Beruflich Dokumente

Kultur Dokumente

Pipe Railing Specifications

Hochgeladen von

Dhina karanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pipe Railing Specifications

Hochgeladen von

Dhina karanCopyright:

Verfügbare Formate

NOTES

PIPE RAILING & POSTS:

Pipe Rails and Posts shall be in accordance with ASTM A53 Grade B for standard weight pipe and

ASTM A500 Grade B, C or D or ASTM A501 for structural tube. Bars for handrail supports shall be

ASTM A36. Posts and End Rails shall be fabricated and installed plumb, 1" tolerance when measured

at 3-6" above the foundation. Corners and changes in tangential longitudinal alignment, may be made

continuous with a 9" bend radius or terminated at adjoining sections with a standard end hoop when

handrails are not required. For changes in tangential longitudinal alignment greater than 45, posts

shall be positioned at a maximum distance of 2-0" each side of the corner and shall not be located

at the corner apex. For curved longitudinal alignments the top and bottom rails and handrails shall be

shop bent to match the alignment radius.

RAILING MEMBER DIMENSIONS TABLE

OUTSIDE WALL

MEMBER DESIGNATION

DIMENSION THICKNESS

Posts 2" NPS (Sch. 40) 2.375" 0.154"

Rails 2" NPS (Sch. 40) 2.375" 0.154"

Rail Joint/Splice Sleeves 1b" NPS (Sch. 40) 1.900" 0.145"

Handrails Joint/Splice Sleeves 1" NPS (Sch. 40) 1.315" 0.133"

Handrails 1b" NPS (Sch. 40) 1.900" 0.145"

Handrail Support Bar 1" Round Bar 1.000" N/A

BASE PLATES:

Base Plates shall be in accordance with ASTM A36 or ASTM A709 Grade 36.

SHIM PLATES:

Shim Plates shall be aluminum in accordance with ASTM B209, Alloy 6061 or 6063. Shim plates shall be

used for foundation height adjustments greater than " and localized irregularities greater than

Field trim shim plates when necessary to match the contours of the foundation. Bevelled shim

plates may be used in lieu of trimmed flat shim plates shown. Stacked shim plates must be bonded

together with adhesive bonding material and limited to a maximum total thickness of b", unless

longer anchor bolts are provided for the exposed thread length.

COATINGS:

The railing shall be hot-dip galvanized after fabrication in accordance with Section 962 of the Specifications.

All nuts, bolts and washers shall be hot-dip galvanized in accordance with Section 962 of the Specifications.

ANCHOR BOLTS:

Anchor bolts shall be in accordance with ASTM F1554 Grade 36. Headless anchor bolts for Adhesive

dgn

Anchors shall be threaded full length. Cutting of reinforcing steel is permitted for drilled hole installation.

\d\projects\standards\roadway\00800-s\00880-01.

All anchor bolts shall have single self-locking hex nuts. Tack welding of the nut to the anchor bolt may

be used in lieu of self-locking nuts. All nuts shall be in accordance with ASTM A563 or ASTM A194. Flat

Washers shall be in accordance with ASTM F436 and Plate Washers (for long slotted holes only), shall be

in accordance with ASTM A36 or ASTM A709 Grade 36. After the nuts have been snug tightened, the

anchor bolt threads shall be distorted to prevent removal of the nuts. Distorted threads and tack welds

shall be coated with a galvanizing compound in accordance with the Specifications.

RESILIENT AND NEOPRENE PADS:

Resilient and Neoprene pads shall be in accordance with Specification Section 932, except that testing

of the finished pads shall not be required. Neoprene pads shall be durometer hardness 60 or 70.

JOINTS:

All fixed joints are to be welded all around and ground smooth. Expansion Joints shall be spaced at

a maximum of 30-0". Field splices similar to the expansion joint detail may be approved by the

Engineer to facilitate shipping and handling, but rails must be continuous across a minimum of two

posts. Only use the Continuity Field Splice (Detail "E") to make the railing continuous for unforeseen

field adjustments.

WELDING:

All welding shall be in accordance with the American Welding Society Structural Welding Code (Steel)

ANSI/AWS D1.1 (current edition). Weld metal shall be E60XX or E70XX. Nondestructive testing of

welds is not required.

C:

SHOP DRAWINGS:

Complete details addressing project specific geometry (line & grade) showing post and expansion joint

locations must be submitted by the Contractor for the Engineers approval prior to fabrication of the

railing. Shop drawings shall be in accordance with the Specifications.

PAYMENT:

rd960rh

Guiderail shall be paid for under the contract unit price for Pipe Guiderail (Steel), LF (Item No.

515-1-1). Payment for the Guiderail will be plan quantity measured as the length along the center

line of the top rail, and includes rails, posts, rail splice assembly, base plates, anchor bolts, nuts,

washers, resilient or neoprene pads and all incidental materials and labor required to complete

installation of the Guiderail.

11: 49 AM

46:

12/30/2011

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

STEEL PIPE GUIDERAIL

01/01/11 FY 2012/2013 880 1

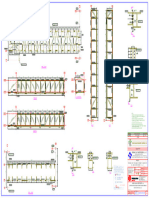

1-6" 6-0" (Max.) ~ Equal Panels Post Spacing

Varies (4" Min.,

(Typ.) (Typ.) 1-6" Max.) (Typ.)

Continuity Field Splice

1-6" (as required) see Detail "E"

Rail Expansion Joint (Typ.)

(Typ.) Sheet 4 (Typ.)

see Detail "D" Sheet 4

Rail ~ 2" NPS

Sch. 40 (Typ.)

NOTES:

See Detail "C"

NPS = Nominal Pipe Size

Sheet 4

-6"

STRUCTURES EXPANSION JOINTS NOTE:

3

* Keyed construction joints in Index No. 520 Gravity

Wall are not considered to be expansion joints.

Top of Sidewalk

or Bikeway 9" Minimum from free end of concrete Rail expansion joints to be located in panels above

structure expansion joints * (30-0" maximum spacing). CROSS REFERENCE:

and expansion joints (Typ.)

Ground Line For Details "C", "D" and "E", see Sheet 4.

ELEVATION

TYPICAL RAILING DETAILS & RAILINGS ON GRADES 0% TO 5%

Han

1-6"

Min.

See Plans for

continuation or

1-6" 6-0" (Max.) ~ Equal Panels Post Spacing termination

See Plans for Handrail ~ 1b" NPS

See "Typical Railing Details" limits of railing

continuation or (Typ.) (Typ.) Sch. 40 (Typ.)

for post & rail details

termination

limits of railing

dgn

\d\projects\standards\roadway\00800-s\00880-02.

1-6"

Min.

-10"

2

Top of

Sidewalk

Han

-6"

3

-10"

M ax.

-6"

2

Grade

2

M ax.

-6"

C:

30-0" Max. for Slopes > 6.25%

40-0" Max. for Slopes = 6.25% 5-0" Min.

Ramp Top Landing

5-0" Min.

30-0" Max. for Slopes > 6.25%

rd960rh

6-0" Min. 40-0" Max. for Slopes = 6.25% Intermediate Landing

RAMP REQUIREMENTS LANDING REQUIREMENTS

Bottom Landing Ramp

ELEVATION

(Showing Inside Face of Railing) For slopes greater than 5%: Max. landing slope = 2%

Max. ramp slope = 8.33% Max. landing cross-slope = 2%

50 AM

Max. ramp cross-slope = 2.0%

46:

11:

RAILINGS ON GRADES STEEPER THAN 5% TO 8.33%

12/30/2011

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

STEEL PIPE GUIDERAIL

01/01/12 FY 2012/2013 880 2

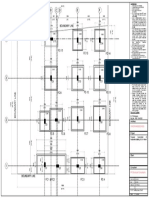

6-0" (Max.) ~ Equal Panels Varies ~ Equal spacing

6-0" Max. on Steps Post

"

2

R

Equal to one

CJP 1"

tread length

-6"

3

Handrail

DETAIL "A" - PLAN VIEW

HANDRAIL TERMINATION

-6"

1-6" 1-6"

Han

3

Min. (Typ.)

See "Typical Railing

Details", Sheet 2 for

post & rail details

-6"

See "Typical Railing Details",

2"

-10"

3

Sheet 2 for post & rail details

See Index No. 521

2

or Contract Plans

9"

for step details

-6"

Concrete sidewalk to extend 6" min. behind ra Min.

3

RAILING CONTINUATION BEYOND STEPS

2"

(Bottom shown, Top similar) Equal to one

tread length

Handrail Handrail continuous

At Landing

5-0" Min.

Varies ~ Equal spacing Han Length of Landing

(Top Landing)

6-0" Max. on Steps

Steel Handrail required for three or more

steps (Handrail and cheekwalls continuous

at landings) Handrail ~ 1" NPS (Sch. 40) 9" Min. Wide

-6"

cheekwall both sides

2"

-10"

dgn

2

Handrail Termination Han

\d\projects\standards\roadway\00800-s\00880-03.

See Detail "A" (Typ.) See Index No. 521

or Contract Plans

for Step Details 1-6"

Min.

2"

Equal to one

tread length

-0" M ax. for one run of steps

-10"

Bottom of

R

(T

Equal to one

9

cheekwall

yp

2

"

tread width

-10"

.)

5-0" Min.

2

-6"

Length of Landing

2"

p "

1

9

.)

9" Min. Wide

R

y

cheekwall both sides

-6"

(T

-10"

3

C:

2"

2

See Index No. 521

Han

or Contract Plans

6

-10"

for Step Details

ELEVATION

2

rd960rh

(At-Grade Steps)

Handrail Termination,

2"

See Detail "A" (Typ.)

50 AM

9"

2"

46:

Min.

11:

6-0"

(Bottom Landing) ALTERNATE END TREATMENT

9"

12/30/2011

Min.

GUIDERAIL ON STEPS & STAIRS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

STEEL PIPE GUIDERAIL

01/01/12 FY 2012/2013 880 3

7 1-6"

2 16"

Hand " 1" Venting Hole

Top Rail ~ 2"

& Rod Plate

1 NPS, Sch. 40

1 2"

3"

Guiderai

Bolt

Post Handrail

6"

3"

2"

1

1

CJP CJP

Post

R

" (Max.) H

(T

1

9

1

R 1 2"

y

4

"

3 1 3 3 1 for Anchor Bolts with

p

16 1 4" 2 4" 2 4" 1 4"

.)

Flat Washers (Typ.)

8" Post ~ 2"

1" Bar NPS, Sch. 40

SECTION B-B SECTION C-C

(Handrail Connection) BASE PLATE DETAIL

4" 1" Venting Hole 1 5"

4

3 1

(Typ.) CJP CJP

4" 3 4"

Post

3"

Guiderai

1

Bolt Bottom Rail ~

8" Plate (Aluminum)

6"

2" NPS, Sch. 40

yp.) Resil

or Neoprene Pads

2"

3"

1

3" "

2

Plate

6"

"

1 3 3 1

2"

T

1"

(centered) 2 8" 38" 3 8" 2 8" " x 1" Long Sl

" (

2"

1

Holes for Anchor Bolts

2

11" with Plate Washers (Typ.) b" Venting C C

" Ste

or " (Max.) H Holes, Bottom Rail

for Anchor Bolts with

Flat Washers (Typ.)

SHIM PLATE PLATE WASHER ALTERNATE BASE

DETAIL DETAIL PLATE DETAIL

Bevel bottom of post as required

(Recommended for Top of Step Cheekwalls) to maintain plumb posts (Typ.)

1-0"

DETAIL "C" - RAIL CONNECTIONS

6"* 6" (Handrail Not Shown)

" x " Pa

Stainless Steel (Type 316 1 1

3" 3" 2" ( 4") ~ Expansion Joint

or 18-8 Alloy) Set Screw.

1 1

Set Screw must be set 4" ( 4") ~ Field Splice Slip Joint

flush against outside face

dgn

of rail (Typ.)

\d\projects\standards\roadway\00800-s\00880-04.

Rail or Handrail Section

Top Rail

Steel Sleeve:

1

Rail or 1 2" NPS (Sch. 40) for Rails Match Grade of

Handrail Section 1" NPS (Sch. 40) for Handrails Ramp or Stairs

Round over both ends Post

1

of rails 8" (Typ.)

* At the Contractors option, embedded length may

be 4" when a " plug weld is substitute

DETAIL "D" - EXPANSION JOINT the " set s

(FIELD SPLICE SLIP JOINT SIMILAR) Bottom Rail

Handrail

1-8"

" x " Pa

1

Stainless Steel (Type 316 4" Max. Gap

C:

Match Grade of B

or 18-8 Alloy) Set Screws.

1 1 1

1

1 Ramp or Stairs

Set Screws must penetrate 1 8" 3 Sp. @ 2 2" 3 Sp. @ 2 2" 8"

the full wall thickness of the

inner sleeve and set flush 1 1

14" 1 4"

against outside face of rail

rd960rh

(Typ.) Rail or Handrail

Section

51 AM

DETAIL "B" - RAIL AND HANDRAIL

46:

Rail Round over both ends Steel Sleeve: (Showing Sloped Condition for Stairs or Ramp)

11:

Section 1 1

of rails 8" (Typ.) 1 2" NPS (Sch. 40) for Rails

1" NPS (Sch. 40) for Handrails

12/30/2011

DETAIL "E" - CONTINUITY CROSS REFERENCE:

FIELD SPLICE For locations of Details "C", "D" and "E", see Sheet 2.

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

STEEL PIPE GUIDERAIL

07/01/10 FY 2012/2013 880 4

1

42"

5-0" Std. ~

3-0" Min. Clear

Between Handrails

Guider

Anchor Bolts

1

1 2" NPS (Sch. 40) Handrail

-9"

1

Guiderail & Anchor Guiderail & Anchor

M easured from Step Nosings

-6"

1" Bar

-6"

Base Plate with Shim

3

plates (as required) (Typ.)

6" Standard,

-10"

4" Sidewalk with 7b" for Ramps

Thickened Edge requiring handrails " Thick Resil

2

1 or Neoprene Pad (Typ,)

-9"

42"

1

42" Min.

1

1

0" Standard 42"

% Max.(away 2" for Ramps

2"

2"

2"

Slope2

Top of

2"

from drop-off) step nosing

Slope2 % Max.( away

from drop-off)

)

M in.

M in.

M in.

6"

6"

6"

-0"

(

(

Varies)

1

Step Cheekwall

** Steel

Anchors

** Steel

** Steel

Anchors

Anchors

45

Drop-off (

Back Face of

Gravity Wall

Varies 9"

(3 Min.) TYPICAL SECTION ON STEPS & STAIRS

dgn

9" Width of Structure at

\d\projects\standards\roadway\00800-s\00880-05.

(Min.) 6" Embedment Depth

TYPICAL SECTION ON CONCRETE SIDEWALK TYPICAL SECTION ON GRAVITY WALL

(Other Retaining Walls Similar)

2 ~ " Anchor Bolts (**)

Edge Shim Self-Locking Hex Nuts & Washers.

(8" long

6"

x " 1

8" Min. Beveled

x thickness (Min.)

Epoxy Mortar (Type F) in

Build-up (Typ.)

as reqd.) accordance with Specification

Section 926

Base Plate

NOTES:

C:

** 2 ~ " x 8" Steel Anc

3" Min. Embedment Galvanized Steel Bolts (As Shown) (C-I-P); Galvanized U-Bolts

3b" Core Drilled Permitted (C-I-P); Galvanized Adhesive Anchors Permitted

Hole (b"), Clean (***); Expansion Anchors Not Permitted.

hole in accordance *** Adhesive anchors shall be fully threaded headless anchor bolts

rd960rh

2"

Full size Shim Plates with Specification set in drilled holes (manufacturer recommended diameter) with

1

when required for Section 416 an Adhesive Bonding Material System in accordance with

height adjustment

Specification Section 937 and installed in accordance with

Specification Section 416. The minimum embedment is 6".

Seal end of post with a

52 AM

1 " Thick Resil

1 2" (Min.) wide plastic or galvanized steel plug

bed of Adhesive or Neoprene Pad

46:

Bonding Material

11:

DETAIL "F" (OPTIONAL SHIMMING DETAIL OPTIONAL SIDEWALK ANCHORAGE DETAIL

FOR CROSS SLOPE CORRECTION)

12/30/2011

(Used in lieu of Beveled Shim Plates)

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

STEEL PIPE GUIDERAIL

01/01/11 FY 2012/2013 880 5

Das könnte Ihnen auch gefallen

- Stainless Steel Handrail SystemsDokument32 SeitenStainless Steel Handrail Systemsmikedigitalegg100% (2)

- Chevron BracingDokument4 SeitenChevron Bracingapi-369789750% (2)

- Section 05120 Structural Steel Part 1Dokument43 SeitenSection 05120 Structural Steel Part 1jacksondcplNoch keine Bewertungen

- Acrowskaf: Boral Formwork & ScaffoldingDokument24 SeitenAcrowskaf: Boral Formwork & ScaffoldingScooby DooNoch keine Bewertungen

- Joint Penetration Groove Welds MemoDokument3 SeitenJoint Penetration Groove Welds MemoRobertBostanNoch keine Bewertungen

- NZS 1664-1-1997 Aluminium Structures Limit State Design PDFDokument8 SeitenNZS 1664-1-1997 Aluminium Structures Limit State Design PDFlaiju p b0% (1)

- MEZZANINE FLOORS FOR WAREHOUSING & PRODUCTIONDokument4 SeitenMEZZANINE FLOORS FOR WAREHOUSING & PRODUCTIONRanjit MarimuthuNoch keine Bewertungen

- 11-Continuous Composite Beams PDFDokument55 Seiten11-Continuous Composite Beams PDFfNoch keine Bewertungen

- Welding Guide BrochureDokument4 SeitenWelding Guide BrochureAnonymous 6aGAvbNNoch keine Bewertungen

- Steel Top Hats Battens Capacitytables Product Technical ManualDokument16 SeitenSteel Top Hats Battens Capacitytables Product Technical ManualbhukthaNoch keine Bewertungen

- Types of Cracks in Reinforced ConcreteDokument5 SeitenTypes of Cracks in Reinforced ConcretewidiaretnoNoch keine Bewertungen

- Beams AS3600 v1Dokument3 SeitenBeams AS3600 v1Nicky198Noch keine Bewertungen

- Structural Tolerances Bs4 - 2004Dokument4 SeitenStructural Tolerances Bs4 - 2004Anonymous 8bH7sXpcEHNoch keine Bewertungen

- Manual 9T Edge Lifter 2017 V1.0Dokument8 SeitenManual 9T Edge Lifter 2017 V1.0darren dmuscat1hotmail.comNoch keine Bewertungen

- SCI P405 SecureDokument54 SeitenSCI P405 SecurePauloRobertoLiñanFigueiredo100% (1)

- Design Capacity Tables Examples PDFDokument8 SeitenDesign Capacity Tables Examples PDFAS V KameshNoch keine Bewertungen

- Masonry Structures Changes To As 3700 2018 Fact Sheet For Builders PDFDokument2 SeitenMasonry Structures Changes To As 3700 2018 Fact Sheet For Builders PDFalexNoch keine Bewertungen

- Code of Practice for AS5100 Part 5Dokument2 SeitenCode of Practice for AS5100 Part 5Milind TrivediNoch keine Bewertungen

- Comflor Composite Floor Deck Brochure UK PDFDokument92 SeitenComflor Composite Floor Deck Brochure UK PDFducke100% (1)

- DDA 3164 BEAM Shear Deflection and CrackDokument20 SeitenDDA 3164 BEAM Shear Deflection and CrackZayyan RomjonNoch keine Bewertungen

- The Specialists in Industrial Flooring and Handrailing: Tubular StandardsDokument3 SeitenThe Specialists in Industrial Flooring and Handrailing: Tubular StandardsHazim AffendiNoch keine Bewertungen

- Ecotek DesignManual v2015 02Dokument44 SeitenEcotek DesignManual v2015 02benNoch keine Bewertungen

- Steel Onesteel HandbookDokument34 SeitenSteel Onesteel HandbookjlolhnpNoch keine Bewertungen

- Best Practice Guide For Hot Dip Galvanized Bolts and Bolted JointsDokument33 SeitenBest Practice Guide For Hot Dip Galvanized Bolts and Bolted Jointsmàrio ferreiraNoch keine Bewertungen

- Bailey Bridge 7Dokument8 SeitenBailey Bridge 7guillermoNoch keine Bewertungen

- Detailed Design of Single-Storey Steel Portal FramesDokument135 SeitenDetailed Design of Single-Storey Steel Portal FramespodderickNoch keine Bewertungen

- ACI 349-97 Apendice BDokument13 SeitenACI 349-97 Apendice Bainosbarba100% (1)

- Torque and Tension RelationshipDokument23 SeitenTorque and Tension RelationshipChris MedeirosNoch keine Bewertungen

- A Method To Estimate Modulus of Horizontal Subgrade Reaction For A Pile (I.Yoshida, R.Yoshinaka)Dokument17 SeitenA Method To Estimate Modulus of Horizontal Subgrade Reaction For A Pile (I.Yoshida, R.Yoshinaka)TaiCheong LeeNoch keine Bewertungen

- Mitek 12kN Pile FixingDokument2 SeitenMitek 12kN Pile FixingTuroyNoch keine Bewertungen

- SpeediBolt Range DCP SPB 001Dokument24 SeitenSpeediBolt Range DCP SPB 001eusufiqbalNoch keine Bewertungen

- List of Steel Products Made in The UK PDFDokument120 SeitenList of Steel Products Made in The UK PDFAntonio MarrufoNoch keine Bewertungen

- Aluminum StructureDokument7 SeitenAluminum StructureGrahamNoch keine Bewertungen

- Lysaght Roofing SolutionDokument16 SeitenLysaght Roofing SolutionardikurniawanNoch keine Bewertungen

- As 4349.0-2007 - Building Inspections GeneralDokument20 SeitenAs 4349.0-2007 - Building Inspections GeneralKassi Pericleous - BIHNoch keine Bewertungen

- Bollards Catalogue en A4 Metric v.2.0 WebDokument20 SeitenBollards Catalogue en A4 Metric v.2.0 WebspasmNoch keine Bewertungen

- Pryda Builders Guide WebDokument80 SeitenPryda Builders Guide WebRafid Yuda Setiawan0% (1)

- Post TensioningDokument3 SeitenPost TensioningMaheerah Gamieldien-MohamedNoch keine Bewertungen

- AS2601Dokument53 SeitenAS2601chrissieNoch keine Bewertungen

- Building Code Requirements For Structural Concrete Reinforced With Glass FiberReinforced Polymer (GFRP) Bars Code and Commentary 440.11.22 Chapter 22Dokument32 SeitenBuilding Code Requirements For Structural Concrete Reinforced With Glass FiberReinforced Polymer (GFRP) Bars Code and Commentary 440.11.22 Chapter 22Douglas DíazNoch keine Bewertungen

- Project Info Board Detail DimensionsDokument1 SeiteProject Info Board Detail Dimensionsrakib06Noch keine Bewertungen

- Tees Cut From Universal Beams To BS4 Part 1 - 1993Dokument4 SeitenTees Cut From Universal Beams To BS4 Part 1 - 1993naim100% (1)

- Branz Advisory Trower PartitionsDokument6 SeitenBranz Advisory Trower PartitionsMatt Stubbins100% (1)

- Twinson Composite Decking InstallationDokument17 SeitenTwinson Composite Decking InstallationpbrilhanteNoch keine Bewertungen

- Improving Fall Protection Design (DR Goh Yang Miang)Dokument20 SeitenImproving Fall Protection Design (DR Goh Yang Miang)Adam FredrikssonNoch keine Bewertungen

- COLUMNASDokument10 SeitenCOLUMNASRoger Geronimo Jiménez100% (1)

- Orifice PlatesDokument5 SeitenOrifice PlatesJakub KjubNoch keine Bewertungen

- Standard grating installation clearancesDokument1 SeiteStandard grating installation clearancesnalzackNoch keine Bewertungen

- VIGAS HENDRICKSON 45745-147d PDFDokument12 SeitenVIGAS HENDRICKSON 45745-147d PDFCARLOS SALGADONoch keine Bewertungen

- Reinforcing Detailing of R.C.C MembersDokument47 SeitenReinforcing Detailing of R.C.C MembersAmey ShettiNoch keine Bewertungen

- Beam Detailing: Section 8 SP: (S & T) - 1987Dokument23 SeitenBeam Detailing: Section 8 SP: (S & T) - 1987Niraj ShindeNoch keine Bewertungen

- Beam Detailing: Section 8 SP: (S & T) - 1987Dokument23 SeitenBeam Detailing: Section 8 SP: (S & T) - 1987Niraj ShindeNoch keine Bewertungen

- Detailed Specification For Steel ReinforcementDokument6 SeitenDetailed Specification For Steel ReinforcementYoga ArchNoch keine Bewertungen

- RC DetailingDokument82 SeitenRC DetailingkishoreNoch keine Bewertungen

- SP40-Steel Portal FrameDokument82 SeitenSP40-Steel Portal FrameTarun saiNoch keine Bewertungen

- Dimenzije - Buttweld FittingsDokument4 SeitenDimenzije - Buttweld Fittingspetrus erectusNoch keine Bewertungen

- Rebar Detailing 8907Dokument12 SeitenRebar Detailing 8907blackwinterNoch keine Bewertungen

- الخطأ والصواب في تسليح العناصر الانشائيهDokument47 Seitenالخطأ والصواب في تسليح العناصر الانشائيهBen ÂmarNoch keine Bewertungen

- Reinforcing Detailing of R.C.C MembersDokument47 SeitenReinforcing Detailing of R.C.C Membersmanumeet100% (2)

- Introduction To AND: Reinforcement Detailing DrawingDokument43 SeitenIntroduction To AND: Reinforcement Detailing DrawingSandgrouse Raj100% (1)

- Detail 5Dokument1 SeiteDetail 5Dhina karanNoch keine Bewertungen

- Plan +16405 D - D: Semac & Partners L.L.CDokument1 SeitePlan +16405 D - D: Semac & Partners L.L.CDhina karanNoch keine Bewertungen

- Detail 3Dokument1 SeiteDetail 3Dhina karanNoch keine Bewertungen

- pg 19 to 19Dokument1 Seitepg 19 to 19Dhina karanNoch keine Bewertungen

- Detail 1Dokument1 SeiteDetail 1Dhina karanNoch keine Bewertungen

- Detail 5Dokument1 SeiteDetail 5Dhina karanNoch keine Bewertungen

- Detail 16Dokument1 SeiteDetail 16Dhina karanNoch keine Bewertungen

- Detail 20Dokument1 SeiteDetail 20Dhina karanNoch keine Bewertungen

- Detail 3Dokument1 SeiteDetail 3Dhina karanNoch keine Bewertungen

- Detail 2Dokument1 SeiteDetail 2Dhina karanNoch keine Bewertungen

- Detail 6Dokument1 SeiteDetail 6Dhina karanNoch keine Bewertungen

- Detail 7Dokument1 SeiteDetail 7Dhina karanNoch keine Bewertungen

- Detail 1Dokument1 SeiteDetail 1Dhina karanNoch keine Bewertungen

- Man Hours For The Arches To Be PayDokument1 SeiteMan Hours For The Arches To Be PayDhina karanNoch keine Bewertungen

- Design SheetDokument1 SeiteDesign SheetDhina karanNoch keine Bewertungen

- PG 01Dokument1 SeitePG 01Dhina karanNoch keine Bewertungen

- Celong Genial LEECORT (I.m and I.v) : Vitamin C ? SteroidsDokument1 SeiteCelong Genial LEECORT (I.m and I.v) : Vitamin C ? SteroidsDhina karanNoch keine Bewertungen

- STank ScketchDokument1 SeiteSTank ScketchDhina karanNoch keine Bewertungen

- Entrance Arch Parur ModelDokument1 SeiteEntrance Arch Parur ModelDhina karanNoch keine Bewertungen

- F-004 - Leave Application Form-R1 - VLands GroupDokument1 SeiteF-004 - Leave Application Form-R1 - VLands GroupDhina karanNoch keine Bewertungen

- Man Hours For Urban FarmingDokument1 SeiteMan Hours For Urban FarmingDhina karanNoch keine Bewertungen

- COLUMN 300x300: General Design ParametersDokument9 SeitenCOLUMN 300x300: General Design ParametersDhina karanNoch keine Bewertungen

- JK - Dropoff Canopy Green Roof ModelDokument1 SeiteJK - Dropoff Canopy Green Roof ModelDhina karanNoch keine Bewertungen

- Vinoth Footing Details - Rev0 Foundation LayoutDokument1 SeiteVinoth Footing Details - Rev0 Foundation LayoutDhina karanNoch keine Bewertungen

- Entrance Arch Parur ModelDokument1 SeiteEntrance Arch Parur ModelDhina karanNoch keine Bewertungen

- COLUMN 300x300: General Design ParametersDokument9 SeitenCOLUMN 300x300: General Design ParametersDhina karanNoch keine Bewertungen

- Vinoth Footing Details - Rev0 Foundation LayoutDokument1 SeiteVinoth Footing Details - Rev0 Foundation LayoutDhina karanNoch keine Bewertungen

- Bollard Design PDFDokument1 SeiteBollard Design PDFDhina karanNoch keine Bewertungen

- WK PDFDokument1 SeiteWK PDFDhina karanNoch keine Bewertungen

- Canopy - Final Design PDFDokument4 SeitenCanopy - Final Design PDFDhina karanNoch keine Bewertungen

- Diesel Engine Piping DiagramDokument11 SeitenDiesel Engine Piping Diagramshoghi wisesa100% (1)

- BS en 286-3Dokument58 SeitenBS en 286-3wi100% (4)

- Complete Guide On Plans & CalculationsDokument92 SeitenComplete Guide On Plans & CalculationsDIEGOZaf100% (2)

- Technical Specifications: Rotary Blasthole DrillDokument8 SeitenTechnical Specifications: Rotary Blasthole DrillenricoNoch keine Bewertungen

- ICS 27.100 Code for Designing Insulation and Painting of Fossil Fuel Power PlantDokument74 SeitenICS 27.100 Code for Designing Insulation and Painting of Fossil Fuel Power PlantCourage MurevesiNoch keine Bewertungen

- Fiberstrong: Reliable Jacking Pipe Systems in Polyester and Vinylester ResinsDokument4 SeitenFiberstrong: Reliable Jacking Pipe Systems in Polyester and Vinylester ResinsBabikerNoch keine Bewertungen

- For Reference Only: Drill Pipe Performance Characteristics ©Dokument3 SeitenFor Reference Only: Drill Pipe Performance Characteristics ©alekz89100% (1)

- Drainage System Specification FinalDokument3 SeitenDrainage System Specification FinalRico EdureseNoch keine Bewertungen

- Balancing and flow control valves quick reference guideDokument47 SeitenBalancing and flow control valves quick reference guideNoushad P Hamsa100% (1)

- Dead Load Only From The PipeDokument5 SeitenDead Load Only From The PipeНемања Караклајић100% (1)

- Pfi Es-49 PDFDokument8 SeitenPfi Es-49 PDFjxsnyderNoch keine Bewertungen

- And Owner'S Manual: Installation InstructionsDokument48 SeitenAnd Owner'S Manual: Installation InstructionsBondanNoch keine Bewertungen

- Filter,: Type FIA 15 - 200 ( - 8 In.)Dokument12 SeitenFilter,: Type FIA 15 - 200 ( - 8 In.)GogaNoch keine Bewertungen

- TR - Type 1 - L ShapeDokument19 SeitenTR - Type 1 - L ShapeFreedom Love NabalNoch keine Bewertungen

- Piping DesignersDokument60 SeitenPiping DesignersKagira Drawing Soltuion100% (1)

- Tecumsh Manual GRN366461 PDFDokument28 SeitenTecumsh Manual GRN366461 PDFVICTORNoch keine Bewertungen

- FXSQ-A2VEB - Operation ManualDokument17 SeitenFXSQ-A2VEB - Operation Manualsumanth.n nNoch keine Bewertungen

- Cameron-MBS-Multi-Bowl Wellhead System - CedipDokument6 SeitenCameron-MBS-Multi-Bowl Wellhead System - CedipiswantmachooNoch keine Bewertungen

- Manual Instalacion y Operación Bomba Spring - MS1Dokument56 SeitenManual Instalacion y Operación Bomba Spring - MS1JUAN DAVID BALDION BONILLANoch keine Bewertungen

- Cleanliness of SurfacesDokument12 SeitenCleanliness of SurfacesKreshna Wisnu BrataNoch keine Bewertungen

- Branch Reinforcement Pad Requirement CalculationDokument1 SeiteBranch Reinforcement Pad Requirement Calculations.mladinNoch keine Bewertungen

- 39CQM Air HandlingDokument32 Seiten39CQM Air Handlingcarrier SingaporeNoch keine Bewertungen

- TM Midea V8 High Static Pressure Duct VRF Engineering Data Book 20230721 V3Dokument29 SeitenTM Midea V8 High Static Pressure Duct VRF Engineering Data Book 20230721 V3mohamed.irfan.mepNoch keine Bewertungen

- Tuboscope Drill PipeDokument6 SeitenTuboscope Drill PipeOscar CarrascoNoch keine Bewertungen

- BS 4368-1 1998Dokument22 SeitenBS 4368-1 1998virajNoch keine Bewertungen

- Ir 07 01 PDFDokument128 SeitenIr 07 01 PDFfmboy700Noch keine Bewertungen

- 2011 VND O&M ManualDokument12 Seiten2011 VND O&M Manualsequeira.cedric6742Noch keine Bewertungen

- Kal Cret 2005Dokument16 SeitenKal Cret 2005TECHNO CASTNoch keine Bewertungen

- Metal Diaphragm Valve Technical SpecificationsDokument6 SeitenMetal Diaphragm Valve Technical SpecificationsDenial BasanovicNoch keine Bewertungen

- Rig Pre-Commencement Inspection Guide ChecklistDokument115 SeitenRig Pre-Commencement Inspection Guide Checklisthosam ali100% (1)