Beruflich Dokumente

Kultur Dokumente

M17 01

Hochgeladen von

Aya DPrado0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

169 Ansichten14 Seiteneasa m17

Originaltitel

M17-01

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldeneasa m17

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

169 Ansichten14 SeitenM17 01

Hochgeladen von

Aya DPradoeasa m17

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 14

M17 conversion

1. Blade angle definition: >

The angle between Rotary plan and chord line.

2. Blade tipping: prevent impact damage.

3. Fixed pitch propeller blade angle: >

High cruising.

Low T/O approach.

4. Propeller de-icing overshoe element open circuit what should be done:

Replace element.

5. Propeller L/E blade found micro crack: blending & crack check.

6. Two position propeller when oil pressure loss: coarse.

7. AOA with relation to what:

A. Vo; RPM

B. Va; RPM; .

8. Feather oil from feather reverse form ENG oil.

9. AOA constant blade twist. >

10. Blade angle decrease from root to tip. >

11. CTM fine pitch. >

12. Hub belong to which part:

A. ENG.

B. Propeller.

C. Airframe.

13. Step down from ENG to propeller: epicyclic gear.

14. Horizontal balancing of wooden blade by lead to the tip of propeller.

15. When windmilling:

A. AOA increase, torque increase.

B. AOA increase, torque decrease.

C. AOA decrease, torque decrease.

16. Slip definition: The difference between Geometry pitch and Effective pitch. >

17. Hydraulic pitch change mechanism type : >

A. Piston can moving cylinder fix. *

B. Cylinder can moving piston fix.

C. Either of above.

M17 Propeller practice

1. What is the gyroscopic effect on a clockwise rotating propeller (view from the cockpit) on a

right hand turn? >

A. tail will tend to move to the left.

B. Tail will tend to drop.

C. Nose will tend to drop. *

2. The gear segments on the blade roots of a hydromatic propeller mesh with: >

A. the moving cam. *

B. The spider arms.

C. The pitch change mechanism piston.

3. Individual propeller blade indexing is the:

A. initial balancing of one blade against another before initial assembly.

B. Fine adjustment in minutes of one or more propeller blades to bring all blades within the

same degree of similarity. *

C. Final static balancing of the propeller.

4. Repair on a propeller blade shank:

A. must not exceed 0.025 of the blade thickness.

B. Must not exceed 0.025 of the blade width.

C. Are not permitted. *

5. Removal of material from propeller blade tips resulting in reduction of propeller diameter is

known as:

A. cropping. *

B. shedding.

C. Tipping.

6. The aerodynamic and centrifugal turning moments on a propeller act in the same direction:

A. at takeoff.

B. At idling.

C. When the propeller is windmilling in a steep dive. *

7. The angle between the resultant airflow direction and the propeller blade plane of rotation is

known as the: >

A. angle of attack.

B. Helix angle. *

C. Blade angle.

8. A propeller is centralized on the propeller on the propeller shaft by: >

A. front and rear cones. *

B. the spider shims.

C. The preload shims.

9. The distance a propeller moves forward in one revolution when it is giving no thrust is known

as:

A. the experimental mean pitch. *

B. geometric pitch.

C. The slip.

10. The maximum efficiency of a propeller occurs at approximately: >

A. 2000 knots.

B. 350 knots ( 450 mph). *

C. 459 knots.

11. Negative torque control is a method of: >

A. suppressing windmilling propeller drag prior to feathering. *

B. Controlling reversed thrust.

C. Economizing on fuel consumption during cruise conditions.

12. Blending of propeller blade defects refers to the:

A. repainting of blade tips after cropping.

B. Matching of external blade finish.

C. Conversion of sharp edges into smooth curves. *

13. A badly frayed propeller spinner chafing ring:

A. necessitates a spinner.

B. Should be replaced. *

C. Can be left fitted if the spinner rivets have not pulled.

14. If any given propeller blade on an aircraft is in the same relative position as the corresponding

master engine propeller blade, the engines are said to be:

A. Synchronised

B. Synchrophased. *

C. Syncoplated.

15. Individual blade indexing on a hydromatic propeller can be affected by adjusting with the:

A. coarse and fine pitch stop rings.

B. Lead wool in the blade roots. *

C. Gear segment and bush flange.

16. Under normal operation, the point of maximum strain on a propeller blade is at the: >

A. root. *

B. tip.

C. Master station.

17. The thrust of a propeller is normally taken by the : >

A. Propeller rear cone.

B. Torque motor.

C. Front bearing in the reduction gear. *

18. The face of a propeller blade is the: >

A. rear face or flat side. *

B. front face or curved side.

C. Root to which the gear segment is fitted.

19. When checking a propeller shaft for shock loading, the distortion of the shaft is:

A. half the DTI reading. *

B. the DTI reading.

C. Twice the DTI reading.

20. When propeller blades move from reverse pitch to normal they move: >

A. Through coarse pitch.

B. Through fine pitch. *

C. Through feathered pitch.

21. Blade stations on a propeller are measured from: >

A. hub center to blade tip. *

B. blade tip to hub center.

C. Shank to blade tip.

22. Propeller efficiency varies from : >

A. Thrust horsepower over brake horsepower. *

B. Initial horsepower over thrust horsepower.

C. Brake horsepower over thrust horsepower.

23. Propeller slip is the difference between: >

A. collective pitch and effective pitch.

B. Fine pitch and coarse pitch.

C. Geometric pitch and effective pitch. *

24. Small holes near the blade tip in metal tipping on wooden propellers: >

A. allow moisture to drain away. *

B. prevent static electricity.

C. Allow for expansion.

25. The front cone is used on some propellers >

A. as an oil line from the reduction gear to the propeller

B. as a propeller shaft seal

C. to pull the propeller from the shaft *

26. A McCauley 1B90/CM/71/44 propeller has a diameter of

A. 90 in.

B. 71 in. *

C. 44 in.

27. A McCauley 1B90/CM/71/44 propeller has a blade angle at master station

A. 90.

B. 71.

C. 44. *

28. Constant speed propellers with counterweights on the blade clamps use centrifugal force to >

A. increase blade angle *

B. decrease blade angle

C. prevent flutter

29. Centrifugally operated high-pitch stops on some Hartzell propellers

A. prevent the propeller going into coarse pitch in the event of oil failure

B. prevent the propeller feathering when the engine is stopped on the ground *

C. stop windmilling on the ground on free turbine engine

30. The flywheels in a propeller control unit primarily

A. regulate the operating pressures

B. actuate a relief valve

C. actuate a pilot valve *

31. The spring above the rack in a propeller control unit primarily

A. gives cruising rev/min in case of control failure *

B. makes for case of operation in the aircraft cabin

C. dampens pilot valve action

32. The advantage of phosphate compounds over isopropyl alcohol as propeller anti-icing fluids is

>

A. low cost

B. reduced flammability *

C. much better anti-icing properties

33. A knife-edge can be used to check propeller

A. static balance *

B. dynamic balance

C. aerodynamic balance

34. The non-governing or taxi range (reverse to flight idle position) on a trubo-prop assembly is

known as

A. the alpha range

B. the beta range *

C. the delta range

35. A negative torque signal control system provides a signal which

A. increase blade angle *

B. decrease blade angle

C. blade angle keeps constant

36. A thrust sensitive signal is a safety feature which, if a power loss is experienced during takeoff

A. increase blade angle and cause the propeller to feather *

B. increases blade angle only

C. decrease blade angle only

37. If the turbo-prop engine is unable to reach maximum controlled speed of 100%

A. the oil reservoir could be overfilled

B. the fuel control cut off valve could be closed

C. the propeller governor could be fault *

38. If the turbo-prop engine fails to start and the propeller brake is found to be locked

A. the brake could be unlocked by hand turning the propeller in its normal direction

B. the propeller should be removed and blade similarity checked

C. the starter should be replaced *

39. If vibration indication is high on a turbo-prop engine the first action is to

A. check the propeller retaining nut

B. check the bearing nuts and bolts

C. calibrate the vibration meter *

40. The performance of a turbo-prop engine is measured in >

A. Newton

B. Propeller shaft horsepower *

C. Thrust

41. The propeller efficiency of a turbo-prop engine is higher than that of a pure jet at aircraft

speed >

A. below approximately 450 miles per hour *

B. above approximately 450 miles per hour

C. from 450 miles per hour to 650 miles per hour

42. The function of reduction gear of a propeller is >

A. step-up from engine RPM

B. step-down from engine RPM *

C. same RPM as engine

43. One element is open circuit on the de-icing overshoes >

A. change a new overshoe *

B. repair the damaged element

C. renew the damaged element

44. Torque meter measures >

A. thrust of engine

B. shaft horsepower of engine *

C. velocity of engine

45. Frequency of propeller vibration >

A. higher than that of turbine

B. lower than that of turbine *

C. same as that of turbine

46. Shock Load Test >

A. check the face of shaft

B. check the diameter of shaft

C. check the concentricity *

47. In a single acting propeller pitch change mechanism, the blade angle is increases by >

A. oil pressure

B. centrifugal twisting moment

C. aerodynamic twisting moment *

48. A Hydromatic propeller converts linear movement to rotary movements using a >

A. lever assembly

B. rack and pinion

C. cam and gear assembly *

49. The function of a hydraulic mechanical pitch lock is to prevent the propeller from

A. fining off *

B. coarsening

C. reducing below flight fine pitch

50. The minimum propeller pitch is established by the

A. Flight Fine pitch stop

B. Superfine pitch stop *

C. Pitch stop

51. Oil for the Feathering system is taken from

A. a feathering reverse in the engine oil tank *

B. a separate feathering oil tank

C. the engine lubricating system

52. What lubricant is used on the front and rear cones >

A. engine oil

B. none *

C. mineral jelly

53. A series of indentations on a propeller blades

A. should be blended into one smooth depression *

B. can be considered negligible if the maximum depth is not exceeded

C. would render the propeller unserviceable

54. Blending out damage on a propeller blade

A. prevents corrosion

B. restores aerodynamic efficiency

C. prevent stresses being set up by the damage *

55. Before the propeller dome is fitted the blade positions will

A. have to be set correctly

B. be unimportant because the blades will align themselves

C. prevent fitment of the dome if incorrect *

56. When repairing the leading edge of a propeller blade the length of blend should be

A. 10 x depth of blend *

B. 20 x depth of blend

C. 30 x depth of blend

57. If a propeller exceeds its overspeed limits

A. an in situ check is carried out

B. the propeller is removed for inspection *

C. no action is necessary if the overspeed is of short duration

58. The aerodynamic balancing of a propeller is carried out

A. with lead wool or washers

B. by setting the blade angle coarse or fine from the datum *

C. by rotating the blade relative to a fixed pointer

59. How are blades stations designated? >

A. measured in inches from the hub *

B. measured in inches from the tip

C. percentage of blade length

60. Reduction in section thickness by blade reworking must not exceed

A. 20%

B. 25% *

C. 30%

61. In which direction must a blend to the blade face side be made

A. longitudinally *

B. chordwise

C. diagonally

62. Propeller blades are deiced by >

A. electric heating elements wound around the blade root

B. electric heating elements in rubber overshoes on the leading edge of the blades *

C. generating eddy currents in the blades

63. Propeller slip rings >

A. convey oil from pitch control unit to pitch change mechanism

B. minimize slip

C. conduct electrical power for deicing *

64. Electrical power supplies for the propeller deicing are >

A. AC *

B. DC

C. Both AC and DC

65. How can the propeller deicing be varied to suit different rates of icing >

A. increased voltage

B. speed of cycle can be changed *

C. changing propeller speed

66. A reduction gear >

A. allows the propeller to rotate at a lower speed than the engine *

B. reduces the difference between engine and propeller speeds

C. prevents propeller overspeeding

67. What types of reduction gear is used on a turbo propeller engine

A. epicyclic gear *

B. dog tooth gear

C. mesh gear

68. The oil used in the torquemeter system of turbo propeller is

A. DTD 585

B. Pitch control unit oil pressure

C. Engine oil boosted by pump driven off the reduction gear *

69. What is the range of travel of a constant speed propeller?

A. 15 degrees

B. 20 degrees *

C. 30 degrees

70. Before you tighten the ring clamps on an adjustable pitch propeller, what is the last thing you

do?

A. clean all surfaces with oil

B. turn the blades out while tightening the ring clamps *

C. check to see that hub splines are lined up

71. On what part of the propeller is the most stress imposed?

A. on the tips

B. on the hub *

C. on the leading edge

72. What is the meaning of propeller trak?

A. the plane of rotation

B. the path of the propeller blade tip *

C. the distance forward during one revolution

73. The breather of a hydromatic propeller is for the purpose of

A. relieving internal pressure in the engine *

B. acting as a safety valve for extremely high oil pressure

C. preventing air pressure from building up

74. A fixed pitch propeller is more efficient than an adjustable pitch propeller because

A. graduated pitch

B. lighter weight *

C. better cruising performance

75. In the event that the speeder spring in a controllable pitch unit breaks it will cause

A. pressure from the engine oil system to flow past the booster pump

B. the propeller to stay in low pitch

C. the propeller to go in high pitch *

76. The final balancing of metal propeller is obtained by

A. grinding down the tip of the heavy blade with a fine emery wheel

B. inserting lead wool in the concentric holes *

C. paint red and yellow on the light blade at tip

77. A three-way valve is incorporated in a controllable pitch propeller to

A. force oil from the tank to the booster pump

B. relieve scavenger pressure build up

C. direct oil under pressure to the cylinder *

78. When a wooden propeller is put in storage for any length of time it is placed?

A. in a longitudinal position

B. in a horizontal position *

C. packed in special covering

79. How is the horizontal balance of an adjustable propeller obtained?

A. file heavy blade tips with a fine file

B. add adjusting washers to clamp ting bolt

C. add lead wool to the concentric hole *

D. shift clamp ring until balance is obtained

80. Why do you place the propeller in low pitch for the take-off >

A. to keep the engine cool during the take-off

B. in order to obtain maximum horsepower *

C. not a true statement for all types

81. How do you remove a dent from the edge of a steel propeller

A. grind it out with an emery wheel

B. fill with solder and polish off

C. file to a smooth curve and polish (use ruffle file and crocus cloth) *

82. How do you track a wooden blade, if out of track? >

A. add shims to the hub plate

B. cannot be repaired reject it

C. place shims to the rear of hub, between the hub plate and shaft boss *

83. If the cylinder on a two position propeller moves off center it is caused by?

A. badly worn counter weight assembly

B. dry counter weight bearings *

C. vernier lock plate out of adjustment

84. Why should you stop a constant speed propeller in higher pitch during extremely cold

weather?

A. to relieve pressure on the booster pump

B. to keep sufficient oil in the cylinder

C. to prevent congealing of the oil in the cylinder *

85. When you overhaul a propeller the hub is?

A. always annealed

B. magnafluxed *

C. etched in a caustic solution

86. The reason why a wooden propeller has a fabric tip is ?

A. to overcome propeller tip vortices

B. to protect tips when taxiing over gravel runways

C. to prevent longitudinal splitting *

87. Hydromatic propeller differ from controllable pitch propeller? >

A. no counter weights *

B. large counterweights

C. smaller counterweights

88. When checking the final pitch of the propeller on a mandrel on a level you would use?

A. a bubble protractor (universal propeller protractor) *

B. a triangle square

C. a microscope

89. What is the approximate pressure used to feather a propeller

A. 250 lbs

B. 1500 2000 lbs

C. 400 lbs *

90. What is the approximate pressure used to unfeather a propeller?

A. 300 lbs

B. 1500 2000 lbs

C. 600 lbs *

91. How is a wooden propeller balanced?

A. by applying solder to the tipping *

B. by cutting off a portion of the wood

C. by applying paint or vanish on the light side

92. Variation in the blades of a wooden propeller are?

A. zero degrees

B. one degrees

C. one-fourth degree *

D. one-half degree

93. The amount of lead wool that can be placed in the concentric holes in a metal propeller is?

A. one-half ounce

B. one-fourth ounce *

C. two ounces

94. The hole in the tipping of a wood propeller are for purpose of >

A. balancing the propeller

B. allowing moisture to drain out *

C. allowing moisture to enter propeller to prevent its drying out

95. What is full feathering?

A. travel of propeller blade pitch from zero to 180 degrees

B. travel of propeller blade pitch from 90 to 180 degrees

C. travel of propeller blade pitch from zero to 89 degrees *

96. Why is oil-lite bearing used in a constant speed propeller?

A. not so stiff in cold weather

B. to prevent chafing and galling *

C. no friction

97. How do you determine the seating area of shank of the butt end of a propeller blade? >

A. measure with a steel rule

B. consult manufacturers chart

C. use Prussian blue or engineers blue *

98. Why does a fixed pitch propeller cool an engine more?

A. more blade area

B. less hub resistance *

C. more pitch

99. The maximum allowable variation in the blade angle of a wood propeller when measured

from the 36 inch station to the tip is

A. 1.0 degree plus or minus

B. 1.5 degrees plus or minus

C. 0.4 degree plus or minus *

100. The most probable cause of sluggish pitch change in a two position, hydraulically operation

propeller would be

A. broken counterweight bearing shaft

B. a leak in the front cone packing washer

C. too much oil in one of the oil-lite shims on a blade

D. binding of the counterweight bearings *

E. the vernier plate is loose

101. When the hub of a propeller which is fitted to a tapered shaft is seated properly, the hub will

fit

A. at the front and back but does not touch in the center

B. only at the front and the propeller nut

C. at the rear and has no other contact except the propeller nut *

102. If the RPM speeder spring in a constant speed, non-feathering propeller should break, the

most probable result would be

A. the propeller would immediately move into low pitch

B. the propeller would immediately move into high pitch *

C. the speed of the propeller would fluctuate severely

103. If a mechanic should find a transverse scratch across the blade of a propeller one-eighth inch

deep, he should

A. fill the scratch with a plastic filler and then refinish the propeller

B. return the propeller to the manufacturer for repair

C. reject the propeller as unfit for use *

104. The operation of the pilot valve on a hydraulically operated constant speed propeller not

having a feathering arrangement, is controlled by the

A. action of the oil pressure from the booster pump

B. the centrifugal action of the flyweights *

C. action of the booster pump relief valve

105. If a mechanic should find, when examining a wood propeller, that there is a diametrical

looseness between the wood propeller boss and the metal hub, he should

A. metalize the hub and then ream the boss to fit tightly

B. shim up the boss until it fits the hub

C. discard the propeller *

106. The most probable cause of a hydraulically operated, two position propeller shifting into high

pitch on the take-off would be

A. a sudden rise in oil pressure

B. a loose counterweight bearing moving off center

C. a sudden drop in oil pressure *

107. The purpose of the three way valve used in the operation of a two position hydraulically

operated propeller is

A. to direct the oil from the engine through the propeller governor

B. to permit the pilot to use constant speed operation of the propeller

C. to direct the engine oil to the propeller cylinder *

108. What is the basic purpose of installing rear cone spacers? >

A. to achieve bottoming of the rear cone

B. to aid in bottoming of the front cone

C. to prevent bottoming of the front cone *

109. An increase in the tension of the governor speeder spring would result in

A. a change in governor oil pressure from the booster pump

B. a decrease in the propeller blade angle with a corresponding increase in engine RPMs *

C. an increase in the propeller blade angle with a corresponding decrease in engine RPMs

110. A mechanic, in overhauling a damaged propeller, discovers that the propeller blade has a 20

degrees bend at a point where the blade thickness is 0.1 . He should

A. anneal, straighten, and re-heat treat the blade

B. anneal the blade, straightening it during the process

C. return the propeller blade to the manufacturer *

111.If a mechanic should find that the cylinder of the pitch changing mechanism of a hydraulically

operated, non-feathering, constant speed propeller is running off center, the most probable

cause would be

A. propeller bearings are excessively worn

B. one of the inboard oil seals is worn

C. the counterweight bearings are dry *

112. The solutions which a mechanic should used to etch metal propeller blades during inspection

are

A. 20% caustic soda solution cleaning with a 20% nitric acid solution *

B. 20% sulphuric acid cleaning 20% caustic soda

C. 20% nitric acid cleaning with 20% caustic soda

113. What is the pitch of a propeller when fully feathered? >

A. 90 degrees *

B. 75 degrees

C. 0 degree

114. What is done to a steel hub at inspection time?

A. tension is checked

B. it is Rockwell tested

C. it is magnafluxed *

115. A wood propeller is horizontally balanced by >

A. removing wood from under the metal tip

B. shifting the propeller slightly on the hub

C. the use of solder on the copper tips *

116. What is used to measure the angle of a propeller?

A. incidence board

B. tee square

C. bubble propeller protractor *

117. Towards what pitch does centrifugal force tend to twist the blades of a hydromatic propeller?

>

A. high

B. no change

C. low *

118. The most efficient propeller from the theoretical standpoint has what number of blades?

A. one *

B. two

C. three

119. The umbrella on the nose of some hydromatic propeller is for the purpose of

A. dust deflector

B. oil seal

C. crankcase breather *

120. The proper method of greasing a hydromatic peopeller is

A. do not use grease *

B. use a grease fitting

C. use the engine oil system

121. What will cause sluggish operation of an electric propeller?

A. loose spline connection

B. nicks or small dents

C. fouled brushes *

122. During an emergency gear-up landing, the outer six inches of the metal propeller blades are

damaged and a slight damage occurred on the bottom of the fuselage. Otherwise, the airplane

was found to be structurally sound. The proper repair procedure to make the airplane

airworthy would be

A. replace the blades with no further check

B. replace the propeller with a reconditioned propeller

C. replace the blades and check the runout of the crankshaft *

123. The first step in removing the counterweight propeller is

A. place the propeller in low pitch

B. remove spring return while propeller is in low pitch

C. place the propeller in high pitch *

124. When a reversible pitch propeller is taken out of reverse pitch but automatically returns to

reverse pitch when reaching the approximate neutral pitch position, this condition is caused by

A. the cylinder lock engaging

B. improper use of propeller control

C. the cylinder lock not engaging *

125. What is the purpose of the tapered spacer at the rear of the propeller?

A. to center the hub with relation to the center line of the crankshaft *

B. none of these answers is correct

C. to prevent the hub from contacting the nose section studs

126. The letter M on the propeller hub indicates

A. the hub was reworked

B. the hub was not modified

C. the hub was modified for use with a short splined crankshaft *

127. What is the purpose of propeller blade cuffs?

A. protects blade root

B. helps cool engine

C. increase aerodynamic propeller efficiency *

128. The brushes in a Curtiss Electric propeller are replaced when worn

A. 1/8 of an inch

B. to point of the arrow *

C. 3/32 of an inch

129. In extremely cold weather, when operating with a hydraulically operated two position

propeller, it is good practice to leave the propeller in high pitch position when the engine is

not running in order to

A. prevent the oil from draining out of the cylinder

B. keep the piston from seizing the cylinder

C. prevent the oil from congealing in the cylinder *

130. If the governor fails, a hydraulically operated feathering propeller tends to

A. go to low pitch *

B. go to high pitch

C. remain unchanged

131. A precaution necessary to keep the hub from seizing the shaft is to

A. dust the threads with flake graphite

B. dip the nut in engine oil

C. coat the nut with white lead mixed with oil *

132. During the assembly of two-bladed, adjustable pitch aluminum alloy propeller, the proper

procedure for correcting a slight vertical unbalance is to

A. drill the blade butts and add lead wool

B. shift the hub clamp rings *

C. paint the light side

133. Propeller tip speeds are controlled by blade length, number of blades, reduction gears, RPM,

etc. This is important because excessive propeller tip speeds

A. create excessive engine wear

B. effect aircraft balance

C. create high stresses and inefficient thrust qualities *

134. Which of the following is the most important advantage of the reverse-pitch type propeller?

A. better control of the aircraft at high speeds

B. gives additional downwash

C. utilization for braking purposes on the ground *

135. Aerodynamic and centrifugal twisting moment on a propeller blade

A. always act in opposing direction

B. always act in the same directions

C. act in the same direction if the propeller is windmilling *

Das könnte Ihnen auch gefallen

- Aerospace Actuators 2: Signal-by-Wire and Power-by-WireVon EverandAerospace Actuators 2: Signal-by-Wire and Power-by-WireNoch keine Bewertungen

- Mod 17 - Paper 9 (S) MDokument7 SeitenMod 17 - Paper 9 (S) MAhmad AlthaherNoch keine Bewertungen

- Module 17 QuestionDokument3 SeitenModule 17 QuestionUttamNoch keine Bewertungen

- Twisting of the blade angle reduces angle towards rootDokument5 SeitenTwisting of the blade angle reduces angle towards rootamhm2000100% (1)

- MODULE 17 All QuestionDokument75 SeitenMODULE 17 All QuestionSatyam100% (1)

- EASA Part 66 Propeller Question GuideDokument38 SeitenEASA Part 66 Propeller Question GuideuluNoch keine Bewertungen

- 17.2. Propeller Construction.Dokument10 Seiten17.2. Propeller Construction.Anuruddha Rukmal100% (1)

- Fundamentals of propeller design and operationDokument28 SeitenFundamentals of propeller design and operationqwesadNoch keine Bewertungen

- PropellerDokument31 SeitenPropellerronasso7Noch keine Bewertungen

- Module 1 B1Dokument16 SeitenModule 1 B1scribdNoch keine Bewertungen

- M04Dokument66 SeitenM04Tormod BergNoch keine Bewertungen

- Mod 17 MCQ June 2010Dokument12 SeitenMod 17 MCQ June 2010Shrawan Shrestha100% (2)

- Module 04 Part 4Dokument16 SeitenModule 04 Part 4Aviation World0% (1)

- Module 6 Questions Latest Part 66 ExamDokument1 SeiteModule 6 Questions Latest Part 66 ExamShreedharNoch keine Bewertungen

- PTC B1.1 Notes - Sub Module 17.1 (Fundamentals)Dokument44 SeitenPTC B1.1 Notes - Sub Module 17.1 (Fundamentals)DrAmir AhmedNoch keine Bewertungen

- Dgca Module 15 Part 5Dokument14 SeitenDgca Module 15 Part 5nishat529100% (1)

- Propeller QuestionsDokument37 SeitenPropeller QuestionsSundaram MohanNoch keine Bewertungen

- Module 2 Exam Practice Exam Physics: This Is Exam Number 1. 1. 2 3 4 5 6 7 8 9 10 B C B A A A A B B ADokument74 SeitenModule 2 Exam Practice Exam Physics: This Is Exam Number 1. 1. 2 3 4 5 6 7 8 9 10 B C B A A A A B B AAmila FernandoNoch keine Bewertungen

- Part 66 B1 - MODULE 4 3 SERVOMECHANISMSDokument26 SeitenPart 66 B1 - MODULE 4 3 SERVOMECHANISMSyaman91100% (1)

- Piston Engine 1 2017Dokument4 SeitenPiston Engine 1 2017Training Manager SOA100% (1)

- 11 BDokument5 Seiten11 BRzVaan ArfiNoch keine Bewertungen

- Module 16-07 Piston Engine: Supercharging and TurbochargingDokument36 SeitenModule 16-07 Piston Engine: Supercharging and TurbochargingИлларион ПанасенкоNoch keine Bewertungen

- Study Question! Powerplant Section (Gas Turbine)Dokument8 SeitenStudy Question! Powerplant Section (Gas Turbine)IdrisNoch keine Bewertungen

- Module 07 Part 4Dokument17 SeitenModule 07 Part 4Aviation World100% (1)

- JAR 66 Module 1 Propeller Exam PracticeDokument43 SeitenJAR 66 Module 1 Propeller Exam Practicerobija1Noch keine Bewertungen

- Helicopter Aerodynamics From M8Dokument18 SeitenHelicopter Aerodynamics From M8REZA TAJBAKHSHNoch keine Bewertungen

- Propeller - Question BankDokument18 SeitenPropeller - Question BankMai AnhNoch keine Bewertungen

- EASADokument10 SeitenEASAvivaboyNoch keine Bewertungen

- EASA Mod 7A BK 4 Elect TestDokument80 SeitenEASA Mod 7A BK 4 Elect Testghuran khatweNoch keine Bewertungen

- For Full Explanations of All These Questions, and For Many More New and Up-To-Date Questions, With Correct Answers, Full Explanations, Downloadable Material and Tutorial Support, Please VisitDokument43 SeitenFor Full Explanations of All These Questions, and For Many More New and Up-To-Date Questions, With Correct Answers, Full Explanations, Downloadable Material and Tutorial Support, Please Visitariesguy_86Noch keine Bewertungen

- AF Structure ContDokument21 SeitenAF Structure ContlongmilkNoch keine Bewertungen

- Module 07 Part 5Dokument17 SeitenModule 07 Part 5Aviation WorldNoch keine Bewertungen

- M1 Cat-B1 Notes V1.1Dokument49 SeitenM1 Cat-B1 Notes V1.1VinayNoch keine Bewertungen

- Elect Questions For Paper IIDokument49 SeitenElect Questions For Paper IIavijayakumar_1964Noch keine Bewertungen

- EASA Mod 11A BK 11 BatteryDokument53 SeitenEASA Mod 11A BK 11 BatteryarunNoch keine Bewertungen

- ModuleDokument105 SeitenModuleBookMaggot100% (2)

- E LBP B MCQ Mod 5Dokument21 SeitenE LBP B MCQ Mod 5TSuman Jones GiriNoch keine Bewertungen

- Fuel SystemDokument39 SeitenFuel SystemDadang100% (2)

- Mod 2 QuestionsDokument49 SeitenMod 2 Questionscyder100% (1)

- Module 1 - Mathematics Concepts ExplainedDokument23 SeitenModule 1 - Mathematics Concepts Explaineddevraj subediNoch keine Bewertungen

- Your Score: Test ResultsDokument4 SeitenYour Score: Test ResultsEmad MadiNoch keine Bewertungen

- M14 (EASA) SN (PDF by MR - Raza)Dokument9 SeitenM14 (EASA) SN (PDF by MR - Raza)Eimad Attar100% (1)

- Reciprocating Engine Fuel MeteringDokument93 SeitenReciprocating Engine Fuel MeteringhygfgNoch keine Bewertungen

- Mod 13 Pointers 21-01-10Dokument25 SeitenMod 13 Pointers 21-01-10tayyab.aslam100% (1)

- Airframe Electrical FAA QuestionsDokument5 SeitenAirframe Electrical FAA QuestionsJAYACHANDRANNoch keine Bewertungen

- Module 4 Part 66Dokument5 SeitenModule 4 Part 66amaisc100% (2)

- Reff: Charles Otis Page No.-2.3Dokument12 SeitenReff: Charles Otis Page No.-2.3mauryapiaeNoch keine Bewertungen

- Module 3 EasaDokument1 SeiteModule 3 EasaBrandon Sookdeo100% (1)

- Module07 NewDokument208 SeitenModule07 Newarns19Noch keine Bewertungen

- Helicopter Aerodynamics, Structures & Systems ModuleDokument315 SeitenHelicopter Aerodynamics, Structures & Systems Modulesaroj205850% (2)

- Propeller Storage and Preservation GuideDokument8 SeitenPropeller Storage and Preservation Guidetauqir73100% (1)

- Module 07 Part 3 Avionics EquipmntDokument19 SeitenModule 07 Part 3 Avionics EquipmntAviation World100% (1)

- Aircraft Propeller Control and OperationDokument26 SeitenAircraft Propeller Control and Operationgulshan100% (2)

- EASA Mod 4 BK 3 ServosDokument75 SeitenEASA Mod 4 BK 3 ServosPriyanka ShresthaNoch keine Bewertungen

- Module 07 Part 2 ToolsDokument23 SeitenModule 07 Part 2 ToolsAviation World100% (1)

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsVon EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsNoch keine Bewertungen

- Aviation Maintenance Technician Handbook—Airframe (2024): FAA-H-8083-31BVon EverandAviation Maintenance Technician Handbook—Airframe (2024): FAA-H-8083-31BNoch keine Bewertungen

- Enhanced Avionics System A Complete Guide - 2020 EditionVon EverandEnhanced Avionics System A Complete Guide - 2020 EditionNoch keine Bewertungen

- Aim 2009Dokument268 SeitenAim 2009Aya DPradoNoch keine Bewertungen

- 6.1 Aircraft Material - Ferrous: Basic Maintenance Training ManualDokument26 Seiten6.1 Aircraft Material - Ferrous: Basic Maintenance Training ManualAya DPradoNoch keine Bewertungen

- M1 Mathematics PDFDokument284 SeitenM1 Mathematics PDFAya DPradoNoch keine Bewertungen

- Aim 2009Dokument268 SeitenAim 2009Aya DPradoNoch keine Bewertungen

- Owner'S Manual & Service Booklet: Maruti Suzuki India LimitedDokument209 SeitenOwner'S Manual & Service Booklet: Maruti Suzuki India LimitedAya DPrado100% (2)

- Flight Safety Digest PDFDokument288 SeitenFlight Safety Digest PDFAya DPradoNoch keine Bewertungen

- Flight Safety Digest PDFDokument288 SeitenFlight Safety Digest PDFAya DPradoNoch keine Bewertungen

- FAA - Aircraft Maintenance Technician HandbookDokument21 SeitenFAA - Aircraft Maintenance Technician HandbookAalap Shah50% (2)

- Flight Safety Digest PDFDokument288 SeitenFlight Safety Digest PDFAya DPradoNoch keine Bewertungen

- 17.1 Fundamentals - SampleDokument26 Seiten17.1 Fundamentals - SampleAya DPradoNoch keine Bewertungen

- Celerio Owner's Manual PDFDokument209 SeitenCelerio Owner's Manual PDFAya DPrado100% (3)

- 8.4 Flight Stability: Basic Maintenance Training ManualDokument14 Seiten8.4 Flight Stability: Basic Maintenance Training ManualAya DPradoNoch keine Bewertungen

- Module 17A and 17B: PropellerDokument25 SeitenModule 17A and 17B: PropellerSameh Antar100% (1)

- Module 17A and 17B: PropellerDokument25 SeitenModule 17A and 17B: PropellerSameh Antar100% (1)

- Aircraft Hardware Materials and Process 9A Vol 1 PDFDokument51 SeitenAircraft Hardware Materials and Process 9A Vol 1 PDFpbsrivinayNoch keine Bewertungen

- TTS Module 08Dokument225 SeitenTTS Module 08Onur DurmuşNoch keine Bewertungen

- 1 Using The Financial Statements Provided For S S Air CalculateDokument2 Seiten1 Using The Financial Statements Provided For S S Air CalculateAmit PandeyNoch keine Bewertungen

- Uav Design - Part IiDokument1 SeiteUav Design - Part IiPradeep KumarNoch keine Bewertungen

- List of EPAS Acronyms and Definitions - For PublicationDokument15 SeitenList of EPAS Acronyms and Definitions - For Publicationbykr aknNoch keine Bewertungen

- LCLKDokument23 SeitenLCLKHiperion MeisterNoch keine Bewertungen

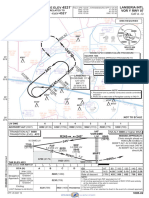

- Fala - Vor y Rwy 07 - Vor-02Dokument1 SeiteFala - Vor y Rwy 07 - Vor-02Richard FloydNoch keine Bewertungen

- Flight Operations Transmission - Fot: Customer Services DirectorateDokument3 SeitenFlight Operations Transmission - Fot: Customer Services DirectorateMahmoud KrayemNoch keine Bewertungen

- EUR Doc 001 - EANPG Handbook (En) - Edition 1, Amd 1Dokument66 SeitenEUR Doc 001 - EANPG Handbook (En) - Edition 1, Amd 1बासुदेव अर्यालNoch keine Bewertungen

- NAVY T-44 Training WorkbookDokument168 SeitenNAVY T-44 Training WorkbookjjfugedyNoch keine Bewertungen

- B737 NG Exterior Preflight TrainingDokument115 SeitenB737 NG Exterior Preflight Trainingvictorbenites86% (22)

- E-CAT35AS001 - Alpha Strike Cards - DropShips and Small CraftDokument52 SeitenE-CAT35AS001 - Alpha Strike Cards - DropShips and Small CraftAye100% (2)

- FAA IA Refresher DatabaseDokument18 SeitenFAA IA Refresher DatabaseDanielNoch keine Bewertungen

- b777 Operations Manual v2Dokument21 Seitenb777 Operations Manual v2Álex Junior100% (1)

- Ipc 9121中文 印制板制造工艺疑难解答pcb制程中的故障排除Dokument32 SeitenIpc 9121中文 印制板制造工艺疑难解答pcb制程中的故障排除cdmingNoch keine Bewertungen

- Service Letter: e A Usgabe) Edition)Dokument1 SeiteService Letter: e A Usgabe) Edition)AO BeltranNoch keine Bewertungen

- EC135 B1 R05EN 00 General 06.10.2015.9531Dokument154 SeitenEC135 B1 R05EN 00 General 06.10.2015.9531uncleshera360Noch keine Bewertungen

- AerotriX - RC Aircraft MaintenanceDokument1 SeiteAerotriX - RC Aircraft MaintenanceMithulin ThomasNoch keine Bewertungen

- Operations at Non Towered AirportsDokument16 SeitenOperations at Non Towered AirportsPeter HuntNoch keine Bewertungen

- 2Dokument2 Seiten2Tyron CastroNoch keine Bewertungen

- CB DC-9 ClassicDokument18 SeitenCB DC-9 ClassicIan de la ONoch keine Bewertungen

- MARANA AVQ Apt. DiagramDokument1 SeiteMARANA AVQ Apt. DiagramjohnNoch keine Bewertungen

- LTA KL2300/24 AUG/JFK-MIA: - Not For Real World NavigationDokument52 SeitenLTA KL2300/24 AUG/JFK-MIA: - Not For Real World NavigationAlcides Francisnei Oliveira da ConceicaoNoch keine Bewertungen

- Aerodynamics assignment density and thermodynamic propertiesDokument2 SeitenAerodynamics assignment density and thermodynamic propertiesCalvin LabialNoch keine Bewertungen

- Iso 24356 2022Dokument11 SeitenIso 24356 2022贾宗林Noch keine Bewertungen

- Cover LetterDokument2 SeitenCover LetterKing SolomonNoch keine Bewertungen

- General Information General Information: (C) Jeppesen Sanderson, Inc., 2020, All Rights ReservedDokument9 SeitenGeneral Information General Information: (C) Jeppesen Sanderson, Inc., 2020, All Rights ReservedOMAR EDUARDO HERRERA GALINDONoch keine Bewertungen

- Module 11A.5.2 L1 2016-08-16Dokument234 SeitenModule 11A.5.2 L1 2016-08-16Abdul Aziz KhanNoch keine Bewertungen

- Supersonic Business Jet Conceptual Design in A Multidisciplinary Design Analysis Optimization EnvironmentDokument21 SeitenSupersonic Business Jet Conceptual Design in A Multidisciplinary Design Analysis Optimization Environmenthemant gahnoliaNoch keine Bewertungen

- Boeing's 787 Dreamliner Vision Case StudyDokument6 SeitenBoeing's 787 Dreamliner Vision Case StudyChole HuNoch keine Bewertungen

- Apron and GateDokument11 SeitenApron and GatedevNoch keine Bewertungen