Beruflich Dokumente

Kultur Dokumente

API 510 Rerating Extract PDF

Hochgeladen von

mjmehta81Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

API 510 Rerating Extract PDF

Hochgeladen von

mjmehta81Copyright:

Verfügbare Formate

PRESSURE VESSEL INSPECTION CODE: IN-SERVICE INSPECTION, RATING, REPAIR, AND ALTERATION 55

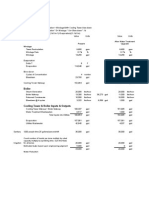

Table 8.1Qualification Limits for Base Metal and Weld Deposit Thicknesses for the CDW Method

(Notch Toughness Testing Required)

Thickness T of

Depth t of Test Repair Groove Thickness of Base

Test Coupon

Groove Welded a Depth Qualified Metal Qualified

Welded

t <t <2 in. (50 mm) <T

2 in. (50 mm)

t <t >2 in. (50 mm)

to unlimited

a The depth of the groove used for procedure qualification shall be deep enough to allow

removal of the required test specimens.

--`,,`,,``,`,```,`,`,,`,,,,,`,``-`-`,,`,,`,`,,`---

8.1.8.2 After the weld is completed, it shall be examined again by the appropriate NDE technique specified in the

repair specification to determine that no defects exist using acceptance standards acceptable to the Inspector or the

applicable construction code.

8.1.8.3 New welds, as part of a repair or alteration in a pressure vessel that were originally required to be

radiographed (e.g. circumferential and longitudinal welds) by the construction code, shall be radiographically

examined in accordance with the construction code. In situations where it is not practical to perform radiography, the

accessible surfaces of each nonradiographed new weld shall be fully examined using UT in lieu of RT and/or other

appropriate NDE techniques to determine that no defects exist. UT in lieu of RT shall follow ASME Code Case 2235

or ASME Code, Section VIII, Division 2, 7.5.5. If other techniques are used rather than the UT in lieu of RT, the joint

efficiency should be reduced to the value corresponding to no radiography. Where use of NDE techniques specified

by the construction code is not possible or practical, alternative NDE techniques may be used provided they are

approved by the engineer and inspector.

8.1.8.4 Acceptance criteria for welded repairs or alterations should be in accordance with the applicable sections of

the ASME Code or another applicable vessel rating code.

8.1.9 Weld Inspection for Vessels Subject to Brittle Fracture

For vessels constructed of materials that may be subject to brittle fracture (per API 579-1/ASME FFS-1, Part 3, or other

analysis) from either normal or abnormal service (including start-up, shutdown, and pressure testing), appropriate

inspection should be considered after welded repairs or alterations. Flaws, notches, or other stress risers could initiate a

brittle fracture in subsequent pressure testing or service. MT and other effective surface NDE methods should be

considered. Inspection techniques should be selected to detect critical flaws as determined by a FFS assessment.

8.2 Rerating

8.2.1 Rerating a pressure vessel by changing its design temperature, minimum metal design temperature, or its

MAWP may be done only after all of the following requirements have been met.

a) Calculations performed by either the manufacturer or an owner/user engineer (or his/her designated

representative) experienced in pressure vessel design, fabrication, or inspection shall justify rerating.

b) A rerating shall be performed in accordance with the requirements of the vessels construction code. Alternately,

calculations can be made using the appropriate formulas in the latest edition of the applicable construction code

provided all of the vessels essential details comply with the applicable requirements of the ASME Code. If the

vessel was designed to an edition or addendum of the ASME Code earlier than the 1999 addendum and was not

designed to ASME Code Case 2290 or ASME Code Case 2278, it may be rerated to the latest edition/addendum

of the ASME Code if permitted by Figure 8.1. Notice that for vessels built to a code earlier than 1968 the original

design allowable stress (based on design factor of 4.0 or 5.0) shall be used.

Provided by IHS Licensee=Maersk Oil and Gas - Qatar/5964822002, User=Woodman, John

No reproduction or networking permitted without license from IHS Not for Resale, 11/11/2014 02:27:05 MST

56 API 510

Obtain original

vessel data.

Was vessel

No built to 1968 or later

edition of ASME Code

(see note 1)? Notes:

1. ASME Code identified as ASME Section VIII,

Div. 1.

Yes

2. Vessel material(s) are defined as material

essential to the structural integrity of the

vessel.

Was the Are vessel

vessel material materials listed in the 3. Material degradation due to operation is

No No

specification replaced by a latest edition/addendum of defined as loss of material strength,

current specification? the ASME Code ductility, or toughness due to creep,

(see note 2)? graphitization, temper embrittlement,

hydrogen attack, fatigue, etc., see API 579.

Yes Yes

Yes Is allowable

Was the stress at rerate No incentive to use the

vessel material temperature per the latest latest edition/addendum of

No

originally certified using edition/addendum of the ASME the ASME Code allowable

UG10 of ASME

--`,,`,,``,`,```,`,`,,`,,,,,`,``-`-`,,`,,`,`,,`---

Code higher than stress for rerating.

Code? original allowable

stress?

No

Yes

Review

Can the operational history.

No vessel material be Yes

certified using UG10 of

ASME Code?

Has the

material been

Yes degraded because of

operation

(see note 3)?

Can the

vessel material

No properties meet a current

material specification? No

Does

the material

toughness meet the Rerate vessel or

Yes

latest edition/addendum of Yes component using the latest

the ASME Code toughness edition/addendum of the ASME

Vessel or components cannot requirements? Code allowable stress.

be rerated using the latest

edition/addendum of the ASME

Code allowable stress.

No

Do the vessel

components satisfy

the impact toughness

No Yes

requirement in API 579, Sec. 3, or

other recognized FFS standards

for the rerated

condition?

Figure 8.1Rerating Vessels Using the Latest Edition or Addendum of the ASME Code Allowable Stresses

Provided by IHS Licensee=Maersk Oil and Gas - Qatar/5964822002, User=Woodman, John

No reproduction or networking permitted without license from IHS Not for Resale, 11/11/2014 02:27:05 MST

PRESSURE VESSEL INSPECTION CODE: IN-SERVICE INSPECTION, RATING, REPAIR, AND ALTERATION 57

c) Current inspection records verify that the pressure vessel is satisfactory for the proposed service conditions and

that the corrosion allowance provided is appropriate. An increase in allowable working pressure or design

temperature shall be based on thickness data obtained from a recent internal or on-stream inspection.

d) The vessel shall be pressure tested using the applicable testing formula from the code used to perform the

rerating calculations unless either of the following is true:

1) the pressure vessel has at some time been pressure tested to a test pressure equal to or higher than the test

pressure required by the construction code and

2) the vessel integrity is confirmed by special nondestructive evaluation inspection techniques in lieu of testing.

e) The rerating is acceptable to the engineer.

8.2.2 The pressure vessel rerating will be considered complete with the attachment of an additional nameplate or

additional stamping that carries the information in Figure 8.2.

Rerated by: ________________________________________

Date Rerated: ______________________________ 20_____

SAP No: ______________________________________

MAWP: _____________ PSIG @ ____________ F

MDMT: _____________ F @ ________ PSIG

Test Pressure: _____________ PSIG

Figure 8.2Sample Additional Nameplate

9 Alternative Rules for E&P Pressure Vessels

9.1 Scope and Specific Exemptions

9.1.1 This section sets forth the minimum alternative inspection rules for pressure vessels that are exempt from the

rules set forth in Section 6 except as referenced in 9.4 and 9.5. Owner/users may choose to use Section 6 instead of

this section for inspection of pressure vessels. Except for Section 6, all of the sections in this inspection code are

applicable to E&P pressure vessels. These rules are provided because of the vastly different characteristics and

needs of pressure vessels used for E&P service. Typical E&P services are vessels associated with drilling,

production, gathering, transportation, and treatment of liquid petroleum, natural gas, natural gas liquids, and

associated salt water (brine).

9.1.2 The following are specific exemptions.

a) Portable pressure vessels and portable compressed gas containers associated with construction machinery, pile

drivers, drilling rigs, well-servicing rigs and equipment, compressors, trucks, ships, boats, and barges shall be

treated, for inspection and recording purposes, as a part of that machinery and shall be subject to prevailing rules

and regulations applicable to that specific type of machine or container.

b) Pressure vessels referenced in Annex A are exempt from the specific requirements of this inspection code.

--`,,`,,``,`,```,`,`,,`,,,,,`,``-`-`,,`,,`,`,,`---

Provided by IHS Licensee=Maersk Oil and Gas - Qatar/5964822002, User=Woodman, John

No reproduction or networking permitted without license from IHS Not for Resale, 11/11/2014 02:27:05 MST

Das könnte Ihnen auch gefallen

- Risk Based Inspection A Complete Guide - 2020 EditionVon EverandRisk Based Inspection A Complete Guide - 2020 EditionNoch keine Bewertungen

- API653 Training Application 170610 UpdateDokument4 SeitenAPI653 Training Application 170610 UpdateesamhamadNoch keine Bewertungen

- Potential Damage PKTDokument7 SeitenPotential Damage PKTFebri Ramdani NugrahaNoch keine Bewertungen

- Api 510Dokument27 SeitenApi 510Alby DiantonoNoch keine Bewertungen

- Sop-miqa-Attk-001 - Pressure Vessel Inspection For Migas Re-Certification (2007)Dokument10 SeitenSop-miqa-Attk-001 - Pressure Vessel Inspection For Migas Re-Certification (2007)Iksan Adityo MulyoNoch keine Bewertungen

- API 510 Course Puspatri Apr 09Dokument185 SeitenAPI 510 Course Puspatri Apr 09ahmedelhajNoch keine Bewertungen

- 5 16259779815014437Dokument26 Seiten5 16259779815014437Hafizul Hisyam Maysih Luzifah100% (1)

- API 510 Spreadsheet To Calculate (Welding ScwiDokument2 SeitenAPI 510 Spreadsheet To Calculate (Welding Scwibryandown100% (1)

- Introduction To RBIDokument18 SeitenIntroduction To RBIMichelle Mc IntyreNoch keine Bewertungen

- ASME U StampDokument2 SeitenASME U StampAJAY1381Noch keine Bewertungen

- Quantitative Risk-Based Inspection Approach For High-Energy Piping Using A Probability Distribution Function and Modification FactorDokument14 SeitenQuantitative Risk-Based Inspection Approach For High-Energy Piping Using A Probability Distribution Function and Modification FactorEmperor RocaNoch keine Bewertungen

- 00 AOC's Meridium MI Work Process Training Example SlidesDokument67 Seiten00 AOC's Meridium MI Work Process Training Example SlidesTommy100% (1)

- 14 LPD Drum FC-D-7 - Rev0 (Contoh)Dokument36 Seiten14 LPD Drum FC-D-7 - Rev0 (Contoh)azzamsiregarekaNoch keine Bewertungen

- Damage Mechanisms For API 653Dokument10 SeitenDamage Mechanisms For API 653Saran KumarNoch keine Bewertungen

- Equipment Inspection Guideline For Pressure vessel-API 510Dokument8 SeitenEquipment Inspection Guideline For Pressure vessel-API 510Ahsun HabibNoch keine Bewertungen

- Ut PittingDokument7 SeitenUt PittingmmNoch keine Bewertungen

- Basic API650Dokument52 SeitenBasic API650Eslam Nagy100% (3)

- API 570 - Exam Prep Course SampleDokument2 SeitenAPI 570 - Exam Prep Course SampleLuis M. LuisNoch keine Bewertungen

- Latest Advances in RBI - Session 1Dokument30 SeitenLatest Advances in RBI - Session 1Ahmed Abd ElmegeedNoch keine Bewertungen

- RSTRENG Report - 08 - 07 - 2015 - 10 - 12 - 14Dokument2 SeitenRSTRENG Report - 08 - 07 - 2015 - 10 - 12 - 14Mustafa Akbar100% (2)

- Calculation Sheet API - 510: Pressure VesselDokument5 SeitenCalculation Sheet API - 510: Pressure Vesselah1525Noch keine Bewertungen

- Tank Bottoms in Atmospheric Storage TanksDokument5 SeitenTank Bottoms in Atmospheric Storage TankslsatchithananthanNoch keine Bewertungen

- Weld Repair of Grade 91 Piping and Components in PDokument27 SeitenWeld Repair of Grade 91 Piping and Components in PKyi HanNoch keine Bewertungen

- API - 510 Points To Remember - 6Dokument3 SeitenAPI - 510 Points To Remember - 6EswaranNoch keine Bewertungen

- API 653 NotesDokument3 SeitenAPI 653 NotesPavan_yoyoNoch keine Bewertungen

- Optimum CosineDokument17 SeitenOptimum CosinetomcanNoch keine Bewertungen

- Crevice Corrosion: Present By: Mohsin Muhyuddin Haroon RasheedDokument19 SeitenCrevice Corrosion: Present By: Mohsin Muhyuddin Haroon RasheedTayyab AhsanNoch keine Bewertungen

- Mech IntegrityDokument1 SeiteMech IntegrityAndy DolmanNoch keine Bewertungen

- 8.inspection CalculationDokument38 Seiten8.inspection CalculationAMAL VISHNUNoch keine Bewertungen

- How To Perform A Damage Mechanism ReviewDokument4 SeitenHow To Perform A Damage Mechanism ReviewianharNoch keine Bewertungen

- Api653 Question N°06 ResponsesDokument3 SeitenApi653 Question N°06 ResponseskorichiNoch keine Bewertungen

- 510 Open Exam B. Rev7Dokument15 Seiten510 Open Exam B. Rev7yrdna nawaiteosNoch keine Bewertungen

- CML PlacementDokument3 SeitenCML PlacementAhmedNoch keine Bewertungen

- Daily Points To Recall (Day 5) : Professional Training and ConsultationDokument3 SeitenDaily Points To Recall (Day 5) : Professional Training and Consultationraobabar21Noch keine Bewertungen

- F.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselDokument7 SeitenF.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselIksan Adityo MulyoNoch keine Bewertungen

- Storage Tank Inspection PDFDokument2 SeitenStorage Tank Inspection PDFtyo wibowoNoch keine Bewertungen

- Dacon Corrossion Under Support PresentationDokument22 SeitenDacon Corrossion Under Support PresentationMohammed Ilyas MohiuddinNoch keine Bewertungen

- RBI Basis JustificationDokument17 SeitenRBI Basis JustificationTommy100% (1)

- P RBI Presentation SlideDokument32 SeitenP RBI Presentation SlideRomeo BoiiNoch keine Bewertungen

- API 510 Study PlanDokument7 SeitenAPI 510 Study Plankoib789100% (2)

- Guide Inspection Plan For CUIDokument6 SeitenGuide Inspection Plan For CUIMohamed SamyNoch keine Bewertungen

- Api 510 2017Dokument1 SeiteApi 510 2017Santiago Cordova Alva0% (2)

- 1 API 653 Memories March 2014 ExamDokument16 Seiten1 API 653 Memories March 2014 ExammajidNoch keine Bewertungen

- Lesson 15 SectionVDokument157 SeitenLesson 15 SectionVAhmed shabanNoch keine Bewertungen

- MD PV Asme v0.1Dokument35 SeitenMD PV Asme v0.1Kamlesh LuharNoch keine Bewertungen

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsVon EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNoch keine Bewertungen

- Asset Integrity Management A Complete Guide - 2020 EditionVon EverandAsset Integrity Management A Complete Guide - 2020 EditionNoch keine Bewertungen

- Corrosion Failures: Theory, Case Studies, and SolutionsVon EverandCorrosion Failures: Theory, Case Studies, and SolutionsNoch keine Bewertungen

- QW 453Dokument1 SeiteQW 453Waqas WaqasNoch keine Bewertungen

- Presentation On Internal Inspection of Vessels TanksDokument39 SeitenPresentation On Internal Inspection of Vessels TanksAbiram VSNoch keine Bewertungen

- TAPPI TIP-0402-31 UT Evaluating Welds QualityDokument5 SeitenTAPPI TIP-0402-31 UT Evaluating Welds Qualitya_parratNoch keine Bewertungen

- Astm G10 - 10Dokument3 SeitenAstm G10 - 10Sofia YuliNoch keine Bewertungen

- Inspection and Testing of WeldsDokument22 SeitenInspection and Testing of WeldsKamarul NizamNoch keine Bewertungen

- Steel Structure TestDokument3 SeitenSteel Structure TestThien MaiNoch keine Bewertungen

- Plastics: ASTM D882 Tensile Properties of Thin Film / Plastic SheetingDokument2 SeitenPlastics: ASTM D882 Tensile Properties of Thin Film / Plastic SheetingRamu MehtoNoch keine Bewertungen

- Technical Datasheet - 2750 - Acceptance Test LaboratoryDokument98 SeitenTechnical Datasheet - 2750 - Acceptance Test LaboratoryAbhishek RajputNoch keine Bewertungen

- Api 107Dokument14 SeitenApi 107Yersin Hernandez AldanNoch keine Bewertungen

- 2-6-ASME Sect. IX-2013-Section of Pipe Welder Qual.-Qw 452.6Dokument1 Seite2-6-ASME Sect. IX-2013-Section of Pipe Welder Qual.-Qw 452.6Tina MartinezNoch keine Bewertungen

- Guidance Note Surface Inspection of Welds No. 6.02: ScopeDokument5 SeitenGuidance Note Surface Inspection of Welds No. 6.02: Scopesiroliver39Noch keine Bewertungen

- Section 10 Specs For Cooling TowerDokument13 SeitenSection 10 Specs For Cooling Towermjmehta81Noch keine Bewertungen

- Specification For Gas Fired Boiler PDFDokument7 SeitenSpecification For Gas Fired Boiler PDFmjmehta81Noch keine Bewertungen

- DEG Column Base RingDokument1 SeiteDEG Column Base Ringmjmehta81Noch keine Bewertungen

- CalculationsDokument2 SeitenCalculationsAliAliNoch keine Bewertungen

- Simulation of Reactive Distillation ColumnDokument6 SeitenSimulation of Reactive Distillation ColumnthanhndbNoch keine Bewertungen

- Stabilisation of Soft Clay Using Ground Granulated Blastfurnace Slag and LimeDokument7 SeitenStabilisation of Soft Clay Using Ground Granulated Blastfurnace Slag and LimeVivek SvkNoch keine Bewertungen

- Analysis of Cement by Banana FiberDokument48 SeitenAnalysis of Cement by Banana FiberKyaw KhineNoch keine Bewertungen

- Specification For Valves P-09-1001 Rev0Dokument29 SeitenSpecification For Valves P-09-1001 Rev0Anonymous H8EsgFCXjWNoch keine Bewertungen

- Fluid PropertiesDokument37 SeitenFluid PropertiesdeusleanNoch keine Bewertungen

- 0199152152Dokument138 Seiten0199152152Afzal UsmanNoch keine Bewertungen

- Inviscid ProblemsDokument6 SeitenInviscid Problemssoe0303Noch keine Bewertungen

- Ecotoxicology and Environmental SafetyDokument10 SeitenEcotoxicology and Environmental SafetyUlfa Mudia SariNoch keine Bewertungen

- Basics of Paint TechnologyDokument9 SeitenBasics of Paint TechnologySantosh Raj100% (1)

- Analysis Synthesis and Design of Chemical Processes Third Edition T LDokument5 SeitenAnalysis Synthesis and Design of Chemical Processes Third Edition T LUzair Wahid0% (1)

- DPP 9Dokument3 SeitenDPP 9Sarvesh DubeyNoch keine Bewertungen

- Light-Exposure Test Method by Xenon-Arc Lamp For Automotive InteriorDokument20 SeitenLight-Exposure Test Method by Xenon-Arc Lamp For Automotive InteriorMahmood KhanNoch keine Bewertungen

- Sample Questions For Anaphy and PhysiologyDokument90 SeitenSample Questions For Anaphy and PhysiologyMaria Jeorgia SalinasNoch keine Bewertungen

- Design of Machine Elements 2019 BeemerDokument145 SeitenDesign of Machine Elements 2019 BeemerSandeep MandaNoch keine Bewertungen

- Growth and Characterization of L-Alanine Potassium Nitrate Single Crystals For Nonlinear Optical ApplicationsDokument5 SeitenGrowth and Characterization of L-Alanine Potassium Nitrate Single Crystals For Nonlinear Optical ApplicationsPalaniswamy SankariahNoch keine Bewertungen

- Lecture 1 Surface and Interfacial PhenomenaDokument26 SeitenLecture 1 Surface and Interfacial Phenomenabattal eduNoch keine Bewertungen

- Physics For Scientists and Engineers, 6e: Chapter 41 - Quantum MechanicsDokument15 SeitenPhysics For Scientists and Engineers, 6e: Chapter 41 - Quantum MechanicsTom TrầnNoch keine Bewertungen

- Crystal Field Theory IIDokument2 SeitenCrystal Field Theory IIabhay j bavishiNoch keine Bewertungen

- Bituminous TestsDokument23 SeitenBituminous TestsikreddyNoch keine Bewertungen

- (Caustic Soda) : Material Safety Data SheetDokument2 Seiten(Caustic Soda) : Material Safety Data SheetKumbang KambingNoch keine Bewertungen

- Eca ChangeoverDokument61 SeitenEca ChangeoverVijai Singh100% (1)

- The Following Tables Provide An Overview of The Key Advantages and Disadvantages of Different Types of Fertilisers On The Market TodayDokument3 SeitenThe Following Tables Provide An Overview of The Key Advantages and Disadvantages of Different Types of Fertilisers On The Market TodayAbdullaNoch keine Bewertungen

- Assignment 1 - Mass and Energy Balance March 2020Dokument2 SeitenAssignment 1 - Mass and Energy Balance March 2020Porkkodi SugumaranNoch keine Bewertungen

- Numerical Investigation On Freezing in Ballast Tank of Ship Navigating in Ice-Bound SeaDokument8 SeitenNumerical Investigation On Freezing in Ballast Tank of Ship Navigating in Ice-Bound SeaAlexander ProkhorenkoNoch keine Bewertungen

- Analytical Profiles of Drug Substances Volume 18 1989Dokument643 SeitenAnalytical Profiles of Drug Substances Volume 18 1989kunalprabhu148100% (3)

- Ceramic XrayDokument9 SeitenCeramic XrayFandi MarcelloNoch keine Bewertungen

- Innoclean Plasma Bipolar General LeafletDokument2 SeitenInnoclean Plasma Bipolar General Leafletwsc wspNoch keine Bewertungen

- Oxidation-Reduction of Borneol PDFDokument8 SeitenOxidation-Reduction of Borneol PDFRalston King Stulla ChambersNoch keine Bewertungen

- Fyp1 Slide PresentationDokument15 SeitenFyp1 Slide PresentationZhelius ZapplinNoch keine Bewertungen

- Corrosion HDBK S2Dokument296 SeitenCorrosion HDBK S2Aleksandra AleksicNoch keine Bewertungen