Beruflich Dokumente

Kultur Dokumente

Raft Foundation Design

Hochgeladen von

afiqCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Raft Foundation Design

Hochgeladen von

afiqCopyright:

Verfügbare Formate

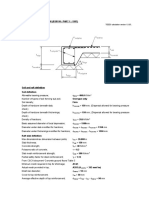

RAFT FOUNDATION DESIGN (BS8110 : PART 1 : 1997)

Tedds calculation version 1.0.11;

A s s la b to p

h s la b

h h c o r e s la b

A s s la b b t m

Soil and raft definition

Soil definition

Allowable bearing pressure; qallow = 75.0 kN/m2

Number of types of soil forming sub-soil; One type only

Soil density; Firm to loose

Depth of hardcore beneath slab; hhcoreslab = 300 mm; (Dispersal allowed for bearing pressure

check)

Density of hardcore; hcore = 20.0 kN/m3

Basic assumed diameter of local depression; depbasic = 2000mm

Diameter under slab modified for hardcore; depslab = depbasic - hhcoreslab = 1700 mm

Raft slab definition

Max dimension/max dimension between joints; lmax = 10.000 m

Slab thickness; hslab = 250 mm

Concrete strength; fcu = 30 N/mm2

Poissons ratio of concrete; = 0.2

Slab mesh reinforcement strength; fyslab = 460 N/mm2

Partial safety factor for steel reinforcement; s = 1.15

From C&CA document Concrete ground floors Table 5

Minimum mesh required in top for shrinkage; A142;

Actual mesh provided in top; A10 (Asslabtop = 393 mm2/m)

Mesh provided in bottom; A10 (Asslabbtm = 393 mm2/m)

Top mesh bar diameter; slabtop = 10 mm

Bottom mesh bar diameter; slabbtm = 10 mm

Cover to top reinforcement; ctop = 25 mm

Cover to bottom reinforcement; cbtm = 25 mm

Average effective depth of top reinforcement; dtslabav = hslab - ctop - slabtop = 215 mm

Average effective depth of bottom reinforcement; dbslabav = hslab - cbtm - slabbtm = 215 mm

Overall average effective depth; dslabav = (dtslabav + dbslabav)/2 = 215 mm

Minimum effective depth of top reinforcement; dtslabmin = dtslabav - slabtop/2 = 210 mm

Minimum effective depth of bottom reinforcement; dbslabmin = dbslabav - slabbtm/2 = 210 mm

Slab edge reinforcement

Mesh provided in top; A10 (Asedgetop = 393 mm2/m)

Mesh provided in bottom; A10 (Asedgebtm = 393 mm2/m)

;

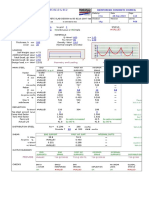

Internal slab design checks

Basic loading

Slab self weight; wslab = 24 kN/m3 hslab = 6.0 kN/m2

Hardcore; whcoreslab = hcore hhcoreslab = 6.0 kN/m2

Applied loading

Uniformly distributed dead load; wDudl = 10.0 kN/m2

Uniformly distributed live load; wLudl = 5.0 kN/m2

Internal slab bearing pressure check

Total uniform load at formation level; wudl = wslab + whcoreslab + wDudl + wLudl = 27.0 kN/m2

PASS - wudl <= qallow - Applied bearing pressure is less than allowable

Internal slab bending and shear check

Applied bending moments

Span of slab; lslab = depslab + dtslabav = 1915 mm

Ultimate self weight udl; wswult = 1.4 wslab = 8.4 kN/m2

Self weight moment at centre; Mcsw = wswult lslab2 (1 + ) / 64 = 0.6 kNm/m

Self weight moment at edge; Mesw = wswult lslab2 / 32 = 1.0 kNm/m

Self weight shear force at edge; Vsw = wswult lslab / 4 = 4.0 kN/m

Moments due to applied uniformly distributed loads

Ultimate applied udl; wudlult = 1.4 wDudl + 1.6 wLudl = 22.0 kN/m2

Moment at centre; Mcudl = wudlult lslab2 (1 + ) / 64 = 1.5 kNm/m

Moment at edge; Meudl = wudlult lslab2 / 32 = 2.5 kNm/m

Shear force at edge; Vudl = wudlult lslab / 4 = 10.5 kN/m

Resultant moments and shears

Total moment at edge; Me = 3.5 kNm/m

Total moment at centre; Mc = 2.1 kNm/m

Total shear force; V = 14.6 kN/m

Reinforcement required in top

K factor; Kslabtop = Me/(fcu dtslabav2) = 0.003

Lever arm; zslabtop = dtslabav min(0.95, 0.5 + (0.25 - Kslabtop/0.9)) = 204.2

mm

Area of steel required for bending; Asslabtopbend = Me/((1.0/s) fyslab zslabtop) = 43 mm2/m

Minimum area of steel required; Asslabmin = 0.0013 hslab = 325 mm2/m

Area of steel required; Asslabtopreq = max(Asslabtopbend, Asslabmin) = 325 mm2/m

PASS - Asslabtopreq <= Asslabtop - Area of reinforcement provided in top to span local depressions is adequate

Reinforcement required in bottom

K factor; Kslabbtm = Mc/(fcu dbslabav2) = 0.002

Lever arm; zslabbtm = dbslabav min(0.95, 0.5 + (0.25 - Kslabbtm/0.9)) = 204.2

mm

Area of steel required for bending; Asslabbtmbend = Mc/((1.0/s) fyslab zslabbtm) = 26 mm2/m

Area of steel required; Asslabbtmreq = max(Asslabbtmbend, Asslabmin) = 325 mm2/m

PASS - Asslabbtmreq <= Asslabbtm - Area of reinforcement provided in bottom to span local depressions is

adequate

Shear check

Applied shear stress; v = V/dtslabmin = 0.069 N/mm2

Tension steel ratio; = 100 Asslabtop/dtslabmin = 0.187

From BS8110-1:1997 - Table 3.8;

Design concrete shear strength; vc = 0.451 N/mm2

PASS - v <= vc - Shear capacity of the slab is adequate

Internal slab deflection check

Basic allowable span to depth ratio; Ratiobasic = 26.0

Moment factor; Mfactor = Mc/dbslabav2 = 0.045 N/mm2

Steel service stress; fs = 2/3 fyslab Asslabbtmbend/Asslabbtm = 19.965 N/mm2

Modification factor; MFslab = min(2.0, 0.55 + [(477N/mm2 - fs)/(120 (0.9N/mm2 +

Mfactor))])

MFslab = 2.000

Modified allowable span to depth ratio; Ratioallow = Ratiobasic MFslab = 52.000

Actual span to depth ratio; Ratioactual = lslab/ dbslabav = 8.907

PASS - Ratioactual <= Ratioallow - Slab span to depth ratio is adequate

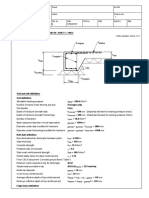

Slab edge design checks

Basic loading

Hardcore; whcoreslab = hcore hhcoreslab = 6.0 kN/m2

Slab self weight; wslab = 24 kN/m3 hslab = 6.0 kN/m2

Slab edge bearing pressure check

Total uniform load at formation level; wudledge = wDudl + wLudl + wslab + whcoreslab = 27.0 kN/m2

PASS - wudledge <= qallow - Applied bearing pressure is less than allowable

Slab edge bending check

Considering a 1.0m width of slab

Divider for moments due to udls; udl = 10.0

Applied bending moments

Span of slab; ledge = depslab + dtslabmin = 1910 mm

Ultimate self weight udl; wedgeult = 1.4 wslab = 8.4 kN/m2

Self weight bending moment; Medgesw = wedgeult ledge2/10 = 3.1 kNm/m

Self weight shear force; Vedgesw = wedgeult ledge/2 = 8.0 kN/m

Moments due to applied uniformly distributed loads

Ultimate udl; wedgeudl = wudlult = 22.0 kN/m2

Bending moment; Medgeudl = wedgeudl ledge2/udl = 8.0 kNm/m

Shear force; Vedgeudl = wedgeudl ledge/2 = 21.0 kN/m

Resultant moments and shears

Total moment (hogging and sagging); Medge = 11.1 kNm/m

Maximum shear force; Vedge = 29.0 kN/m

Reinforcement required in top

K factor; Kedgetop = Medge/(fcu dtslabmin2) = 0.008

Lever arm; zedgetop = dtslabmin min(0.95, 0.5 + (0.25 - Kedgetop/0.9)) = 200

mm

Area of steel required for bending; Asedgetopbend = Medge/((1.0/s) fyslab zedgetop) = 139 mm2/m

Area of steel required; Asedgetopreq = max(Asedgetopbend, Asslabmin) = 325 mm2/m

PASS - Asedgetopreq <= Asedgetop - Area of reinforcement provided in top of slab is adequate

Reinforcement required in bottom

K factor; Kedgebtm = Medge/(fcu dbslabmin2) = 0.008

Lever arm; zedgebtm = dbslabmin min(0.95, 0.5 + (0.25 - Kedgebtm/0.9)) = 200

mm

Area of steel required for bending; Asedgebtmbend = Medge/((1.0/s) fyslab zedgebtm) = 139 mm2/m

Area of steel required; Asedgebtmreq = max(Asedgebtmbend, Asslabmin) = 325 mm2/m

PASS - Asedgebtmreq <= Asedgebtm - Area of reinforcement provided in bottom of slab is adequate

Applied shear stress; vedge = Vedge 1.0m/(1000mm dtslabmin) = 0.138 N/mm2

Tension steel ratio; edge = 100 Asedgetop 1.0m/(1000mm dtslabmin) = 0.187

From BS8110-1:1997 - Table 3.8

Design concrete shear strength; vcedge = 0.451 N/mm2

PASS - vedge <= vcedge - Shear capacity of the slab is not exceeded

Slab edge deflection check

Basic allowable span to depth ratio; Ratiobasicedge = 26.0

Moment factor; Mfactoredge = Medge/dbslabmin2 = 0.251 N/mm2

Steel service stress; fsedge = 2/3 fyslab Asedgebtmbend/Asedgebtm = 108.445 N/mm2

Modification factor; MFedge=min(2.0,0.55+[(477N/mm2-fsedge)/

(120(0.9N/mm2+Mfactoredge))])

MFedge = 2.000

Modified allowable span to depth ratio; Ratioallowedge = Ratiobasicedge MFedge = 52.000

Actual span to depth ratio; Ratioactualedge = ledge/ dtslabmin = 9.095

PASS - Ratioactualedge <= Ratioallowedge - Slab span to depth ratio is adequate

Corner design checks

Basic loading

Corner bearing pressure check

Total uniform load at formation level; wudlcorner = wDudl + wLudl + wslab + whcoreslab = 27.0 kN/m2

PASS - wudlcorner <= qallow - Applied bearing pressure is less than allowable

Slab corner bending check

Cantilever span of slab at corner; lcorner = depslab/(2) + dtslabav/2 = 1310 mm

Moment and shear due to self weight

Considering triangular loading

Maximum ultimate self weight udl; wswult = 1.4 wslab depslab/(2) = 10.1 kN/m

Self weight bending moment; Mcornersw = wswult lcorner2/(6 depslab/(2)) = 2.4 kNm/m

Self weight shear force; Vcornersw = wswult lcorner/(2 depslab/(2)) = 5.5 kN/m

Moment and shear due to udls

Maximum ultimate udl; wcornerudl = ((1.4wDudl)+(1.6wLudl)) depslab/(2) = 26.4 kN/m

Bending moment; Mcornerudl = wcornerudl lcorner2/(6 depslab/(2)) = 6.3 kNm/m

Shear force; Vcornerudl = wcornerudl lcorner/(2 depslab/(2)) = 14.4 kN/m

Resultant moments and shears

Total design moment; Mcorner = Mcornersw+ Mcornerudl = 8.7 kNm/m

Total design shear force; Vcorner = Vcornersw+ Vcornerudl = 19.9 kN/m

Reinforcement required in top of slab at corners

K factor; Kcorner = Mcorner/(fcu dtslabmin2) = 0.007

Lever arm; zcorner = dtslabmin min(0.95, 0.5 + (0.25 - Kcorner/0.9)) = 200

mm

Area of steel required for bending; Ascornerbend = Mcorner/((1.0/s) fyslab zcorner) = 109 mm2/m

Area of steel required; Ascorner = max(Ascornerbend, Asslabmin) = 325 mm2/m

PASS - Ascorner <= Asedgetop - Area of reinforcement provided in top of slab at corners is adequate

Applied shear stress; vcorner = Vcorner/dtslabmin = 0.095 N/mm2

Tension steel ratio; corner = 100 Asedgetop/dtslabmin = 0.187

From BS8110-1:1997 - Table 3.8

Design concrete shear strength; vccorner = 0.451 N/mm2

Pass - vcorner <= vccorner - Shear capacity of the slab is not exceeded

Slab corner deflection check

Basic allowable span to depth ratio; Ratiobasiccorner = 7.0

Moment factor; Mfactorcorner = Mcorner/dtslabmin2 = 0.197 N/mm2

Steel service stress; fscorner = 2/3 fyslab Ascornerbend/Asedgetop = 84.969 N/mm2

Modification factor; MF corner=min(2.0,0.55+[(477N/mm2-fscorner)/

2

(120(0.9N/mm +Mfactorcorner))])

MFcorner = 2.000

Modified allowable span to depth ratio; Ratioallowcorner = Ratiobasiccorner MFcorner = 14.000

Actual span to depth ratio; Ratioactualcorner = lcorner/ dtslabmin = 6.236

PASS - Ratioactualcorner <= Ratioallowcorner - Slab span to depth ratio is adequate

Das könnte Ihnen auch gefallen

- Raft Foundation DesignDokument5 SeitenRaft Foundation Designmihai_serban13100% (1)

- Raft DesignDokument8 SeitenRaft Designomolewa joshuaNoch keine Bewertungen

- Design of Raft FoundationDokument9 SeitenDesign of Raft FoundationAnonymous ciKyr0tNoch keine Bewertungen

- RV Design of Column Base PlateDokument2 SeitenRV Design of Column Base Plateapi-190618655Noch keine Bewertungen

- Corbel BS8110Dokument3 SeitenCorbel BS8110Nugraha BintangNoch keine Bewertungen

- GF SlabDokument8 SeitenGF Slabcheligp1981Noch keine Bewertungen

- Chap 7 Foundation DesignDokument36 SeitenChap 7 Foundation DesignZulhasri WahapNoch keine Bewertungen

- Drop Panel CalculationDokument2 SeitenDrop Panel Calculationsandiok86Noch keine Bewertungen

- Design of DomeDokument5 SeitenDesign of DomeAmarjeet SinghNoch keine Bewertungen

- Vertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisDokument10 SeitenVertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisNeven Ahmed HassanNoch keine Bewertungen

- Column Design - As Per BS CodeDokument16 SeitenColumn Design - As Per BS CodefatinamilinNoch keine Bewertungen

- Composite Beam Simply Supported DesignDokument12 SeitenComposite Beam Simply Supported DesignMario FeghaliNoch keine Bewertungen

- Design of T Beam Using SP16 Economic Depth and CheckDokument10 SeitenDesign of T Beam Using SP16 Economic Depth and CheckRiazahemad B JagadalNoch keine Bewertungen

- Rectangular Spread Footing DesignDokument42 SeitenRectangular Spread Footing DesignJedidiah MelakuNoch keine Bewertungen

- Design of Buildings Windloads ProfHaefnerDokument9 SeitenDesign of Buildings Windloads ProfHaefnerVianda KauriviNoch keine Bewertungen

- View Topic - Pile Cap Design Using SafeDokument5 SeitenView Topic - Pile Cap Design Using SafeParameswaran GanesanNoch keine Bewertungen

- SCBD - Raft Foundation Side Formworks Design Report PDFDokument11 SeitenSCBD - Raft Foundation Side Formworks Design Report PDFJohn Vincent Musngi100% (1)

- Design of Reinforced Concrete Shear WallDokument15 SeitenDesign of Reinforced Concrete Shear WallAnonymous nwByj9L0% (1)

- Structural Design of Raft Foundation Based On Geotechnical AnalysisDokument6 SeitenStructural Design of Raft Foundation Based On Geotechnical AnalysisNaresh KumarNoch keine Bewertungen

- 15 - High Mast Light Pole Foundation DesignDokument20 Seiten15 - High Mast Light Pole Foundation DesignHamOdy SadeqNoch keine Bewertungen

- Z PurlinDokument48 SeitenZ PurlinleroytuscanoNoch keine Bewertungen

- Sepakat Setia Perunding SDN BHD: Design InformationDokument6 SeitenSepakat Setia Perunding SDN BHD: Design InformationAfiq SyahmiNoch keine Bewertungen

- Minimum Thickness of Solid Slab According To ACIDokument1 SeiteMinimum Thickness of Solid Slab According To ACImuhanned100% (1)

- Composite Slab Deck ACI318Dokument4 SeitenComposite Slab Deck ACI318jflttwNoch keine Bewertungen

- Part - 1 Shear Wall Design PDFDokument16 SeitenPart - 1 Shear Wall Design PDFSrishti Project ConsultantsNoch keine Bewertungen

- Software Verification: Example 17Dokument8 SeitenSoftware Verification: Example 17sancloudNoch keine Bewertungen

- Preliminary Design and Load CalcualtionsDokument16 SeitenPreliminary Design and Load CalcualtionsBimal Bhandari100% (1)

- Slab With OpeningDokument16 SeitenSlab With OpeningTomislav Šimag100% (1)

- Strip Footing Analysis & Design (BS8110) Beam Size ReduceDokument3 SeitenStrip Footing Analysis & Design (BS8110) Beam Size ReduceHimura_Noch keine Bewertungen

- Lecture of FootingDokument195 SeitenLecture of FootingMonirul IslamNoch keine Bewertungen

- Wind Load Calculation 29-08-2018Dokument4 SeitenWind Load Calculation 29-08-2018mbhanusagar.keynesNoch keine Bewertungen

- RCC Beams: Doubly Reinforced BeamDokument2 SeitenRCC Beams: Doubly Reinforced BeamSandeep ChavanNoch keine Bewertungen

- Building Story Drift in ETABS PDFDokument10 SeitenBuilding Story Drift in ETABS PDFntirugiribambeNoch keine Bewertungen

- Analysis & Design of Multi Storeyed Buildings V.M.RAJAN, M.E. (Struct), FIE, Former CE/Civil/TANGEDCODokument25 SeitenAnalysis & Design of Multi Storeyed Buildings V.M.RAJAN, M.E. (Struct), FIE, Former CE/Civil/TANGEDCOV.m. RajanNoch keine Bewertungen

- Basement Wall DesignDokument2 SeitenBasement Wall DesignBuddhiraj kadelNoch keine Bewertungen

- Ware House DesignDokument8 SeitenWare House DesignJay-Jay JapsNoch keine Bewertungen

- Wind DesignDokument12 SeitenWind Designknyap78Noch keine Bewertungen

- Axially Loaded Columns - Base Plate DesignDokument2 SeitenAxially Loaded Columns - Base Plate DesignaomareltayebNoch keine Bewertungen

- Apex ConnectionDokument9 SeitenApex ConnectionMihnea OrzaNoch keine Bewertungen

- Section properties and load capacity analysis of steel beamDokument17 SeitenSection properties and load capacity analysis of steel beamSourabh Das100% (1)

- Check of Z Section On Principle Axes: Data InputDokument3 SeitenCheck of Z Section On Principle Axes: Data InputAlden CayagaNoch keine Bewertungen

- Pad Foundation With Two Columns ExampleDokument10 SeitenPad Foundation With Two Columns ExampleakankwasaNoch keine Bewertungen

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Dokument7 Seiten1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12asuncionNoch keine Bewertungen

- Vertical reinforcement (Walls: BS 8110) guidelinesDokument4 SeitenVertical reinforcement (Walls: BS 8110) guidelinesdhanya1995100% (1)

- Isolated footing design example step-by-step guideDokument6 SeitenIsolated footing design example step-by-step guidetopukuet100% (1)

- The Flexure and Shear Design of Corbel (Bracket)Dokument12 SeitenThe Flexure and Shear Design of Corbel (Bracket)Girum MindayeNoch keine Bewertungen

- Calculation PDFDokument126 SeitenCalculation PDFmohammed almahrooqiNoch keine Bewertungen

- Column Design - As Per BS CodeDokument16 SeitenColumn Design - As Per BS CodeYam BalaoingNoch keine Bewertungen

- Design of Isolated Footing with Moment CalculationsDokument28 SeitenDesign of Isolated Footing with Moment CalculationsmeenuNoch keine Bewertungen

- Bracing Connection Work Point PDFDokument2 SeitenBracing Connection Work Point PDFaams_sNoch keine Bewertungen

- Project foundation design calculationsDokument10 SeitenProject foundation design calculationsGautam PaulNoch keine Bewertungen

- Wall Footing DesignDokument102 SeitenWall Footing DesignAUNGPSNoch keine Bewertungen

- 6 Pile GroupDokument4 Seiten6 Pile GroupAnonymous nwByj9L100% (1)

- Ipt Design WorkDokument43 SeitenIpt Design WorkMorice RwakataleNoch keine Bewertungen

- One Way SlabDokument5 SeitenOne Way SlabShoaib Mohammad Quraishi100% (2)

- Fixed Base Plate ExampleDokument5 SeitenFixed Base Plate ExamplevtalexNoch keine Bewertungen

- RC Raft FoundationDokument6 SeitenRC Raft FoundationNaziemi AhmadNoch keine Bewertungen

- RC Raft Foundation (BS8110) - Part2Dokument1 SeiteRC Raft Foundation (BS8110) - Part2Himura_Noch keine Bewertungen

- Slab Foundation Design 1Dokument6 SeitenSlab Foundation Design 1Renato ZanescoNoch keine Bewertungen

- Raft Foundation Design (Bs8110: Part 1: 1997) : SslabtopDokument2 SeitenRaft Foundation Design (Bs8110: Part 1: 1997) : SslabtopafiqNoch keine Bewertungen

- 1) Column Design 1) Column DesignDokument4 Seiten1) Column Design 1) Column DesignafiqNoch keine Bewertungen

- Vertices F 1Dokument2 SeitenVertices F 1afiqNoch keine Bewertungen

- Column Design AnalysisDokument4 SeitenColumn Design AnalysisafiqNoch keine Bewertungen

- 1) Column Design 1) Column DesignDokument4 Seiten1) Column Design 1) Column DesignafiqNoch keine Bewertungen

- Vertical F 1Dokument2 SeitenVertical F 1afiqNoch keine Bewertungen

- Selection of Inlet & Overflow Pipe (Whichever Is Smaller)Dokument2 SeitenSelection of Inlet & Overflow Pipe (Whichever Is Smaller)afiqNoch keine Bewertungen

- Osd 11 DocxDokument2 SeitenOsd 11 DocxafiqNoch keine Bewertungen

- AavqeDokument4 SeitenAavqeafiqNoch keine Bewertungen

- AavqeDokument4 SeitenAavqeafiqNoch keine Bewertungen

- Vertices F 1Dokument2 SeitenVertices F 1afiqNoch keine Bewertungen

- Selection of Inlet & Overflow Pipe (Whichever Is Smaller)Dokument2 SeitenSelection of Inlet & Overflow Pipe (Whichever Is Smaller)afiqNoch keine Bewertungen

- CALCULATING FORCES AND MOMENTS ON A RETAINING WALLDokument3 SeitenCALCULATING FORCES AND MOMENTS ON A RETAINING WALLafiqNoch keine Bewertungen

- Osd 11 DocxDokument2 SeitenOsd 11 DocxafiqNoch keine Bewertungen

- Osd 11 DocxDokument2 SeitenOsd 11 DocxafiqNoch keine Bewertungen

- Vertices F 1Dokument2 SeitenVertices F 1afiqNoch keine Bewertungen

- Vertices F 1Dokument2 SeitenVertices F 1afiqNoch keine Bewertungen

- Vertical Forces 1Dokument2 SeitenVertical Forces 1afiqNoch keine Bewertungen

- Vertices F 1Dokument3 SeitenVertices F 1afiqNoch keine Bewertungen

- Vertical Forces 4Dokument3 SeitenVertical Forces 4afiqNoch keine Bewertungen

- Vertical Forces 2Dokument2 SeitenVertical Forces 2afiqNoch keine Bewertungen

- Calculate propping force and overturning moments for retaining wallDokument2 SeitenCalculate propping force and overturning moments for retaining wallafiqNoch keine Bewertungen

- Calculating horizontal and vertical forces, moments and bearing pressure for retaining wallDokument2 SeitenCalculating horizontal and vertical forces, moments and bearing pressure for retaining wallafiqNoch keine Bewertungen

- Vertical F 1Dokument3 SeitenVertical F 1afiqNoch keine Bewertungen

- Vertical Forces 5Dokument3 SeitenVertical Forces 5afiqNoch keine Bewertungen

- Vertical Forces 5Dokument2 SeitenVertical Forces 5afiqNoch keine Bewertungen

- Vertical Forces 2Dokument2 SeitenVertical Forces 2afiqNoch keine Bewertungen

- Vertical Forces 2Dokument2 SeitenVertical Forces 2afiqNoch keine Bewertungen

- Vertical Forces 2Dokument2 SeitenVertical Forces 2afiqNoch keine Bewertungen

- Vertical Forces 2Dokument2 SeitenVertical Forces 2afiqNoch keine Bewertungen

- Vertical Forces 1Dokument2 SeitenVertical Forces 1afiqNoch keine Bewertungen

- DHPL Equipment Updated List Jan-22Dokument16 SeitenDHPL Equipment Updated List Jan-22jairamvhpNoch keine Bewertungen

- Distribution of Laptop (Ha-Meem Textiles Zone)Dokument3 SeitenDistribution of Laptop (Ha-Meem Textiles Zone)Begum Nazmun Nahar Juthi MozumderNoch keine Bewertungen

- Lorilie Muring ResumeDokument1 SeiteLorilie Muring ResumeEzekiel Jake Del MundoNoch keine Bewertungen

- Rebranding Brief TemplateDokument8 SeitenRebranding Brief TemplateRushiraj Patel100% (1)

- Flare Finance Ecosystem MapDokument1 SeiteFlare Finance Ecosystem MapEssence of ChaNoch keine Bewertungen

- 01-Azeotropic Distillation (IL Chien)Dokument35 Seiten01-Azeotropic Distillation (IL Chien)Shivam Vinoth100% (1)

- Corruption in PakistanDokument15 SeitenCorruption in PakistanklutzymeNoch keine Bewertungen

- Resume Ajeet KumarDokument2 SeitenResume Ajeet KumarEr Suraj KumarNoch keine Bewertungen

- Programme Report Light The SparkDokument17 SeitenProgramme Report Light The SparkAbhishek Mishra100% (1)

- 3 Intro To Ozone LaundryDokument5 Seiten3 Intro To Ozone LaundrynavnaNoch keine Bewertungen

- Qatar Airways E-ticket Receipt for Travel from Baghdad to AthensDokument1 SeiteQatar Airways E-ticket Receipt for Travel from Baghdad to Athensمحمد الشريفي mohammed alshareefiNoch keine Bewertungen

- MSBI Installation GuideDokument25 SeitenMSBI Installation GuideAmit SharmaNoch keine Bewertungen

- ITSCM Mindmap v4Dokument1 SeiteITSCM Mindmap v4Paul James BirchallNoch keine Bewertungen

- Fundamentals of Real Estate ManagementDokument1 SeiteFundamentals of Real Estate ManagementCharles Jiang100% (4)

- Mayor Byron Brown's 2019 State of The City SpeechDokument19 SeitenMayor Byron Brown's 2019 State of The City SpeechMichael McAndrewNoch keine Bewertungen

- Mba Assignment SampleDokument5 SeitenMba Assignment Sampleabdallah abdNoch keine Bewertungen

- Peter Wilkinson CV 1Dokument3 SeitenPeter Wilkinson CV 1larry3108Noch keine Bewertungen

- Taxation of interest income paid to foreign corporationsDokument1 SeiteTaxation of interest income paid to foreign corporationsCass CataloNoch keine Bewertungen

- ARMOR Winter-Spring 2018 EditionDokument84 SeitenARMOR Winter-Spring 2018 Editionmai100Noch keine Bewertungen

- KDL 23S2000Dokument82 SeitenKDL 23S2000Carlos SeguraNoch keine Bewertungen

- UW Computational-Finance & Risk Management Brochure Final 080613Dokument2 SeitenUW Computational-Finance & Risk Management Brochure Final 080613Rajel MokNoch keine Bewertungen

- Notes On Lesson: Faculty Name Code Subject Name CodeDokument108 SeitenNotes On Lesson: Faculty Name Code Subject Name CodeJeba ChristoNoch keine Bewertungen

- Aptio ™ Text Setup Environment (TSE) User ManualDokument42 SeitenAptio ™ Text Setup Environment (TSE) User Manualdhirender karkiNoch keine Bewertungen

- Introduction To Succession-1Dokument8 SeitenIntroduction To Succession-1amun dinNoch keine Bewertungen

- The Value of Repeat Biopsy in SLEDokument8 SeitenThe Value of Repeat Biopsy in SLESergio CerpaNoch keine Bewertungen

- TX Set 1 Income TaxDokument6 SeitenTX Set 1 Income TaxMarielle CastañedaNoch keine Bewertungen

- Biggest Lessons of 20 Years InvestingDokument227 SeitenBiggest Lessons of 20 Years InvestingRohi Shetty100% (5)

- Cib DC22692Dokument16 SeitenCib DC22692Ashutosh SharmaNoch keine Bewertungen

- Conplast SP430 0407Dokument4 SeitenConplast SP430 0407Harz IndNoch keine Bewertungen

- POS CAL SF No4 B2 BCF H300x300 7mmweld R0 PDFDokument23 SeitenPOS CAL SF No4 B2 BCF H300x300 7mmweld R0 PDFNguyễn Duy QuangNoch keine Bewertungen