Beruflich Dokumente

Kultur Dokumente

Measurement Procedures

Hochgeladen von

Henry MaedaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Measurement Procedures

Hochgeladen von

Henry MaedaCopyright:

Verfügbare Formate

PROCEDURES AND CODE OF CONDUCT FOR MEASUREMENTS OF IMPORTED PETROLEUM

PRODUCTS Commented [M1]: Review of the heading

INTRODUCTION MEASUREMENT PROCEDURE ON IMPORTED PETROLEUM

PRODUCT

This document contains Guidelines/ Procedures intended for use in the petroleum

measurement operations .Essentially, these procedures /Guidelines relate to

measurements of petroleum products. Used to determine arrival quantity.

Throughout these Guidelines there are references to well-known standards documents

published by the American Petroleum Institute, Institute of Petroleum, and American

Society for Testing Material. ISGOT International safety Guide for Oil tankers and

Terminal

DISCLAIMER

Inspections for on board measuring instruments is on the measuring done under the

Weights and Measures Act Cap 340 2002.

These procedures are heavily relay on the international best practices and standard

procedures. This procedures is emphasize on the use of the relevant legal unit of

measurements, the SI system In accordance to the country metrological system In any

case the use of other unit besides SI Units is against the national authority laws and OIML

Document 2 consolidated editions of 2002 The Legal unit of Measurements, in which the

Tanzania is the member state through Weights and Measures Agency.

The Guidelines should be interpreted as representing general minimum requirements.

They should not be viewed as prescriptive Commented [HJG2]: Nimeongezea literature ktk kipengele

hiki. Tukitazame

ON BOARD OPERATIONS

.

I. INFORMATION AND DOCUMENTATION

1. Information in Preparation for Discharge

a) Cargo specifications.

b) Whether or not the cargo includes toxic components, for example H2S, benzene,

lead additives, etc.

c) Any other characteristics of the cargo requiring special attention, for example, high

true vapour pressure (TVP).

d) Flashpoint (where applicable) of products and their temperatures upon arrival,

particularly when the cargo is non-volatile.

Weights and Measures Agency Page 1

e) Cargo quantities loaded and disposition in ships tanks.

f) Quantity and disposition of slops.

g) Any unaccountable change of ullage in ships tanks since loading.

h) Water dips in cargo tanks (where applicable).

i) Preferred order of discharge.

j) Maximum attainable discharge rates and pressures.

k) Whether tank cleaning, including crude oil washing, is required.

l) Approximate time of commencement and duration of ballasting into permanent

ballast tanks and cargo tanks

2. Information in Preparation for Loading and Bunkering:

a) Details of last cargo carried, method of tank cleaning (if any) and state of the cargo

tanks and lines.

b) Where the vessel has part cargoes on board, grade, volume and tank distribution.

c) Maximum acceptable loading rates and topping off rates.

d) Maximum acceptable pressure at the ship/shore cargo connection during loading.

e) Cargo quantities acceptable from terminal nominations.

f) Proposed disposition of nominated cargo and preferred order of loading.

g) Maximum acceptable cargo temperature (where applicable).

h) Maximum acceptable true vapour pressure (where applicable).

i) Proposed method of venting.

j) Quantities and specifications of bunkers required.

k) Disposition, composition and quantities of ballast together with time required for

discharge and maximum light freeboard.

3. Information on the certificates

a) Ship particulars( Showing detail description of the shp

b) Tank calibration certificate (a valid certificate showing the valid of the tanks)

c) Bill of lading

Weights and Measures Agency Page 2

d) Ullage temperature interface calibration certificate

e) Certificate of quantity

f) Certificate of quality

Reference

ISGOT International safety Guide for Oil tankers and Terminal

Weights and Measures Agency Page 3

II. INSPECTIONS OF PETROLEUM MEASURING DEVICES

Standard Practice for the Manual Gauging of Petroleum and Petroleum Products in the

marine vessel

The procedures for manually gauging the liquid level of petroleum and petroleum

products in non-pressure fixed-roof, floating-roof tanks and marine tank vessels, (b)

procedures for manually gauging the level of free water which may be found with the

petroleum or petroleum products, (c) methods used to verify the length of gauge tapes

under field conditions and the influence of bob weights and temperature on the gauge

tape length, and (d) the influences that may affect the position of gauging reference point

(either the datum plate or the reference gauge point). Throughout this standard the term

petroleum will be used to denote petroleum, petroleum products, or

Inspection is made on Portable Electronic Gauging Equipment (commonly known as (UTI

Ullage Temperature interface) if

i. Portable electronic gauging devices (PEGDs) must consist of an electronic sensing

device suspended on a measuring tape, and housing with readouts.

ii. On custody transfer gauging, these devices shall be capable of demonstrating the

same measurement accuracy as the non-electronic gauging tape and bob, and

shall be calibrated or verified against a reference devices

Marking

i. The graduated tape, the sensor probe and the body of the winding frame of each

PEGD shall be marked with unique serial number(s) that can be annotated on the

calibration certificate for the purpose of audit trail

ii. The zero point of the level measured by a portable electronic gauging tape shall be

the reaction point at which the sensor detects a liquid surface when operating in the

outage mode.

iii. The zero offset distance shall be verified and stated on the certificate of the said

unit.

On Marine electronic gauging (Automatic Tank Gauging (ATG) Inspector shall make

observance if

i. Minimum Measurable Level, the ATG is able to measure levels as near to the

bottom of the tank as possible.

ii. All marine ATGs shall be capable of withstanding the pressure, temperature, and

other environmental conditions likely to be encountered in marine service.

iii. When an ATG is installed in a corrosive service, any parts exposed to the liquid or

vapours shall be of durable, corrosion-resistant construction.

iv. Product temperature should be measured at the same time as the tank level is

measured. The temperature should be representative of the tank contents

Weights and Measures Agency Page 4

v. All parts of the ATG in contact with the product and compatible with the product, to

avoid both product contamination and ATG corrosion.

vi. If The ATG is designed to meet its intended operating conditions

vii. On vessels that are fitted with ATGs and a second means of measurement, that

gauge point for the second measurement location should have the same reference

height (otherwise correction will be required) as well as be located in line

longitudinally (forward to after) with the ATG.

viii. The system permit accurate comparison between manual gauging and automatic

tank gauging, a manual calibration check point is provided close (within 3 feet or 1

meter) to the ATG.

ix. Marine ATGs is installed in accordance with the ATG manufacturers instructions

x. Marine ATGs is calibrated at the factory against a manual gauging tape or

reference certified by the appropriate national standards organizations.

xi. Initial verification, the calibration of the ATGs has been checked against manual

tank gauging performed

xii. Verification is designed and carried out to confirm the ATG is properly calibrated.

(After completion of cargo loading at a load port and prior to discharge at a

discharge port, normal practice is to check the reading of the ATG against manual

tank gauging. The manual gauging levels are normally used for the cargo reports).

xiii. If the reading by ATG and the reading by manual gauging agree within(6

millimetres).

xiv. ATG verification records should be documented and the record should be ready for

inspection by involved parties. The records has been kept for a minimum period of

one year

xv. The ATG reading and the manual gauging should be repeated three times (or five

times if there are waves in the tank). If the reading by ATG and the reading by

manual gauging differ by more than (6 millimetres). The average of the manual

gauge readings and the ATG readings should be compared. For best accuracy,

xvi. The vessel should be on an even keel and upright. In situations where both trim and

list exist, every effort should be made to eliminate at least one condition, preferably

list

Manual of Petroleum Measurement Standards Chapter 3Tank Gauging

Section 1AStandard Practice for the Manual Gauging of Petroleum and Petroleum

Products

Manual of Petroleum Measurement Standards Chapter 3-Tank Gauging Section 5-

Standard Practice for Level Measurement of Light Hydrocarbon Liquids On board

Marine Vessels by Automatic Tank Gauging

Weights and Measures Agency Page 5

III. MEASUREMENT AND CALCULATIONS

These procedures are intended to guide the user through the steps necessary to

calculate static liquid quantities, at atmospheric conditions, in upright, cylindncal tanks

and marine tank vessels. The procedures define terms employed in the calculation of

static petroleum quantities.

The procedure also specifies equations that allow the values of some correction factors to

be computed. Fundamental to this process is the understanding that in order for different

parties to be able to reconcile volumes, they must start with the same basic information

(tank capacity table, levels, temperatures, and so forth) regardless of whether the

information is gathered automatically or manually.

Calculation sequence

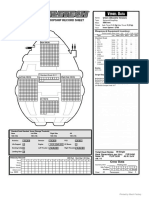

Determination of liquid level

Using portable gauging equipment commonly known as ullage temperature interface

(UTI) the ullage of the product shown on the stowage plan report is measured on the ship

compartments (ship tanks). Establish and record the ullage and the product temperature.

Determination of total observed volume (TOV)

The TOV is obtained from the vessels calibration tables, which are entered with one of

the following:

a. The observed ullage or innage, if the trim and/or list corrections are a volumetric

adjustment. The amount of trim and/or list correction will need to be applied to the TOV

quantity to arrive at a trim and/or list corrected TOV

b. The trim and/or list corrected ullage or innage.

c. The observed ullage or innage and the vessels trim. Some calibration tables show

varying TOV values for the same gauge under differing conditions of trim.

Density determination

Product density will be obtained from authorised local institution which is the the

responsible for product quality analysis.

WMA use the density obtained from their product analysis report.

Calculation of gross observed volume GOV

To calculate the GOV for marine vessels tanks, deduct the FW volume from the TOV

GOV= TOV- FW

Note

Free Water (FW) volume is obtained from the vessel's capacity tales, which are entered

with the FW innage or ullage. FW is subject to the effects of trim and list, and the

previously referenced trim and list corrections are applicable to free water

Gross standard volume (GSV)

Weights and Measures Agency Page 6

The GSV is calculated by multiplying the GOV by the correction for the effect of

temperature on liquid (or volume correction factor).

GSV = GOV.X VCF

Note

Correction for the effect of temperature on a liquid (CTL) or Volume correction factor

(VCF)

If a volume of petroleum liquid is subjected to a change in temperature, its density will

decrease as the temperature rises or increase as the temperature falls. This density

change is proportional to the thermal coefficient of expansion of the liquid and

temperature. The correction factor for the effect of the temperature on the density of a

liquid is called CTL or VCF. The CTL factor is a function of the Base Density of the liquid

and its temperature. The function of this correction factor is to adjust the volume of liquid

at observed temperature to its volume at a standard temperature. The most common

standard temperatures are , 15C, and 20C

Calculation of Weight in Air

Usually, weight in air is calculated by multiplying the GSV by the appropriate weight

correction factor.

Gross standard weight (in air) = GSV x WCF

Note

The WCF is found in the various tables that are contained in Volume XI and Volume XII of

API MPMS Chapter 11.1.

These volumes detail the "Intraconversion between Volume Measures and Density

Measures." These two volumes contain 26 different tables. Because of the diversity of

these tables, it is possible to approach the calculation process from various directions

using different tables. Where possible, the most direct conversion process (table) should

be used to arrive at the answer.

For example, a surveyor wishes to calculate the GSV to metric tons rather than to use

Table 11 to convert NSV to long tons and then Table 13 to convert the long tons to metric

tons. Commented [M3]: More literature review

Manual of Petroleum Measurement Standards Chapter 12-Calculation of Petroleum Quantities

Section I-Calculation of Static Petroleum

Part I-Upright Cylindrical Tanks and Marine Quantities Vessels

SECOND EDITION, NOVEMBER 2001

Weights and Measures Agency Page 7

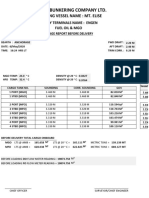

IV. REPORT AND RECONCILLIATIONS

Data collections

The shipment of petroleum or petroleum products by marine vessels may result in a

difference between the load port (Bill of Lading) and discharge port (Outturn) quantities.

This difference, or volume gain or loss, is caused by one or more of the following:

a) Physical gains or losses.

b) Discrepancies or errors in liquid level or meter measure-ments, determining

temperature, sampling, and laboratory testing methods.

c) Inconsistencies or errors in calculations.

Reconciliation of marine cargo quantity

Procedures are intended to provide a basis for analysing and reconciling the quantity

differences (gains/losses) resulting from marine custody transfer movement(s) of

petroleum and petroleum product cargoes.

Gathering all relevant ship and shore measurement data for analysis and reconciliation.

Marine transfer inspection reports include a shore gauging (or metering) report, a vessel

gauging report, a time log, a line fill verification report, and information to calculate a

Vessel Experience Factor (VEF).

Other important information may need to be collected from other sources, such as the

terminal and the vessel.

The VAR provides a useful format for the organization of basic cargo data and also

provides calculations recommended in this procedure. Any shore-to-shore variances are

broken down according to Total Calculated Volume (TCV), Free

Water (FW), Gross Standard Volumes (GSV), during each stage of the voyage.

Voyage analysis report VAR

The VAR provides a useful format for the organization of basic cargo data and also

provides calculations recommended in this procedure. Any shore-to-shore variances are

broken down according to Total Calculated Volume (TCV), Free Water (FW), Gross

Standard Volumes (GSV), Sediment and Water (S & W), and Net Standard Volumes

(NSV) during each stage of the voyage.

Comparison of Shore Quantities in Custody Transfer

TCV FW GSV S&W

Outturn TCV Outturn FW B/L Outturn GSV B/L Outturn S & W B/L S & W

B/L TCV FW GSV

TCV Difference FW Difference GSV Difference S & W Difference

Weights and Measures Agency Page 8

Vessel/Shore Quantities at Load Port(s)

TCV FW GSV NSV

Vessel Loaded Vessel Loaded FW Vessel Loaded GSV Theoretical Shore TCV

TCV B/L FW B/L GSV B/L TCV

B/L TCV

TCV Difference. FW Difference GSV Difference Shore TCV Diff

Theoretical

Vessel/Shore Quantities at Discharge Port(s)

TCV FW GSV TCV: VEF Adjusted

Vessel Vessel Discharged Vessel Discharged Theoretical Outturn

Discharged TCV FW GSV TCV

Outturn TCV Outturn FW Outturn GSV Outturn TCV

TCV Difference FW Difference GSV Difference Theoretical Shore TCV

Diff

Transit Comparison of Vessel Quantities at Load and Discharge Port(s)

TCV FW GSV

Vessel Arrival TCV Vessel Arrival FW Vessel Arrival GSV

Vessel Sailing TCV Vessel Sailing FW Vessel Sailing GSV

TCV Difference. FW Difference GSV Difference Theoretical

TCV Difference FW Difference GSV Difference

Request for the voyage summary and reconciliation report (VSRR)

The VSRR is designed to consolidate the reported facts of the voyage, together with any

relevant background information, in an effort to explain the reason(s) for the voyage gain

or loss.

Check on reconciliation, observance of the following factors

Failure to follow proper operating practices.

The use of defective or non-standard measurement equipment.

The environment at the time the measurements are taken.

Observed tank height differences between opening andclosing measurements.

The use of incorrect tank tables or the improper use of tank tables.

The use of incorrect quantity correction factors (i.e., VCFor WCF).

Temperature and density stratification (may also have an effect on floating roof

correction calculations).

Weights and Measures Agency Page 9

The use of incorrect conversion factors when converting between systems of

measurement.

Random errors in measurement.

Failure to use properly calibrated equipment.

Failure to perform cargo measurement operations in accordance with API

standards

Improper or lack of, use of trim, list and wedge corrections.

Incorrect closed system gauge height adjustments (i.e., retrofitted equipment or

location).

Weather and sea conditions.

Inconsistencies between automatic, closed and manual measurements.

Inconsistencies in the gauge point locations.

Inconsistencies in the use of capacity tables.

Unslotted standpipes used for measurement.

Difference in vessels cargo line fills condition, load port vs. Discharge port.

Cling age, load port vs. discharge port.

Deliberately biased measurements in favour of one party or another.

Reference to the Petroleum standards

Reference

The list below are the references of the

Manual of Petroleum Measurement Standards Chapter 17Marine Measurement

Section 5Guidelines for Cargo Analysis and Reconciliation of Cargo Quantities

Weights and Measures Agency Page 10

LIST OF REFERENCE DOCUMENT

1. Manual of Petroleum Measurement Standards Chapter 17Marine Measurement

Section 5Guidelines for Cargo Analysis and Reconciliation of Cargo Quantities

2. Manual of Petroleum Measurement Standards Chapter 17Marine Measurement

Section 5Guidelines for Cargo Analysis and Reconciliation of Cargo Quantities

3. ISGOT International safety Guide for Oil tankers and Terminal

4. Weights and Measures Act 2002

5. OIML Document 2 Legal Units of Measurements

6. Marine Vessels by Automatic Tank Gauging Manual of Petroleum Measurement

Standards Chapter 3-Tank Gauging Section 5-Standard Practice for Level

Measurement of Light Hydrocarbon Liquids On board

7. ISGOT International safety Guide for Oil tankers and Terminal

Weights and Measures Agency Page 11

Das könnte Ihnen auch gefallen

- Custody Transfer in Tank GaugingDokument5 SeitenCustody Transfer in Tank GaugingAnonymous UCveMQNoch keine Bewertungen

- 2020 Loss Control For TradersDokument8 Seiten2020 Loss Control For TraderskoushkiNoch keine Bewertungen

- Tank+Calibration OP 0113 WebsiteDokument2 SeitenTank+Calibration OP 0113 WebsiteMohamed FouadNoch keine Bewertungen

- BP Measurement Manual Part I PDFDokument281 SeitenBP Measurement Manual Part I PDFOsamaNoch keine Bewertungen

- Procedure Waterdraw Calibration CEC FMC PRD en 0005Dokument18 SeitenProcedure Waterdraw Calibration CEC FMC PRD en 0005TahirNoch keine Bewertungen

- Feasibility Study Report of Custody Transfer Flow Meter With Master MeterDokument32 SeitenFeasibility Study Report of Custody Transfer Flow Meter With Master MeterKaisar Jamil100% (1)

- Manual of Petroleum Measurement StandardsDokument20 SeitenManual of Petroleum Measurement StandardsPedro Pablo Nuñez LeonNoch keine Bewertungen

- Liquid Flow Meter Proving and LACT UnitsDokument4 SeitenLiquid Flow Meter Proving and LACT UnitsDayo IdowuNoch keine Bewertungen

- Thermo Scientific Orion LaboratoryDokument100 SeitenThermo Scientific Orion Laboratoryibnu samsiNoch keine Bewertungen

- Tank Gauging & Associated StandardsDokument33 SeitenTank Gauging & Associated StandardsLindsey Patrick100% (1)

- Amspec Techtalk A Stands For API Gravity 4Dokument5 SeitenAmspec Techtalk A Stands For API Gravity 4Sudea CadabaNoch keine Bewertungen

- Petroleum Products Measurement and Quality AssuranceDokument16 SeitenPetroleum Products Measurement and Quality Assuranceابوالحروف العربي ابوالحروفNoch keine Bewertungen

- Oil Tanks Calibration Course OverviewDokument2 SeitenOil Tanks Calibration Course OverviewAttalla100% (1)

- Alberta PetroleumDokument38 SeitenAlberta Petroleumsadegh1366Noch keine Bewertungen

- Manual TP Prover Vessel PDFDokument7 SeitenManual TP Prover Vessel PDFWilfredo MolinaNoch keine Bewertungen

- Fundamentals of Liquid Measurement IDokument6 SeitenFundamentals of Liquid Measurement Imanuel_medcoNoch keine Bewertungen

- Sop-010-Manual Sampling of Petroleum and Petroleum Products (NGL)Dokument8 SeitenSop-010-Manual Sampling of Petroleum and Petroleum Products (NGL)AmnaKamranNoch keine Bewertungen

- VEFDokument4 SeitenVEFcaptramyNoch keine Bewertungen

- Weights and Measures BSTI RulesDokument8 SeitenWeights and Measures BSTI RuleskafilussNoch keine Bewertungen

- Presentation - GGS - Tank CalibrationDokument28 SeitenPresentation - GGS - Tank CalibrationParameshNoch keine Bewertungen

- Verifying Flowmeter AccuracyDokument8 SeitenVerifying Flowmeter AccuracynokarajuNoch keine Bewertungen

- B) Correction Factor Per Degree C: Cargo CalculationsDokument3 SeitenB) Correction Factor Per Degree C: Cargo CalculationsBurakNoch keine Bewertungen

- Tank Gauging System Specification For Full Containment TankDokument15 SeitenTank Gauging System Specification For Full Containment TanksineNoch keine Bewertungen

- 5.22.18 Statements ConformityDokument29 Seiten5.22.18 Statements ConformityVinod KGNoch keine Bewertungen

- Measurement Accuracy and Sources of Error in Tank Gauging 2270Dokument6 SeitenMeasurement Accuracy and Sources of Error in Tank Gauging 2270CRT ServicesNoch keine Bewertungen

- Cargo Calculations - Tanker WorkDokument1 SeiteCargo Calculations - Tanker Worksameh metwallyNoch keine Bewertungen

- Laboratory Projects 1 - Pipeline ConstructionDokument9 SeitenLaboratory Projects 1 - Pipeline ConstructionMaximiano FerrazNoch keine Bewertungen

- Homework 1 ME 531 2018 WebDokument4 SeitenHomework 1 ME 531 2018 WebEhab WilsonNoch keine Bewertungen

- Calibration of LPG ProversDokument19 SeitenCalibration of LPG ProversanafadoNoch keine Bewertungen

- Unit Conversion Related To Oil and Gas IndustryDokument20 SeitenUnit Conversion Related To Oil and Gas IndustryNavin KumarNoch keine Bewertungen

- API Gravity FormulasDokument2 SeitenAPI Gravity FormulasCH PurnimaRajesh100% (1)

- Petroleum Testing InstrumentsDokument118 SeitenPetroleum Testing InstrumentsFebrian IsharyadiNoch keine Bewertungen

- Additional Text in Red: 12.3 Converting Between Mass and WeightDokument2 SeitenAdditional Text in Red: 12.3 Converting Between Mass and WeightRang Dong Bui100% (2)

- Contol Ebook PDFDokument71 SeitenContol Ebook PDFbab_ooNoch keine Bewertungen

- Tank Calibration PPPDokument15 SeitenTank Calibration PPPDas100% (1)

- Status of Iso 8217Dokument10 SeitenStatus of Iso 8217Paul BreaNoch keine Bewertungen

- OIML R120-E10Dokument37 SeitenOIML R120-E10Roxana apazaNoch keine Bewertungen

- ISO 8217 2010 Fuel Standard For Marine Distillate FuelsDokument2 SeitenISO 8217 2010 Fuel Standard For Marine Distillate FuelsiceburnerNoch keine Bewertungen

- Ullage Report For DeliveryDokument72 SeitenUllage Report For DeliveryAbu Syeed Md. Aurangzeb Al MasumNoch keine Bewertungen

- Catalogo Electromagnetic FlowmeterDokument28 SeitenCatalogo Electromagnetic FlowmeterM. Noor Khafit0% (1)

- Wedge Formula DESKTOP BH644DPDokument2 SeitenWedge Formula DESKTOP BH644DPMed Amine RessadNoch keine Bewertungen

- Manual of Petroleum Measurement StandardsDokument25 SeitenManual of Petroleum Measurement StandardsDebashish BanerjeeNoch keine Bewertungen

- Recommended International Code of Practice For The Storage and Transport of Edible Fats and Oils in BulkDokument12 SeitenRecommended International Code of Practice For The Storage and Transport of Edible Fats and Oils in BulkMohamad YusofNoch keine Bewertungen

- Realistic Pipe Prover Volume Uncertainty - Paul MartinDokument26 SeitenRealistic Pipe Prover Volume Uncertainty - Paul MartinSim Yun YoungNoch keine Bewertungen

- ISO 11223 Measurement of Content of Storage TankDokument62 SeitenISO 11223 Measurement of Content of Storage Tankneosucre syukriNoch keine Bewertungen

- SOP-017-Testing of Specific Gravity of CondensateDokument9 SeitenSOP-017-Testing of Specific Gravity of CondensateAmnaKamranNoch keine Bewertungen

- API MPMS Chapter 18.2 Custody Transfer of Crude Oil From Lease Tanks Using Alternative Measurement MethodsDokument32 SeitenAPI MPMS Chapter 18.2 Custody Transfer of Crude Oil From Lease Tanks Using Alternative Measurement MethodsorlandoNoch keine Bewertungen

- Oiml R43 (1981)Dokument15 SeitenOiml R43 (1981)BellbrujaNoch keine Bewertungen

- Types of Storage TanksDokument5 SeitenTypes of Storage Tanksmarioarancibia2012Noch keine Bewertungen

- Ship Tank CalibrationDokument8 SeitenShip Tank CalibrationrkkannaNoch keine Bewertungen

- Petroleum Calculation SeriesDokument7 SeitenPetroleum Calculation SeriesAnonymous UCveMQNoch keine Bewertungen

- Tank Strapping CalibrationDokument2 SeitenTank Strapping CalibrationSana AlzakiNoch keine Bewertungen

- Manual of Petroleum MeasurementDokument7 SeitenManual of Petroleum Measurementsreeyuktha50% (2)

- Tabel ASTMDokument19 SeitenTabel ASTMAnton SujarwoNoch keine Bewertungen

- Crude Assay vs. HTSDDokument0 SeitenCrude Assay vs. HTSDmahmoudmakladNoch keine Bewertungen

- Gauge Gauge Tank Body:: FunctionsDokument9 SeitenGauge Gauge Tank Body:: FunctionsMahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Petroleum Refinery MACT Standard Guidance: Revised DocumentDokument135 SeitenPetroleum Refinery MACT Standard Guidance: Revised DocumentFarizal AmriNoch keine Bewertungen

- OIML R 95 - Ships' TankDokument15 SeitenOIML R 95 - Ships' TankanafadoNoch keine Bewertungen

- API MSPS Chapter 17-6 - Guidelines For Determining The Fullness of Pipelines Between Vessels and Shore Tanks PDFDokument9 SeitenAPI MSPS Chapter 17-6 - Guidelines For Determining The Fullness of Pipelines Between Vessels and Shore Tanks PDFthongNoch keine Bewertungen

- P01 2017 OilPolPrev FormDokument4 SeitenP01 2017 OilPolPrev FormMade PutraNoch keine Bewertungen

- Report PDFDokument49 SeitenReport PDFHenry MaedaNoch keine Bewertungen

- Oil and Gas AuditDokument7 SeitenOil and Gas AuditShamsur Rahman Russell100% (1)

- Natural Gas Energy Measurement PDFDokument354 SeitenNatural Gas Energy Measurement PDFHenry Maeda100% (3)

- Tanzania50 Uk ScholarshipDokument1 SeiteTanzania50 Uk ScholarshipHenry MaedaNoch keine Bewertungen

- Regional and International Legal MetrologyDokument12 SeitenRegional and International Legal MetrologyHenry MaedaNoch keine Bewertungen

- En-DTR CMK-02Dokument51 SeitenEn-DTR CMK-02Henry MaedaNoch keine Bewertungen

- Aeia Eooufa Training ProposalDokument10 SeitenAeia Eooufa Training ProposalHenry Maeda100% (1)

- Material PropertiesDokument1 SeiteMaterial PropertiesGörögh ImreNoch keine Bewertungen

- Gas Cylinders Regulation 2012-15.10.2012-PETER CHUWADokument5 SeitenGas Cylinders Regulation 2012-15.10.2012-PETER CHUWAHenry MaedaNoch keine Bewertungen

- ReportDokument49 SeitenReportHenry MaedaNoch keine Bewertungen

- Gum NPL UkDokument32 SeitenGum NPL UkHenry MaedaNoch keine Bewertungen

- Trafc Act 30-1973Dokument48 SeitenTrafc Act 30-1973Henry MaedaNoch keine Bewertungen

- API 620 Tank CalculationsDokument11 SeitenAPI 620 Tank CalculationsPrashant Malve64% (11)

- Gum NPL UkDokument32 SeitenGum NPL UkHenry MaedaNoch keine Bewertungen

- Practical Scada Systems For IndustryDokument1 SeitePractical Scada Systems For IndustryHenry MaedaNoch keine Bewertungen

- Design of Functional Specifications For Industrial Automation Systems (Scada, PLC, and DCS)Dokument1 SeiteDesign of Functional Specifications For Industrial Automation Systems (Scada, PLC, and DCS)Henry MaedaNoch keine Bewertungen

- Design of Functional Specifications For Industrial Automation Systems (Scada, PLC, and DCS)Dokument1 SeiteDesign of Functional Specifications For Industrial Automation Systems (Scada, PLC, and DCS)Henry MaedaNoch keine Bewertungen

- Hazardous Areas ClassificationDokument3 SeitenHazardous Areas ClassificationHenry MaedaNoch keine Bewertungen

- Poisson'sDokument2 SeitenPoisson'sHenry MaedaNoch keine Bewertungen

- Practical Troubleshooting and Problem Solving of Industrial Data CommunicationDokument1 SeitePractical Troubleshooting and Problem Solving of Industrial Data CommunicationHenry MaedaNoch keine Bewertungen

- Costald 06-82Dokument6 SeitenCostald 06-82boyd.george@bp.com100% (1)

- JRC 20080506 Infoday Tirana Myrvete PazajDokument15 SeitenJRC 20080506 Infoday Tirana Myrvete PazajHenry MaedaNoch keine Bewertungen

- Calculation of Vessel Experience FactorDokument1 SeiteCalculation of Vessel Experience FactorHenry Maeda67% (3)

- Chapter 6Dokument42 SeitenChapter 6Henry MaedaNoch keine Bewertungen

- Gas Ship Measurement Guidelines: 1 Gas Measure 9/99 Version 01/98 Rev 4Dokument40 SeitenGas Ship Measurement Guidelines: 1 Gas Measure 9/99 Version 01/98 Rev 4Henry MaedaNoch keine Bewertungen

- 3 2 06Dokument3 Seiten3 2 06Henry MaedaNoch keine Bewertungen

- ABB - 4 Biggest MistakesDokument7 SeitenABB - 4 Biggest MistakesAnargha BhattacharyaNoch keine Bewertungen

- Calculation of Liquid Petroleum QuantitiesDokument10 SeitenCalculation of Liquid Petroleum QuantitiesHenry MaedaNoch keine Bewertungen

- Installation, Operation and Maintenance Manual: ROOTS Meters & InstrumentsDokument32 SeitenInstallation, Operation and Maintenance Manual: ROOTS Meters & InstrumentsHenry MaedaNoch keine Bewertungen

- DSP QBDokument8 SeitenDSP QBNithya VijayaNoch keine Bewertungen

- Conventional and Computed TomographyDokument29 SeitenConventional and Computed TomographyJerome D FlorentinoNoch keine Bewertungen

- Azhar Marketing Final PPRDokument9 SeitenAzhar Marketing Final PPRafnain rafiNoch keine Bewertungen

- SKF BeyondZero White Paper 12761ENDokument12 SeitenSKF BeyondZero White Paper 12761ENdiosmio111Noch keine Bewertungen

- Freelance Contract AgreementDokument10 SeitenFreelance Contract AgreementGayathri Prajit100% (1)

- CBD20LDokument1 SeiteCBD20LFelix StancioiuNoch keine Bewertungen

- A218437 HUET PDFDokument271 SeitenA218437 HUET PDFKayser_MNoch keine Bewertungen

- Digit Sep 09Dokument107 SeitenDigit Sep 09dukerexNoch keine Bewertungen

- DAR Vol1-2013Dokument744 SeitenDAR Vol1-2013chitransh2002Noch keine Bewertungen

- Kompresi MobilDokument58 SeitenKompresi Mobilfatah hamid100% (1)

- Fresher Jobs July 31Dokument18 SeitenFresher Jobs July 31Harshad SonarNoch keine Bewertungen

- Case Study (3 To 5 Months Test Plan) : Test Deliverable Responsibility Completion TimeDokument1 SeiteCase Study (3 To 5 Months Test Plan) : Test Deliverable Responsibility Completion Timepry_kumNoch keine Bewertungen

- Galley Steward Knowledge: Free Screening / Interview GuidelineDokument2 SeitenGalley Steward Knowledge: Free Screening / Interview GuidelineAgung Mirah Meyliana100% (2)

- Pathfinder House RulesDokument2 SeitenPathfinder House RulesilililiilililliliI100% (1)

- Business PlanDokument20 SeitenBusiness PlanRona BautistaNoch keine Bewertungen

- Introduction To Parallel Programming 1st Edition Pacheco Solutions ManualDokument5 SeitenIntroduction To Parallel Programming 1st Edition Pacheco Solutions Manualyvonnewelchdoafexwzcs100% (11)

- BBBB - View ReservationDokument2 SeitenBBBB - View ReservationBashir Ahmad BashirNoch keine Bewertungen

- 1LA7070-4AB10-Z A11 Datasheet en PDFDokument1 Seite1LA7070-4AB10-Z A11 Datasheet en PDFKraponis TylnessNoch keine Bewertungen

- Quote Generator DocumentDokument47 SeitenQuote Generator DocumentPrajwal KumbarNoch keine Bewertungen

- Unit 13 Developing, Using, and Organizing Resources in A Specialist AreaDokument21 SeitenUnit 13 Developing, Using, and Organizing Resources in A Specialist AreaKan SonNoch keine Bewertungen

- 0 - Resume - Preity Thadani PDFDokument3 Seiten0 - Resume - Preity Thadani PDFClash ClashhNoch keine Bewertungen

- Intructional Tools With The Integration of TechnologyDokument44 SeitenIntructional Tools With The Integration of TechnologyAlwyn SacandalNoch keine Bewertungen

- NCAA Safety Bulletin 23-4 - AprilDokument21 SeitenNCAA Safety Bulletin 23-4 - AprilANoch keine Bewertungen

- The Dell Direct Model: What It Means For Customers (Users) : - ProsDokument12 SeitenThe Dell Direct Model: What It Means For Customers (Users) : - ProsAbhinandan MattelaNoch keine Bewertungen

- Guia de Desinstalación de ODOO EN UBUNTUDokument3 SeitenGuia de Desinstalación de ODOO EN UBUNTUjesusgom100% (1)

- Assignment 1: Unit 3 - Week 1Dokument80 SeitenAssignment 1: Unit 3 - Week 1sathiyan gsNoch keine Bewertungen

- Theories of International TradeDokument33 SeitenTheories of International Tradefrediz79Noch keine Bewertungen

- Losses in Valves and FittingsDokument17 SeitenLosses in Valves and FittingsMintesnot AberaNoch keine Bewertungen

- Union Class Dropship 3025Dokument1 SeiteUnion Class Dropship 3025A KNoch keine Bewertungen

- Gas Turbine Performance CalculationDokument7 SeitenGas Turbine Performance CalculationAtiqur RahmanNoch keine Bewertungen