Beruflich Dokumente

Kultur Dokumente

Oil Mist Lubrication Tutorial

Hochgeladen von

최승원Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Oil Mist Lubrication Tutorial

Hochgeladen von

최승원Copyright:

Verfügbare Formate

GETTING THE FACTS ON OIL MIST LUBRICATION

By

Don Ehlert

Mgr. of EPC Sales

Lubrication System Co.

Houston, Texas USA

Don Ehlert is methods for applying oil mist to rotating

currently equipment. Key questions to be addressed

Manager for include:

EPC Sales at

Lubrication What is oil mist and how is it generated?

Systems Co., a How has oil mist evolved over the past forty

Colfax years? Where oil mist is currently applied?

Company, What are the advantages of oil mist

located in Houston, TX. His current lubrication? How to justify oil mist

responsibilities include providing technical lubrication?

training and sales presentations. Don is also

responsible for quotation assemblies for Oil mist is considered a best practice by

both domestic and foreign engineering many companies in the process industries.

companies and end users. He also provides

technical support to oil mist users world INTRODUCTION

wide. Since joining LSC in 1984, he has

filled positions in equipment assembly, field This discussion is on oil mist lubrication and

maintenance, field installation, field details what oil mist is, how the systems

management, sales and sales management. work, how it is applied to rotating

He has been instrumental with the equipment and user experiences after

development of oil mist related products and applying oil mist. The primary focus will be

accessories for special applications. on retrofit of oil mist on existing pumps and

Prior to LSC Mr. Ehlert had spent time in motors, as they are the most prevalent

the US Navy providing maintenance and applications in the HPI. However it is

operation support on aircraft for the important to note that numerous other

hydraulic and flight control systems. applications benefit from oil mist including

gear boxes, blowers, turbines and pillow

ABSTRACT block bearings, to name a few.

Early in this discussion it is important to

Oil mist lubrication is a proven and note that oil mist lubrication does not cure

environmentally clean technology for the or prevent all lubrication related failures of

lubrication of rotating equipment in process rotating equipment. It is not unheard of to

industries. The use of oil mist lubrication experience a bearing failure shortly after

has grown dramatically worldwide conversion to oil mist. This is not due to the

delivering increased reliability to many lubrication by oil mist but rather due to pre-

types of rotating equipment. Many existing bearing conditions that led to an

advances have been made in both the inevitable failure; oil mist will not heal a

technology of oil mist system design and compromised bearing. However, oil mist

Copyright 2011 by Turbomachinery Laboratory, Texas A&M University

greatly extends the life of bearings versus Application of Pure Oil Mist in the

alternative lubrication methods. The reasons Petrochemical Plant (4) and Practical

for this will be explored in more detail later, Experience with Oil Mist Lubrication (5).

but can be summarized in that bearing

temperatures run significantly cooler with

oil mist, ambient contaminants cannot enter

the bearing housing and the automated

system ensures the right amount of lubricant

all the time.

HISTORY OF OIL MIST

Oil mist has been applied to equipment in

the HPI, CPI, Steel Mills, Pulp & Paper Early systems were installed by simply

Mills, Textile Plants, Rock Quarries, laying the piping header in the pipe rack and

Automotive Plants and others. A taking the shortest route possible between

commonality of applying oil mist across all two points, the header and the application

industries is the importance of not only the point, a straight line. With this type of

oil mist generator but also the piping installation the header would often sag

distribution system. Historically, any between supports creating shallow pockets

unsatisfactory results or disappointment with of oil in the line. Then the application drop,

oil mist lubrication were due to issues with connected on the bottom of the header,

the distribution system. The following would channel the liquid oil onto the

discussion provides a brief history of oil reclassifier which was mounted in the

mist and the evolution of design over the bottom of the drop pipe or on top of the

years. pump, figure1.

Oil mist was developed in Europe in the In these instances this caused plugging of

early 1900s to replace grease and the reclassifiers and prevented the oil mist

circulating oil systems on high speed spindle from lubricating the bearings. As oil

bearings. It was then introduced to the US viscosity increases in cold weather the

industry in 1948 with the steel industry system plugging was more pronounced and

being the first to use it. Applying oil mist on caused some users to switch to lower

rotating equipment in the refining industry viscosity oils in the colder months to try and

dates back to the late 1960s where one of alleviate the problem. Where these problems

the first installations was in Amuay occurred the oil mist system was labeled as

Venezuela and then moved into the US unreliable when the piping installation was

market shortly thereafter. A paper written by the real issue.

Mr. Charlie Miannay (3) in 1974, while at

Exxon Aruba, is the first technical Another hurdle encountered with early oil

publication relating to oil mist in the HPI. mist application to pumps was due to the

Chevron, Exxon and Shell were the first to method of delivering the mist into the

use oil mist on a wide scale in the US. Many bearing housing. Typically a single

articles have been written on oil mist reclassifier mounted in the middle of the

lubrication that stress the simplicity of oil bearing housing was employed with venting

mist and equipment reliability taking place through the bearing housing

improvements. More recent articles that seals. It was discovered, through extensive

discussed the application of pure oil mist failure root cause analysis, that bearing

and practical experience are Large Scale windage could cause the mist to bypass the

Copyright 2011 by Turbomachinery Laboratory, Texas A&M University

bearing via the oil drain back ports, leading 1 to 3 micron, are physically too small to

to bearing failure. This was more prominent carry water or particulates throughout the

on double row thrust bearings. piping system. The larger and or heavier

particles that could possibly carry

contaminates fall out of suspension either in

the reservoir or in the piping system.

Therefore only fresh clean oil is delivered to

the bearings for lubrication. Contaminated

oil is not re-circulated through the bearings

as with a sump system (6).

The mist is generated by passing air through

a vortex or venturi, figure 3, chamber where

it picks up oil with a vacuum, siphoning

effect, and introduces it into the high

Additionally, early pure mist applications velocity air stream where the oil is atomized

used a small hole drilled through the drain into the small particles, thus creation of the

plug as a discharge, allowing excess mist oil mist. A pressure drop occurs as the air

and coalesced liquid oil to blow onto the passes through the vortex or venturi which

base plate, figure 2. These issues led some creates the mist header pressure of 500MM

early users of oil mist to believe the systems (20 of water column).

were not reliable and a housekeeping

problem. These areas of early concern were

addressed in subsequent system distribution

and application designs, detailed in the

following section.

WHAT IS OIL MIST LUBRICATION

Oil mist is a centralized lubrication system

that continuously and efficiently atomizes

oil into small particles and then conveys and This air oil mixture is known as oil mist; it is

delivers the correct amount of lubricant to not a VOC, Volatile Organic Compound or a

bearings and metal surfaces which improves vapor, it is an aerosol that consists of 1 part

the lubrication process and extends of oil to 200,000 equal parts of air. This

machinery life. The oil mist particles when mixture is well below the lean limits of

generated are nominally in the 1 to 3 micron flammability (7) and is non explosive.

range and are referred to as dry mist. Dry Regarding toxicity (8); the American

mist particles are too small for lubrication Conference of Government Industrial

but are easily transported, via air flow, Hygienists; gives a threshold limit value of

throughout the piping header system. The 5mg/m3 for a normal 8 hour workday.

mist travels at a velocity of 7.3 meters per Simply, this means that oil mist in

second (24 feet per second) in a continuous concentrations found around oil mist

laminar flow at a pressure of 500 MM (20 lubricated machinery in typical open air HPI

water column or .74 PSI). facilities is not a health hazard.

Oil mist can be referred to as the ultimate oil The particle size distribution of the oil mist

filter. The dry mist or small particles of oil, is an important characteristic for successful

Copyright 2011 by Turbomachinery Laboratory, Texas A&M University

lubrication. A large volume of very small arrangement prevents liquid oil from

mist particles (< 1.5 microns) can lead to draining down to the MDMs and plugging

inadequate lubrication, as particles of this the reclassifiers.

size will not coalesce to allow wetting.

Conversely, a large volume of large mist The MDMs are now

particles (> 3 microns) will fall out of equipped with a sight

suspension prior to reaching the application glass below the

points. Careful selection of the correct oil reclassifiers to allow a

coupled with the design advantages of the visual of liquid oil

vortex mist head can assure the mist collecting with a push

distribution necessary for the system. button drain valve that

allows for the

Additionally, the velocity of oil mist travel collected oil to be

through the distribution piping is important drained off, either to

for proper lubrication. High mist velocity an oily water sewer

will cause the smaller particles to coalesce cup or oil collection

and wet out after impinging on the piping device. This

walls. Low mist velocity will not support arrangement allows

the flow of oil mist particles in suspension. only the oil mist to flow through the

reclassifier and into the bearing to be

Regardless of the control of particle size lubricated. A fresh clean oil supply that

distribution and mist velocity, some level of continuously lubricates the bearings and

oil will coalesce in the piping. The modern pressurizes the bearing housing to eliminate

oil mist system installation, figure 4, is the intrusion of air borne contaminates. Oil

designed to accommodate this coalesced oil, mist lubricates operating equipment and

returning it to the generator, unlike some of preserves/protects idled or standby

the problematic layouts of the past. equipment all from the same system.

LUBRICATION WITH OIL MIST

There are two types of oil mist, Figure 6.

Dry oil mist is generated at the OMG and

The header pipe, normally field routed, is allows the mist to be conveyed throughout

supported, braced and sloped to facilitate the the piping header system. Wet oil mist is

return of liquid oil to the oil mist generator applied to the bearings for lubrication. As

(OMG) where it is recycled in the systems the dry oil mist travels down the drop pipe

operation. The drop pipe is connected on the en route to the equipment it passes through a

top side of the header and extends up over reclassifier (orifice fitting) creating a

and down to the mist distribution manifold turbulent area where it picks up in velocity.

(MDM), figure 5, where the reclassifiers are The small particles coalesce, forming larger

located in a horizontal plane. This piping particles, and become wet mist; they are

Copyright 2011 by Turbomachinery Laboratory, Texas A&M University

now large enough for lubrication. It is figure 8, prior to exiting the housing. The

critical that the reclassifier be located within flow through characteristic is more critical

2 meters (6.6 feet) of the application point to on multiple row bearings; however, the flow

prevent the larger particles from falling out through

of suspension and not flowing onto the

bearings.

The preferred method of application for any

bearing is to pass the mist through the

rolling elements from side to side or top to

bottom for positive lubrication. Oil mist

flow is critical to the system and lubrication

of the bearings; no or low flow allows the

particles to fall out of suspension and not requirement is not always necessary with

travel into the bearings for lubrication. single row bearings in applications such as

electric motors where the load is constant

After the oil mist flows through the bearing and thrust is not an issue.

it travels towards the vent/drain, figure 7,

whose port size is critical. Should the APPLYING OIL MIST

vent/drain port be too small and restrict the

flow it will create a back pressure in the There are two methods of applying oil mist:

housing that will restrict the flow through dry sump or pure mist and wet sump or

the bearing. The decreased flow into and purge mist. The dry sump and wet sump

through the bearings will reduce the amount terms are not to be confused with dry mist or

of oil being applied to the bearing. The wet mist. Dry mist and wet mist is

vent/drain port diameter must be 3 to 4 times referencing oil particle sizes; dry sump and

larger than the diameter of the reclassifier(s) wet sump is referencing the application of

orifice(s) to prevent a restriction of the flow. oil mist to equipment being lubricated.

This must be closely monitored when more

than two reclassifiers are feeding into a Dry sump or pure mist, figure 9, is

common bearing housing. commonly used on rolling element or anti

friction bearings and the oil mist is the only

source of lubrication for these bearings. The

pure mist not only lubricates the bearing it

also provides a slight positive pressure in the

bearing housing that eliminates the intrusion

of air borne contaminates, i.e. dust and

moisture. Thus it lubricates operating

equipment while protecting and preserving

idled or standby equipment as it creates an

ideal environment for the operating and idle

bearings.

Current edition API pumps are designed for

the oil mist to flow through the bearings,

Copyright 2011 by Turbomachinery Laboratory, Texas A&M University

purge to prevent the intrusion of air borne

contaminates and is not sufficient to provide

prolonged lubrication for the bearings or

gearing should the oil level be lost.

Although the benefits of purge mist do not

match those of pure mist, and there are

additional costs associated with necessary

accessories, substantial cost savings are

realized for these applications. The primary

benefit of purge mist is extended oil change

intervals achieved with the positive pressure

preventing thermal cycling in the housing.

Typical oil change intervals are extended

from twice per year to one change every two

to three years.

A thin film of fresh clean oil is continuously

being applied to the bearings that allows the

bearings to operate cooler and with less

friction. Bearings being lubricated with pure

oil mist typically operate 2C to 4C (25F

to 35F) cooler than oil sump lubricated

bearings. Bearings life is increased from the

cooling effect; a 5.6C (10F) drop in

bearing temperature increases bearing life

by approximately 11% (9). Also, the mist Oil sampling is recommended when oil

flow through the bearing carries wear change intervals are extended to insure that

particles away and since there is no oil sump the oil quality is not compromised over the

to allow recirculation of dirty or extended period of time. This is very cost

contaminated oil the bearings operate in a effective on cooling tower fan gear boxes

clean environment which also extends due to the location and man hours required

bearing life. for the task of changing oil and performing

lubrication related maintenance activities.

Pure oil mist also allows for the removal of

cooling water to bearing housings. As

equipment comes up to operating

temperature it is expanding and the cooling

water is trying to cool and contract which

can preload bearings and cause failure.

Removal of cooling water also reduces cost

associated with the maintenance and upkeep

of the cooling water system.

Wet sump or purge mist is commonly used

on sleeve or plain bearings, figure 10, and

on gear boxes such as the general purpose

type or cooling tower fan gear boxes, figure

11. Oil mist in this application acts only as a

Copyright 2011 by Turbomachinery Laboratory, Texas A&M University

With purge mist the vent is just as critical as specifications / designs to follow when new

with pure mist. Excessive pressure in the equipment is purchased for green field

bearing housing or gear box due to back projects, the following section will focus on

pressure from the vent line can easily give a retrofitting oil mist to existing pumps and

false, high, oil level indication in the oil motors.

level sight glass, figure 12. A high false oil

level in the sight glass is in reality a low oil RETROFITTING PUMPS TO OIL

level in the housing which may result in MIST

bearing or gear failure.

Over hung and between bearing pumps are

fairly easy to retrofit to pure oil mist in the

field, without equipment shutdown, since

the bearing housings are designed to house

only the bearings and the lubricant. Draining

the oil and applying oil mist is performed by

removing plugs and attaching the oil mist

inlet and vent/drain lines either with pure or

purge mist, figure 13. When purge mist is

used, additional components are required to

maintain the oil level and to contain the oil

mist.

OIL MIST APPLICATIONS

Oil mist applications are bearings of all

types and gears that are located in rotating

equipment found in process industries. The

most common applications for oil mist

lubrication in the HPI are pumps and

motors. Pillow block bearings, turbines and

gear boxes are also common applications but

not in the same quantities. With grass root or

green field projects equipment, pumps and

motors, are specified to be purchased for oil

mist lubrication and manufacturing

specifications are followed to insure proper When lubricating rotating equipment with

lubrication. pure mist there are several items to be aware

of; driver HP, RPM, bearing housing

Oil mist installation is relatively internal configuration and the seals. When

straightforward in these cases, when trained the driver is 150Kw (200 HP) and above

technicians are performing or supervising with an RPM of 3000 or higher the

the project. Brown field, or retrofit, projects reclassifiers should be sized for a heavy

have greater installation complexity due to service factor; when below 150Kw (200 HP)

industry practices used at the time of and 3000 RPM or less the reclassifiers may

equipment manufacture. Some of this be sized for a moderate service factor.

equipment could easily be 30 to 40 years old

and oil mist was not considered when the Older bearing housing internal

equipment was manufactured. As there are configurations may require plugging of

Copyright 2011 by Turbomachinery Laboratory, Texas A&M University

drain back ports where they exist. This any issues to arise. Should the temperature

ensures that oil mist will pass through the hold steady or increase the oil needs to be

bearings removing the remote possibility of replaced and the pump scheduled for a

circumvention. Situations where this is bearing replacement. It is not uncommon to

required will be addressed shortly. expect and experience some bearing failures

Additionally, labyrinth or lip seals should be when converting to pure oil mist. This

used as bearing isolators may block the mist indicates the bearing life was already

flow and jeopardize a multiple row bearing. jeopardized or possibly the pump is

operating too far from its BEP.

Older pumps typically have a single inlet

port located on top of the housing where oil Should this be the case or if the pump is

mist can be applied with a single reclassifier operating at 3000 RPM and the driver is

sized to accommodate both the thrust and 150Kw (200 HP) or greater the pump may

radial bearings. With this application the oil require two lubrication points to provide

mist creates a pressure in the central housing sufficient lubrication to the thrust bearing

and forces the mist through the bearings and (10). This modification may be performed in

the housing seals to insure lubrication for the field, figure 14, without taking the pump

the outboard rolling element of the multiple out for rework. A small 1/8 NPT port can

row bearing as well as the single row radial be tapped into the bearing end cap to allow

bearing. The low point vent/drain requires a for another reclassifier to provide lubrication

defined restriction to insure that the oil mist directly onto the thrust bearing. This

passes through the bearings before exiting

through the housing seals.

Slinger rings have been a somewhat

controversial topic, specifically whether

they should remain or be removed when

applying oil mist. LSCs experience

demonstrates that they pose no threat to the

communication of pure oil mist and the

additional labor to remove them is

unnecessary. It should be noted that,

although not problematic, additional noise in

vibration readings are likely from running arrangement should resolve any lubrication

the rings dry after converting to pure mist. issues and should bearing failure persist

there is the probability that other pump

Converting from oil sump to pure mist in the related issues should be investigated. As the

field one must take bearing temperature and pump goes into the repair facility for rework

vibration readings before, during and after it would be wise to remove the slinger rings,

draining the oil. Taking the bearing plug the drain back ports, tap both end caps

temperature and vibration readings prior to for inlet ports and insure that the bearing

draining the oil provides a base line to work housing seals are containing the oil mist and

from. Readings should be taken allowing it to vent only at the bottom port.

immediately after the oil is drained and then

again every 5 minutes for at least 20 Older model between bearing pumps

minutes. Typically the bearing temperature commonly have the oil inlet and drain ports

will drop 10 F to 20 F in the first 10 in the same plane, figure 15, which does not

minutes. This indicates that the bearings are support the flow of oil mist through the

in good condition and one should not expect rolling elements. When this is the case a

Copyright 2011 by Turbomachinery Laboratory, Texas A&M University

bearing application. Due to the high

frictional condition typically placed on the

end of the rollers, additional measures are

necessary to ensure proper oil mist

application. Care must be exercised to

ensure oil mist is directed precisely on the

shoulders of the bearing element in an

abundant quantity to provide adequate

lubrication.

RETROFITTING MOTORS TO OIL

directional reclassifier must MIST

be used. The directional

reclassifier extends down Electric motor construction is not governed

into the bearing housing and by detailed industries standards such as API.

the orifice port is directed at As a result, oil mist conversion for motors

the mid level point of the top although not complicated requires more

rolling element so that the effort than for their pump counterparts.

mist is directed onto the However, motor manufacturers are making

bearing. This is more critical significant strides in meeting user demands

on double or multiple row and requirements for oil mist application. In

bearings than it is on a single fact, some manufacturers have motors

row bearing. designed specifically to accommodate oil

mist with little to no extra effort.

At times the bearing housing

may require modifications to TEFC motors that are grease lubricated are

accept the directional excellent candidates for pure oil mist, figure

reclassifiers, figure 16. When this is 17. Typically, 15Kw (20 HP) and greater

encountered the pump will have to be show significant payback values for oil mist

retrofitted to purge oil mist until it is taken conversion. For motors not manufactured

out of service and modifications can be specifically to accommodate oil mist,

made to the housing. It is possible that a several factors must be considered during

reclassifier can be mounted on a horizontal the conversion.

plane that would direct the mist into the

rolling elements.

When applying pure oil mist there are

certain application conditions that must be

considered prior to conversion. The first

condition is where a pump is operating far

from its BEP. In this case, the pump should

be converted to purge mist (remain on purge

if already mist lubricated) until it can be

taken out of service and re-rated for its

current application. At that time the pump

can be converted to pure mist. The second

condition to consider is a tapered roller

Copyright 2011 by Turbomachinery Laboratory, Texas A&M University

First, all grease must be removed from the JUSTIFICATION OF OIL MIST

bearing cavity and the inlet / outlet lines

prior to applying oil mist. The low pressure Many grass roots projects are justified based

oil mist is not capable of displacing the on previous user experience with oil mist

grease from these areas. Next, winding and the resultant benefits of reduced

epoxy and lead wire insulation must be maintenance costs and increased uptime and

confirmed as compatible with the oil. Many product throughput. However, this

epoxies and insulation materials have no experience factor does not always translate

compatibility issues, yet this should be to automatic inclusion in a project and the

reviewed. Also, the internal porting to the need to justify the investment in oil mist is a

junction box (where the lead wires enter) common requirement.

must be thoroughly sealed to prevent oil The obvious improvement of reduced pump

mist from entering the box. Additionally, as repairs may in many cases be sufficient to

the oil mist will enter the housing around the justify investing in oil mist, figure 19.

rotor and the operation of the motor will

cause the mist to wet out and settle in the

lower housing of the motor, a case drain,

figure 18, must be installed in the

condensate drain plug port on the coupling

end of the motor. Finally, the fan end

condensate drain plug must be removed and

replaced with a standard plug to prevent

leakage and venting at the fan end.

However, when viewing the example from

US refineries, where the average MTBR for

pumps is reported between 60 and 70

months, figure 20, further savings and

benefits may be required, not relying on

pump bearing failures alone (11).

Copyright 2011 by Turbomachinery Laboratory, Texas A&M University

reductions range between 35% and 50% and

when applied to the example of 600 pumps

equates to an annual savings of

approximately $410,000.

Another savings is a reduction in cooling

water usage. When a bearing housing is

converted from sump lubrication to pure oil

mist, cooling water is not required (12).

Elimination of the cooling water in the

With hundreds and often thousands of bearing housing reduces the water treatment

pumps and motors in a process facility, it and maintenance related issues associated

takes little imagination to understand the with the water. By removing the water from

massive man hours required to maintain oil the pumps it is estimated that 3 pump

quality and levels as well as re-greasing failures are eliminated in a typical medium

requirements to achieve respectable sized industrial facility. This equates to an

reliability. For a facility with 600 pumps estimated annual savings of $156,000.

and 600 motors, the time required for

routine lubrication is approximately 3,000 Periodic pump switching from Pump A to

man hours per year. This time can be Pump B, which is a recommended practice

redirected from routine lubrication to for pump reliability (13), also provides

proactive failure avoidance and reliability justification for oil mist. When switching

improvement tasks. The fully burdened from pump A to pump B it is not uncommon

savings for redirected man hours can easily for a failure to occur which results in the

reach $100,000 or more per year. possibility of lost production. A reduction of

these failures equates to an additional .33

Often bearing failures are under represented days per year for production which equates

in facility MTBR calculations. This is to a savings of approximately $330,000

because mechanical seal failures are deemed dollars.

as the root cause, and during seal change out

the bearings are replaced simultaneously. Double pumping is a common occurrence

With careful root cause analysis, however, it during peak production seasons. This does

is often discovered that a bearing issue led to not create a total loss of production but it

the premature failure of the seal. reduces the product output and there is a loss

of production in the peak season. Using oil

mist helps to eliminate failures when double

pumping and the estimated savings is

$450,000 dollars.

Motors are excellent applications for oil mist

(14) since the grease lubricated bearings

account for about 90% of all motor failures,

figure 22. Reducing the motor bearing

failures with oil mist contributes to the

justification and by reducing motor failures

Irrespective of the time taken to determine there is also a reduction of additional pump

true root cause of failures, data has been failures that are caused by motor failures.

collected that demonstrates oil mist reduces With a population of 600 motors the savings

mechanical seal failure, figure 21. These

Copyright 2011 by Turbomachinery Laboratory, Texas A&M University

because of the constant supply of fresh,

clean oil and the slight positive pressure that

is created internally.

A fan application that has not seen the

benefits of oil mist, even with considerable

lubrication related reliability issues, is that

of the air cooled heat exchanger (ACHE)

bearings. Traditionally these bearings and

their motor drivers have been lubricated

with grease either manually or automated.

Both methods require system maintenance

from converting to oil mist equates to and, given the location of the fans, do not

approximately $368,000 dollars. always receive the proper attention

Oil is another item that is often overlooked necessary. Even with fastidious

in the justification process. It has been maintenance, grease lubrication has inherent

documented that converting to oil mist deficiencies timing and amount of grease

reduces the amount of oil normally used in application, cross-contamination concerns,

sump lubrication. Converting 600 pumps solidifying and liquefying in lines

from the traditional oil sump to oil mist (automated systems) and mechanical failures

provides annual savings of approximately of the delivery systems themselves.

$36,000 dollars.

However, applying mist has historically

Over an extended amount of time, pump been avoided because of the legitimate

failures have proven to be a root cause of concern of stray mist escaping the bearing

major fires that result in substantial repair housing and adhering to the tube bundles of

cost and lost production, often totaling the ACHE. This would consequently create

several million dollars per occurrence, not the ideal surface for adhering all dust, dirt

including potential health and safety liability and other ambient particulates drawn

and environmental impact. With an through to the tube bundle by the fan,

estimated fire every 10 years, the reduction rapidly reducing its heat transfer properties.

of pump-failure related fires through the use In 2007, a bearing was designed specifically

of oil mist equates to approximately for ACHE applications that contains oil mist

$2,390,000 per year. and allows it to be removed from the fan

area for reuse, figure 23. Additionally, the

With the noted savings totaling over $4 bearing design allows for shaft

million, the justification for investing in oil misalignment and thermal growth

mist is very real, with payback periods well common culprits to bearing failure.

under 2 years, often calculated in only

months. Accelerated wear testing was performed that

demonstrated significant improvement in

NEW HPI OIL MIST APPLICATION performance versus premium grease bearing

alternatives; no bearing failures or visible

As noted earlier, pumps and motors are the bearing wear could be produced with

most common applications for oil mist due loadings far exceeding field conditions. In

to the quantity present as compared to other early 2010, three trial systems were installed

mist applications such as gear boxes, at major North American refineries and all

blowers, turbines, and pillow block bearings are performing up to expectations as of this

on FD / ID fans. All benefit from oil mist writing. In addition to the bearings, a major

Copyright 2011 by Turbomachinery Laboratory, Texas A&M University

CONCLUSION

Oil mist lubrication is a proven technology

when systems are properly installed and

applied to rotating equipment. Systems have

been performing in the HPI for 40 years and

providing cost justified results. The closed

loop oil mist system is the Best Available

Technology (16) for lubrication of process

equipment.

motor manufacturer partnered to develop a The oil mist systems low maintenance and

vertically mounted motor designed to operating expenses with improved rotating

contain oil mist. These motors are currently equipment reliability have resulted in

on trial and have performed flawlessly. maintenance credits as much as 95% over

ACHE bearings and motors are another conventional lubrication in some major HPI

excellent application for oil mist (15). facilities (4).

CURRENT MIDDLE EAST Their versatility for working in all climates,

INSTALLATIONS no temperature limits, preventing the

intrusion of air borne contaminates, and

Owner No. Sys. Yrs. Location providing lubrication of operating

Sadaf 10 20 Saudi Arabia equipment while protecting/preserving

Kemya 8 10 Saudi Arabia standby equipment make these systems

Saudi Chevron 18 10 Saudi Arabia valuable to plant reliability.

Ras Tanuar Ref 5 8 Saudi Arabia

Aramco Juaymah 2 10 Saudi Arabia

Samref 2 4 Saudi Arabia

Aramco GOSP1 2 5 Saudi Arabia

Sabic 8 8 Saudi Arabia

Saudi Yambu 1 10 Saudi Arabia

Sharq 21 2 Saudi Arabia

Yansab 15 2 Saudi Arabia

Bapco 13 20 Bahrain

Qchem 11 9 Qatar

Ras Laffan Olefin 5 2 Qatar

Enoc Processing 10 12 Dubai

Gasco 2 10 Abu Dhabi

Copyright 2011 by Turbomachinery Laboratory, Texas A&M University

REFERENCES

11) Bloch, H. P, Ehlert, D. C 2008

1) Bloch, H. P. 2010 Get the Facts on Oil Mist Lubrication

Advice on Pump-Related Oil Changes, Hydrocarbon Processing Magazine

Oil Mist Lubrication

Machinery Lubrication Magazine 12) Bloch, H. P. 2008

Justify Your Equipment Reliability

2) Bloch, H. P. 2010 Enhancement

Fighting Black Oil and Understanding Maintenance & Reliability Magazine

Bearing Housing Upgrade Opportunities

Hydrocarbon Processing Magazine 13) Bloch, H. P. 2009

Understanding Periodic Pump Switching

3) Mianny, C. R. 1974 and Parallel Operation

Improve Bearing Life with Oil Mist Hydrocarbon Processing Magazine

Lubrication

Hydrocarbon Processing 14) Bloch, H. P. 2008

Using Oil Mist on Electric Motors

4) Bloch, H. P. 1980 Lubrication Management & Technology

Large Scale Application of Pure Oil Mist

in the Petrochemical Plant 15) Duncan, P. W. 2010

ASME Paper 80-C12/LUB-25 Oil Mist Lubrication for Fin Fan Shafts

Hydrocarbon Processing Magazine

5) Towne, Charlie 1982

Practical Experience with Oil Mist 16) Rehmann, Chris, Bloch, H. P. 2010

Lubrication Closed Loop Oil Mist, Best Available

ASLE Technology

Machinery Lubrication Magazine

6) Ioannides, Stathis Professor 1992

Cleanliness and its Improvement on

Bearing Performance

STLE Conference

7) Bloch, H. P. 2010

Letter to the Editor Hydrocarbon

Processing April Issue

8) Bloch, H. P. 1987

Oil Mist Lubrication Handbook

ISBN 0-88173-256-7

9) Nelik, Lev 1993

Bearing Life Extension and Reliability

International Conference on Improving

Pump Reliability

10) Fred Paben 1998

Retrofit of Oil Mist Lubrication System

Pump Reliability & Maintenance

Magazine

Copyright 2011 by Turbomachinery Laboratory, Texas A&M University

Das könnte Ihnen auch gefallen

- Stress Analysis of Piston Using Pressure Load and Thermal LoadDokument8 SeitenStress Analysis of Piston Using Pressure Load and Thermal LoadInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Viscosity IndexDokument9 SeitenViscosity Indexromadhinho0% (1)

- Well Intervention Course: OrganizationsDokument31 SeitenWell Intervention Course: OrganizationsAkol Majook100% (1)

- Flow MeasurementDokument81 SeitenFlow MeasurementmohamedNoch keine Bewertungen

- Practical Experience With Oil Mist LubricationDokument8 SeitenPractical Experience With Oil Mist Lubricationannccknarime100% (1)

- Grease Lubrication Mechanisms in Rolling Bearing Systems: Piet M. LugtDokument4 SeitenGrease Lubrication Mechanisms in Rolling Bearing Systems: Piet M. LugtAntonio Marques SilvaNoch keine Bewertungen

- Transportation of Hydrogen Gas in Existing Carbon Steel PipelinesDokument26 SeitenTransportation of Hydrogen Gas in Existing Carbon Steel Pipelines최승원Noch keine Bewertungen

- Supplementary Specification To NORSOK M-004 Insulation For Piping and EquipmentDokument44 SeitenSupplementary Specification To NORSOK M-004 Insulation For Piping and Equipment최승원100% (1)

- GeislingerDokument5 SeitenGeislingerSameh Jeep100% (1)

- Structural Health MonitoringVon EverandStructural Health MonitoringDaniel BalageasNoch keine Bewertungen

- Hydrodynamic or Full Fluid Film LubricationDokument59 SeitenHydrodynamic or Full Fluid Film LubricationAbhishek Singh ChauhanNoch keine Bewertungen

- Babbitt Information For PouringDokument8 SeitenBabbitt Information For PouringmarciofelipessantosNoch keine Bewertungen

- Forsthoffer’s Component Condition MonitoringVon EverandForsthoffer’s Component Condition MonitoringBewertung: 4 von 5 Sternen4/5 (2)

- Fluid Film Lubrication - Osborne Reynolds Centenary: FLUID FILM LUBRICATION - OSBORNE REYVon EverandFluid Film Lubrication - Osborne Reynolds Centenary: FLUID FILM LUBRICATION - OSBORNE REYNoch keine Bewertungen

- Torsional Vibration of Turbomachinery - Duncan N. Walker PDFDokument136 SeitenTorsional Vibration of Turbomachinery - Duncan N. Walker PDFkolle_sdestefa100% (1)

- Troubleshooting VTP Vertical Turbine PumpDokument20 SeitenTroubleshooting VTP Vertical Turbine PumpKrrish100% (1)

- Vci Guideline For Bolted Flanged Joint Assembly in Process Plants PDFDokument21 SeitenVci Guideline For Bolted Flanged Joint Assembly in Process Plants PDFrodrigoperezsimoneNoch keine Bewertungen

- F Me A of Journal BearingDokument6 SeitenF Me A of Journal BearingkulilistrikNoch keine Bewertungen

- Geometry of Screw Compressor Rotors and Their ToolsDokument17 SeitenGeometry of Screw Compressor Rotors and Their ToolsPhox IndiaNoch keine Bewertungen

- Sleeve or Plain Bearing LubricationDokument3 SeitenSleeve or Plain Bearing LubricationVolety_Sarma_1703100% (1)

- (International Centre For Mechanical Sciences 297) Neville F. Rieger (Eds.) - Rotordynamics 2 - Problems in Turbomachinery-Springer-Verlag Wien (1988) PDFDokument579 Seiten(International Centre For Mechanical Sciences 297) Neville F. Rieger (Eds.) - Rotordynamics 2 - Problems in Turbomachinery-Springer-Verlag Wien (1988) PDFDendyAdantaNoch keine Bewertungen

- Practical Approaches To Controllong Sludge and Varnish in Turbine OilsDokument17 SeitenPractical Approaches To Controllong Sludge and Varnish in Turbine OilsDimas Febrian SaputraNoch keine Bewertungen

- Top 10 Rotating Equipment Engineer Interview Questions and AnswersDokument17 SeitenTop 10 Rotating Equipment Engineer Interview Questions and AnswersSathishkumar VeluNoch keine Bewertungen

- Supercharging and TurbochargingDokument15 SeitenSupercharging and Turbochargingmhawan104Noch keine Bewertungen

- Review of Rotor Balancing MethodsDokument16 SeitenReview of Rotor Balancing MethodsFallo SusiloNoch keine Bewertungen

- NORSOK Standard Jacket PipesDokument28 SeitenNORSOK Standard Jacket PipesvuongNoch keine Bewertungen

- Rotor Dynamics of Aircraft Gas Turbine EnginesDokument5 SeitenRotor Dynamics of Aircraft Gas Turbine EnginesfengrotorNoch keine Bewertungen

- Kingsbury Leg ComponentsDokument3 SeitenKingsbury Leg ComponentsHatem Abdelrahman100% (1)

- Biodiesel: Vegetable Oil Refining Biomass To Liquid Vegetable Oil Used As FuelDokument38 SeitenBiodiesel: Vegetable Oil Refining Biomass To Liquid Vegetable Oil Used As FuelKyada RadhikaNoch keine Bewertungen

- Journal Bearing LubricationDokument5 SeitenJournal Bearing LubricationkulilistrikNoch keine Bewertungen

- Properties of LubricantDokument6 SeitenProperties of LubricantEl Sayed ZakariaNoch keine Bewertungen

- Centrifugal Compressor Case StudyDokument13 SeitenCentrifugal Compressor Case Studybbmoksh100% (1)

- MOTS 44 - Rev. 2.0 - MOG FP PRO STD 0044 Valving and IsolationDokument27 SeitenMOTS 44 - Rev. 2.0 - MOG FP PRO STD 0044 Valving and IsolationKingston RivingtonNoch keine Bewertungen

- Hydrogen ServiceDokument15 SeitenHydrogen Servicejharsh87Noch keine Bewertungen

- Guidelines For Diesel Engine Lubrication Impact of Low Sulphur Fuel On Lubrication of Marine EnginesDokument23 SeitenGuidelines For Diesel Engine Lubrication Impact of Low Sulphur Fuel On Lubrication of Marine EngineshamidrezachamaniNoch keine Bewertungen

- FLUID FILM BEARINGS Selection, Troubleshooting and RepairDokument30 SeitenFLUID FILM BEARINGS Selection, Troubleshooting and RepairsurawutwijarnNoch keine Bewertungen

- Tribology of Reciprocating Engines: Proceedings of the 9th Leeds–Lyon Symposium on Tribology Held in Bondington Hall, the University of Leeds, England 7–10 September 1982Von EverandTribology of Reciprocating Engines: Proceedings of the 9th Leeds–Lyon Symposium on Tribology Held in Bondington Hall, the University of Leeds, England 7–10 September 1982Noch keine Bewertungen

- TR 01 CorrosionRefineriesDokument104 SeitenTR 01 CorrosionRefineries최승원100% (1)

- Water TreatmentDokument45 SeitenWater TreatmentSarim ChNoch keine Bewertungen

- Tyre PyrolysisDokument6 SeitenTyre PyrolysisHande CambazNoch keine Bewertungen

- PVT AnalysisDokument41 SeitenPVT AnalysisEmad Aamer100% (2)

- Membrane 2Dokument51 SeitenMembrane 2Abhishek GadhwalNoch keine Bewertungen

- Challenges of Welding of Catalyst TubesDokument16 SeitenChallenges of Welding of Catalyst TubesTravis SkinnerNoch keine Bewertungen

- Magnetic Bearing: by NAME: N.Harshavardhan Reddy ID. NO: 18D41A0369 CLASS: Mechanical:BDokument15 SeitenMagnetic Bearing: by NAME: N.Harshavardhan Reddy ID. NO: 18D41A0369 CLASS: Mechanical:BChinnu Nani AHNoch keine Bewertungen

- The Role of Soot Particles in The Tribological Behavior of Engine Lubricating OilsDokument10 SeitenThe Role of Soot Particles in The Tribological Behavior of Engine Lubricating OilsSebastian JosephNoch keine Bewertungen

- Norsok Standard - Process Design (P-001r3)Dokument29 SeitenNorsok Standard - Process Design (P-001r3)Thitikorn WassanarpheernphongNoch keine Bewertungen

- 075 Oil Mist Application Manual PDFDokument34 Seiten075 Oil Mist Application Manual PDFAdolfo EirasNoch keine Bewertungen

- PresentationDokument27 SeitenPresentationVishal SalveNoch keine Bewertungen

- VUD Vacuum DehydratorsDokument7 SeitenVUD Vacuum DehydratorsZaqueu Santos OliveiraNoch keine Bewertungen

- Airless TyresDokument20 SeitenAirless TyresKingsly Jasper100% (1)

- Effective Varnish Removal From Turbine Lubrication SystemsDokument9 SeitenEffective Varnish Removal From Turbine Lubrication SystemsOsman AhmedNoch keine Bewertungen

- Gear Drive Issues Why Belt Is BetterDokument5 SeitenGear Drive Issues Why Belt Is BetterfranzumarragaNoch keine Bewertungen

- A Review of Tilting Pad Bearing TheoryDokument31 SeitenA Review of Tilting Pad Bearing TheoryJose Luis RattiaNoch keine Bewertungen

- Gimbals Election GuideDokument14 SeitenGimbals Election GuideRina PngNoch keine Bewertungen

- Backstop For ConveyorDokument28 SeitenBackstop For ConveyorabdulscribdNoch keine Bewertungen

- Evaluation of Tilting Pad Thrust Bearings PDFDokument10 SeitenEvaluation of Tilting Pad Thrust Bearings PDFVILLANUEVA_DANIEL2064Noch keine Bewertungen

- Effects of Clearance On Damping in Fluid Film Bearing: Spectra Quest, IncDokument10 SeitenEffects of Clearance On Damping in Fluid Film Bearing: Spectra Quest, IncjamariekoniNoch keine Bewertungen

- Numerical Estimation of Fatigue Life Analysis of Gas Turbine Blade PDFDokument27 SeitenNumerical Estimation of Fatigue Life Analysis of Gas Turbine Blade PDFaarthiNoch keine Bewertungen

- Gearbox Health Condition Monitoring A Brief ExpositionDokument11 SeitenGearbox Health Condition Monitoring A Brief ExpositionSetti SureshNoch keine Bewertungen

- NotesOnFluidFilmJournalBearing OverviewDokument72 SeitenNotesOnFluidFilmJournalBearing OverviewAsemota OghoghoNoch keine Bewertungen

- Aircraft Gas Turbine EngineDokument27 SeitenAircraft Gas Turbine Enginepriyanka_667739682Noch keine Bewertungen

- Diamondfaces The New Dimension in Mechanical Seal TechnologyDokument20 SeitenDiamondfaces The New Dimension in Mechanical Seal TechnologyadamNoch keine Bewertungen

- Iso TC 108 SC 2 N 666Dokument58 SeitenIso TC 108 SC 2 N 666Rahul B. WaghaleNoch keine Bewertungen

- Improved Performance Model of Turbocharger Centrifugal CompressorDokument7 SeitenImproved Performance Model of Turbocharger Centrifugal CompressorjswxieNoch keine Bewertungen

- GearboxDokument6 SeitenGearboxedhy_03Noch keine Bewertungen

- Best Practices in Compressor MountingDokument9 SeitenBest Practices in Compressor MountingDaniel Puello RodeloNoch keine Bewertungen

- Effect of Piston Design and Optimization ReciprocatingDokument129 SeitenEffect of Piston Design and Optimization ReciprocatingRajendra JadhavNoch keine Bewertungen

- Vibration AnalysisDokument4 SeitenVibration AnalysisJournalNX - a Multidisciplinary Peer Reviewed JournalNoch keine Bewertungen

- Spirax Ball Float Steam Trap FT-14Dokument2 SeitenSpirax Ball Float Steam Trap FT-14Nikhil RajanNoch keine Bewertungen

- How To Improve Internal Combustion Engine EfficiencyDokument8 SeitenHow To Improve Internal Combustion Engine EfficiencyJakob LarssonNoch keine Bewertungen

- Gas Turbine Heat Transfer Ten Remaining Hot Gas Path ChallengesDokument9 SeitenGas Turbine Heat Transfer Ten Remaining Hot Gas Path Challengeseankibo100% (1)

- Mechanical Seals: Power Plant BasicsDokument26 SeitenMechanical Seals: Power Plant BasicsService Port100% (1)

- GERB Tuned Mass Damper BrochureDokument6 SeitenGERB Tuned Mass Damper BrochureAhmad WaalNoch keine Bewertungen

- High Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorVon EverandHigh Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorNoch keine Bewertungen

- Coupling GuardsDokument10 SeitenCoupling Guards최승원Noch keine Bewertungen

- ISI7Dokument42 SeitenISI7최승원Noch keine Bewertungen

- Fired Heater Tube Fretting. - Boiler and Pressure Vessel Engineering - Eng-TipsDokument2 SeitenFired Heater Tube Fretting. - Boiler and Pressure Vessel Engineering - Eng-Tips최승원Noch keine Bewertungen

- HSP 201Dokument16 SeitenHSP 201최승원Noch keine Bewertungen

- Hot Tap Procedure Checklist: Estlake VinylsDokument3 SeitenHot Tap Procedure Checklist: Estlake VinylsNiraNoch keine Bewertungen

- Design of Coupling Enclosures by Michael M. CalistratDokument8 SeitenDesign of Coupling Enclosures by Michael M. Calistrat최승원Noch keine Bewertungen

- Case Study 01Dokument27 SeitenCase Study 01최승원Noch keine Bewertungen

- Hot Tapping Procedure GuideDokument6 SeitenHot Tapping Procedure GuideSadam Bin MuzammalNoch keine Bewertungen

- Fired Heater Tube Fretting. - Boiler and Pressure Vessel Engineering - Eng-TipsDokument2 SeitenFired Heater Tube Fretting. - Boiler and Pressure Vessel Engineering - Eng-Tips최승원Noch keine Bewertungen

- 28at 28XP 28XPS 28exp 8PG BW Oct2015 - 2Dokument8 Seiten28at 28XP 28XPS 28exp 8PG BW Oct2015 - 2Madjid HernandezNoch keine Bewertungen

- 4 Rules of Fired Heater OperationDokument17 Seiten4 Rules of Fired Heater Operation최승원Noch keine Bewertungen

- Hydrogen Sulfide and Pipeline CorrosionDokument39 SeitenHydrogen Sulfide and Pipeline Corrosion최승원100% (1)

- Removable Reusable Blanket Insulation: Engineering Reusable Solutions For A Sustainable PlanetDokument6 SeitenRemovable Reusable Blanket Insulation: Engineering Reusable Solutions For A Sustainable Planet최승원Noch keine Bewertungen

- 2005 Utkast NorsokDokument30 Seiten2005 Utkast NorsokFarzad RezaeiNoch keine Bewertungen

- Acid Salt Corrosion in A Hydrotreatment Plant of A Petroleum RefineryDokument8 SeitenAcid Salt Corrosion in A Hydrotreatment Plant of A Petroleum Refinery최승원Noch keine Bewertungen

- Loop-Seal ProblemsDokument1 SeiteLoop-Seal Problems최승원Noch keine Bewertungen

- Investigation and Repair of Heat Exchanger FlangeDokument12 SeitenInvestigation and Repair of Heat Exchanger Flange최승원Noch keine Bewertungen

- Orrosion Nder Nsulation: AtiphonDokument49 SeitenOrrosion Nder Nsulation: Atiphon최승원Noch keine Bewertungen

- An Overview of Problems and Solutions For Components Subjected To Fireside of BoilersDokument15 SeitenAn Overview of Problems and Solutions For Components Subjected To Fireside of Boilers최승원Noch keine Bewertungen

- Orrosion Nder Nsulation: AtiphonDokument49 SeitenOrrosion Nder Nsulation: Atiphon최승원Noch keine Bewertungen

- 12 OperatingexperienceofCFBboilerburninglignitewithhighshrinkageashproperty VidyaDokument9 Seiten12 OperatingexperienceofCFBboilerburninglignitewithhighshrinkageashproperty VidyaBookkeeperNoch keine Bewertungen

- A Review On Boiler Depositionfoulage Prevention AnDokument7 SeitenA Review On Boiler Depositionfoulage Prevention An최승원Noch keine Bewertungen

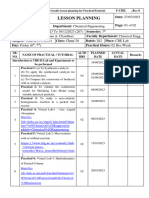

- CH-20 - CRE-2 (3170501) - 2st Batch-Practical Lesson PlanningDokument2 SeitenCH-20 - CRE-2 (3170501) - 2st Batch-Practical Lesson PlanningRohan ChaudhariNoch keine Bewertungen

- Ultrafiltration Membranes for Dairy and Food ProcessingDokument4 SeitenUltrafiltration Membranes for Dairy and Food ProcessingLalit VashistaNoch keine Bewertungen

- Anaerobic Biological Wastewater TreatmentDokument4 SeitenAnaerobic Biological Wastewater TreatmentKhalilRoumaniNoch keine Bewertungen

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDokument37 SeitenWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsmanoNoch keine Bewertungen

- Specifications for Materials M 262Dokument2 SeitenSpecifications for Materials M 262FRANZ RICHARD SARDINAS MALLCONoch keine Bewertungen

- Sch40 80 ASTM A53Dokument2 SeitenSch40 80 ASTM A53Keshia Murillo PinnockNoch keine Bewertungen

- Ansys Fluent 12.0 Theory Guide - 7.1Dokument3 SeitenAnsys Fluent 12.0 Theory Guide - 7.1Tg DgNoch keine Bewertungen

- COMPLETE NOTES Domestic SewageDokument75 SeitenCOMPLETE NOTES Domestic SewageRukaiya ShaikhNoch keine Bewertungen

- Additional Course Material: Physical Properties of FluidsDokument43 SeitenAdditional Course Material: Physical Properties of Fluidssilswal1988Noch keine Bewertungen

- Hydraulic Calculation For Fire Protec PDFDokument3 SeitenHydraulic Calculation For Fire Protec PDFRaviNoch keine Bewertungen

- FIGURE 1-13: Example 1-1Dokument1 SeiteFIGURE 1-13: Example 1-1Kwanchai ChoicharoenNoch keine Bewertungen

- Christmas Tree (Oil Well)Dokument1 SeiteChristmas Tree (Oil Well)ibhavinNoch keine Bewertungen

- A10-U-2005 Sampling Package Analyzer P&IDDokument1 SeiteA10-U-2005 Sampling Package Analyzer P&IDzhangNoch keine Bewertungen

- Agitator DatasheetDokument1 SeiteAgitator DatasheetpavanNoch keine Bewertungen

- LS12-50 Stationary Screw Compressor Parts ListDokument34 SeitenLS12-50 Stationary Screw Compressor Parts ListwaleedNoch keine Bewertungen

- CHME 202 - Fluid Mechanics Homework #3Dokument10 SeitenCHME 202 - Fluid Mechanics Homework #3d dNoch keine Bewertungen

- Engineering Mechanics and Fluid Mechanics WorkbookDokument55 SeitenEngineering Mechanics and Fluid Mechanics WorkbookSWAGATAM BAZNoch keine Bewertungen

- Joy T - Chapter 2B&3BDokument88 SeitenJoy T - Chapter 2B&3BAlya AhmedNoch keine Bewertungen

- Determining Limiting and Excess Regents 1Dokument2 SeitenDetermining Limiting and Excess Regents 1Zulkarnain AjoiNoch keine Bewertungen

- Bessel Application, Circular FinDokument4 SeitenBessel Application, Circular FinAditya PeriNoch keine Bewertungen

- Chavan Motors SolapurDokument2 SeitenChavan Motors SolapurAfzalpatelNoch keine Bewertungen

- Reliable Vertical Pump for Chemical ApplicationsDokument8 SeitenReliable Vertical Pump for Chemical ApplicationsMehmet ArvasiNoch keine Bewertungen

- Experimental Analysis and Computational-Fluid-Dynamics Modeling of Pilot-Scale Three-Phase SeparatorsDokument15 SeitenExperimental Analysis and Computational-Fluid-Dynamics Modeling of Pilot-Scale Three-Phase Separators기계공학과/김수빈Noch keine Bewertungen