Beruflich Dokumente

Kultur Dokumente

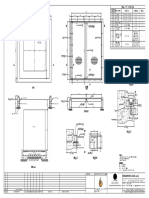

Shear Box

Hochgeladen von

sridharCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Shear Box

Hochgeladen von

sridharCopyright:

Verfügbare Formate

SOIL MECHANICS LABORATORY

8. Direct Shear Small Shearbox (Ref BS 1377 1991 Part 7)

1. Objective

To determine the relationship between measured shear stress at failure and normal applied stress.

2. Principles

In the direct shear test a square prism of soil is laterally restrained and sheared along a mechanically induced

horizontal plane while subjected to a pressure applied normal to that plane. The shearing resistance offered by the

soil as one portion is made to slide on the other is measured at regular intervals of displacement. Failure occurs

when the shearing resistance reaches the maximum value which the soil can sustain.

The small shearbox apparatus is designed for carrying out undrained tests of this kind on soil specimens of 60 mm

or 100 mm square and 20 mm to 25 mm high.

Test data enable the effective shear strength parameters c and to be derived.

3 Procedure

3.1 Apparatus

a) A container for the specimen (the shearbox) which is square in plan and divided horizontally into two halves.

b) An outer container (the carriage) in which the shearbox can be placed to enable the test specimen to be

submerged under water during the test (if required).

d) Two perforated spacer plates of about the same size in plan as the porous plates, if necessary.

e) A loading cap to cover the top spacer plate or porous plate, fitted with a central ball seating through which

vertical load is applied to the specimen.

f) A calibrated means of applying a vertical force to the loading cap such as a loading yoke.

g) A motorized loading device capable of applying horizontal shear to the vertically loaded specimen at constant

rates of displacement and capable of applying a horizontal displacement to the specimen of at least 8 mm.

h) A calibrated force-measuring device, suitably

mounted.

i) A calibrated dial gauge or displacement transducer suitably mounted to measure the relative horizontal

displacement of the two halves of the shearbox.

j) A calibrated dial gauge or displacement transducer capable of measuring the vertical deformation of the specimen

during the test, readable to 0.002 mm.

Calibrated vernier external/internal caliper for measuring the internal dimensions and height of the cutting ring or

test specimen to 0.1 mm.

Calibrated vernier depth-gauge or a micrometer gauge on a suitable comparator support for measuring the depth to

the top of the specimen when in the shearbox, and the projection of the top cap, to an accuracy of 0.1 mm.

3.2 Checking and preparation of apparatus

Determine and record the mass of the cutter to 0.01 g. Determine the mass of the tray or watch glass to 0.01 g.

Verify and record the mean internal dimensions of the cutter to 0.1 mm.

Ensure that the shearbox components are clean and dry. Clamp the two halves of the box securely together with the

clamping screws, fit the baseplate and assemble the shearbox securely in the carriage.

Determine the internal plan dimensions (L1 L2) of the shearbox to 0.1 mm, and calculate the plan area A (in mm2).

Determine the mean depth from the top surface of the upper half to the top of the baseplate (h1) to 0.1 mm.

Measure and record the thickness of each porous plate and spacer plate to 0.1 mm. Determine the combined

thickness of plates to be used for the test (tp).

Preparation and assembly of shearbox: Assemble the shearbox with two halves securely clamped together, fit the

baseplate andplace it securely in position in the carriage.

Place a spacer plate on the base of the box if necessary, followed by a porous plate.

Preparation of specimen: Specimens of either cohesive or non-cohesive soil may be tested in the shearbox.

Preparation procedures depend on the type of soil. The size of the largest particle shall not exceed one-tenth of the

height of the specimen. A non-cohesive sample shall be large enough to provide three separate specimens to avoid

having to re-use the same material.

3.3 Preparation of specimen of cohesionless soil:

The procedure depends on whether the soil is dry and can be poured, or damp and needs to be tamped, or saturated.

Dry sand, loose: Prepare a quantity of soil somewhat larger than that required for the test specimen, as and

determine its mass to 0.1 g.

Place or pour the sand directly into the assembled shearbox from the quantity of known

mass.

07/03/2016 jpm 08 Shearbox

NOTE A loose density is often achieved by rapid pouring from a small height.

Level the surface of the specimen using a suitable template.

Collect any spilled or removed material, weigh the total of the unused soil to 0.1 g and determine the initial mass of

the specimen (mo) by difference.

Place the porous plate on the specimen. Gently bed down the plate to form a level surface, ensuring there is a

uniform clearance all round.

Measure the distance from the top of the shearbox to the top surface of the plate, to 0.1 mm (h2).

Place the top spacer plate (if necessary) and the loading cap carefully on top of the porous plate, with a uniform

clearance all round.

3.4 Test procedure

Position the carriage on its bearings on the machine bed, and adjust the drive unit to the correct starting point of the

shear test. Secure the horizontal displacement gauge in position.

Measure the height of the top of the load cap above the top of the box (h3) to 0.1 mm.

Assemble the loading system so that the loading yoke is supported by the ball seating on top of the load cap.

Measure the height of the top of the load cap above the top of the box again (h4) to 0.1 mm. The difference (h3 h4)

gives the settlement of the specimen under the seating pressure provided by the loading yoke.

Secure the vertical deformation gauge in position so that it can measure the vertical movement of the centre of the

loading cap, ensuring that it allows enough movement in either direction.

Record the initial zero reading.

Consolidation: Apply a normal force to the specimen, to give the desired vertical (normal) stress, n (in kPa),

smoothly and as rapidly as possible without jolting. Start the clock at the same instant if consolidation

readings are significant.

NOTE Dry sand or free-draining saturated sand consolidates very rapidly, therefore consolidation readings are not

necessary and a rapid test is suitable.

For a rapid test in which consolidation takes place very rapidly, the rate of displacement should induce failure

within a period of 5 min to 10 min. A constant rate of 1mm per min is acceptable.

Ensure that all adjacent components from the constant rate of displacement device through to the load measuring

device and its point of restraint are properly in contact, but under zero horizontal load.

Remove the clamping screws which lock the two halves of the shearbox together.

Raise the upper half of the box, keeping it level, by turning the lifting screws. The amount of clearance between the

two halves should be enough to prevent them coming together during the test, but shall not permit extrusion of the

soil between them.

Record the initial readings of the horizontal displacement gauge, the vertical deformation gauge and the force

measuring device.

Shearing: single stage tests (form 7(c)).

Start the test and at the same instant start the timer. Record readings of the force measuring device, the horizontal

displacement gauge, the vertical deformation gauge and elapsed time, at regular intervals of horizontal displacement

such that at least 20 readings are taken up to the maximum load (peak shear strength). Readings of force and

displacement at 15 sec intervals may be taken.

Continue shearing and taking readings beyond the maximum force, or until the full travel of the apparatus has been

reached if there is no defined peak, then stop the test.

Reverse the direction of travel of the carriage and return the two halves of the shearbox to their original alignment.

Remove the vertical force and loading yoke from the specimen.

Transfer the specimen from the shearbox to a small tray, taking care not to lose any soil.

Weigh the specimen on the tray to 0.1 g.

3.5 Calculations and plotting

Form 7(a) of Appendix A.

m0 m d

Calculate the initial moisture content, wo (in %) if necessary, from the equation: w0 = x100

md

Where m0 = initial mass of specimen (in g), md = final mass of dry soil (in g)

md x1000

Calculate the initial dry density, d (in Mg/m3) from the equation: d =

AH 0

Where A is the plan area of the specimen (in mm2); Ho is the initial height of the specimen (in mm).

For a disturbed specimen formed in the shearbox, H0 is calculated from h1, h2 and the appropriate plate thickness tp

Stresses and displacements: From each set of data obtained during the shear test calculate the horizontal shear force,

P (in N), applied to the specimen.

P

Calculate the shear stress, (in kPa), for each set of readings from the equation: = x1000

A

9810m

Calculate the normal stress, n, (in kPa), applied to the specimen from the equation: n =

A

2 08 Shearbox jpm 07/03/2016

Where m is the mass of the hanger and hanger weights (or equivalent mass if a lever-arm loading system is used)

applied to the loading cap (in kg).

Graphical plots: form 7(d) For each specimen of a set of single-stage tests, plot the following graphs.

a) Shear stress (in kPa) as ordinates against horizontal displacement (in mm) as abscissae.

b) Change in height (vertical deformation) of the specimen (in mm) as ordinates against horizontal

displacement (in mm) as abscissae, if required.

c) From each stress-displacement graph read off the value of the maximum shear stress (the peak strength) and

the corresponding horizontal displacement and change in specimen height.

d) Plot each value of peak strength, f (in kPa), as ordinates against the corresponding normal stress, n (in kPa)

applied for that test as abscissae, both to the same linear scale.

e) If it can be assumed that the relationship is linear, the slope of the line and its intercept with the shear strength

axis can be derived from the line of best fit through the plotted points. The slope gives the angle of shearing

resistance (in degrees), and the intercept gives the apparent cohesion c (in kPa), both in terms of effective

stress.

3 Report

Forms 7 (a), 7(c) and 7(d) may be used

3 08 Shearbox jpm 07/03/2016

4 08 Shearbox jpm 07/03/2016

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Create Keygen YourselfDokument1 SeiteCreate Keygen YourselfKaali PutraNoch keine Bewertungen

- Connection Design ExamplesDokument81 SeitenConnection Design ExamplesAlo100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Connection Design For UPN 240Dokument20 SeitenConnection Design For UPN 240sridharNoch keine Bewertungen

- Connection Design For UPN 240Dokument20 SeitenConnection Design For UPN 240sridharNoch keine Bewertungen

- Metric and Inch (Sae) Fasteners: All ModelsDokument22 SeitenMetric and Inch (Sae) Fasteners: All ModelsLenin100% (1)

- Design Calculations of Hvac SystemDokument168 SeitenDesign Calculations of Hvac SystemMohamedAhmedFawzy100% (3)

- Hydrotesting Quad Joint PipesDokument15 SeitenHydrotesting Quad Joint PipesTrust EmmaNoch keine Bewertungen

- LTE Network Issue Analysis Guideline V1Dokument29 SeitenLTE Network Issue Analysis Guideline V1Amir Miftahudin100% (1)

- Grove-GMK7550 Product GuideDokument56 SeitenGrove-GMK7550 Product GuideabguyNoch keine Bewertungen

- Zelio Logic RelaysDokument16 SeitenZelio Logic Relayswww.otomasyonegitimi.comNoch keine Bewertungen

- Toyota Multiplex ResistanceDokument21 SeitenToyota Multiplex ResistanceYdelkadiasmela Dominguezmorel100% (4)

- Design of Rectangular Column Section by Limit-State MethodDokument44 SeitenDesign of Rectangular Column Section by Limit-State Methodsridhar100% (1)

- Sample - Pipe Support - 1Dokument4 SeitenSample - Pipe Support - 1sridharNoch keine Bewertungen

- RC Column DesignDokument1 SeiteRC Column DesignsridharNoch keine Bewertungen

- Concrele Products: Available in OPC & SRCDokument2 SeitenConcrele Products: Available in OPC & SRCsridharNoch keine Bewertungen

- LoadingDokument2 SeitenLoadingsridharNoch keine Bewertungen

- 8 INH Solid-July17Dokument1 Seite8 INH Solid-July17sridharNoch keine Bewertungen

- 3D ViewDokument4 Seiten3D ViewsridharNoch keine Bewertungen

- Pipe Rack Status 09032022Dokument1 SeitePipe Rack Status 09032022sridharNoch keine Bewertungen

- Load Calc - Pipe SupportsDokument3 SeitenLoad Calc - Pipe SupportssridharNoch keine Bewertungen

- UES - Weld Bending Stress CalculationDokument3 SeitenUES - Weld Bending Stress CalculationsridharNoch keine Bewertungen

- 6INCH Solid-AugDokument1 Seite6INCH Solid-AugsridharNoch keine Bewertungen

- 8INH BC-JulyDokument1 Seite8INH BC-JulysridharNoch keine Bewertungen

- 4 INH Hollow-July PDFDokument1 Seite4 INH Hollow-July PDFsridharNoch keine Bewertungen

- 4 INH Solid-July17Dokument1 Seite4 INH Solid-July17sridharNoch keine Bewertungen

- Water Absor-8 INH-BC - JulyDokument1 SeiteWater Absor-8 INH-BC - JulysridharNoch keine Bewertungen

- 6 INH Hollow-JulyDokument1 Seite6 INH Hollow-JulysridharNoch keine Bewertungen

- Light Weight Blk-CatalogueDokument2 SeitenLight Weight Blk-CataloguesridharNoch keine Bewertungen

- Kerbstone CatalogueDokument1 SeiteKerbstone CataloguesridharNoch keine Bewertungen

- 6INCH Solid-AugDokument1 Seite6INCH Solid-AugsridharNoch keine Bewertungen

- HourdiDokument1 SeiteHourdisridharNoch keine Bewertungen

- Oman Oil Company Exploration & ProductionDokument2 SeitenOman Oil Company Exploration & ProductionsridharNoch keine Bewertungen

- Cavity Block Thermal and Acoustic Insulation SpecificationsDokument2 SeitenCavity Block Thermal and Acoustic Insulation SpecificationssridharNoch keine Bewertungen

- 4 INH Hollow-JulyDokument1 Seite4 INH Hollow-JulysridharNoch keine Bewertungen

- 8INH BC-JulyDokument1 Seite8INH BC-JulysridharNoch keine Bewertungen

- Diesel Tank Bund Wall DRGDokument1 SeiteDiesel Tank Bund Wall DRGsridhar100% (2)

- 502-Propane Sub Cooler Skid Foundation CalculationDokument14 Seiten502-Propane Sub Cooler Skid Foundation CalculationsridharNoch keine Bewertungen

- Ds of Back Pressure Valve (GF) - Brine Pump DischargeDokument17 SeitenDs of Back Pressure Valve (GF) - Brine Pump DischargesridharNoch keine Bewertungen

- 090.040-CS - Quantum HD 2015-09 PDFDokument116 Seiten090.040-CS - Quantum HD 2015-09 PDFrobert_barnette_eco100% (1)

- Fix276 (3) TradeDokument115 SeitenFix276 (3) TradeaiilnwwcyxewmskahnNoch keine Bewertungen

- OSHA Regulation on Storing and Handling Compressed Gas CylindersDokument9 SeitenOSHA Regulation on Storing and Handling Compressed Gas CylindersLaylla SilvaNoch keine Bewertungen

- API GravityDokument1 SeiteAPI Gravityscribd_thakurNoch keine Bewertungen

- TeSys GV3 - GV3P18 PDFDokument2 SeitenTeSys GV3 - GV3P18 PDFtomtom56Noch keine Bewertungen

- Examen Dell Networking Series Switches V PDFDokument30 SeitenExamen Dell Networking Series Switches V PDFJulio Cesar Agudelo BenitezNoch keine Bewertungen

- Appraisal Form TemplateDokument7 SeitenAppraisal Form TemplateShilpa PandeyNoch keine Bewertungen

- 1400p ManualDokument21 Seiten1400p ManualrugerNoch keine Bewertungen

- Electrical Load Estimation - Part One Electrical KnowhowDokument9 SeitenElectrical Load Estimation - Part One Electrical KnowhowRon NombriNoch keine Bewertungen

- Configure and Organize Cash Budget ManagementDokument23 SeitenConfigure and Organize Cash Budget ManagementEric CostaNoch keine Bewertungen

- 7000 118-363, C1, R5 SUPREME AIS Installation Short InstructionDokument4 Seiten7000 118-363, C1, R5 SUPREME AIS Installation Short Instructionchefradio CFCARTHAGENoch keine Bewertungen

- Experienced DGM seeks senior roleDokument5 SeitenExperienced DGM seeks senior rolekavas26Noch keine Bewertungen

- 7607 TRX Operation DegradedDokument95 Seiten7607 TRX Operation DegradedGovindaraju HSNoch keine Bewertungen

- Minggu 4 - JavascriptDokument58 SeitenMinggu 4 - Javascriptcikiaaulia anisNoch keine Bewertungen

- FIREGUARD Foam - Chamber - FCADokument6 SeitenFIREGUARD Foam - Chamber - FCAEdward Chan AcostaNoch keine Bewertungen

- BOM Interfaces - White PaperDokument23 SeitenBOM Interfaces - White PapersreeharireddylNoch keine Bewertungen

- Vtu Tea-1 J2EE Notes Ch-3Dokument17 SeitenVtu Tea-1 J2EE Notes Ch-3junaidnizNoch keine Bewertungen

- Changeover Switches: General Catalogue 2011-2012Dokument4 SeitenChangeover Switches: General Catalogue 2011-2012Yanuar ZulkarnainNoch keine Bewertungen

- Care Your HornDokument8 SeitenCare Your HornAlvaro Suarez VazquezNoch keine Bewertungen

- Nor GrenDokument4 SeitenNor GrenefrenNoch keine Bewertungen

- JVC KD-SD631 Manuel D'utilisationDokument42 SeitenJVC KD-SD631 Manuel D'utilisationteuiragNoch keine Bewertungen

- Classified: Your Local MarketplaceDokument4 SeitenClassified: Your Local MarketplaceDigital MediaNoch keine Bewertungen