Beruflich Dokumente

Kultur Dokumente

DLT Manual

Hochgeladen von

nhariwijaya0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

6 Ansichten7 SeitenTank Level Gauge - Manual

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenTank Level Gauge - Manual

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

6 Ansichten7 SeitenDLT Manual

Hochgeladen von

nhariwijayaTank Level Gauge - Manual

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 7

DAEHAN SENSOR MyiTy,

Gear Type Level Transmitter

with Level Sensor

DLT — Series

Only Local Indicator

Product Name

DLT - 1100

INNOBIZ

@®) c-

1993 DAEHAN SENSOR CO, LTD,

All rights reserved

Table of Contents

1, Introduction

2, Features

3, Specification

4, Installation

5, Check Point Before A/S

SPECIFICATIONS

Media : Only Liquid

300

Temperature : 0'C ~ 70°C

Pressure : A,T.M

Material : Head Housing ~ Aluminum

Socket — Aluminum

Flange ~ SUS304 Pri2"

(Option— SUS316)

Float ~ SUS304

(Option— SUS316)

Wire — SUS316

Introduction

‘As the liquid level increases, the float in the tank rises up,

While the wire connected to the float is being wound, the gauge shows the level of

the content in the tank,

Features

Because it can be installed easily, it can be applied to all the existing

equipments or tanks of any type,

This product is generally used for liquid level control, and alarming with

simple installation,

It is able to use for water, purified water, and fuel tank,

DAEHAN SENSOR

INSTALL & CALIBRATION.

Installation

Accessories

— =

e8otom piece "oes @ Mounting part

LAC | (ee.

See a oR EEE ce a

a SS 1

Installation

1, As shown in the picture, center of 90° elbow

should keep vertical position to the center

of DLT Sensor body,

2, As shown in the picture, center of 90° elbow

should keep vertical position to the center

of DLT Sensor float,

3, It should keep distance of minimum 500mm

between Sensing-tape and inside wall of the

tank,

4, It should keep distance of 250mm between

Sensing tape pipe and outside wall of the

tank,

5, Pipe should be vertical without bending,

In case of using connected pipes, check if

thre is any obstacle or crack,

DAEHAN SENSOR

INSTALL & CALIBRATION

Installation

1, Installation of the guide wire knob goes as

following,

2-1, After dissembling the cap of the knob, disconnect

the wire holder, and pull the guide wire,

ue We Sting

2-2, Loosen the nut assembled to the wire holder,

insert the guide wire into the hole.

2-3, As shown in the picture, after inserting the wire

holder into the nipple, pull the wire while

holding down with foot, (This process follows

the bottom anchor installation, )

2-4, Tighten the wire holder nut, then the tension

of the guide wire maintains by the wire holder

spring.

3, As shown in the picture, the distance between

guide wire should keep within 40+/-5mm,

4, Bottom anchor installation goes as shown in the

picture, After connecting the guide wire to fix bolt,

keeping the taut tension of the wire by assembling

the nut, cut the wire with argin of Sem ~ 10cm, [Guide Wire

5, Installation of the float goes as following,

6-1, Connet the sensing tape to the bolt of the joint

clamp of float,

6-3, Keep the guide wire

vertically installed,

6—4, Be cautious to keep

the sensing tape not to

be twisted or kinked,

DAEHAN SENSOR

INSTALL & CALIBRATION

Installation

1, When installing a sensing tape, open the 90

elbow cap and check if the tape is not kinked

or twisted,

2, Try to move the sensing tape careflly,

Check the smooth movement of the float inside

the tank, and the normal movement of the

indicator of the DLT Sensor,

3, Once the check is complete, close the cap of the

90 elbow, assemble them with tight sealing, to

avoid entering of rainwater or any other liquid

into the cap,

DAEHAN SENSOR

CHECK POINT & A/S

Check & A/S

Check the state of sensor, float and gear,

The state of sensor, float, tape, wire (inside and outside) is normal?

Check if water or liquid exists inside of the sensor housing,

The state of tape is normal? Is there any bending or break?

The state of float guide wire is normal?

Head Office

94-2, Yongdap-dong, Seongdong—gu, Seoul, Korea

R&D Office

2-71, Jeonong—dong, Dongdaemun-gu, Seoul, Korea

Tel : 02-2213-9888(ft) Fax : 02-2245-3482

e.mail : master@dh34.com Domain : www.dh34,com

DAEHAN SENSOR

Das könnte Ihnen auch gefallen

- Flange Management System Procedure - Rev 1Dokument10 SeitenFlange Management System Procedure - Rev 1nhariwijayaNoch keine Bewertungen

- Foam Pig Selection GuideDokument8 SeitenFoam Pig Selection Guidesajay2010Noch keine Bewertungen

- Foam Pig Selection GuideDokument8 SeitenFoam Pig Selection Guidesajay2010Noch keine Bewertungen

- Flange Management System Procedure - Rev 1Dokument10 SeitenFlange Management System Procedure - Rev 1nhariwijayaNoch keine Bewertungen

- Staff's On-Duty/Off-Duty: JabatanDokument1 SeiteStaff's On-Duty/Off-Duty: JabatannhariwijayaNoch keine Bewertungen

- Atlas Aluminium Datasheet 3003 Rev Oct 2013Dokument3 SeitenAtlas Aluminium Datasheet 3003 Rev Oct 2013PrakashNoch keine Bewertungen

- Katalog BioOneDokument14 SeitenKatalog BioOnenhariwijayaNoch keine Bewertungen

- Brosur Icon Apartment PDFDokument2 SeitenBrosur Icon Apartment PDFnhariwijayaNoch keine Bewertungen

- Shipment Schedule: Siam Maspion Terminal, PTDokument1 SeiteShipment Schedule: Siam Maspion Terminal, PTnhariwijayaNoch keine Bewertungen

- Shipment Schedule: Siam Maspion Terminal, PTDokument1 SeiteShipment Schedule: Siam Maspion Terminal, PTnhariwijayaNoch keine Bewertungen

- S Umber Jay A CatalogueDokument0 SeitenS Umber Jay A CatalogueJennifer BakerNoch keine Bewertungen

- Jaguarlift Katalog CHWDDokument1 SeiteJaguarlift Katalog CHWDnhariwijayaNoch keine Bewertungen

- Draft Schedule IFR Commissioning SupportDokument1 SeiteDraft Schedule IFR Commissioning SupportnhariwijayaNoch keine Bewertungen

- Schedule Jetty 1 August 2018Dokument1 SeiteSchedule Jetty 1 August 2018nhariwijayaNoch keine Bewertungen

- Shipment Schedule: Siam Maspion Terminal, PTDokument1 SeiteShipment Schedule: Siam Maspion Terminal, PTnhariwijayaNoch keine Bewertungen

- Company Profile R0 2016 (SBA)Dokument4 SeitenCompany Profile R0 2016 (SBA)nhariwijayaNoch keine Bewertungen

- Training Report Safety K PuuDokument3 SeitenTraining Report Safety K PuunhariwijayaNoch keine Bewertungen

- Installation and Operating Instructions: Kunkle Valve Pressure Relief ValvesDokument2 SeitenInstallation and Operating Instructions: Kunkle Valve Pressure Relief ValvesnhariwijayaNoch keine Bewertungen

- Jetty 1 Apr 2018Dokument1 SeiteJetty 1 Apr 2018nhariwijayaNoch keine Bewertungen

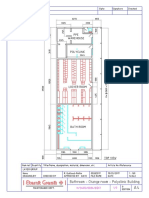

- 0026EG17 Bathroom - Change Room - Polyclinic BuildingDokument2 Seiten0026EG17 Bathroom - Change Room - Polyclinic BuildingnhariwijayaNoch keine Bewertungen

- WPS & PQRDokument84 SeitenWPS & PQRjoseph.maquez24100% (4)

- PLTU PJB MUARA KARANG (Kontrak Payung Jasa Cleaning Kondensor & HE)Dokument18 SeitenPLTU PJB MUARA KARANG (Kontrak Payung Jasa Cleaning Kondensor & HE)nhariwijayaNoch keine Bewertungen

- Kelly Salary Guide 2017Dokument48 SeitenKelly Salary Guide 2017diki100% (2)

- Work Schedule Cleaning TANKER - PT AKR NILAMDokument1 SeiteWork Schedule Cleaning TANKER - PT AKR NILAMnhariwijayaNoch keine Bewertungen

- Scope of Work - Naptha Tank Internal Cleaning 3000009815Dokument2 SeitenScope of Work - Naptha Tank Internal Cleaning 3000009815nhariwijaya100% (1)

- Chiller Supply and Return PID ExistingDokument1 SeiteChiller Supply and Return PID ExistingnhariwijayaNoch keine Bewertungen

- Chiller Supply and Return PID ExistingDokument1 SeiteChiller Supply and Return PID ExistingnhariwijayaNoch keine Bewertungen

- Denah Kantor SBADokument1 SeiteDenah Kantor SBAnhariwijayaNoch keine Bewertungen

- Salary Guide 2017 PDFDokument48 SeitenSalary Guide 2017 PDFnhariwijayaNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)