Beruflich Dokumente

Kultur Dokumente

Effect of Fly Ash On Mechanical Properties of M30 and M60 Grade Concrete

Hochgeladen von

IAEME PublicationOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Effect of Fly Ash On Mechanical Properties of M30 and M60 Grade Concrete

Hochgeladen von

IAEME PublicationCopyright:

Verfügbare Formate

International Journal of Civil Engineering and Technology (IJCIET)

Volume 8, Issue 3, March 2017, pp. 193200 Article ID: IJCIET_08_03_020

Available online at http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=3

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

IAEME Publication Scopus Indexed

EFFECT OF FLY ASH ON MECHANICAL

PROPERTIES OF M30 AND M60 GRADE

CONCRETE

A. Venkateswara Rao

Associate Professor, Department of Civil Engineering,

K.L University, Vijayawada - 522502, Andhra Pradesh, India

K. Srinivasa Rao

Professor, Department of Civil Engineering, College of Engineering,

Andhra University, Visakhapatnam - 530003, Andhra Pradesh, India

ABSTRACT

Concrete is one of the highest consumed primary construction material in the world

with a vital role in the construction field. Production of one ton of cement produces

nearly one ton of CO2 causing environmental problems. So there is a need to reduce

cement production and use some additives to make concrete sustainable. Due to

growing environmental awareness, there is an increasing interest in the use of fly ash.

It can be used either as an admixture or as partial replacement of cement or as partial

replacement of fine aggregate and also as supplementary addition to achieve different

properties of concrete. This paper presents the experimental investigations on the effect

of fly ash content on compressive strength of M60 and M30 grades of concrete at an

age of 7, 28, 56 and 91 days.

Key words: Concrete, Fly ash, Compressive strength, Cement.

Cite this Article: A. Venkateswara Rao and K. Srinivasa Rao, Effect of Fly Ash On

Mechanical Properties of M30 and M60 Grade Concrete. International Journal of Civil

Engineering and Technology, 8(3), 2017, pp. 193200.

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=3

1. INTRODUCTION

Concrete has been the leading, extensively used construction material as its ingredients are

easily available, manufacturing cost of it is less and also durable over other construction

material. Cement is one of the chief ingredients, also responsible for strength of concrete and

globally the demand for cement is increasing year by year due to increase in utility of cement

for the development of infrastructure and sustainability, Previous investigations reveals that

concrete has been prepared by introducing some additives called as mineral admixtures, beside

its basic ingredients to investigate their effect on strength, durability and other properties of

concrete. Fly ash is one such material easily available as it (fly ash) is the waste product in

http://www.iaeme.com/IJCIET/index.asp 193 editor@iaeme.com

Effect of Fly Ash On Mechanical Properties of M30 and M60 Grade Concrete

thermal plants. Past investigations [1, 2] have revealed that fly ash can be utilized as an

important constituent of concrete. It can be used with partial replacement of cement, or

replacement of fine aggregate. The present study involves in replacement of cement with

different percentages of fly ash and its performance at different ages of concrete.

2. PREVIOUS STUDIES

Aman Jatale,et al. [3] have studied the effect on strength and mechanical properties of M15,

M20 and M25 grades of concrete by replacing cement with 20, 40 and 60% of fly ash. Tests

for compression are conducted on 150 mm cubes. It was concluded that with use of fly ash,

workability improved, setting time increases, strength and modulus of elasticity decreases. The

decrease in strength at early ages is more. Finally concluded that fly ashcan be gain fully used

in making concrete strong, durable, Eco-friendly and economical.

Dragas, J., et al.[4] reviewed the research on properties of concrete replacing cement by 30-

70% of fly ash and the mechanisms are discussed and concluded that with addition of fly ash

water demand for given workability decreased, strength and modulus of elasticity decreased

and with w/c ratio below 0.4 and addition of fly ash more than cement replaced gives more

strength compared to the results of conventional concrete without fly ash.

Nath, P. and Sarker, P. [5] investigated the durability properties of high strength concrete

replacing cement with 30 and 40% of class F fly ash sourced from Western Australia. The 28

day compressive strength, drying shrinkage sorptivity and rapid chloride permeability were

determined. It was concluded that the 28 day compressive strength varied from 65 to 85 MPa

and the fly ash samples showed less drying shrinkage over control concrete specimens without

fly ash, inclusion of fly ash reduced sorptivity and chloride ion permeation significantly.

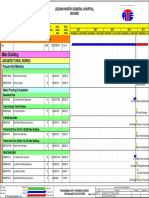

3. EXPERIMENTAL PROGRAM

3.1. Mix Proportions

The present experimental investigation on concrete consists of replacing cement with varying

fly ash content of 30, 40 and 50% by weight of cement besides one mix without fly ash, total

four mixes are selected. The mix proportion of the present study is 1: 1.39: 3.43 and 1 : 1.8 :

3.14 (cement: fly ash: fine aggregate: coarse aggregate) and water content of 0.32 and 0.48 for

M60 and M30 grades of concrete respectively obtained from guide lines of IS: 10262-2009 [6]

and IS: 456-2000 [7] and the proportions are finalized after testing several trial mixes. The

Ordinary Portland cement of 53 grade [8], fine aggregates conforming to zone-II, coarse

aggregate as per IS:383 [9] code provisions, class F fly ash [10] collected from N.T.P.C,

Visakhapatnam are used for present study. No admixture is used for M30 grade concrete and

SP 430 DIS [10, 11] is used as admixture for M60 grade concrete.

3.2. Method of testing

The cubes of 100 mm and cylinders of 150 mm diameter and 300 mm height are prepared for

studying the response of different concrete mixes at elevated temperatures. The specimens are

demoulded after 24 h from the time of casting and placed in potable water for curing. After

specified period (7, 28, 56 and 91 days) of curing the specimens are removed from water and

allowed to dry in air Three specimen cubes of 100 mm size are tested in 3000 kN compression

testing machine as per IS 516 [12] at ages of 7, 28, 56 and 91 for each percentage, age and the

average value of compressive strength is considered. Three specimen cylinders are tested in

3000 kN compression testing machine as per IS 5816 [13] at ages of 7, 28, 56 and 91 for each

percentage, age and the average value of compressive strength is considered Cubes during

casting and cube specimen under compression test are shown in Fig.1 and Fig.2 respectively.

http://www.iaeme.com/IJCIET/index.asp 194 editor@iaeme.com

A. Venkateswara Rao and K. Srinivasa Rao

Figure 1 Cubes during casting

Figure 2 Cube under compression test

4. RESULTS AND DISCUSSIONS

4.1. Compressive strength

Percentage compressive strength is the ratio of compressive strength of any percentage of fly

ash or age to that of 28 day strength of controlled concrete (reference concrete) at room

temperature multiplied by 100. Behaviour of fly ash on compressive strength of M60 and M30

grades of concrete are shown graphically in Fig.3 and Fig.4 respectively.

From Fig.3, the values of percentage compressive strength of M60 grade concrete (HSC)

for 0, 30, 40 and 50% fly ash at room temperature at an age of 7 days are 95.5, 94.1, 92.8 and

87.4. At the same time, the values at an age of 28 days are 100.00, 101.5, 99.8 and 97.9, While,

the values at an age of 56 days are 103.3, 104.7, 102.3 and 99.5, whereas the values at an age

of 91 days are 105.3, 108.6, 105.6 and 101.5 respectively.

From Fig.4, the values of percentage compressive strength of standard concrete for 0, 30,

40 and 50% fly ash at room temperature, at an age of 7 days are 90.2, 88.6, 87.9 and 77.2. At

the same time, the values at an age of 28 days are 100, 102.2, 89.6 and 79.3. At the same time

the values at an age of 56 days are 103.3, 104.6, 100.6 and 97.2, whereas the values at an age

of 91 days are 105.2, 107, 103.9 and 99.6 respectively.

http://www.iaeme.com/IJCIET/index.asp 195 editor@iaeme.com

Effect of Fly Ash On Mechanical Properties of M30 and M60 Grade Concrete

Figure 3 Variation of percentage compressive strength with percentage of fly ash for M60 grade

concrete at room temperature

Figure 4 Variation of percentage compressive strength with percentage of fly ash for M30 grade

concrete at room temperature

4.2. Split tensile strength

Percentage split tensile strength is the ratio of split tensile strength of any percentage of fly ash

or age to that of 28 day strength of controlled concrete (reference concrete) at room temperature

multiplied by 100. Behaviour of fly ash on split tensile strength of M60 (HSC) and M30 (SC)

grades of concrete are shown graphically in Fig.5 and Fig.6 respectively.

From Fig.5, the values of percentage split tensile strength of HSC for 0, 30, 40 and 50% fly

ash at room temperature at an age of 7 days are 88.2, 86.6, 84.7 and 68.5. At the same time, the

values at an age of 28 days are 100.0, 101, 97.7 and 92.3, While, the values at an age of 56 days

are 101.0, 102.3, 101.9, 98.3, whereas the values at an age of 91 days are 104.8, 106.6, 102.9

and 100.0 respectively.

http://www.iaeme.com/IJCIET/index.asp 196 editor@iaeme.com

A. Venkateswara Rao and K. Srinivasa Rao

From Fig.6, the values of percentage split tensile strength of SC for 0, 30, 40 and 50% fly

ash at room temperature at an age of 7 days are 88.7, 87.7, 84.0 and 77.2. At the same time, the

values at an age of 28 days are 100, 102.4, 96.5, 85.9, While, the values at an age of 56 days

are 102, 103, 100.3 and 92.3, whereas the values at an age of 91 days are 106.8, 108.6, 104.7

and 101.89 respectively.

Figure 5 Variation of percentage residual split tensile strength with percentage of fly ash for M60

grade concrete at (27C) room temperature

Figure 6 Variation of percentage residual split tensile strength with percentage of fly ash for M30

grade concrete at (27C) room temperature

4.3. Stress-Strain behaviour

The Stress-Strain behaviour of high strength concrete (M60) and standard concrete (M30) with

various replacements of cement with 0, 30, 40 and 50% of fly ash is shown in Fig.7 and Fig.8

respectively. The experimental results revealed that the replacing cement between 30% to 50%

with fly ash ductility and stiffness was decreased for M60 grade concrete and for M30 grade

concrete, the replacing cement between 30% to 50% with fly ash ductility and stiffness was

decreased.

http://www.iaeme.com/IJCIET/index.asp 197 editor@iaeme.com

Effect of Fly Ash On Mechanical Properties of M30 and M60 Grade Concrete

Figure 7 Variation of Stress-Strain at room temperature for M60 grade concrete

Figure 8 Variation of Stress-Strain at room temperature for M30 grade concrete

CONCLUSIONS

1. Compressive strength of M60 grade concrete increases for 30% ly ash concrete compared to

controled concrete without fly ash at all ages of 28, 56 and 91 days.

2. Compressive strength of M30 grade concrete increases for 30% ly ash concrete compared to

controled concrete without fly ash at all ages of 28, 56 and 91 days.

3. At an age of 7 days the compressive strength of M60 grade concrete decreases for 30, 40 and

50% fly ash concrete compared to controled concrete without fly ash.

4. Compressive strength of M30 grade concrete decreases for 30, 40 and 50% fly ash concrete

compared to controled concrete without fly ash at an age of 7 days.

5. Compressive strength of M30 and M60 grades of concrete decreases for 40 and 50% fly ash

concrete compared to controled concrete without fly ash and concrete with 30% fly ash at all

ages of 28, 56 and 91 days.

6. Percentage of residual split tensile strength of M60 grade concrete increases for 30% ly ash

concrete compared to controled concrete without fly ash at all ages of 28, 56 and 91 days.

http://www.iaeme.com/IJCIET/index.asp 198 editor@iaeme.com

A. Venkateswara Rao and K. Srinivasa Rao

7. Split tensile strength of M30 grade concrete increases for 30% ly ash concrete compared to

controled concrete without fly ash at all ages of 28, 56 and 91 days.

8. At an age of 7 days the split tensile strength of M60 grade concrete decreases for 30, 40 and

50% fly ash concrete compared to controled concrete without fly ash.

9. Split tensile strength of M30 grade concrete decreases for 30, 40 and 50% fly ash concrete

compared to controled concrete without fly ash at an age of 7 days.

10. Split tensile strength of M30 and M60 grades of concrete decreases for 40 and 50% fly ash

concrete compared to controled concrete without fly ash and concrete with 30% fly ash at all

ages of 28, 56 and 91 days.

11. Concrete with high percentages of above 40% fly ash can be used in situations where strength

is not important economy is required.

12. At early ages the compressive strength of fly ash concrete is less over conventional concrete

without fly ash.

13. At early ages the split tensile strength of fly ash concrete is less over conventional concrete

without fly ash.

14. Finally it is concluded that concrete replacing cement with 30% fly ash can be used in

construction of structures.

REFERENCES

[1] Hand Book on High Volume Fly Ash Concrete Technology, 3 rd edition (2005).

[2] Malhotra, V.M.; Mehta, P.K.: High Performance High Volume Fly Ash Concrete.

Supplement Cementer Materials for Sustainable Development. Inc., Ottawa, Canada

(2005).

[3] Aman Jatale, Kartikey Tiwari, Sahil Khandelwal, "Effects on Compressive Strength When

Cement Is Partially Replaced By Fly-Ash", IOSR Journal of Mechanical and Civil

Engineering (IOSR-JMCE), Volume 5, Issue 4 (Jan. - Feb. 2013), PP 34-43.

[4] Dragas, J, Mrinkovic, S., Igrjatovic, Tovic, N., " Properties of High Volume Fly Ash

Concrete And its Role in Sustainability Development" International Conference on

Contemporary Achievements in Civil Engineering, 24-25 April 2014, Subotica, Serbia.

[5] Nath, P., and Sarker, P., "Effect of Fly Ash on the Durability Properties of High Strength

Concrete" Science Direct, The Proceedings of the Twelfth East Asia- Pacific Conference

on Structural Enginering and Construction, Vol.14, 2011, pp. 1149-1156.

[6] IS 10262-2009, Recommend Guidelines for Concrete Mix Design, Bureau of Indian

Standards, New Delhi, India.

[7] IS 456-2000, "Indian Code of practice for Plain and Reinforced concrete for genaral

building construction Bureau of Indian Standards, New Delhi, India.

[8] IS: 12269 Specifications for 53 grade Portland cement, Bureau of Indian Standards, New

Delhi, India.

[9] IS 383-1970 specifications for Coarse and Fine Aggregates from natural sources for

concrete, Bureau of Indian Standards, New Delhi, India.

[10] IS: 9103-1999, "Specifications for Admixtures for concrete", Bureau of Indian Standards,

New Delhi, India.

[11] Manual on Complast SP 430-DIS from Foscroc Chemicals Ltd.

[12] IS 516-1959(Reaffirmed 1999) Indian Standard Methods 0f tests for strength of concrete,

Bureau of Indian Standards, New Delhi. India.

[13] Ahmed Sahib Mahdi, Mohammad Sukri Mustapa, Mohd Amri lajis and Mohd warikh abd

Rashid, Effect of Holding Time on Mechanical Properties of Recycling Aluminium Alloy

Aa6061 through Ball Mill Process, International Journal of Mechanical Engineering and

Technology, 6(9), 2015, pp. 133-142.

http://www.iaeme.com/IJCIET/index.asp 199 editor@iaeme.com

Effect of Fly Ash On Mechanical Properties of M30 and M60 Grade Concrete

[14] S. Kiran Kumar and Dr. S. Siddiraju, Effect of Steel and Polypropylene Fiber on

Mechanical Properties of Concrete. International Journal of Civil Engineering and

Technology, 7(3), 2016, pp.342346.

[15] Bibha Kumari and Vikas Srivastava, Effect of Waste Plastic and Fly Ash on Mechanical

Properties of Rigid Pavement. International Journal of Civil Engineering and Technology,

7(5), 2016, pp.247256.

[16] G. Vamsi Durga Mohan, K. S. Rao and P. Srinivasa Rao. Enhancement in Mechanical

Properties of Vibratory Welded Joints: An Overview. International Journal of Mechanical

Engineering and Technology, 8(2), 2017, pp. 5055.

[17] IS 5816-1999, "Method of test for splitting tensile strength of concrete", Bureau of Indian

Standards, New Delhi, India.

[18] Saha Arkan , et al., (2014), Strength Development Characteristics of High Strength

Concrete Incorporating an Indian Fly ash", "International Journal of technology

enhancements and emerging engineering research", vol.2, issue 6, (2014), pp. 101-107.

http://www.iaeme.com/IJCIET/index.asp 200 editor@iaeme.com

Das könnte Ihnen auch gefallen

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDokument10 SeitenImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationNoch keine Bewertungen

- Voice Based Atm For Visually Impaired Using ArduinoDokument7 SeitenVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationNoch keine Bewertungen

- Broad Unexposed Skills of Transgender EntrepreneursDokument8 SeitenBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationNoch keine Bewertungen

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDokument16 SeitenA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationNoch keine Bewertungen

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDokument9 SeitenA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationNoch keine Bewertungen

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDokument14 SeitenModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationNoch keine Bewertungen

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDokument7 SeitenA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationNoch keine Bewertungen

- Various Fuzzy Numbers and Their Various Ranking ApproachesDokument10 SeitenVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationNoch keine Bewertungen

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDokument16 SeitenInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationNoch keine Bewertungen

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDokument13 SeitenA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationNoch keine Bewertungen

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDokument19 SeitenApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationNoch keine Bewertungen

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDokument9 SeitenEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationNoch keine Bewertungen

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDokument15 SeitenAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationNoch keine Bewertungen

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDokument18 SeitenRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationNoch keine Bewertungen

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDokument9 SeitenFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationNoch keine Bewertungen

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDokument13 SeitenAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationNoch keine Bewertungen

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDokument8 SeitenKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationNoch keine Bewertungen

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDokument13 SeitenOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationNoch keine Bewertungen

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDokument7 SeitenModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationNoch keine Bewertungen

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDokument8 SeitenDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationNoch keine Bewertungen

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDokument9 SeitenAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationNoch keine Bewertungen

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDokument10 SeitenA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationNoch keine Bewertungen

- Sentiment Analysis Approach in Natural Language Processing For Data ExtractionDokument6 SeitenSentiment Analysis Approach in Natural Language Processing For Data ExtractionIAEME PublicationNoch keine Bewertungen

- A Review of Particle Swarm Optimization (Pso) AlgorithmDokument26 SeitenA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationNoch keine Bewertungen

- A Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceDokument5 SeitenA Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceIAEME PublicationNoch keine Bewertungen

- Formulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationDokument7 SeitenFormulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationIAEME PublicationNoch keine Bewertungen

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDokument7 SeitenQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationNoch keine Bewertungen

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDokument13 SeitenPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationNoch keine Bewertungen

- Ion Beams' Hydrodynamic Approach To The Generation of Surface PatternsDokument10 SeitenIon Beams' Hydrodynamic Approach To The Generation of Surface PatternsIAEME PublicationNoch keine Bewertungen

- Evaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesDokument6 SeitenEvaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesIAEME PublicationNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Water Fired Chiller/Chiller-Heater: We Are Friendly To The EarthDokument12 SeitenWater Fired Chiller/Chiller-Heater: We Are Friendly To The EarthAsad KhanNoch keine Bewertungen

- Clamart Sport CentreDokument7 SeitenClamart Sport CentreSwetha Krishnan100% (1)

- Stair Pressurization CalculationDokument2 SeitenStair Pressurization Calculationnaruto256100% (1)

- RKO 135 29 Northern BLVDDokument141 SeitenRKO 135 29 Northern BLVDQueens Post50% (2)

- Klc-Sas Downtown Formwork Report 0607-2022Dokument6 SeitenKlc-Sas Downtown Formwork Report 0607-2022Naggi IññoçêntNoch keine Bewertungen

- Pile Dia and Minimum ReinforcementDokument1 SeitePile Dia and Minimum ReinforcementMAHTAB HOSSAIN100% (1)

- Din en 13084-7:2006-06 (E)Dokument1 SeiteDin en 13084-7:2006-06 (E)Romeo Di SarioNoch keine Bewertungen

- Egger Flooring: Inspiring Variety For Your HomeDokument44 SeitenEgger Flooring: Inspiring Variety For Your HomeshinobisefirotNoch keine Bewertungen

- QUESTIONS of AREA 2Dokument23 SeitenQUESTIONS of AREA 2JHONA THE IGUANANoch keine Bewertungen

- CompressiveStrength (ASTM-C39) Test ReportDokument21 SeitenCompressiveStrength (ASTM-C39) Test ReportNadira PervinNoch keine Bewertungen

- Jerry El Bazouni - Brief Portfolio-OptimisedDokument15 SeitenJerry El Bazouni - Brief Portfolio-OptimisedArch. JB DesignNoch keine Bewertungen

- 3 3 4 A EnergycodesDokument3 Seiten3 3 4 A Energycodesapi-3839138000% (1)

- Specification For RCC Boundary KM Stone and Guard Stone 1. ScopeDokument3 SeitenSpecification For RCC Boundary KM Stone and Guard Stone 1. ScopeAakash2013Noch keine Bewertungen

- 1,000 SQFT: ResidensiDokument2 Seiten1,000 SQFT: ResidensiSoon Yee WongNoch keine Bewertungen

- 03.00.08.14. Menghitung Pressure Blower Silo PDFDokument88 Seiten03.00.08.14. Menghitung Pressure Blower Silo PDFRachmat Cahaya Putra100% (2)

- Slab EstimateDokument4 SeitenSlab Estimatedarkkaizer23Noch keine Bewertungen

- Abu Dhabi Investment Council BuildingDokument7 SeitenAbu Dhabi Investment Council BuildingJinaliDoshiNoch keine Bewertungen

- Causes and Repair of CracksofDokument16 SeitenCauses and Repair of CracksofBharath PbbpNoch keine Bewertungen

- Variable Refrigerant Flow Systems: Outdoor Units - Systems Up To 25 TonsDokument4 SeitenVariable Refrigerant Flow Systems: Outdoor Units - Systems Up To 25 TonsFadojutimi AyomiposiNoch keine Bewertungen

- 2005 ASHRAE HANDBOOK FUNDAMENTALS. I-P Edition. Supported by ASHRAE ResearchDokument9 Seiten2005 ASHRAE HANDBOOK FUNDAMENTALS. I-P Edition. Supported by ASHRAE ResearchVigneshNoch keine Bewertungen

- Wood Faktory: Al Wasead Al AqariyaDokument10 SeitenWood Faktory: Al Wasead Al Aqariyaismet mehmetiNoch keine Bewertungen

- TestDokument23 SeitenTestAGunaSekaranNoch keine Bewertungen

- Opa 465-960 Uc8 Eco TD 0322Dokument24 SeitenOpa 465-960 Uc8 Eco TD 03227tddprzxbbNoch keine Bewertungen

- 6.6 Design of Column Jacketing: (Sandesh, Shiyam, Shlok, Sonam, Subash, Swastik)Dokument3 Seiten6.6 Design of Column Jacketing: (Sandesh, Shiyam, Shlok, Sonam, Subash, Swastik)Official 074BCEGHNoch keine Bewertungen

- PUB Stipulated Standards Requirements For Water Fittings PDFDokument75 SeitenPUB Stipulated Standards Requirements For Water Fittings PDFrajmohan198512Noch keine Bewertungen

- Programme-Balance of ActivitiesDokument82 SeitenProgramme-Balance of ActivitiesP Eng Suraj SinghNoch keine Bewertungen

- Basic Components of Building StructureDokument5 SeitenBasic Components of Building StructureUsman ShahidNoch keine Bewertungen

- Master Calc HVAC SubmittalsDokument29 SeitenMaster Calc HVAC Submittalshasanadel88Noch keine Bewertungen

- BOQ-FATORY BD English 04 January 2010Dokument42 SeitenBOQ-FATORY BD English 04 January 2010jimmiilongNoch keine Bewertungen

- TTA-TWE Catálogo (Inglés)Dokument138 SeitenTTA-TWE Catálogo (Inglés)kuraimund100% (1)