Beruflich Dokumente

Kultur Dokumente

Planilla de Madera PDF

Hochgeladen von

CESAR CANEOOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Planilla de Madera PDF

Hochgeladen von

CESAR CANEOCopyright:

Verfügbare Formate

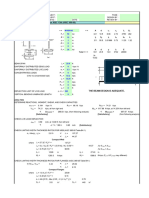

Daniel PROJECT : PAGE :

Tian Li CLIENT :

JOB NO. : DATE:

DESIGN BY :

REVIEW BY :

Wood Beam Design Base on NDS 2005

INPUT DATA

DL = 40 lbs / ft MEMBER SIZE = 6x8 No. 1, Southern Pine

LL = 40 lbs / ft

SELF = 9 lbs / ft MEMBER SPAN = 15 ft Camber =>0.3 in (1.5 DL deflection)

TL = 89 lbs / ft

PLL = 2000 lbs (Non concurrent point live load, see IBC Tab 1607.1 or UBC Tab16-A) Code Designation

Does member support plaster ? (See IBC Tab 1604.3 or UBC Tab 16-D) 1 Select Structural, Douglas Fir-Larch

(1= yes, 0= no) 1 Yes 2 No. 1, Douglas Fir-Larch

Does member have continuous lateral support ? 3 No. 2, Douglas Fir-Larch

(1= yes, 0= no) 1 Yes 4 Select Structural, Southern Pine

Code Duration Factor, CD Condition 5 No. 1, Southern Pine

1 0.90 Dead Load 6 No. 2, Southern Pine

2 1.00 Occupancy Live Load Choice => 5

3 1.15 Snow Load CD CM Ct Ci CL

4 1.25 Construction Load 1.25 1.00 1.00 1.00 1.00

5 1.60 Wind/Earthquake Load CF CV Cc Cr

6 2.00 Impact Load 1.00 1.00 1.00 1.00

}

Choice => 4 Construction Load

DESIGN SUMMARY

L = 15.0 ft 1. Check Bending: M / S < Fb

w = 49 lbs/ft 2,066 psi = 2,063 psi Say ok

PLL = 2000 lbs <= Case 2 Governs !

R = 2,367 lbs 2. Check Shear: 1.5 V / A < Fv

85 psi < 219 psi

L

ok

V d w P ll = 2,336 lbs

2

L

w L 2 P llL 3. Check Live Load Deflection:

M 3 6 0

ll

= 8,876 ft-lbs

8 4

0.19 in < 0.50 in ok

5wll L

P ll L

4 3

ll = 0.19 in

L

384 EI 48EI 4. Check Long-term Deflection:

240

( 0 .5 d l l l )

5w(0.5dl ll ) L 4 P ll L 3

(0.5dl ll ) = 0.27 in 0.27 in < 0.75 in ok

384 EI 48EI

ANALYSIS

6 x 8 Properties Maximum length permitted by:

b = 5.50 in E'min = N/A

d = 7.50 in lE = N/A 8wtlS F b

L

A = 41.3 in Bending : wtl = 28.2 ft (case 1)

2

in

3

S = 51.6 RB = N/A

P ll 8wdl S F b Pll

2

in L

4

I = 193 FbE = N/A

* wdl

E = Ex = 1700 ksi Fb = N/A = 15.0 ft (case 2)

Fb = 1,650 psi F = FbE / Fb* = N/A

Fv = 175 psi, (CH included to comply with NDS 97) 2 A

E' = 1,700 ksi Shear : L F V 2d = 136.5 ft (case 1)

1.5wtl

Fb ' = 2,063 psi

Fv ' = 219 psi 2 A

L F V 2 d 2 P ll = 165.4 ft (case 2)

1.5wdl wdl

CASE 1: DL+LL Governs => CASE 2: DL+PLL

CHECK THE BEAM CAPACITY WITH AXIAL LOAD

AXIAL LOAD P = 4.5 kips

THE ALLOWABLE COMPRESSIVE STRESS IS

Fc ' = F c C D C P C F = 900 psi

Where Fc = 1750 psi

CD = 1.60

CF = 1.00 (Lumber only)

CP = (1+F) / 2c - [(1+F) / 2c) - F / c] = 0.321

2 0.5

Fc * = F c C D C F = 2800 psi

Le = Ke L = 1.0 L = 180 in

d = 7.5 in

SF = slenderness ratio = 24.0 < 50 [Satisfies NDS 2005 Sec. 3.7.1.4]

FcE = 0.822 E'min / SF = 985 psi

2

E'min = 690 ksi

F = FcE / Fc* = 0.352

c = 0.8

THE ACTUAL COMPRESSIVE STRESS IS

fc = P / A = 109 psi < Fc ' [Satisfactory]

THE ALLOWABLE FLEXURAL STRESS IS

Fb ' = 2640 psi, [ for CD = 1.6 ]

THE ACTUAL FLEXURAL STRESS IS

fb = (M + Pe) / S = 2393 psi < Fb ' [Satisfactory]

CHECK COMBINED STRESS [NDS 2005 Sec. 3.9.2]

(fc / Fc' ) + fb / [Fb' (1 - fc / FcE)]

2

= 1.034 < 4/3 [Satisfactory]

Hence the beam design is adequate.

Note: This is straight beam. The top of the beam is continuously braced by the plywood sheathing and nonslenderness factor,

CL , adjustment is necessary for gravity load. For axial load , the only strong axis factor, CP , should be consided.

Das könnte Ihnen auch gefallen

- Daniel Tian Li: DesignationDokument3 SeitenDaniel Tian Li: DesignationCESAR CANEONoch keine Bewertungen

- Wood Beam Design Based On NDS 2018: Input Data & Design SummaryDokument2 SeitenWood Beam Design Based On NDS 2018: Input Data & Design SummaryZiyad MonierNoch keine Bewertungen

- Design of Base RingDokument1 SeiteDesign of Base RingMohammed Faizal Nv100% (1)

- Slab Design Code A: InputDokument12 SeitenSlab Design Code A: InputjatinNoch keine Bewertungen

- Steel Beam Design With Gravity Loading Based On AISC Manual 14th Edition (AISC 360-10)Dokument22 SeitenSteel Beam Design With Gravity Loading Based On AISC Manual 14th Edition (AISC 360-10)AlphaNoch keine Bewertungen

- Falsework Design For Steel Girder Bridge Based On NDS 2018 & AASHTO 17thDokument18 SeitenFalsework Design For Steel Girder Bridge Based On NDS 2018 & AASHTO 17thjklo12Noch keine Bewertungen

- Distribution Factors 22mDokument8 SeitenDistribution Factors 22mJose Rivera RamirezNoch keine Bewertungen

- CTC Drum Data SheetDokument4 SeitenCTC Drum Data Sheetjdaig17Noch keine Bewertungen

- Beam GravityDokument11 SeitenBeam GravitylucianduNoch keine Bewertungen

- Daily drilling fluid report provides key metricsDokument5 SeitenDaily drilling fluid report provides key metricsnardo_ingNoch keine Bewertungen

- Coastal River Engineeirng Design of Interior HeaderDokument1 SeiteCoastal River Engineeirng Design of Interior HeaderMuhammad irfan javaidNoch keine Bewertungen

- f M π /4) d S D /2) t P (D/2) : Southern Region Houston, TexasDokument4 Seitenf M π /4) d S D /2) t P (D/2) : Southern Region Houston, Texasmohamed amine AtiaNoch keine Bewertungen

- LiftingLugStress Rev 1.5Dokument17 SeitenLiftingLugStress Rev 1.5mohdshakir bahariNoch keine Bewertungen

- 6817-PR-CN-0601 Att 2 - RevADokument1 Seite6817-PR-CN-0601 Att 2 - RevANhật Quang PhạmNoch keine Bewertungen

- LRFD Live Load Distribution Factors: Bridge DivisionDokument13 SeitenLRFD Live Load Distribution Factors: Bridge DivisionKamran AhmedNoch keine Bewertungen

- Hanger Clamps - FabricationDokument10 SeitenHanger Clamps - FabricationDario WicaksonoNoch keine Bewertungen

- Lifting Lug Calculation - Concrete BucketDokument3 SeitenLifting Lug Calculation - Concrete Bucketali akbarNoch keine Bewertungen

- LRFD LIVE LOAD DISTRIBUTIONDokument15 SeitenLRFD LIVE LOAD DISTRIBUTIONJordy CoolNoch keine Bewertungen

- General Shear Local ShearDokument1 SeiteGeneral Shear Local ShearpankajNoch keine Bewertungen

- Design of Purlin as per IS801-1975Dokument107 SeitenDesign of Purlin as per IS801-1975Pallavi GurnuleNoch keine Bewertungen

- Drawing by: Job number: Id: Project:: Pitch (Θ) =0° Roll (Φ) =0° TopDokument2 SeitenDrawing by: Job number: Id: Project:: Pitch (Θ) =0° Roll (Φ) =0° TopDylanLiNoch keine Bewertungen

- Daniel Tian Li: Design of Post-Tensioned Concrete Floor Based On ACI 318-05Dokument12 SeitenDaniel Tian Li: Design of Post-Tensioned Concrete Floor Based On ACI 318-05Waheed AhmadNoch keine Bewertungen

- Line sizing gas analysisDokument9 SeitenLine sizing gas analysisVăn HoàngNoch keine Bewertungen

- Guide to Steel Beam Design ExampleDokument66 SeitenGuide to Steel Beam Design ExampleVince GarciaNoch keine Bewertungen

- RCC31 One-Way Slabs (A&D)Dokument15 SeitenRCC31 One-Way Slabs (A&D)Md Mukarram RezaNoch keine Bewertungen

- Distribution Factors 40mDokument8 SeitenDistribution Factors 40mJose Rivera RamirezNoch keine Bewertungen

- JETTY 3000dwt: Title Document No.: Breasting Dolphin-Engineering Calculation Revision: Issued Date: CompanyDokument2 SeitenJETTY 3000dwt: Title Document No.: Breasting Dolphin-Engineering Calculation Revision: Issued Date: CompanyAnonymous nXGOGxyeNoch keine Bewertungen

- SYP SL Rafter Design For UpliftDokument3 SeitenSYP SL Rafter Design For UpliftTariqul IslamNoch keine Bewertungen

- 2 ND Order Analysis ExampleDokument76 Seiten2 ND Order Analysis ExampleChristian Pinto100% (1)

- Jib Crane Design Sell PDFDokument13 SeitenJib Crane Design Sell PDFBülent KabadayiNoch keine Bewertungen

- RCC31 One-Way Slabs (A&D)Dokument17 SeitenRCC31 One-Way Slabs (A&D)ali billNoch keine Bewertungen

- Falsework Design For Steel Girder Bridge Based On NDS and AASHTO SpreadsheetDokument6 SeitenFalsework Design For Steel Girder Bridge Based On NDS and AASHTO SpreadsheetAmin ZuraiqiNoch keine Bewertungen

- Enhanced Steel BeamDokument4 SeitenEnhanced Steel BeamBang SutresNoch keine Bewertungen

- Project 22 Beam 1 AnalysisDokument9 SeitenProject 22 Beam 1 Analysisyoshdog@gmail.comNoch keine Bewertungen

- Handrail and Baluster Design CheckDokument2 SeitenHandrail and Baluster Design CheckjoshNoch keine Bewertungen

- Beam GravityDokument34 SeitenBeam GravitycurlyjockeyNoch keine Bewertungen

- RCC31R Rigorous One-Way SlabsDokument148 SeitenRCC31R Rigorous One-Way SlabsMohammad Twaha JaumbocusNoch keine Bewertungen

- Lift Calculation DemoDokument4 SeitenLift Calculation Demoa_toups0% (1)

- Bracket Member SS2Dokument7 SeitenBracket Member SS2yoshdog@gmail.comNoch keine Bewertungen

- S1 BasementDokument23 SeitenS1 BasementMuhammad Imran ZafarNoch keine Bewertungen

- Beam ProjectDokument55 SeitenBeam Projectyoshdog@gmail.comNoch keine Bewertungen

- RCC31 One-Way Slabs (A&d)Dokument15 SeitenRCC31 One-Way Slabs (A&d)josefNoch keine Bewertungen

- Passed Report - Glass - 17.5mmDokument29 SeitenPassed Report - Glass - 17.5mmsaravqwerty100% (1)

- b9.1Dokument1 Seiteb9.1EakJhuanNoch keine Bewertungen

- Compressive Strength Beam DesignDokument70 SeitenCompressive Strength Beam DesignDjuned0% (1)

- Properties: Load Category Magnitude (KLF) Location (FT, %) DirectionDokument8 SeitenProperties: Load Category Magnitude (KLF) Location (FT, %) Directionyoshdog@gmail.comNoch keine Bewertungen

- Beam Project ChangesDokument12 SeitenBeam Project Changesyoshdog@gmail.comNoch keine Bewertungen

- Masonry Wall Design at Horizontal Bending, Based On ACI 530-05 Input Data & Design SummaryDokument1 SeiteMasonry Wall Design at Horizontal Bending, Based On ACI 530-05 Input Data & Design Summaryazamislam726537Noch keine Bewertungen

- Beam PropertiesDokument8 SeitenBeam Propertiesyoshdog@gmail.comNoch keine Bewertungen

- General Shear Local ShearDokument1 SeiteGeneral Shear Local ShearPankaj SherwalNoch keine Bewertungen

- CFS 12CS4x070 50 FTDokument9 SeitenCFS 12CS4x070 50 FTyoshdog@gmail.comNoch keine Bewertungen

- Section A-A, 1:40: Part No Section (MM) Quantity (Nos) Working Drawing Weight KG/PC Total KGDokument1 SeiteSection A-A, 1:40: Part No Section (MM) Quantity (Nos) Working Drawing Weight KG/PC Total KGRanjit Kumar ShahNoch keine Bewertungen

- CHECKLIST PEMERIKSAAN FISIK PEKERJAAN PELEBARAN DERMAGA C1 PELABUHAN PANJANGDokument6 SeitenCHECKLIST PEMERIKSAAN FISIK PEKERJAAN PELEBARAN DERMAGA C1 PELABUHAN PANJANGIyus SopandiNoch keine Bewertungen

- STEEL DESIGN - Beam Summary DesignDokument1 SeiteSTEEL DESIGN - Beam Summary DesignOsama MamdouhNoch keine Bewertungen

- Input Values: Spacing CalculationsDokument7 SeitenInput Values: Spacing CalculationsNAVEED AHMAD NAZNoch keine Bewertungen

- Bridge Slab DesignDokument9 SeitenBridge Slab Designsudhirkumarsharma1966Noch keine Bewertungen

- Solution Manual for an Introduction to Equilibrium ThermodynamicsVon EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNoch keine Bewertungen

- M Britt - Helix Preset Pack 1Dokument4 SeitenM Britt - Helix Preset Pack 1CESAR CANEONoch keine Bewertungen

- AUDIOOLive 16XL Final PDFDokument107 SeitenAUDIOOLive 16XL Final PDFCESAR CANEONoch keine Bewertungen

- Heintz 23 May 2002 Vny Fema-356Dokument21 SeitenHeintz 23 May 2002 Vny Fema-356Antonio Herrera Pérez100% (1)

- Simplified Seismic Analysis Procedures For Elevated TanksDokument19 SeitenSimplified Seismic Analysis Procedures For Elevated TanksCesar Yoshio Sanchez HuchiyamaNoch keine Bewertungen

- Pod x3 EsquematicosDokument162 SeitenPod x3 EsquematicosCESAR CANEONoch keine Bewertungen

- MeAmBobbo PodHD GuideDokument207 SeitenMeAmBobbo PodHD Guide_FlyMan_Noch keine Bewertungen

- Steady State Analysis Model for CSI Reference Manual ExampleDokument14 SeitenSteady State Analysis Model for CSI Reference Manual ExampleCESAR CANEONoch keine Bewertungen

- Planilla de Madera PDFDokument2 SeitenPlanilla de Madera PDFCESAR CANEONoch keine Bewertungen

- SDSDDokument9 SeitenSDSDCESAR CANEONoch keine Bewertungen

- Symbols and Legend: Boddington Gold Mine Expansion ProjectDokument16 SeitenSymbols and Legend: Boddington Gold Mine Expansion ProjectCESAR CANEONoch keine Bewertungen

- Figur AsDokument1 SeiteFigur AsCESAR CANEONoch keine Bewertungen

- Truck FrontEndLoader DimensionsDokument8 SeitenTruck FrontEndLoader DimensionsCESAR CANEONoch keine Bewertungen

- Groundwater VerificationManual Slide PDFDokument48 SeitenGroundwater VerificationManual Slide PDFJuan PabloNoch keine Bewertungen

- Usace Slope StabilityDokument44 SeitenUsace Slope Stabilityj_mustainNoch keine Bewertungen

- GWS Open Web Joists - 1973Dokument36 SeitenGWS Open Web Joists - 1973CESAR CANEO100% (1)

- Slope ModelingDokument252 SeitenSlope ModelingRado Rinaldo SiregarNoch keine Bewertungen

- Slide VerificationManual Part1Dokument127 SeitenSlide VerificationManual Part1Alex BustamanteNoch keine Bewertungen

- Kranco Overhead Cranes c1970 PDFDokument67 SeitenKranco Overhead Cranes c1970 PDFCESAR CANEONoch keine Bewertungen

- US Steel Hot Rolled Carbon Steel Structural Shapes - 1950Dokument71 SeitenUS Steel Hot Rolled Carbon Steel Structural Shapes - 1950CESAR CANEONoch keine Bewertungen

- AvoidCommonBridgeCraneProblems 1976 CorrectedDokument3 SeitenAvoidCommonBridgeCraneProblems 1976 CorrectedCESAR CANEONoch keine Bewertungen

- Standard Iron & Wire Works Joists 1959Dokument47 SeitenStandard Iron & Wire Works Joists 1959CESAR CANEONoch keine Bewertungen

- Armco-Sheffield J & DJ Series c.1972Dokument2 SeitenArmco-Sheffield J & DJ Series c.1972CESAR CANEONoch keine Bewertungen

- Historical Steel Beams 1873 To 1952Dokument137 SeitenHistorical Steel Beams 1873 To 1952darkwing888100% (14)

- Anthes Allspans Joist Design Manual - 1963Dokument32 SeitenAnthes Allspans Joist Design Manual - 1963CESAR CANEONoch keine Bewertungen

- Explicacion Del Aisc - Perfiles AntiguosDokument2 SeitenExplicacion Del Aisc - Perfiles AntiguosCESAR CANEONoch keine Bewertungen

- Kranco Overhead Cranes c1970Dokument384 SeitenKranco Overhead Cranes c1970CESAR CANEONoch keine Bewertungen

- CISC 1977 Handbook WWFShapesDokument2 SeitenCISC 1977 Handbook WWFShapesCESAR CANEONoch keine Bewertungen

- CISC 1967 Handbook Rolled Welded ShapesDokument21 SeitenCISC 1967 Handbook Rolled Welded ShapesCESAR CANEO0% (1)

- Evolution of Telecommunications GenerationsDokument45 SeitenEvolution of Telecommunications GenerationsSai RamNoch keine Bewertungen

- Mastercam 8.1 Beta 4: New Verification Engine in Beta 4! Sub-Programs Post ChangesDokument48 SeitenMastercam 8.1 Beta 4: New Verification Engine in Beta 4! Sub-Programs Post ChangesSaul Saldana LoyaNoch keine Bewertungen

- Secondary SourcesDokument4 SeitenSecondary SourcesKevin NgoNoch keine Bewertungen

- WP 13 General Annexes - Horizon 2023 2024 - enDokument43 SeitenWP 13 General Annexes - Horizon 2023 2024 - enLuchianNoch keine Bewertungen

- Lesson Plan in Science 10 2nd QuarterDokument5 SeitenLesson Plan in Science 10 2nd QuarterJenevev81% (21)

- Educ 61 Module 5 ActivityDokument4 SeitenEduc 61 Module 5 ActivityMitchille GetizoNoch keine Bewertungen

- Cylindrical Plug Gage DesignsDokument3 SeitenCylindrical Plug Gage DesignskkphadnisNoch keine Bewertungen

- AdultChatDkz - ENGLISH - Freelance Worker-SignedDokument5 SeitenAdultChatDkz - ENGLISH - Freelance Worker-SignedDanielNoch keine Bewertungen

- Design TheoryDokument2 SeitenDesign Theoryhamidreza mohseniNoch keine Bewertungen

- ButeDokument89 SeitenButeNassime AmnNoch keine Bewertungen

- ECOSYS FS-2100D Ecosys Fs-2100Dn Ecosys Fs-4100Dn Ecosys Fs-4200Dn Ecosys Fs-4300Dn Ecosys Ls-2100Dn Ecosys Ls-4200Dn Ecosys Ls-4300DnDokument33 SeitenECOSYS FS-2100D Ecosys Fs-2100Dn Ecosys Fs-4100Dn Ecosys Fs-4200Dn Ecosys Fs-4300Dn Ecosys Ls-2100Dn Ecosys Ls-4200Dn Ecosys Ls-4300DnJosé Bonifácio Marques de AmorimNoch keine Bewertungen

- Preparation for the entrance examDokument4 SeitenPreparation for the entrance examMinh ChâuNoch keine Bewertungen

- Cop Y: Queueing TheoryDokument7 SeitenCop Y: Queueing TheoryDiego VásquezNoch keine Bewertungen

- What Is The Procedure For Graceful Shutdown and Power Up of A Storage System During Scheduled Power OutageDokument5 SeitenWhat Is The Procedure For Graceful Shutdown and Power Up of A Storage System During Scheduled Power OutageNiraj MistryNoch keine Bewertungen

- Us00-000 831 01 02 02Dokument18 SeitenUs00-000 831 01 02 02Cristian Camilo0% (1)

- Vocabulary Extension Starter Without AnswersDokument1 SeiteVocabulary Extension Starter Without AnswersPatrcia CostaNoch keine Bewertungen

- PGSuperDokument71 SeitenPGSuperVietanh PhungNoch keine Bewertungen

- Format Question Bank RevisedDokument21 SeitenFormat Question Bank RevisedkhananuNoch keine Bewertungen

- Industrial Applications of Olefin MetathesisDokument7 SeitenIndustrial Applications of Olefin Metathesisdogmanstar100% (1)

- Assumptions of Indifference CurveDokument12 SeitenAssumptions of Indifference CurveAbhishek RavalNoch keine Bewertungen

- (Acta Universitatis Gothoburgensis) Tryggve Göransson - Albinus, Alcinous, Arius Didymus (1995) PDFDokument128 Seiten(Acta Universitatis Gothoburgensis) Tryggve Göransson - Albinus, Alcinous, Arius Didymus (1995) PDFMarcos EstevamNoch keine Bewertungen

- 38-13-10 Rev 2Dokument128 Seiten38-13-10 Rev 2Gdb HasseneNoch keine Bewertungen

- Thandeka, Learning To Be White: Money, Race, and God in America (New York: Continuum International Publishing Group, 1999), 169 PPDokument2 SeitenThandeka, Learning To Be White: Money, Race, and God in America (New York: Continuum International Publishing Group, 1999), 169 PPFefa LinsNoch keine Bewertungen

- Hydro Cyclone: Centripetal Force Fluid ResistanceDokument10 SeitenHydro Cyclone: Centripetal Force Fluid ResistanceMaxwell ToffahNoch keine Bewertungen

- Public Speaking RulesDokument12 SeitenPublic Speaking RulesAnonymous 0ejRGUpmo1Noch keine Bewertungen

- 6.1 Calculation of Deflection: 1) Short Term Deflection at Transfer 2) Long Term Deflection Under Service LoadsDokument7 Seiten6.1 Calculation of Deflection: 1) Short Term Deflection at Transfer 2) Long Term Deflection Under Service LoadsAllyson DulfoNoch keine Bewertungen

- Chapter 2 Planning Business MessagesDokument15 SeitenChapter 2 Planning Business MessagesNuriAisyahHikmahNoch keine Bewertungen

- Concept MappingDokument8 SeitenConcept MappingRashid LatiefNoch keine Bewertungen

- Ata 47-NGS R25Dokument148 SeitenAta 47-NGS R25NadirNoch keine Bewertungen

- E02-E02 Rev 3 Jun 2017 Selection of Elec Equip in Hazardous AreaDokument6 SeitenE02-E02 Rev 3 Jun 2017 Selection of Elec Equip in Hazardous AreaSALMANNoch keine Bewertungen