Beruflich Dokumente

Kultur Dokumente

Salt Fog Test Report

Hochgeladen von

WajahatOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Salt Fog Test Report

Hochgeladen von

WajahatCopyright:

Verfügbare Formate

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev.

ABSTRACT

The Steel Coupons were subjected to salt fog exposure in accordance with the RTCA/DO-160G, Section

14.3.6.7, Category T, Severe Salt Fog test. The test hardware was exposed to forty-eight (48) hours of salt fog

followed by a twenty-four (24) hour dry out, and then repeated once more. A visual examination of the test

hardware after application of the salt fog environment revealed varying degrees of corrosion on some of the

coupons. The test hardware was returned to the customer for evaluation following test completion.

Page 2 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

REPORT REVISION RECORD

REV. DATE DESCRIPTION OF CHANGE

NA 2014-07-30 ORIGINAL RELEASE

A 2014-09-25 Removed superfluous information as directed by Valeriya Mihaylova email dated

09/24/2014 15:41

Page 3 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

TABLE OF CONTENTS

TITLE PAGE

SALT FOG TEST SUMMARY............................................................................................................................. 5

1.0 TEST HARDWARE ..................................................................................................................................... 5

2.0 TEST REQUIREMENTS WITH TOLERANCES ....................................................................................... 5

3.0 TEST SETUP................................................................................................................................................ 6

TABLE 1: QUALTEST FURNISHED MEASUREMENT & TEST EQUIPMENT ..................................... 6

TABLE 2: MATERIEL IDENTIFICATION .................................................................................................. 6

TABLE 3: CHART RECORDER SETUP ...................................................................................................... 6

4.0 TEST DESCRIPTION .................................................................................................................................. 6

TABLE 4: SALT FOG TEST ACTIVITIES................................................................................................... 7

5.0 CONCLUSION ............................................................................................................................................. 7

Figure 1: Control Sample appearance prior to salt fog exposure ................................................................... 8

Figure 2: Liquid Wrench Sample appearance prior to salt fog exposure ....................................................... 8

Figure 3: DuPont Sample appearance prior to salt fog exposure ................................................................... 9

Figure 4: L.C.Wax Alumaslick Sample appearance prior to salt fog exposure ............................................. 9

Figure 5: Nanoprotech Sample appearance prior to salt fog exposure......................................................... 10

Figure 6: Ultra Lube Sample appearance prior to salt fog exposure ............................................................ 10

Figure 7: WD-40 Sample appearance prior to salt fog exposure ................................................................. 11

Figure 8: Blaster Sample appearance prior to salt fog exposure .................................................................. 11

Figure 9: Test setup for the first forty-eight hours of salt fog exposure ...................................................... 12

Figure 10: Coupon appearance after forty-eight hours of salt fog exposure ................................................ 12

Figure 11: Test setup for the second forty-eight hours of salt fog exposure ................................................ 13

Figure 12: Steel Control Sample appearance after completing salt fog exposure........................................ 13

Figure 13: Steel Liquid Wrench Sample appearance after completing salt fog exposure ........................... 14

Figure 14: Steel DuPont Sample appearance after completing salt fog exposure........................................ 14

Figure 15: Steel L.C.Wax Alumaslick Sample appearance after completing salt fog exposure .................. 15

Figure 16: Steel Nanoprotech Sample appearance after completing salt fog exposure ............................... 15

Figure 17: Steel Ultra Lube Sample appearance after completing salt fog exposure .................................. 16

Figure 18: Steel WD-40 Sample appearance after completing salt fog exposure ........................................ 16

Figure 19: Steel Blaster Sample appearance after completing salt fog exposure ........................................ 17

Appendix A: Salt fog data charts ......................................................................................................................... 18

Chart 1: Salt fog temperature chart Preconditioning and Cycle 1............................................................. 19

Chart 2: Salt fog temperature chart Cycle 1 .............................................................................................. 20

Chart 3: Salt fog temperature chart Cycle 1 .............................................................................................. 21

Chart 4: Salt fog dry-out temperature and humidity chart Cycle 1 ........................................................... 22

Chart 5: Salt fog temperature chart Preconditioning and Cycle 2............................................................. 23

Chart 6: Salt fog temperature chart Cycle 2 .............................................................................................. 24

Chart 7: Salt fog dry-out temperature and humidity chart Cycle 2 ........................................................... 25

Page 4 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

SALT FOG TEST SUMMARY

Responsible Test Conductor: Jeremy Hill

1.0 TEST HARDWARE

Nine (9) 4x4 Steel Coupons:

One (1) Control Sample

One (1) Liquid Wrench Sample

One (1) DuPont Sample

One (1) L.C.Wax Alumaslick Sample

One (1) Nanoprotech Sample

One (1) Ultra Lube Sample

One (1) WD-40 Sample

One (1) Blaster Sample

2.0 TEST REQUIREMENTS WITH TOLERANCES

The purpose of this test is to determine the effectiveness of protective coatings and finishes on materials. It

may also be applied to determine the effects of salt deposits on the physical and electrical aspects of materiel.

Perform forty-eight (48) hour of salt fog exposure at 353C, followed by twenty-four (24) hour dry out at

ambient temperature with relative humidity <50%.

Repeat initial step one more time for a total of ninety-six (96) hour salt fog exposure.

Test articles are to be photographed at post 1st 48 hour run, post 1st 24 hour dry out, post 2nd 48 hour run, and

post 2nd 24 hour dry out.

Tolerance:

Standard Ambient: 2510C, 20 - 80% Relative Humidity, Site Pressure

Distilled water is used for salt fog production to minimize any undesired contaminants

2.1 Test Specification:

RTCA/DO-160G, Section 14.3.6.7, Category T, Severe Salt Fog

Valeriya Mikhaylova, Nanoprotech USA, email dated 7/7/2014 at 3:00 PM: take photographs after each 48-

hour exposure

Page 5 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

3.0 TEST SETUP

TABLE 1: QUALTEST FURNISHED MEASUREMENT & TEST EQUIPMENT

(Measuring instruments used in testing are calibrated per ANSI/NCSL Z540-1 and/or ANSI/NCSL Z540.3, and are NIST traceable)

Asset # Item Manufacturer Model Number Calibration Due

100073 Chart Recorder Honeywell DR450T 2014-10-12

100140 pH Meter Fisher Scientific Accumet Basic Before Use

100140-1 pH 4 Buffer Inorganic Ventures LOT#G2-WCS02024 2015-06-01

100140-2 pH 7 Buffer Inorganic Ventures LOT#G2-WCS02045 2015-06-01

100473 Humidity Sensor E+E Elektronik EE23 2014-11-29

100476 Chart Recorder Honeywell DR45AT 2014-10-01

100695 Scale A&D FX-300i WP 2014-08-07

100821 Temp/Humid Chamber Russels RD-16-2-2-AC NA

100897 Salt Fog Chamber Singleton SCCH23 NA

101246 Thermo/Hygrometer Fisher Scientific 14-648-52 2014-10-30

TABLE 2: MATERIEL IDENTIFICATION

Type Manufacturer Lot Number Expiration Date

Sodium Chloride Morton RI13032049 N/A

Sodium Hydroxide Ricca 2301881 01 Jan 2015

Distilled Water Crystal Springs N/A N/A

TABLE 3: CHART RECORDER SETUP

Asset # Channel Pen Type of Sensor Function

100073 01 01 100 RTD Monitor salt fog chamber air temperature (C)

100476 01 01 100 RTD Monitor dry-out chamber air temperature (C)

100476 04 04 Humidity Transducer Monitor dry-out chamber relative humidity (%)

The salt solution was prepared using 95 parts (by weight) of distilled water and 5 parts (by weight) of sodium

chloride. The sodium chloride had a minimum purity of 99.95%, as certified by the manufacturer. The pH was

maintained between 6.5 and 7.2 using sodium hydroxide, as needed. Chamber operation to specification was

verified prior to installing the test hardware. The test hardware was placed on a non-corrosive grate in the

chamber.

4.0 TEST DESCRIPTION

4.1 Non-Qualtest Personnel, Including Organization, Present for All or Part of the Test:

None

Page 6 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

4.2 Powered/Operational State of the Hardware and by Whom:

The test hardware was not operated during the test.

4.3 Test Activities and Resulting Measurements from Observed/Recorded Data:

Atmospheric Conditions: Temp (C): 24 Relative Humidity (%): 54 Pressure: Site Ambient

The test hardware was placed in the salt fog chamber in its normal orientation as shown in Figure 10. The test

activities are summarized in Table 4.

TABLE 4: SALT FOG TEST ACTIVITIES

Collection Rate Collection Rate Specific Gravity

Date End Time Nearest to Atomizer Farthest from Atomizer pH

(ml/cm2/hour) (ml/cm2/hour) Pre-test Post-test

07/18/14 --- Trial Run (chamber operation verified)

07/21/14 0925 Start 2-hour precondition period

07/21/14 1345 Start 1st 48-hour salt fog period

07/22/14 --- 1.58 1.50 1.58 1.58 6.81 1.032 1.034

07/23/14 --- 1.67 1.46 1.67 1.67 6.79 1.032 1.032

st

07/23/14 1345 End 1 48-hour salt fog period

07/23/14 1350 Start 1st 24-hour dry-out period

07/24/14 1350 End 1st 24-hour dry-out period

07/24/14 1355 Start 2-hour precondition period

07/24/14 1600 Start 2nd 48-hour salt fog period

07/25/14 --- 1.58 1.46 1.58 1.67 6.74 1.032 1.031

07/26/14 --- 1.67 1.67 1.79 1.83 6.68 1.032 1.032

nd

07/26/14 1600 End 2 48-hour salt fog period

07/26/14 1605 Start 2nd 24-hour dry-out period

07/27/14 1605 End 2nd 24-hour dry-out period

Temperature and humidity data supporting Table 4 is shown in Charts 1 through 7. Figures 13 through 30

present the photographic results of test hardware salt fog exposure.

4.4 Limitations or Departures from the Test Requirements and Authorizing Source:

None

5.0 CONCLUSION

A visual examination of the test hardware after application of the salt fog environment revealed varying

degrees of corrosion on some of the coupons. The test hardware was returned to the customer for evaluation

following test completion.

Page 7 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Figure 1: Control Sample appearance prior to salt fog exposure

Figure 2: Liquid Wrench Sample appearance prior to salt fog exposure

Page 8 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Figure 3: DuPont Sample appearance prior to salt fog exposure

Figure 4: L.C.Wax Alumaslick Sample appearance prior to salt fog exposure

Page 9 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Figure 5: Nanoprotech Sample appearance prior to salt fog exposure

Figure 6: Ultra Lube Sample appearance prior to salt fog exposure

Page 10 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Figure 7: WD-40 Sample appearance prior to salt fog exposure

Figure 8: Blaster Sample appearance prior to salt fog exposure

Page 11 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Figure 9: Test setup for the first forty-eight hours of salt fog exposure

Figure 10: Coupon appearance after forty-eight hours of salt fog exposure

Page 12 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Figure 11: Test setup for the second forty-eight hours of salt fog exposure

Figure 12: Steel Control Sample appearance after completing salt fog exposure

Page 13 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Figure 13: Steel Liquid Wrench Sample appearance after completing salt fog exposure

Figure 14: Steel DuPont Sample appearance after completing salt fog exposure

Page 14 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Figure 15: Steel L.C.Wax Alumaslick Sample appearance after completing salt fog exposure

Figure 16: Steel Nanoprotech Sample appearance after completing salt fog exposure

Page 15 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Figure 17: Steel Ultra Lube Sample appearance after completing salt fog exposure

Figure 18: Steel WD-40 Sample appearance after completing salt fog exposure

Page 16 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Figure 19: Steel Blaster Sample appearance after completing salt fog exposure

Page 17 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Appendix A: Salt fog data charts

Page 18 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Chart 1: Salt fog temperature chart Preconditioning and Cycle 1

Page 19 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Chart 2: Salt fog temperature chart Cycle 1

Page 20 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Chart 3: Salt fog temperature chart Cycle 1

Page 21 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Chart 4: Salt fog dry-out temperature and humidity chart Cycle 1

Page 22 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Chart 5: Salt fog temperature chart Preconditioning and Cycle 2

Page 23 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Chart 6: Salt fog temperature chart Cycle 2

Page 24 of 25 UNCLASSIFIED QR216-02 Rev. A

Qualtest, Inc. UNCLASSIFIED Report: 09010-97853 Rev. A

Chart 7: Salt fog dry-out temperature and humidity chart Cycle 2

Page 25 of 25 UNCLASSIFIED QR216-02 Rev. A

Das könnte Ihnen auch gefallen

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesVon EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNoch keine Bewertungen

- Certificate IEC 61701 Salt-Mist Poly-And-MonoDokument5 SeitenCertificate IEC 61701 Salt-Mist Poly-And-Monosunny0% (1)

- NDT Procedure PCN Test1Dokument32 SeitenNDT Procedure PCN Test1anon_249267450Noch keine Bewertungen

- Instruction Manual: NXDS Scroll PumpDokument48 SeitenInstruction Manual: NXDS Scroll PumpAdam TaylorNoch keine Bewertungen

- Test Report No.: Version-No.: Date: Subsystem: Model:: TÜV Rheinland ItaliaDokument23 SeitenTest Report No.: Version-No.: Date: Subsystem: Model:: TÜV Rheinland ItaliaSugeng WahyudiNoch keine Bewertungen

- CA-40-02 Rev.03E UT Procedure Fer AWS D1.1-2015Dokument24 SeitenCA-40-02 Rev.03E UT Procedure Fer AWS D1.1-2015hoangdiep phanNoch keine Bewertungen

- Safety of Household and Similar Electrical Appliances Part 2:particular Requirements For HumidifiersDokument157 SeitenSafety of Household and Similar Electrical Appliances Part 2:particular Requirements For HumidifiersFemko CorporationNoch keine Bewertungen

- RE150727C28 - AMobile - GT7800 Series - 301 908-1Dokument30 SeitenRE150727C28 - AMobile - GT7800 Series - 301 908-1openid_6iaTksxPNoch keine Bewertungen

- UT ProcedureDokument35 SeitenUT ProcedureEdAlmNoch keine Bewertungen

- Verification Test Report J11458-Val: Product Tested: Test Type: StandardDokument33 SeitenVerification Test Report J11458-Val: Product Tested: Test Type: StandardtalaindioNoch keine Bewertungen

- PNNL 25077rev2Dokument110 SeitenPNNL 25077rev2Febrian Dimas Adi NugrahaNoch keine Bewertungen

- Indirect Verification PDFDokument1 SeiteIndirect Verification PDFSai FujiwaraNoch keine Bewertungen

- FCC TEST REPORT (15.407) : Bureau Veritas Consumer Products Services (H.K.) LTD., Taoyuan BranchDokument62 SeitenFCC TEST REPORT (15.407) : Bureau Veritas Consumer Products Services (H.K.) LTD., Taoyuan BranchSIMAH CELAYANoch keine Bewertungen

- T-215Z-0501 - 1 - 0030 TBE For Laboratory Equipments PDFDokument80 SeitenT-215Z-0501 - 1 - 0030 TBE For Laboratory Equipments PDFmokhtariNoch keine Bewertungen

- ML111790231 PDFDokument68 SeitenML111790231 PDFMoch FaridNoch keine Bewertungen

- Steam DrumDokument10 SeitenSteam DrumMuhammad AbbasNoch keine Bewertungen

- MAN205-0176000EN Rev MDokument70 SeitenMAN205-0176000EN Rev MConstantin ZamfirNoch keine Bewertungen

- Brookfield Manual PDFDokument36 SeitenBrookfield Manual PDFAnonymous T32l1RNoch keine Bewertungen

- Certificado UL1703 Celda SolarDokument70 SeitenCertificado UL1703 Celda SolarIEE SOLARNoch keine Bewertungen

- SHAW SADP Dewpoint Meter Instruction ManualDokument24 SeitenSHAW SADP Dewpoint Meter Instruction ManualБаясгаланNoch keine Bewertungen

- Ver5 Ver6 OLE16-0044-04 CLU056 15kh LM-80 ReportDokument23 SeitenVer5 Ver6 OLE16-0044-04 CLU056 15kh LM-80 Reporttata kaisserliNoch keine Bewertungen

- VCU-245 Seismic Test ReportDokument44 SeitenVCU-245 Seismic Test ReportDalibor84Noch keine Bewertungen

- Accutemp EGF2083A2450 Electric GriddleDokument12 SeitenAccutemp EGF2083A2450 Electric Griddleaparna_sagi391Noch keine Bewertungen

- Qualanod SpecDokument62 SeitenQualanod SpecwilliamNoch keine Bewertungen

- QCS EP UT-01 Rev06Dokument21 SeitenQCS EP UT-01 Rev06m_armoutiNoch keine Bewertungen

- A-Qac-Pro-730-38930 Rev ADokument10 SeitenA-Qac-Pro-730-38930 Rev ARamzi ZoghlamiNoch keine Bewertungen

- NEMA Gasket Aging - 105-AdvanceDokument8 SeitenNEMA Gasket Aging - 105-AdvancerkcNoch keine Bewertungen

- EMC Test Report: DraftDokument234 SeitenEMC Test Report: Draftyari yaryarNoch keine Bewertungen

- Operation and Instruction Manual: K60094 Portable Heated Oil Test CentrifugeDokument14 SeitenOperation and Instruction Manual: K60094 Portable Heated Oil Test CentrifugeWILMARNoch keine Bewertungen

- QubeDokument80 SeitenQubeTarra SyabrienaNoch keine Bewertungen

- SWLD TOTL - 190.015MPWp SCI DOC 007 - R0Dokument128 SeitenSWLD TOTL - 190.015MPWp SCI DOC 007 - R0alex lambertNoch keine Bewertungen

- BVS3000 Operation ManualDokument14 SeitenBVS3000 Operation ManualTJ 4 SectionNoch keine Bewertungen

- Inspection & Testing Requirements Scope:: Test and Inspection PerDokument3 SeitenInspection & Testing Requirements Scope:: Test and Inspection PerWael ChouchaniNoch keine Bewertungen

- S229750.01 60335 1Dokument133 SeitenS229750.01 60335 1Jishnu MmNoch keine Bewertungen

- 16.4. Mmf-Ax-bx-Vdr-0014 Hydrotest Procedure Rev. 0Dokument28 Seiten16.4. Mmf-Ax-bx-Vdr-0014 Hydrotest Procedure Rev. 0Fauzan Rusmayadi Reharder100% (1)

- NDT Procedure PCN Test1Dokument32 SeitenNDT Procedure PCN Test1Tamilarasan100% (1)

- CLX-Ex Online Residual Chlorine Monitor: Owner'S ManualDokument45 SeitenCLX-Ex Online Residual Chlorine Monitor: Owner'S ManualIgor DoroshchukNoch keine Bewertungen

- EMC Test Report - SampleDokument56 SeitenEMC Test Report - Sampleabhishek_modemNoch keine Bewertungen

- Analysis of Crude Oil Samples PDFDokument62 SeitenAnalysis of Crude Oil Samples PDFezzataNoch keine Bewertungen

- Test Plan For Primary Circuit and Balance of Plant InstrumentationDokument34 SeitenTest Plan For Primary Circuit and Balance of Plant InstrumentationHardik LanghnojaNoch keine Bewertungen

- Hydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkDokument8 SeitenHydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkCipta Adikarya100% (1)

- Test Report Solar Reflectance Index (SRI) Measurements According To ASTM E1980 On Paving Cement Mortar Supplied by SMS Holdings (PVT) LTDDokument4 SeitenTest Report Solar Reflectance Index (SRI) Measurements According To ASTM E1980 On Paving Cement Mortar Supplied by SMS Holdings (PVT) LTDThilan SenarathneNoch keine Bewertungen

- En 61010-1 Short Circuit Box TUVDokument74 SeitenEn 61010-1 Short Circuit Box TUVatm037Noch keine Bewertungen

- NORMS AND TECHNICAL SPECIFICATIONS OF TESTING INSTRUMENTS - Rev 2021Dokument86 SeitenNORMS AND TECHNICAL SPECIFICATIONS OF TESTING INSTRUMENTS - Rev 2021goyalmanoj100% (1)

- Method Statement - Polarity TestDokument5 SeitenMethod Statement - Polarity TestKhaled Badawy100% (1)

- Ut - Bhe Nde Nu 700mw RH RT Rev 00 Latest Ut Procedure 14-02-2014Dokument17 SeitenUt - Bhe Nde Nu 700mw RH RT Rev 00 Latest Ut Procedure 14-02-2014JoelNoch keine Bewertungen

- Saline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentDokument13 SeitenSaline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentBhavanishankar ShettyNoch keine Bewertungen

- Test Report Part 24 PDFDokument36 SeitenTest Report Part 24 PDFPabl OrozkoNoch keine Bewertungen

- FCC PART 15.407 IC RSS-210, ISSUE 8, DEC 2010 Test and Measurement ReportDokument86 SeitenFCC PART 15.407 IC RSS-210, ISSUE 8, DEC 2010 Test and Measurement ReportaslamNoch keine Bewertungen

- DNV Comparison of Offshore Structural StandardsDokument219 SeitenDNV Comparison of Offshore Structural StandardsNils Antoine Freund100% (2)

- 20le463fccic R1Dokument35 Seiten20le463fccic R1Grzegorz BielawskiNoch keine Bewertungen

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptDokument13 SeitenJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNoch keine Bewertungen

- Testing of Non - Metallic Materials For Use With Drinking WATER (BS 6920: 2000)Dokument8 SeitenTesting of Non - Metallic Materials For Use With Drinking WATER (BS 6920: 2000)whwy99Noch keine Bewertungen

- Hydro 40 01Dokument1 SeiteHydro 40 01Hanuman RaoNoch keine Bewertungen

- NBT 47013.3-2015 EngDokument180 SeitenNBT 47013.3-2015 EngCourage100% (1)

- Adco - Dodsal - Welspun: Inspection ReportDokument6 SeitenAdco - Dodsal - Welspun: Inspection ReportejazalmNoch keine Bewertungen

- Pocket Guide to Preventing Process Plant Materials Mix-upsVon EverandPocket Guide to Preventing Process Plant Materials Mix-upsNoch keine Bewertungen

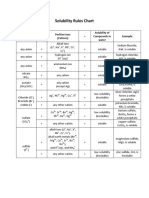

- Solubility Rules ChartDokument2 SeitenSolubility Rules ChartLumwanga MukadiNoch keine Bewertungen

- Lab 4.2 Flame Test Lab: BackgroundDokument2 SeitenLab 4.2 Flame Test Lab: Background7sky7harveyNoch keine Bewertungen

- Atorvastatin Calcium Trihydrate Farmacopea BPDokument3 SeitenAtorvastatin Calcium Trihydrate Farmacopea BPGuadalupe EnriquezNoch keine Bewertungen

- Msds Acid Alkohol (Lar - Asam Alkohol)Dokument8 SeitenMsds Acid Alkohol (Lar - Asam Alkohol)ReniNoch keine Bewertungen

- GlassDokument23 SeitenGlasssamatha100% (1)

- Pollutants of Wastewater Characteristics in Textile IndustriesDokument5 SeitenPollutants of Wastewater Characteristics in Textile Industriessusetya saptoadiNoch keine Bewertungen

- ACID URONIC Determination of The Uronic Acid ContentDokument4 SeitenACID URONIC Determination of The Uronic Acid ContentMayra ValdiviesoNoch keine Bewertungen

- XanthatesDokument6 SeitenXanthatesFredy CastillejoNoch keine Bewertungen

- Aluminum ChlorideDokument1 SeiteAluminum ChlorideK.m. Ehsan Morshed RanaNoch keine Bewertungen

- Watersoftner UltraSoft 400 - ManualDokument36 SeitenWatersoftner UltraSoft 400 - Manualbece13Noch keine Bewertungen

- Chapter 8 SALTSDokument75 SeitenChapter 8 SALTSSiti Hajar Abd HamidNoch keine Bewertungen

- CHEMISTRY BOOK 2 ObjDokument44 SeitenCHEMISTRY BOOK 2 ObjHaris AkhtarNoch keine Bewertungen

- Separation and Analysis of A Ternary MixtureDokument3 SeitenSeparation and Analysis of A Ternary MixtureGregbr62Noch keine Bewertungen

- ATP Question Paper 41 PDFDokument16 SeitenATP Question Paper 41 PDFMuhammad TauseefNoch keine Bewertungen

- Metode Analisa FCC 88 - New LogoDokument4 SeitenMetode Analisa FCC 88 - New LogoyurinaNoch keine Bewertungen

- BondingDokument24 SeitenBondingapi-422428700Noch keine Bewertungen

- Laboratory Waste Management GuideDokument54 SeitenLaboratory Waste Management GuideMei YeeNoch keine Bewertungen

- Minerals: From Essentials of Medical Biochemistry by R.C. GuptaDokument245 SeitenMinerals: From Essentials of Medical Biochemistry by R.C. GuptaMalliga SundareshanNoch keine Bewertungen

- Metals: Physical Properties of MetalDokument6 SeitenMetals: Physical Properties of MetalAllen Jierqs SanchezNoch keine Bewertungen

- Ion Exchange Resins: Summarized Data SheetDokument8 SeitenIon Exchange Resins: Summarized Data Sheetsree devumNoch keine Bewertungen

- Bahrmann2011 (Ethyl Hexanol)Dokument6 SeitenBahrmann2011 (Ethyl Hexanol)Ilham FajriNoch keine Bewertungen

- AFE CAV A: Product BulletinDokument2 SeitenAFE CAV A: Product BulletinyfcozNoch keine Bewertungen

- Alginato HPLCDokument7 SeitenAlginato HPLCDavid SanabriaNoch keine Bewertungen

- Bucklin Cat March 2004 PDFDokument141 SeitenBucklin Cat March 2004 PDFandx100% (3)

- 10 1002@bio 3725Dokument8 Seiten10 1002@bio 3725Orin khasanatul amanahNoch keine Bewertungen

- Jee Main 2019 Jan ChemDokument84 SeitenJee Main 2019 Jan ChemBhavesh KriplaniNoch keine Bewertungen

- Geopolymer Future ConcreteDokument9 SeitenGeopolymer Future ConcretemayaNoch keine Bewertungen

- Sodium: John GorhamDokument5 SeitenSodium: John GorhamsergiochepoNoch keine Bewertungen

- 2004 MRSM Without AnswerDokument49 Seiten2004 MRSM Without AnswerChoong Wen JianNoch keine Bewertungen

- Key Process Considerations For Caustic Treatment in CDUDokument4 SeitenKey Process Considerations For Caustic Treatment in CDUVenkatesh Kumar RamanujamNoch keine Bewertungen