protective Surface FilmsDokument7 SeitenPTFE Tribology and The Role of Mechanochemistry in The Development of Protective Surface FilmsAnnamalai PalaniappanNoch keine Bewertungen

- Elastomeric Materials PDFDokument84 SeitenElastomeric Materials PDFAnonymous oyUAtpKNoch keine Bewertungen

- SMA ApplicationsDokument5 SeitenSMA Applicationschandran usumbasseriNoch keine Bewertungen

- Polymer Rheology: Understanding Flow BehaviorDokument13 SeitenPolymer Rheology: Understanding Flow BehaviorIhana GabrielaNoch keine Bewertungen

- Cbse Class 12 Project File On PolymerDokument14 SeitenCbse Class 12 Project File On PolymerSHIVAM SINGHNoch keine Bewertungen

- (RSC PAPERBACKS) G. Scott - Polymers and The Environment-Royal Society of Chemistry (2003)Dokument148 Seiten(RSC PAPERBACKS) G. Scott - Polymers and The Environment-Royal Society of Chemistry (2003)nimraNoch keine Bewertungen

- Metitherm Technical BrochureDokument62 SeitenMetitherm Technical BrochureHussain ElarabiNoch keine Bewertungen

- Bref Polymer EsDokument319 SeitenBref Polymer EsMaFher JimenezNoch keine Bewertungen

- Optimum CaCO3 Level for Flexible PU FoamDokument10 SeitenOptimum CaCO3 Level for Flexible PU FoamrozichkaNoch keine Bewertungen

- Azithromycin SuspensionDokument9 SeitenAzithromycin Suspensionjkarlsr69Noch keine Bewertungen

- MicrospheresDokument48 SeitenMicrospheresVouge Mode100% (2)

- Polymers & PolymerizationDokument20 SeitenPolymers & PolymerizationAtul GautamNoch keine Bewertungen