Beruflich Dokumente

Kultur Dokumente

TV7 U Operator Manual

Hochgeladen von

eliastc760 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

21 Ansichten40 Seitentm 11-6625-274-12 test electron tube

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldentm 11-6625-274-12 test electron tube

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

21 Ansichten40 SeitenTV7 U Operator Manual

Hochgeladen von

eliastc76tm 11-6625-274-12 test electron tube

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 40

TM 11-6625-274-12

DEPARTMENT OF THE ARMY TECHNICAL MANUAL

OPERATOR’S AND ORGANIZATIONAL

MAINTENANCE MANUAL

TEST SETS, ELECTRON TUBE 'TY-7/U,

TV-7AJU, TV-7B/U AND TYV-7D/U

HEADQUARTERS, DEPARTMENT OF THE ARMY

14 JUNE 1960

STM 11-6625-274-12

TECHNICAL MANUAL HEADQUARTERS

No. 11-6625-274-12

CuarteR 1.

Section 1

Xu.

Carrer 2.

Section 1

1.

1

IV.

August 1959,

11-8625-27-

1 pertains to. packaging and repackaging: TM 11-6625-274-10P, 11 June 1988,

P, 11 June 1958, ag pertains to the me

DEPARTMENT OF THE ARMY

WASHINGTON 25, D.C., 14 June 1960

TEST SETS, ELECTRON TUBE

T-7/U, TV-7A/U, TV-7B/U, AND TV-70/U

INTRODUCTION

General

Scope

Forms and records

Description and data

Purpose and use

‘Technieal characteristicn

‘Table of components

Description of test set

Differences in models

INSTALLATION AND OPERATING INSTRUCTIONS

Servier upon receipt of equipment

Unpacking

Checking unpacked equipment

Controls and indicator

General

Controls, indicators, and jacks

Operation under usual conditions

General instructions

‘Test lends

Tube test sockets

‘Tube test data

Adapters

Operating test set

Starting. procedure

Operating procedure

Checking filament continuity (12-volt Filament tubes)

Reading meter

Gas test

Noise test

Panel lamp test

Testing special tube types

Testing subminiature tubes

Stopping procedure

much of TM 11-083, 29 September 1853, including C1, 2 8

2, as pertains to operation and organizational maintenance

jenance allocation chart.

10

n

12

8

u“

6

16

10

u

u

u

13

4

14

4

15

16

16

Ww

18

18

19

19

19

19

20

rember 1955; C2, 8

9 much of C4, 26

snd a0 much of TM.

CHATTER

CHAPTER,

Section

APPENDIX

0.

1

0

un.

Operation under unusual conditions

General .

Operation nt low temperatures .

Operation under tropical conditions

Operation in desert climates

MAINTENANCE INSTRUCTIONS

General o

Materials required

Preventive maintenance

Visual inspection

Equipment performat

Removal of chassis

‘Tube replacement

Preferred-type tubes

Replacement of Jamps

SHIPMENT, LIMITED STORAGE, AND DEMOLITION

TO PREVENT ENEMY USE

Shipment and limited storage

Removal from service :

Repackaging for shipment or limited storaze

Demolition of materiel to prevent enemy nse

Authority for demolition

Methods of destruction

REFERENCES,

checklist

OPERATOR'S MAINTENANCE REPAIR PARTS AND

SPECIAL TOOLS LIST

MAINTENANCE ALLOCATION CHART

ood

28

30

a1

32

34

35

36

a8

39

0

a

a,

a

BSSSRIRRS

30

30

32.

33

34

aT

CHAPTER 1

INTRODUCTION

1. Scope

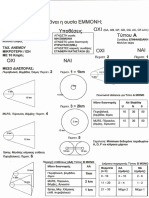

a. This manual deseribes Test Sets, Electron

Tube TV-7/U (fig. 1), TV-TA/U (fig. 2),

TV-7B/U (fig. 3), and TV-7D/U (fig. 4), and

covers installation, operation, and first and

second echelon maintenance. It includes in-

Figure 1. Test Set, Electron Tube 1-2/1

Section 1, GENERAL

structions for operation under usual and uns

usual conditions, cleaning and inspection of

the equipment, and replacement of parts avail-

able to first and second echelon maintenance

personnel.

leas running speres,

Figure 2, Test Set, Electron Tube TV-TA/U, lees running spares

Figure §. Test Set, Flectran Tube TV-TRIT. lees rianing spares.

Figure 4. Test Set, Electron Tube TV-FDIM, lose running anares

b, Official nomenclature followed by (*) is

used to indicate all. models of the equipment

item covered in this manual. Thus, Test Set,

Electron Tube TV-7(*)/U_ represents Test.

Sets, Electron Tube TV-7/U, TV-TA/U, TV

7B/U, and TV-7D/U.

2. Forms and Records

0. Electronic Failure Report. Fill out and

forward DD Form 787-1, Electronic Failure

Report-Signal Equipment, to the Commanding

Officer, U. 8. Army Signal Equipment Support

Agency, Fort Monmouth, N.J., as prescribed

in AR 700-39.

b. Unsatisfoctory Equipment Report. Fill

out and forward AF TO Form 29, Unsat

factory Report, to the Commander, Air Mate-

Command, Wright-Patterson Air Force

Base, Ohio, as prescribed in AF TO 00-85D-54.

¢. Report of Damaged or Improper Ship-

‘ment. Fill out and forward DD Form 6, Re-

port of Damaged or Improper Shipment, as

prescribed in AR 700-58 (Army), Navy Ship-

ping Guide, Article 1850-4 (Navy), and AFR.

1-4 (Air Force).

d._ Preventive Maintenance Form. Prepare

DA Form 11-266 (fig. 11 and 12), Maintenance

Cheek List for Signal Equipment (Test Equip-

ment), in accordance with instructions on the

form.

e. Parts List Form. Any comments con-

cerning omissions and discrepancies in appen-

dix II or IT in this manual will be prepared

on DA Form 2028 and forwarded directly to

the Commanding Officer, U.S. Army Signal

Equipment Support Agency, Fort Monmouth,

N. J. ATTN: SIGFM/ES-ML.

J. Comments on Manual. Forward all other

comments on this manual direct to the Com-

manding Officer, U.S. Army Signal Publica-

tions Agency, Fort Monmouth, N. J.

Section Il, DESCRIPTION AND DATA

3. Purpose and Use

Test Set, Electron Tube TV-7(*)/U is a

portable tube tester of the dynamic mutual

conductance type. It is used to test and to

measure performance capabilities and to de-

termine rejection limits for electron tubes used

n receivers, low-powered transmitters, and

many other electronic equipments, The follow-

ing tests ean be made with Test Set Electron

Tube TV-7(*)/U:

y test (ballast tubes).

b. Dynamic mutual conductance test (am-

plifier tubes).

Emi

a. Contin

. n test (rectifier tubes).

d. Gas test (amplifier tubes).

Noise test.

Panel lamp test.

Shorts test.

at

4, Technical Characteristics

Power Supply:

Input voltage 103.5 to 126.5 volts ac,

single phase,

Frequency 50 to 1,000 eps.

Power consumption .. 45 watts at 115 volts,

50 eps.

Meter .. 0 to 120 arbitrary

uni

Operating tempera- --40° to +125°

ture limits Fahrenheit

Number of tubes 2.

Indicator lights:

PILOT .. One type 47.

SHORTS ... One type NE-45.

FUSE One type 81.

5. Table of Components

The components of Test Set, Electron Tube

TV-7(*)/U are listed in a below and the spare

parts in b below.

Components.

van ad

~ a ve | tom | tet | lw

1 | Test act including tubes and lamps oie | 8% | 15% | 18

1 | Adapter 105: 8528, 829-B or 832-A. tubes

1 | Adapter B107: 2039 tube :

1 | Adapter E104: Subminiature tubes .

1 | Adapter X10B: socket sever, T-pin miniature (TV-1D/0)

1 | Adapter X7B: socket saver, 9-pin miniature (TV-7D/U) .

1 | Adapter X3B: socket saver, octal (TV-7D/U)

2 | Test leads .

tet | Running spares (2 below) 8

b. Spare Parts. binder inside the cover holds TB 11-6083-1

= = (tube test data book (par. 15)). The cover is

hinged by slip hinges and can be removed from

1 | Electron tube, type SYSWGTA the case.

1 | Hlectron tube, type 23 b. An indicating meter and all controls,

1 | Lamp, neon NE-45 knobs, pushbuttons, sockets, and indicating

1 | Lamp, incandescent No. 47 lamps are on the front panel. The necessary

1 | Lamp, incandescent No. 81 data for setting and operating the controls to

test the various tube types are contained in the

Description of Test Set

(fig. 1-4)

a, Test Set, Electron Tube TV-7(*)/U

(test set) is self-contained in a carrying case

equipped with a carrying handle, The cover

secured to the case by luggage-type fasten-

ers. Retainer brackets on the inside of the

cover are used to secure and store the power

cable, pin straighteners for 7- and 9-pin minia-

tube test data book (a above). One end of the

alternating current (ac) line cord is perma.

nently attached to the panel; the other end

terminates in a male plug.

7. Differences in Models

Test Sets, Electron Tube TV-7(*)/U are

similar in purpose, operation, and appearance.

Some models have been modified to improve

operational features. External differences are

ture tubes, and adapters (par. 16). A ring as follows:

im 7 Tone wea Teen

F RANGE on FUNCTION Not used, Not used. Not used, Used.

‘SWITCH.

BIAS and SHUNT controls ..... | Markings en- | Markings etched | Markings etched | Markings etched

graved on @ into test set {into test set to teat et

il. panel. panel. panel

SHORTS lamp .. No panel Panel marking, snel marking. | Panel marking.

‘marking.

Subminiature tube test socket | Rectangular. Round on some | Rectangular. Rectangular,

109, ‘equipments,

Storage clip for ae line cord plug. | Not used. Used. Used. Used,

Storage clips for test leads Not used. Not ured. Used. Used.

Tip of test lead plug (2 each) ... | 8/82-Inch 5/64-inch 8/82-inch 8/82-inch,

diameter. diameter. diameter. diameter.

Tee wer TaN Ta Teen

Grid (G), plate (P), and NOISE | Accommodates | Accommodates | Accommodates | Accommodates

jacks. 5/64-inch 3/32-inch 12/32-inch

iameter tip diameter tip diameter tip

plugs. plugs. plugs.

Gasket around edge of cover Used. Used. Used.

Not provided. | Provided.

Socket eaver adapters X10B, X7B,

'4 XB, 7-pin and 9-pin’mini-

ature and octal base.

Not provided.

Not provided.

CHAPTER 2

INSTALLATION AND OPERATING INSTRUCTIONS

Section I. SERVICE UPON RECEIPT OF EQUIPMENT

8. Unpacking

a, Packaging Data. When packed for ship-

ment, the test set is packaged in an inner

fiberboard carton, Spare parts are in a small,

corrugated carton, protected by 2 sleeve on

top of the test set. The inner fiberboard carton

is sealed with gummed tape, and is then placed

within an outer fiberboard carton, with all

seams and joints sealed with water-resistant,

pressure-sensitive tape. A wooden packing

case may also be used when a multiple of four

test sets is shipped. The wooden packing case

stages

[235

<> szyroe

Fiatneoaro

will be strapped only for intertheater ship-

ment. A typical packing case and its contents

are shown in figure 5.

(1) The inside dimensions of a packing

case that contains four packaged test

sets is approximately 18% by 20Y

by 15% inches; the volume is 4.8

cubic feet, and the weight is 106

pounds.

(2) The outside dimensions of a test set

packed in fiberboard cartons is 214%

by 10% by 814 inches; the volume is

1 of

" Figereonro

ct Exmron

i tot

i en

1 it

t tt

' it nore:

t tt WOODEN PACKING CASE 1S USED

i tot WneN Packie MULTIPLES OF

| Foun rest sers

(wore

‘rwes28-274

Figure §. Typical packaging.

12 cubie feet, and the weight is 21%

pounds.

Removing Contents.

(1) Cut and fold back the metal straps

(when used).

(2) Remove the nails from the wooden

cover and one side of the wooden

packing case with a nailpuller. Re-

move the cover and the side. Do not

attempt to pry off the cover or the

side; prying may damage the equip-

ment.

(3) Remove the envelope that contains the

technical manuals.

(4) Remove the outer fiberboard carton

from the wooden packing case.

(5) Open the outer fiberboard carton and

(6) Open the inner fiberboard carton and

remove the contents.

9. Checking Unpacked Equipment

Check the equipment against the packing

list. When no packing list accompanies the

equipment, use the table of components (par.

5) as a general check. If the equipment is

damaged, refer to paragraph 2. After a test set

is removed from its fiberboard container, re-

lease the fasteners, open the cover, and proceed

as follows:

a, Check to see that the adapters (fig. 8)

are held firmly to the cover.

b. Check all controls for ease of rotation.

Tighten loose knobs.

¢. Check for a broken meter glass and

broken lamps.

d. Check the 2c line cord, test leads, and

rubber gasket around the edge of the cover

remove the inner fiberboard carton. (except on TV-7/U) for signs of deterioration,

Section I, CONTROLS AND INDICATORS

10. General

Improper setting of the FILAMENT VOLT-

AGE switch (fig. 6) or incorrect operation of

the pushbutton switches may damage the tube

under test. Be sure that all the controls and

switches are set properly before testing tubes.

11. Controls, Indicators, und Jacks

Switches and Controls.

POWER switch cassie | ON: Connects. ac

power to test

set.

OFF:

Removes ac

power from

test tet.

FILAMENT VOLT-

‘AGE (20-position

Provides an 18-step selection

of filament voltages from

rotary switch) 0.6-volt to 117 volts ac.

BLST.: Enables ballast

tubes to be

tested for con-

tinuity and

supplies volt

age to certain

rectifier tubes,

for emission

tests,

OFF: Removes voltage

from FILA-

MENT VOLT-

AGE switch,

FILAMENT selectors, | Connects filament of tube

eft and right (10.

position, S:section

rotary switches)

GRID selector (10-po- |

ition, B-section

rotary switch)

‘under test to filament volt-

age supply.

‘When set in one of positions

1.9, connects control grid

of tube under test to bias

‘and signal voltages.

PLATE selector (10-

position, B-section

rotary switch)

When set in one of positions

1.8, connects plate of tube

under test to plate voltage

supply.

When set in one of positions

1.9, connects sereen grid of,

tube under test to screen

voltage supply.

| When set in one of positions

1.9, connects cathode of

tube under test to desired

SCREEN selector (10-

position, B-section

rotary switch)

CATHODE selector

(10-position rotary

switch, 0-position

open) test circuit.

SUPPRESSOR selector | When set in one of positions

(10-position rotary | 1-9, connects suppressor

switch, O-position grid of tube under test to

open) Aesired teat cirenit.

io ental

FUNCTION SWITCH

(1L-position, 8-sec-

tion rotary ‘switch

(TV-7D/0), 10-

position, 6-tection

rotary switch on all . Subminiature tubes of the flat or in-line-

contact type with pins or leads are tested in

flat socket X109 (fig. 9). The tube pins or

leads must be inserted so that the dot on the

base of the tube is directly in line with the

small, molded dot on the socket.

c. Subminiature tube types are identified in

the test data book by a star beside the type

number. The applicable basing for the various

round types is indicated in the Notations col-

umn. The basing designation letter refers to

the diagrams shown in figure 10.

cincuLan

Figure 9. Top view of sockets X109 (flat)

and X110 (circular).

26. Stopping Procedure

Set the POWER switch to the OFF po-

sition.

? 8

2 2

o! 2 9

8 c

B f

? ee

ns 2 3

oe! . 40

° €

Figure 10. Basing diagrams for subminiature

tubes (letters, A, B,C, D, B, and F identify

basing for use with test data book).

b. Remove the tube under test from the

test socket.

¢. Place the adapters, if used, under the

clamps on the inside of the cover.

d. Disconnect the ac line cord from the

power source and wind it counterclockwise

around the retainer bracket on the inside of

the cover. Secure the plug under the storage

clip (TV-7B/U and TV-7D/U, fig. 8 and 4),

or under the coiled ac line cord (TV-7/U and

TV-7A/U).

€. Place the test leads, if used, in the stor-

age clips (not on TV-7/U). On the TV-7/U,

store the test leads under the coiled ac line

cord or as shown in figure 1.

f. Close the cover and secure the fasteners.

Section V. OPERATION UNDER UNUSUAL CONDITIONS

27. General

The test set is designed for normal operation

through a temperature range from —40° F to

+125°F. The operation of the equipment may

be more difficult in regions where extreme cold,

heat, humidity, or moisture conditions prevail.

Paragraphs 28 through 30 provide operational

information that may be used to minimize the

effects of regional extremes.

20

28. Operation at Low Temperatures

Subzero temperatures and climatic condi-

tions associated with cold weather may effect

the efficient operation of the test set.

a, Extreme cold makes the ac line cord and

other rubber parts stiff and brittle. Handle

the equipment carefully to avoid cracking the

insulation on the ac line cord and on the test

leads.

b. Keep the equipment in a warm, dry lo-

cation. If possible, keep the test set in a heated

enclosure. A standby heater is not provided

therefore, leave the test set turned on if possi-

ble.

c. Allow the test set to warm up for 10 to

15 minutes before testing tubes. The length

of warmup time depends upon the temperature

of the surrounding air.

d. If equipment that has been exposed to

the cold is brought into a warm room, moisture

will form on it and may cause fogging of the

meter glass! Dry the equipment thoroughly.

e. Keep the cover of the test set closed at

all times when the equipment is not in opera-

tion, This will prevent an accumulation of

moisture within the equipment due to sweating.

29. Operation Under Tropical Conditions

Warm, damp climates expose the equipment

to damage from moisture and fungus. The

high relative humidity causes condensation

when the temperature of the equipment drops

below that of the surrounding air. Adequate

ventilation will minimize this condition. Keep

the cover of the test set closed as much as

possible, Wipe all moisture and fungus from

the exterior of the test set with a clean, lint-

free cloth.

30. Operation in Desert Climates

Desert climates expose the test set to damage

from dirt, dust, sand, and the effects of strong

sunlight. Provide means for keeping dust and

sand from entering the holes in the test sockets,

adapters, and jacks, and from accumulating

around the pushbuttons and other moving parts

of the test set. Clean and dust the equipment

frequently. When not in use, keep the cover

closed to keep dust and dirt out of the exposed

parts.

CHAPTER 3

MAINTENANCE INSTRUCTIONS

31. General

The procedures in paragraphs 32 through

39 are to be performed by the operator or

organizational maintenance personnel. Oper-

ator’s maintenance consists of preventive main-

tenance (par. 33), visual inspection (par. 84),

and replacement of electron tubes (par. 37)

and lamps (par. 39). Organizational mainte-

nance of the test set is limited to preventive

maintenance (par. 33) and to the replacement

of the adapters (fig. 8), knobs and pushbut-

tons, indicator light lens, cable clamps, and.

clip insulators. The only tools required are

those tools normally available to the repair-

man-user because of his assigned mission.

32. Materials Required

The materials required for operator's and

organizational maintenance are as follows:

a, Cleaning compound (Federal stock No.

7930-395-9542).

b. Cleaning cloth.

¢. Sandpaper, #0000.

33. Preventive Maintenance

DA Form 11-266. DA Form 11-266 (fig.

11 and 12) is a preventive maintenance check-

list to be used by the operator and organi-

zational maintenance personnel. Items not

applicable to the test set are lined out in figure

12. References in the ITEM block in figure 12

are to paragraphs that contain additional

maintenance information pertinent to the par-

ticular item, Instructions for the use of the

form appear on the form.

b. Items. The information shown below

supplements DA Form 11-266. The item num-

bers correspond to the ITEM numbers on the

form,

1 | Use a clean cloth to remove dust, dirt; m

ture, and grease from the case, the front

panel, and the adapters. If necessary, wet

a cloth with eleaning compound and then

wipe the parts with a dry, clean cloth

2 | Inspect the clips that hold the adapters and

the clips that hold the test leads (TV-7B/U

and TV-1D/U) for tight spring action.

Check the ring binder for proper operation.

Check the PILOT, FUSE, and SHORTS

lamps for broken glass. Check to see that

the socket-saver adapters (fig. 7) are tightly

secured in thelr respective test sockets.

of pun 1p saoed “gos-11 uutog Yq “IT eanbag

or-zi-viz-szs9ns

pyeagy coum | 09, a9 22

OUPED preven | 09, 8248 7 |

Nfdb- AL FONL NOYLIITI “LIS LEFL

LMaMdINOS TWNDIS Od ASI XO3HD SORYNALNIVH

23

Neziep2-6299n ‘pu § evOod ‘g9s-11 wavy WG “Et 24nbIg

LNIWIIO7TA IY VOI FIN ONILNIOW

MO7IHIF NINN OL OPLAOAIS

"NIAOVE SSUTI YILIN “IH WIL!

“

34, Visual Inspection

a, When the equipment fails to perform

properly, check the items listed below.

(1) Test leads, if used, poorly connected

or improperly connected.

Incorrect. pushbutton depressed.

Improper setting of selector switches

or controls (par. 185(3) ).

Battery or resistors improperly con-

nected (par. 24a).

FUSE lamp defective.

LINE ADJUST control improperly

adjusted (par. 17¢).

b. If the above checks do not locate the

trouble, proceed to the equipment performance

checklist (par. 35).

(2)

(3)

4)

(5)

(6)

35. Equipment Performance Checklist

a, General. The equipment performance

checklist provides a procedure for systemati

cally checking equipment performance. All cor-

reetive measures that the operator or the

organizational maintenance man can perform

are given in the Corrective measures column.

When using the checklist, start at step 1 and

follow each step in order. If the corrective

‘measures indicated do not repair the equipment,

troubleshooting is required by higher echelon.

Note on the repair tag how the equipment per-

formed and the corrective measures that were

taken. Perform the steps in b below.

b. Checklist

Connect ac Tine cord to

power source,

Set switch to ON position.

1 Ae Tine cord.

2 POWER switch,

MmOdp E> emE

3. Meter,

4° Pushbutton 1—

LINE ADI.

5 LINE ADJUST

‘control knob.

Depress pushbutton

Rotate control knob, while

holding pushbutton 1—

LINE ADJ, down, unti

meter pointer is directly

over LINE TEST mark

6 Selectors, Set selectors as directed in

paragraph 17e(1).

7 FUNCTION Rotate switch through the

SWITCH. five SHORTS positions

8 POWER switch,

Set switch to OFF position.

Check se line cord connection

Remove (par. 392) and check

(par. 23) PILOT lamp; re

place if defective.

Remove (par. 390) and check

(par. 23) FUSE lamp; re-

place if defective,

Higher echelon repair required,

Defective type 86 tube: replace

tube (par. 37) «

Higher echelon repair required

PILOT lamp lights

Pointer stays at zero.

Meter pointer moves

up-seale,

Meter pointer moves

when control knob is

turned.

Check for low-line voltage if

pointer will not adjust

properly,

Higher echelon repair required.

When selector pointer is be

bbe tight and point | tween two numbers or two

directly at a number | letters, rotate switch fully

for letter. The switch | counterclockwise. Loosen

detents shovld be | knob setscrew, tum knob un-

posi til it points directly at the

first number or letter, and

tighten setscrew,

Tighten loose knobs.

If switch detents are not

tive, higher echelon repair is

required

Cheek switch settings.

Replace SHORTS lamp (par.

).

igher echelon repair required.

Selector knobs should

SHORTS lamp glows

at positions 2 and 3

of switch,

PILOT Iamp goes out.

26

16 | Adapter E105

(fg. 8).

l17 | Adapter E107

(fig. 8).

Testing tube type 3E29,

829-B, or 832-A.

Testing tube type 2C29.

proper pushbutton

is depressed.

Meter indicates condi-

tion of tube when

pushbutton 3 —

MUT. COND. is de-

pressed,

Meter indicates condi-

tion of tube when

pushbutton 3 —

MUT. COND. is de-

pressed.

a ao =a oo

z[e Bet eccrdg to text beng

: pertrmed

A |10 |Tube under test. | Insert in proper test socket. | Tube pins enter test | Check for bent pins. Straighten

Md Make connections as re- socket without fore- pins of miniature tubes

0 quired. 1 ‘one of the pin straighteners.

11 |PowR switch | Set switch to ON poston. | PILOT lap lights

E fia [Water Checking tae Tor dynam | Meter pointer nd | Hrmeter pointer rapa wer

a Mmtant conductance em: | “estes ‘cndon of | "tbe onder tox maybe de

$ ton ot ae tthe. ‘onder teat | fective

1 when proper pe | Check siting of electors and

P Suttons Spree. | won

x Tet tor tbe

E Higher ehlon eal ogied

N |13 [BIAS control | Gns test. Meter pointer can be | Adjust BIAS control knob un-

jsed to 10_by | tl pnts inten 10 hen

. tersing| control | proceed wih gaw tert

; thot

E [14 |Panettamp test | Checking a panel (ist) | A. goed lamp wil | Make good contact betwen

F | [Pee temp tet 2) | nde Sap and se ket

8 cial conte stings

| Lp nye efsies check

M | other lamps if available.

x nig elon ei eid

N his [Adapter B10e | Testing long lead subminae | Mtr indicates cndl- | Uneplekng deve on adap

ce Mes) | “tare tbe Sion of tobe ‘een | tervnove tbe sp and down

to check seating of leads, and

secure locking device. ‘Test

tube again.

Cheek control settings.

Cheek Notations column in

test data book for type bas-

Ing used. Compare place-

ment of tube leads to basing

diagram (fg. 10)

Replace adapter and check tube

‘again. If meter pointer does

rot move when correct push-

button is depressed, test

another tube.

Higher echelon repair required.

Check seating of adapter and

tube.

Check plate lead for good

connection.

Cheek setting of controls.

Test another tube. If meter

pointer does not move, re-

place adapter.

Higher echelon repair required,

Check seating of tube and

‘adapter. Remove adapter

and tube and squeeze spring

contacts closer together if

necessary.

Check setting of controls.

Replace adapter and tubo in

test socket and test tube

agai

8

Hung com

19

MOZ>E NOMA

Socket x109

Socket X110

| Testing flat subminiature

(fg. 9). tube.

Testing, round submi

(fz. 9) tobe.

tion of

proper

tion of

proper

Meter indicates condi-

is depressed.

| Test. another tube. If meter

pointer does not move, re

place adapter.

Higher echelon repair required

Check to ace that dot on base

fof tube is aligned with dot

fon test socket.

Slide tube leads up and down

in teat ocket to insure good

contact.

‘Check setting of controls.

‘Test another tube.

Higher echelon repair required.

tube when

pushbutton

tube Tends up and down

in test socket to insure good

contact.

Cheek setting of controls.

Check Notations column in test

data book for type basing

used. Compare placement of

tube leads to basing diagram

(fig. 10).

‘Test another tube.

Higher echelon repair required.

‘tube when

pushbutton

is depressed.

20

a

22

wona

ITube under test.

POWER switch.

‘Ac line cord.

Remove from test socket.

Set to OFF position.

Remove ac line cord plug

from power souree.

PILOT lamp goes out.

36, Removal of Chassis

q

(2)

(3)

@)

(5)

Removal.

Unsnap the latches and open the cover

of the test set.

Unwind the ac line cord from the

retainer bracket and remove the cover

from the test set. Remove the cover

by sliding it to one side until the

hinge pins are disengaged.

Remove the screws that secure the

front panel to the case.

Hold the front panel to the case, turn

the test set over, and gently place it

on a clean, flat surface.

Slowly lift the test set case upward

until it is clear of the chassis.

b. Replacement.

qa)

Position the test set case so that the

handle is forward.

@)

(3)

()

Carefully lower the test set into the

case. Be sure that no wires are caught

between the front panel and the edge

of the case.

Replace the screws that secure the

front panel to the case. Tighten the

screws in rotation a little at a time to

prevent binding.

Replace the cover on the case, wind

the ac line cord counterclockwise on

the retainer bracket, secure the plug

under the clip (not on TV-7/U), close

the cover, and secure the latches.

37. Tube Replacement

When

trouble occurs, check the ac line cord

connection and the control settings before re-

moving any tubes. If tube failure is suspected,

use the tube substitution method (a below) to

check the tubes.

a7

Caution: Do not rock or rotate a tube when

removing it from a socket; pull it straight out

with a tube puller.

a, Tube Substitution Method. Replace a

suspected tube (b below) with a new tube. If

the equipment still does not work, remove the

new tube and put back the original tube. Repeat

this procedure with the other tube. If the test

set is still inoperative, other checks are re-

quired (par. 35).

b. Replacing Tubes in Test Set, Electron

Tube TV-7(*)/U. Check the tubes in the test

set as follows:

(1) Remove the chassis from the case

(par. 36a)

(2) Remove the tube clamp (fig. 18) from

the threaded stud and remove the

tube.

Caution: Be careful not to hit the

meter case with tube type 83 when

removing the tube.

(3) Replace the tube (a above) with one

of the running spares.

(4) Set the tube (or a replacement) in

the socket and secure it with the tube

clamp.

(5) Replace the chassis in the case (par,

360)

38. Preferred-Type Tubes

A preferred-type electron tube, type

SYB3WGTA, has been developed as a direct re-

placement for nonpreferred types 5Y3GT and

BYBWGT (par. 7). The 5Y8WGTA is used in

the power supply. When replacement of a

BYSGT or a 5Y3WGT is necessary, replace it

with a BYSWGTA. Do not substitute a 5Y3GT

or a 5YSWGT for a 5Y3WGTA.

Figure 13. Tube location

39. Replacement of Lamps

The FUSE, PILOT, and SHORTS lamps are

removable from the front panel of the test set.

a, The FUSE lamp and PILOT lamp have

28

bayonet-type bases. Unscrew and remove the

PILOT lamp indicator jewel to gain access to

the PILOT lamp. To remove either lamp, press

downward, turn the lamp to the left, and lift

straight up. To replace the FUSE or PILOT

lamp, insert the lamp in the appropriate socket,

press downward, turn the lamp to the right,

and release it. Replace the PILOT lamp indi:

cator jewel.

b. The SHORTS lamp has a screw-type

base. Remove the lamp by turning it to the

left; replace the lamp by turning it to the

right.

2

CHAPTER 4

SHIPMENT, LIMITED STORAGE, AND DEMOLITION

TO PREVENT ENEMY USE

40. Removal From Service

‘Set the POWER switch to the OFF po- Flexible corrugated fiberboard ... 10 sq ft

sition and disconnect the test set from the Waterproof wrapping paper

power source.

b.

the cover.

a.

e.

around the retainer bracket and place the plug.

under the clip (not on TV-7/U).

test leads under

(TV-1/U and TV-7A/U) or as shown in fig-

ures 1 and 2. On the

‘TV-7D/U, insert one end of the test leads into

the storage clips and connect the alligator clips @

to the studs (fig. 3 and 4).

d. Close the cover and secure it with the

latches,

41. Repackaging for Shipment or Limited

‘The exact procedure for repackaging de-

Place the

the coiled ac line cord

TV-7B/U and the

Section |. SHIPMENT AND LIMITED STORAGE

Place the adapters under the clamps on Metal strapping (%- by 0.020-inch) .. | 8 ft

| 10 sa ft

Gummed paper tape aft

Pressure-sensitive tape aft

(Nore Strarning sels reqitd)

Woode

Wind the ac line cord counterclockwise 18% by 10%-by 7% Lea (9 bd ft)

b. Packaging.

(1) Technical manual. Package the tech-

sure-sensitive tape.

pressure-sensitive tape.

(3) Test set. The procedure used to pack-

age the test set is the same as the

procedure used to package the spare

pends on the material available and the condi- parts ((2) above)

tions under which the equipment is to be — c. Packing.

shipped or stored. Adapt the procedures out- (1) Fabricate a wooden box.

lined below whenever circumstances permit. (2) Place the packaged test set (b(3)

‘The information concerning the original pack- above) in the wooden box.

aging (par. 8) will also be helpful.

(3) Place the spare parts (b(2) above)

and the technical manuals on top of

a. Material Requirements. The following the test set.

materials are required for repackaging Test (4) Nail down the wooden cover.

Set, Electron Tube TV-7(*)/U. For stock (5) Strap the wooden box when inter-

numbers of materials, consult SB 88-100.

30

theater shipment is involved.

nical manuals within a close-fitting

bag fabricated of waterproof wrap-

ping paper. Seal the seams with pres-

Spare parts. Wrap each part within

a layer of flexible corrugated fiber-

board, Seal the seams with gummed

paper tape. Overwrap the flexible

corrugated fiberboard with water-

proof wrapping paper and seal with

METAL grnars

srane pants ofl)

SOLE wis | antu |5e] 3 | og ‘wee able igi souaone = mam fe] /°8 wureme ASI1 SLUWd TVNOILINN4 NOT3HDA LSuld ‘Il u9}205 35 36 Figure 15. Electron tubes and lamps.

Das könnte Ihnen auch gefallen

- Albert Speer Oral History SummaryDokument2 SeitenAlbert Speer Oral History Summaryeliastc76Noch keine Bewertungen

- ISF ProgrammeDokument49 SeitenISF Programmeeliastc76Noch keine Bewertungen

- Κείμενο 3Dokument1 SeiteΚείμενο 3eliastc76Noch keine Bewertungen

- Atp-85 Eda V1 eDokument18 SeitenAtp-85 Eda V1 eeliastc76100% (1)

- SWISSINT Course Guide 2018Dokument24 SeitenSWISSINT Course Guide 2018eliastc76100% (1)

- Analektahieroso 02 PapagoogDokument581 SeitenAnalektahieroso 02 Papagoogeliastc76Noch keine Bewertungen

- John Allen ΚΕΦ.4Dokument38 SeitenJohn Allen ΚΕΦ.4eliastc76Noch keine Bewertungen

- ATP-45 - Writing and Reporting and Hazard Prediction of Chemical, Biological, Radiological and Nuclear Incidents (Operator's Manual)Dokument448 SeitenATP-45 - Writing and Reporting and Hazard Prediction of Chemical, Biological, Radiological and Nuclear Incidents (Operator's Manual)eliastc76100% (1)

- Avinrcuon Xno: Xapti Anixnevih' Xno U8Dokument2 SeitenAvinrcuon Xno: Xapti Anixnevih' Xno U8eliastc76Noch keine Bewertungen

- Eival Ouoia EMMONH NAI OXI A: Ytto8EoeicDokument7 SeitenEival Ouoia EMMONH NAI OXI A: Ytto8Eoeiceliastc76Noch keine Bewertungen

- ΣΕΚΓ ΤΕΣΤDokument10 SeitenΣΕΚΓ ΤΕΣΤeliastc7625% (4)

- Xapti Anixnevthe Xno U9: QVRXV Uon9Dokument2 SeitenXapti Anixnevthe Xno U9: QVRXV Uon9eliastc76Noch keine Bewertungen

- RaiffeisenDokument3 SeitenRaiffeiseneliastc76Noch keine Bewertungen

- Calendar of Activities 2015Dokument1 SeiteCalendar of Activities 2015eliastc76Noch keine Bewertungen

- NATO BookDokument262 SeitenNATO Bookeliastc76100% (1)

- Brochure CI 2014 ENGDokument24 SeitenBrochure CI 2014 ENGeliastc76Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)