Beruflich Dokumente

Kultur Dokumente

F3524gsi 7039 0710 PDF

Hochgeladen von

Mohamed Essam0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

264 Ansichten2 SeitenOriginaltitel

F3524GSI-7039-0710.pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

264 Ansichten2 SeitenF3524gsi 7039 0710 PDF

Hochgeladen von

Mohamed EssamCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

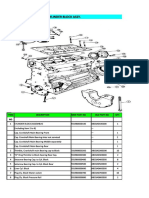

F3524GSI

VHP Series Four Gas Engine

560 - 840 BHP (418 - 627 kWb)

Specifications

Cylinders: Inline 6

Piston Displacement: 3520 cu. in.(58 L)

Bore & Stroke: 9.375 x 8.5 (238 x 216 mm)

Compression Ratio: 8:1

Jacket Water System Capacity: 48.5 gal. (184 L)

Lube Oil Capacity: 72 gal. (273 L)

Starting System: 125 - 150 psi air/gas 24V electric

Dry Weight: 15,000 lb. (6804 kg)

Image may not be an accurate

representation of this model

Standard Equipment

AIR CLEANER - Dry type with rain shield and service indicator. ENGINE ROTATION - Counterclockwise when facing flywheel.

AIR FUEL RATIO CONTROL (AFR) Integrated ESM AFR catalyst rich-burn EXHAUST OUTLET Single vertical at rear. Flexible stainless steel connection

control, main fuel gas regulator actuators, exhaust O2 sensor(s), and post with 6" (152 mm) pipe flange.

turbocharger exhaust thermocouple. Factory mounted and tested. AFR maintains FLYWHEEL - Approx. WR2 = 155000 lb-in2; with ring gear (208 teeth), machined

emissions through load and speed changes. The ESM AFR meets Canadian to accept two drive adapters: 31.88" (810 mm) pilot bore, 30.25" (768 mm) bolt

Standards Association Class 1, Division 2, Group A, B, C & D (Canada & US) circle, (12) 0.75"-10 tapped holes; or 28.88" (734 mm) pilot bore, 27.25" (692

hazardous location requirements. Note: For dual fuel applications, ESM AFR mm) bolt circle, (12) 0.625"-11 tapped holes and (12) 0.75"-10 tapped holes.

system will control the primary fuel source only. FLYWHEEL HOUSING - No. 00 SAE.

BARRING DEVICE - Manual. FUEL SYSTEM One natural gas, 4" (102 mm) updraft carburetors and one

BATTERY BOX - Designed to accommodate two series 31 12 VDC batteries. mounted Fisher 99, 2" (51 mm) gas regulator, 30-60 psi (207-414 kPa) fuel inlet

Includes power disconnect switch and 20 foot (6.1 m) cable for connection to pressure required. 10 foot (3 m) harness provided for ESM control of customer

ESM Power Distribution Box. supplied fuel shutoff valve.

BEARINGS - Heavy duty, replaceable, precision type. GOVERNOR - Electric throttle actuator controlled by ESM with throttle position

BREATHER - Closed system. feedback. Governor tuning is performed using ESP. ESM includes option of a load-

CONNECTING RODS - Drop forged steel, rifle drilled. coming feature to improve engine response to predictable step loads.

CONTROL SYSTEM - Waukesha Engine System Manager (ESM) integrates IGNITION SYSTEM - Ignition Power Module Diagnostics (IPM-D) - controlled by

spark timing control, speed governing, air/fuel ratio control, detonation protection, ESM, with spark timing optimized for varying speed-load conditions. Dual voltage

start-stop control, diagnostic tools, fault logging and engine safeties. The Engine energy levels automatically controlled by ESM to maximize spark plug life and

Control Unit (ECU) is the central brain of the control system and main customer improve starting. The diagnostics feature of ESM can be used to help monitor

interface. Connection to the ESM is via a 25 foot (7.6 m) harness to a local panel, spark plug life via predictive maintenance. Shielded ignition components meet

through MODBUS RTU slave RS-485 connection, and through the Electronic Canadian Standard Association Class 1, Division 2, Group A, B, C & D (Canada &

Service Program (ESP). Customer connections are only required to the local panel, US) hazardous location requirements.

fuel valve, and 24V DC power supply. Compatible with Woodward load sharing INTERCOOLER - Air-to-water.

module. ESM meets Canadian Standards Association Class I, Division 2, Group A, LEVELING BOLTS

B, C & D (Canada & US) hazardous location requirements. LIFTING EYES Requires 9.5 ton Working Load Limit (W.L.L. anchor shackles.

CRANKCASE - Integral crankcase and cylinder frame. Main bearing caps drilled LUBRICATION - Full pressure, gear type pump. Full flow lube oil filter, 20 gallon

and tapped for temperature sensors. Does not include sensors. (76 litres) capacity, with replaceable depth-type elements and flexible connections,

CRANKSHAFT - Forged steel, seven main bearings, counterweighted, and shipped loose. MICROSPIN bypass filter, engine mounted. Lube oil strainer,

dynamically balanced. mounted. Air/gas motor driven prelube pump, requires final piping.

CYLINDERS - Removable wet type bainitic cast iron cylinder liners, chrome plated MANIFOLD - Exhaust, water cooled.

on outer diameter. OIL COOLER - Shell and tube type with thermostatic temperature controller and

CYLINDER HEADS - Six interchangeable. Four valves per cylinder, with water pressure regulating valve. Mounted on left hand side.

cooled exhaust valve seats. Roller valve lifters and hydraulic push rods. Flange OIL PAN - Base type. 72 gallon (273 L) capacity including filter and cooler.

mounted ignition coils.

PAINT - Oilfield orange primer.

ELECTRONIC SERVICE PROGRAM (ESP) - Microsoft Windows-based

program provided on CD-ROM for programming and interface to ESM. Includes PISTONS - Aluminum with floating pin. Oil cooled. 8:1 compression ratio.

E-Help for troubleshooting any ESM faults. A serial cable is provided for SHIPPING SKID - For domestic truck or rail.

connection from a customer-supplied PC to the ECUs RS-232 port. TURBOCHARGER - (1) with water-cooled bearing housing and adjustable

ENGINE MONITORING DEVICES Factory mounted and wired sensors for lube wastegate.

oil pressure and temperature, intake manifold temperature and pressure, jacket VIBRATION DAMPER - Viscous type.

water temperature, and Exhaust O2 content, all accessible through ESM. ESM WATER CIRCULATING SYSTEM, AUXILIARY CIRCUIT - Belt driven water

continually monitors combustion performance through individual knock sensors circulating high capacity pump for intercooler and lube oil cooler. See S654319

to provide detonation protection. Dual magnetic pick-ups are used for accurate performance curve for use with standard 10" diameter crankshaft pulley.

engine speed monitoring. ESM provides advanced diagnostics of engine and all

WATER CIRCULATING SYSTEM, ENGINE JACKET - Belt driven water circulating

ESM sensors and logs any faults into non-volatile flash memory. Sensors meet

pump. Cluster type thermostatic temperature regulating valve, full flow bypass

Canadian Standards Association Class 1, Division 2, Group A, B, C, & D (Canada &

type with 165 - 170F (74 - 77C) start to open thermostats. ANSI 4" (102

US) hazardous location requirements.

mm) 125 psi flange connections on inlet and outlet.

POWER RATINGS: F3524GSI VHP Series Gas Engines

Brake Horsepower (kWb Output)

130F (54C) I.C. Water Temperature

1200 RPM 1000 RPM 900 RPM 800 RPM

Displ. cu.

Model C.R. Bore & Stroke in. (mm) in. (litres) C I C I C I C I

F3524GSI 8:1 9.375'' x 8.5'' (238 x 216) 3520 (58) 840 840 700 700 630 630 560 560

(626) (626) (522) (522) (470) (470) (418) (418)

1200 rpm 1000 rpm

Power bhp (kWb) 840 (626) 700 (522)

BSFC (LHV) Btu/bhp-hr (kJ/kWh) 7895 (11168) 7596 (10745)

Fuel Consumption Btu/hr x 1000 (kW) 6632 (1942) 5317 (1558)

NOx g/bhp-hr (mg/nm3 @ 5% O2) 15.60 (5857) 15.60 (5766)

Emissions

CO g/bhp-hr (mg/nm3 @ 5% O2) 12.80 (4743) 12.30 (4556)

THC g/bhp-hr (mg/nm3 @ 5% O2) 0.50 (222) 0.60 (227)

NMHC g/bhp-hr (mg/nm3 @ 5% O2) 0.15 (59) 0.16 (60)

Heat to Jacket Water Btu/hr x 1000 (kW) 2046 (600) 1655 (485)

Heat to Lube Oil Btu/hr x 1000 (kW) 297 (87) 239 (70)

Balance

Heat

Heat to Intercooler Btu/hr x 1000 (kW) 114 (33) 70 (21)

Heat to Radiation Btu/hr x 1000 (kW) 379 (111) 337 (99)

Total Exhaust Heat Btu/hr x 1000 (kW) 1905 (558) 1434 (420)

Induction Air Flow scfm (Nm3/hr) 1236 (1861) 991 (1492)

Exhaust

System

Intake/

Exhaust Flow lb/hr (kg/hr) 5752 (2608) 4612 (2092)

Exhaust Temperature F (C) 1196 (644) 1128 (609)

Typical heat data is shown, however no guarantee is expressed or implied. Consult your Dresser Waukesha Application Engineering Department for system

application assistance.

All natural gas engine ratings are based on a fuel of 900 Btu/ft3 (35.3 MJ/nm3) SLHV, with a 91 WKI. For conditions or fuels other than standard, consult the

Dresser Waukesha Application Engineering Department.

Data based on standard conditions of 77F (25C) ambient temperature, 29.53 inches Hg (100kPa) barometric pressure, 30% relative humidity (0.3 inches HG / 1

kPa water vapor pressure).

Fuel consumption based on ISO3046/1-1995 with a tolerance of +5% for commercial quality natural gas having a 900 BTU/ft3 (35.3 MJ/nm3) SLHV.

Heat data based on fuel consumption +2%.

Heat rejection based on cooling exhaust temperature to 77F (25C).

Rating Standard: All models - Ratings are based on ISO 3046/1-1986 with mechanical efficiency of 90% and Tcra (clause 10.1) as specified above limited to

10 F (5 C). Ratings are also valid for SAE J1349, BS5514, DIN6271 and AP17B-11C standard atmospheric conditions.

C = ISO Standard Power/Continuous Power Rating: The highest load and speed which can be applied 24 hours per day, seven days per week, 365 days

per year except for normal maintenance. It is permissible to operate the engine at up to 10% overload, or a maximum load indicated by the intermittent

rating, whichever is lower, for two hours in every 24 hour period.

I = Intermittent Service Rating: The highest load and speed that can be applied in variable speed mechanical system application only. Operation at this

rating is limited to a maximum of 3500 hours per year.

Consult your local Waukesha representative for system application assistance. The manufacturer reserves the right to change or modify without notice, the design or

equipment specifications as herein set forth without incurring any obligation either with respect to equipment previously sold or in the process of construction except

where otherwise specifically guaranteed by the manufacturer.

85.65"

(2175 mm)

Dresser, Inc.

Dresser Waukesha

1101 West St. Paul Avenue

Waukesha, WI 53188-4999

T. 262 547 3311

F. 262 549 2795

Bulletin 7039 0710

2010 Dresser, Inc. All rights reserved. Waukesha, VHP, ESM, Microspin, and WKI are

trademarks/registered trademarks of Dresser, Inc., Dresser Waukesha www.dresser.com/waukesha

Das könnte Ihnen auch gefallen

- 5 6215436109652951289Dokument37 Seiten5 6215436109652951289Kamrullah STNoch keine Bewertungen

- EFI Basics PDFDokument168 SeitenEFI Basics PDFgene_buckets100% (2)

- Maxxforce Advance Diezel Power PDFDokument114 SeitenMaxxforce Advance Diezel Power PDFPhạm Nhất100% (1)

- Marine Motor Notes Edition 2017 by Rajesh Singh GuliaDokument350 SeitenMarine Motor Notes Edition 2017 by Rajesh Singh GuliaMARINE GURUJI89% (9)

- Docslide - Us - Waukesha VHP Esm Manual PDFDokument221 SeitenDocslide - Us - Waukesha VHP Esm Manual PDFRandy Marzeind50% (2)

- Cat c18 GeneratorDokument8 SeitenCat c18 Generatorchaku1811100% (3)

- 3TNE68Dokument28 Seiten3TNE68Mohsen MoghadamNoch keine Bewertungen

- Waukesha L5794GSI SpecDokument2 SeitenWaukesha L5794GSI SpecPaulusIwan100% (3)

- Aerospace Engine DataDokument5 SeitenAerospace Engine DatapbonnetNoch keine Bewertungen

- CaterpilarDokument4 SeitenCaterpilarpangestu66100Noch keine Bewertungen

- Deutz BF6M 1013 Operation ManualDokument118 SeitenDeutz BF6M 1013 Operation ManualAlex HS96% (23)

- Ficha Técnica Engine Gas L7042GSI PDFDokument2 SeitenFicha Técnica Engine Gas L7042GSI PDFCamilo Sanchez VanegasNoch keine Bewertungen

- Caterpillar XQ2000 Containerized Diesel Generator SetDokument10 SeitenCaterpillar XQ2000 Containerized Diesel Generator SetMacAllister MachineryNoch keine Bewertungen

- L7042GL - Specification Data PDFDokument2 SeitenL7042GL - Specification Data PDFpedro perez Marin100% (1)

- Ignition Coils TypesDokument27 SeitenIgnition Coils TypesMohamed EssamNoch keine Bewertungen

- Leroy Somer - Voltage Regulator R450 Installation and MaintenanceDokument20 SeitenLeroy Somer - Voltage Regulator R450 Installation and MaintenanceMohamed Essam75% (4)

- Motores Waukesha L5790gsiDokument2 SeitenMotores Waukesha L5790gsiEdgar Castro67% (3)

- 12V275GL 1Dokument2 Seiten12V275GL 1Zailand R100% (1)

- F3521GLDokument2 SeitenF3521GLRose Marie100% (1)

- Fire Alarm Nfpa PDFDokument12 SeitenFire Alarm Nfpa PDFMohamed EssamNoch keine Bewertungen

- LF 162 FMJDokument27 SeitenLF 162 FMJMarcelo Assunção100% (3)

- VGF24GL GLD 8068 0710Dokument2 SeitenVGF24GL GLD 8068 0710npsNoch keine Bewertungen

- L36GL Data Sheet PDFDokument2 SeitenL36GL Data Sheet PDFManuel ValdiviesoNoch keine Bewertungen

- Operating Manual For Diesel Engines ABC Type 6/8/12/16DZC: GoedgekeurdDokument3 SeitenOperating Manual For Diesel Engines ABC Type 6/8/12/16DZC: GoedgekeurdCristian Ferchiu0% (1)

- 3512B 1500RPM 1300KW BrochureDokument4 Seiten3512B 1500RPM 1300KW BrochuresalembatopNoch keine Bewertungen

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesVon EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNoch keine Bewertungen

- G3512 SpecDokument4 SeitenG3512 SpecnunkpNoch keine Bewertungen

- Waukesha 12VAT27GLC Engine DataDokument4 SeitenWaukesha 12VAT27GLC Engine Datasopian320100% (1)

- 12V at 27 GLDokument4 Seiten12V at 27 GLMadhana GopalNoch keine Bewertungen

- L7044GSI: VHP Series Four Gas EngineDokument2 SeitenL7044GSI: VHP Series Four Gas EngineferyNoch keine Bewertungen

- B30D MkVI ADT - Nov '09Dokument738 SeitenB30D MkVI ADT - Nov '09BassieNoch keine Bewertungen

- 21 1 21 - UsDokument3 Seiten21 1 21 - UsMinaSaeed100% (1)

- Waukesha L7042 GSI SpécificationsDokument2 SeitenWaukesha L7042 GSI SpécificationssuptedNoch keine Bewertungen

- L7042gsi 7011 0710Dokument2 SeitenL7042gsi 7011 0710A2 BhaskarNoch keine Bewertungen

- F3514GSI: VHP Series Four Gas EngineDokument2 SeitenF3514GSI: VHP Series Four Gas EngineferyNoch keine Bewertungen

- ГПУ-VHP5904 dgsDokument2 SeitenГПУ-VHP5904 dgsBD MNNoch keine Bewertungen

- L7044gsi 7045 0710Dokument2 SeitenL7044gsi 7045 0710Martin Alejandro NievaNoch keine Bewertungen

- L5794gsi (E) pb7058-0905Dokument2 SeitenL5794gsi (E) pb7058-0905ikatparNoch keine Bewertungen

- Specifications: VHP5904LTDokument2 SeitenSpecifications: VHP5904LTmuhammad wafiNoch keine Bewertungen

- L7042GSI: VHP Series Gas Engine Extender SeriesDokument2 SeitenL7042GSI: VHP Series Gas Engine Extender SeriesferyNoch keine Bewertungen

- Compressor L7044GSI-7045 - 1210Dokument2 SeitenCompressor L7044GSI-7045 - 1210Dedy Chasan Aflah MutoharNoch keine Bewertungen

- VHP Series Four Gas Engine: Standard EquipmentDokument2 SeitenVHP Series Four Gas Engine: Standard EquipmentferyNoch keine Bewertungen

- VHP7104GSI/GSID: VHP Series Four Gas Enginator Generating System Featuring ESM TechnologyDokument2 SeitenVHP7104GSI/GSID: VHP Series Four Gas Enginator Generating System Featuring ESM TechnologyferyNoch keine Bewertungen

- VHP7104GSI/GSID: Basic SpecificationsDokument2 SeitenVHP7104GSI/GSID: Basic SpecificationsferyNoch keine Bewertungen

- VHP5904LT: Basic SpecificationsDokument2 SeitenVHP5904LT: Basic SpecificationsferyNoch keine Bewertungen

- VHP5904GSI/GSID: Basic SpecificationsDokument2 SeitenVHP5904GSI/GSID: Basic SpecificationsferyNoch keine Bewertungen

- ГПУ 16V275GL DgsDokument2 SeitenГПУ 16V275GL Dgsardhanteknik53Noch keine Bewertungen

- VHP5904LTD: Basic SpecificationsDokument2 SeitenVHP5904LTD: Basic SpecificationsferyNoch keine Bewertungen

- VHP Series Gas Engine: 366 - 515 BHP (273 - 384 KWB) 366 - 515 BHP (273 - 384 KWB)Dokument2 SeitenVHP Series Gas Engine: 366 - 515 BHP (273 - 384 KWB) 366 - 515 BHP (273 - 384 KWB)feryNoch keine Bewertungen

- VHP Series Gas Engine Extender Series: 886 - 1547 BHP (660 - 1154 KWB)Dokument2 SeitenVHP Series Gas Engine Extender Series: 886 - 1547 BHP (660 - 1154 KWB)feryNoch keine Bewertungen

- CAT Engine Specifications: G3512 LE Gas Petroleum EngineDokument4 SeitenCAT Engine Specifications: G3512 LE Gas Petroleum EngineJeff LNoch keine Bewertungen

- APG Series Gas Enginator Generating System Featuring ESM TechnologyDokument2 SeitenAPG Series Gas Enginator Generating System Featuring ESM TechnologyferyNoch keine Bewertungen

- Specifications: Standard EquipmentDokument2 SeitenSpecifications: Standard Equipmentardhanteknik53Noch keine Bewertungen

- CAT Engine Specifications: 3516B Offshore Generator SetDokument6 SeitenCAT Engine Specifications: 3516B Offshore Generator SetKarel GómezNoch keine Bewertungen

- Caterpillar RC1000 Containerized Diesel Generator SetDokument4 SeitenCaterpillar RC1000 Containerized Diesel Generator SetMacAllister MachineryNoch keine Bewertungen

- Especificaciones Motor Waukesha 9390Dokument2 SeitenEspecificaciones Motor Waukesha 9390joseantoniogoncorNoch keine Bewertungen

- Lehw0124 01Dokument6 SeitenLehw0124 01Hosam HamdyNoch keine Bewertungen

- Offshore SCR Power Module: FeaturesDokument4 SeitenOffshore SCR Power Module: FeaturesAmjadNoch keine Bewertungen

- 7044 Ops ManualDokument683 Seiten7044 Ops ManualsimjopaulNoch keine Bewertungen

- Cat C32 ACERT Spec Sheet - CommercialDokument13 SeitenCat C32 ACERT Spec Sheet - CommercialMario Godoy100% (1)

- Wauk 8lat27glDokument2 SeitenWauk 8lat27gljesseNoch keine Bewertungen

- (Lehw0191-00) 3512c (HD) Ataac With DGBDokument4 Seiten(Lehw0191-00) 3512c (HD) Ataac With DGBvictor.ciprianiNoch keine Bewertungen

- Cat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Dokument4 SeitenCat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Oghale B. E. OmuaborNoch keine Bewertungen

- Waukehsa P9390GSI - EspecificaçõesDokument2 SeitenWaukehsa P9390GSI - EspecificaçõesAlan SantosNoch keine Bewertungen

- Diesel Engines 12V 4000 M93/M93L: For Fast Vessels With Low Load Factors (1DS)Dokument2 SeitenDiesel Engines 12V 4000 M93/M93L: For Fast Vessels With Low Load Factors (1DS)cesarNoch keine Bewertungen

- XQ1000 Lehx0532Dokument6 SeitenXQ1000 Lehx0532Anonymous uZJfsg819LNoch keine Bewertungen

- C250D6Dokument4 SeitenC250D6Jose Javier Orellana ArmacanquiNoch keine Bewertungen

- G3520 Lehe2832 02 PDFDokument6 SeitenG3520 Lehe2832 02 PDFCostas Aggelidis100% (1)

- P9390gsi 7012 0710Dokument2 SeitenP9390gsi 7012 0710lutharmg2Noch keine Bewertungen

- EG 3P/EG 6P/EG 10P: ApplicationsDokument4 SeitenEG 3P/EG 6P/EG 10P: ApplicationsAseels PakNoch keine Bewertungen

- Cat C9 Genset Spec Sheet PDFDokument4 SeitenCat C9 Genset Spec Sheet PDFmartin_costalNoch keine Bewertungen

- GS JD 350Dokument7 SeitenGS JD 350Miguel Angel Pavon CarbonellNoch keine Bewertungen

- Generator CatalogeDokument2 SeitenGenerator CatalogeEngAhmedNoch keine Bewertungen

- Caterpillar XQ1250G Containerized Gas Generator SetDokument6 SeitenCaterpillar XQ1250G Containerized Gas Generator SetMacAllister MachineryNoch keine Bewertungen

- Exacta 21 - Midas Hmi Complete System - Control and Screens - 12-2-2014 - BPDokument48 SeitenExacta 21 - Midas Hmi Complete System - Control and Screens - 12-2-2014 - BPMohamed Essam0% (1)

- NCR (200-1) Code 326 W.O (1-2017) ReplyDokument3 SeitenNCR (200-1) Code 326 W.O (1-2017) ReplyMohamed EssamNoch keine Bewertungen

- MBS ASK en 1211Dokument55 SeitenMBS ASK en 1211Mohamed EssamNoch keine Bewertungen

- Quotation: Doc. Ref No: PH-IMS-SP 07-FR04 Revision / Issue:0/2 Date:1/12/2015Dokument6 SeitenQuotation: Doc. Ref No: PH-IMS-SP 07-FR04 Revision / Issue:0/2 Date:1/12/2015Mohamed EssamNoch keine Bewertungen

- Sensors and Electrical Connectors: TroubleshootingDokument7 SeitenSensors and Electrical Connectors: TroubleshootingManuel Ruiz CayunNoch keine Bewertungen

- Notice of Engine ModificationDokument10 SeitenNotice of Engine Modificationjuan manuelNoch keine Bewertungen

- F01 PowertrainDokument39 SeitenF01 PowertrainPhan VănNoch keine Bewertungen

- IO-320 Operator Manual 60297-31Dokument5 SeitenIO-320 Operator Manual 60297-31Josue Eleazar Guerrero DuranNoch keine Bewertungen

- 2013 Chevrolet Sail (B12 Manual Transmission)Dokument5 Seiten2013 Chevrolet Sail (B12 Manual Transmission)Joel LópezNoch keine Bewertungen

- 11OBDGS1 Engine DiagnosticsDokument59 Seiten11OBDGS1 Engine DiagnosticsMandy MoalemNoch keine Bewertungen

- Aircraft Propulsion Systems PDFDokument9 SeitenAircraft Propulsion Systems PDFsivasakthivellllllllNoch keine Bewertungen

- Carburetor - 2001 Outboard 75 (Elpt 4) 1f75412yn - Crowley MarineDokument23 SeitenCarburetor - 2001 Outboard 75 (Elpt 4) 1f75412yn - Crowley MarineJuan David Ricárdez PérezNoch keine Bewertungen

- Qdoc - Tips - Parts Catalogue Simpson EngineDokument50 SeitenQdoc - Tips - Parts Catalogue Simpson EngineabhilashNoch keine Bewertungen

- B21et Pea BOMDokument9 SeitenB21et Pea BOMvanapeerNoch keine Bewertungen

- Tumble Flap SwitchoverDokument1 SeiteTumble Flap SwitchoverMubariz MohamedNoch keine Bewertungen

- 7 9033 CDDokument2.694 Seiten7 9033 CDNil Acuña100% (2)

- 98 Exciter 135 SE EXS1200Dokument72 Seiten98 Exciter 135 SE EXS1200wilsonmoto15Noch keine Bewertungen

- Model: Frequency: Fuel Type:: Generator Set Data SheetDokument3 SeitenModel: Frequency: Fuel Type:: Generator Set Data SheetForesight MisrNoch keine Bewertungen

- Manual Operador IO540 SeriesDokument127 SeitenManual Operador IO540 SeriesyessikaNoch keine Bewertungen

- Chain Saw GuideDokument22 SeitenChain Saw GuideJoanne MowatNoch keine Bewertungen

- CT201 - Motor Greasing Rev1Dokument1 SeiteCT201 - Motor Greasing Rev1ahmad shahnonNoch keine Bewertungen

- Screenshot 2023-09-13 at 9.46.16 AMDokument203 SeitenScreenshot 2023-09-13 at 9.46.16 AMshanehaynes75Noch keine Bewertungen

- Epa Fr92129QSL9G5Dokument1 SeiteEpa Fr92129QSL9G5acere18Noch keine Bewertungen