Beruflich Dokumente

Kultur Dokumente

Electrofusion Unit MSA350

Hochgeladen von

viksofOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Electrofusion Unit MSA350

Hochgeladen von

viksofCopyright:

Verfügbare Formate

MSA350 Operating Instructions

MSA350 Operating Instructions

Table of Contents

Introduction 1

Validity 2

Product Description 2

Operation Controls 3

Barcode Reader 4

Protocol Memory 5

Service Opening 5

Power Supply 6

Mains Supply 6

Generator 6

Extension Cables 6

Starting Up 7

Operation with Standard Configuration 8

Overview of Operating Procedure 8

Switching on 9

Input Fusion Data 9

Start Fusion Process 10

Terminate Fusion 10

Finish Fusion 10

Protocol Display 11

12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Additional Functions 12

Enter Operator Identification 13

Enter Job Number 13

Query Fusion Preparation 14

Query Infotext 14

Enter Fusion Data Manually 15

Repeat Fusion 16

Setting Display Contrast 17

Choose Language 17

Configuration 18

Date and Time Z5, Z50, Z51 18

Operator Identification Z20, Z21 19

Enter Fusion Data Manual Z30 ON/OFF 19

Job Number Z40 Z41 20

Enter Job Number Manually Z42 ON/OFF 20

Infotext Z43 ON/OFF 20

Maintenance Z6, Z60 21

Fusion Preparation Z0 ON/OFF 21

Display Fusion Time Z10 ON/OFF 21

Enter Languages 21

Protocol 23

General Use of the Protocol 23

Print Protocol 23

PC Communication 25

Operating Instructions 2157.70.28A 12. April 2000

MSA350 Operating Instructions

Error Messages 26

Coded Messages 26

Uncoded Messages 28

Product Information 30

Maintenance 32

Cleaning 32

Function Check-up 32

Accident Prevention 33

Operating the Unit 33

Check before Operation 34

Protection of the Unit 34

Defect Unit 34

Opening the Unit 35

12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Introduction

Dear Customer,

Thank you for choosing this product. We are confident you

will be completely satisified with its performance.

This electrofusion control unit sets new standards by

combining a very low weight with a high level of perform-

ance. We have put utmost care into the development,

manufacturing and inspection of this product, thus

ensuring its efficiency and user-friendliness.

For your own safety, please carefully study these instruc-

tions concerning appropriate use of the product and how

to avoid unnecessary accidents.

Thank you.

Operating Instructions 2157.70.28A 12. April 2000 1

MSA350 Operating Instructions

Validity

These Operating Instructions are valid for the MSA350

series beginning with unit number 10 000. The unit

number is located on the identification plate on the right-

hand side of the unit.

Product Description

The MSA350 is an electrofusion control unit for the

electrofusion jointing of polyethylene pipes.

Fusion programming of fittings can be accomplished with

a fusion barcode Interleaved 2/5 according to

ISO/TC138/SC5/WG12.

All relevant data for fusion and tracing back past opera-

tions are stored in the MSA350 and can be retrieved for

evaluation or further processing in a variety of ways.

The MSA350 can be specially configurated for different

purposes. (See chapter Configuration)

2 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Operation

Controls

The display and control functions are located on the front

plate.

START/STOP (1) 5

ENTER (2)

RIGHT (3)

LEFT (4) 4 3

2

UP (5)

DOWN (6)

6

Operating Instructions 2157.70.28A 12. April 2000 3

MSA350 Operating Instructions

Barcode Reader

The barcode reader operates best when held at an angle

of 1030 degrees from the perpendicular and is run across

the barcode strip in one continuous swipe.

After use, return the barcode reader to its protective case.

As an option, a barcode scanner is also available.

4 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Protocol Memory

During the fusion process, data is recorded and stored in a

fusion protocol.

There is a detailed description of this feature in the chapter

Protocol.

Service Opening

The socket to connect a cable from a PC or printer is

located underneath the hinged lid on the right side of the

MSA350. When working outdoors, the lid should be kept

closed.

Operating Instructions 2157.70.28A 12. April 2000 5

MSA350 Operating Instructions

Power Supply

This unit is designed for a single-phase alternating current

of 230 volts and a frequency of 5060 hertz. (For more

specific details see chapter Product Information)

Mains Supply

Power connections must have safety conductors and

fuses with 16A (inert). A FI safety switch is recommended.

Generator

There are no set rules to determine the necessary gene-

rator output. Requirements will vary depending on the

settings on the generator as well as various environmental

factors.

Extension Cables

Only use extension leads with a diameter of more than 2.5

mm2. All leads should be completely unwound from there

holders.

6 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Starting Up

Verify that the MSA350 stands firmly and the ventilators

have an unobstructed air supply.

Confirm correct power connections.

Use the MSA350 according to the Operating Instructions.

Operating Instructions 2157.70.28A 12. April 2000 7

MSA350 Operating Instructions

Operation with Standard Configuration

Overview of Operating Procedure

MSA350 GB

FUSION DATA?

^^^^ 21C 14:20

MNU MNU 25/05/1999

Fitting

MSA350 GB

FUSION DATA?

7.15 21C 14:20

MNU MNU 25/05/1999

Barcode

GF I * 32mm START

N 15/4384

7.15 21C

MNU MNU END

Start

GF I * 32mm STOP

N 15/4383

31s 1.71kJ

MSA350 GB

FUSION CYCLE 15/4383

COMPLETE

14:20

25/05/1999

MSA350 GB

SAVING RECORD 15/4383

PLEASE WAIT

38s 7.41kJ 14:20

25/05/1999

GF I * 32mm MSA350 GB

15/4383

E0 N 15/4383

38s 7.41kJ 14:20

25/05/1999

COOLING TIME IN MSA350 GB

15/4383

MINUTES: 10

14:20

25/05/1999

8 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Switching on

Connect unit to the power source. The MSA350 is then

switched on.

MSA350 GB

FUSION DATA?

^^^^ 21C 14:20

MNU MNU 25/05/1999

Connect fitting.

Input Fusion

Data

If fusion data is requested, swipe the barcode of the fitting.

MSA350 GB

FUSION DATA?

7.15 21C 14:20

MNU MNU 25/05/1999

Display of fitting data:

GF I * 32mm START

N 15/4384

7.15 21C

MNU MNU END

Operating Instructions 2157.70.28A 12. April 2000 9

MSA350 Operating Instructions

Start Fusion

Process

The MSA350 is now ready for fusion.

Press START/STOP to initiate fusion.

GF I * 32mm STOP

N 15/4383

31s 1.2kJ

Terminate Fusion

The fusion process can be terminated at any time by

pressing START/STOP. In this case, an error message

will appear. (See chapter Error Messages)

Finish Fusion

The fusion operation data is stored in memory.

MSA350 GB

FUSION CYCLE 15/4383

COMPLETE

14:20

25/05/1999

MSA350 GB

SAVING RECORD 15/4383

PLEASE WAIT

38s 7.65kJ 14:20

25/05/1999

10 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Protocol Display

After the operation data has been stored, the protocol and

the remaining cooling time are displayed alternately.

GF I * 32mm MSA350 GB

15/4383

E0 N 15/4383

38s 7.65kJ 14:20

25/05/1999

COOLING TIME IN MSA350 GB

15/4383

MINUTES: 10

14:20

25/05/1999

If no cooling time is required by the fusion programme of

the fitting, only the protocol will be displayed.

When the cooling time is over, the external fitting clamp

can be removed.

Operating Instructions 2157.70.28A 12. April 2000 11

MSA350 Operating Instructions

Additional Functions

The diagram shows the sequence of display windows

(menus). By pressing UP or DOWN the display changes

from one menu to the next.

MSA350 GB

FUSION DATA?

^^^^ 21C 14:20

MNU MNU 25/05/1999

MSA350 GB

>U:39.5V

t:0000s

14:20

MNU MNU EDT 25/05/1999

MSA350 GB

CONFIGURATION

20/40/51/60

14:20

MNU MNU 25/05/1999

MSA350 GB

LANGUAGE: GB

14:20

MNU MNU NXT 25/05/1999

MSA350 GB

CONTRAST

14:20

MNU MNU EDT 25/05/1999

12 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Enter Operator

Identification

If the configuration Identification Required (Z21) is

activated, the display will ask the operator to enter his

operator identification barcode after the fusion data has

been entered.

OPERATOR MSA350 GB

???

14:20

25/05/1999

When the operator identification is entered, the language

will be set according to the language on the operators

identification card.

Operator identification which has been entered remains in

memory until the date changes. It can be erased by

reading in the same identification barcode or by reading in

a different identification barcode.

Enter Job

Number

If the configuration Job Number Required (Z41) is

activated, the display will ask the operator to enter the job

number from the job barcode.

JOB NUMBER MSA350 GB

??? EXAMP1

14:20

25/05/1999

The job number is stored in memory until the date

changes. It can be erased by entering the same job

barcode or by entering a different job barcode.

Operating Instructions 2157.70.28A 12. April 2000 13

MSA350 Operating Instructions

Query Fusion

Preparation

If the configuration Query Fusion Preparation (Z0) is

activated, the following confirmations will be requested

after entering the fusion data:

MSA350 GB

SCRAPED/CLEANED

<YES> EXAMP1

A1234567890Z

14:20

ENT 25/05/1999

Press ENTER, if the pipe ends are scraped and cleaned.

Depending on whether a clamp is being used or not,

answer the following questions with YES or NO.

Select YES or NO by pressing the right button and

confirm with ENTER.

MSA350 GB

CLAMPING TOOL?

<YES> EXAMP1

A1234567890Z

14:20

NXT ENT 25/05/1999

Query

Infotext

If the configuration Query Infotext (Z43) is activated, the

display will ask the operator to enter the text after entering

the fusion data:

1. MSA350 GB

TITEL EXAMP1

A1234567890Z

?INPUT 14:20

UP DWN LFT RGT ENT 25/05/1999

14 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

MSA350 GB

2.

TITEL EXAMP1

A1234567890Z

?INPUT 14:20

UP DWN LFT RGT ENT 25/05/1999

The point at which the cursor stands can be edited. To

change the position press RIGHT and LEFT, select the

desired figures with UP and DOWN. Press ENTER to

confirm.

Enter Fusion

Data Manually

If Enter Fusion Data Manually (Z30) is configured, the

operator has the option of giving in the fusion data by

hand.

In the Fusion Data menu, press DOWN to enter fusion

data manually. The cursor is on fusion voltage. This

value can now be entered.

MSA350 GB

>U:39.5V

t:0000s EXAMP1

A1234567890Z

14:20

MNU MNU EDT 25/05/1999

Press RIGHT to activate the editing function. The point at

which the cursor stands can now be edited. To change the

position press RIGHT and LEFT, select the desired figures

with UP and DOWN. Press ENTER to confirm.

MSA350 GB

>U:?9.5V

t:0000s EXAMP1

A1234567890Z

14:20

UP DWN LFT RGT ENT 25/05/1999

Press DOWN to switch to Enter Fusion Time.

Operating Instructions 2157.70.28A 12. April 2000 15

MSA350 Operating Instructions

MSA350 GB

U:24.0V

>t:0000s EXAMP1

A1234567890Z

14:20

MNU MNU EDT 25/05/1999

Edit and enter the figures as described above.

Confirm entered data with ENTER.

39.5V 38s START

N 15/4384

7.15 21C

MNU MNU END

Press START/STOP to begin fusion.

Repeat Fusion

A fitting can be re-processed with the master card barcode

(Z3)

1. Allow the fitting to cool down completely.

2. Enter master card barcode.

3. Enter fusion barcode.

4. The original fusion number or unit number is suggested

but can be changed if necessary.

5. Press START/STOP to initiate fusion.

16 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Setting Display

Contrast

The display contrast can be changed.

MSA350 GB

CONTRAST

EXAMP1

A1234567890Z

14:20

MNU MNU EDT 25/05/1999

Press RIGHT to enter the editing mode. Press UP and

DOWN to adjust the contrast. Press ENTER to confirm.

Choose

Language

The display language of the unit can be changed during

operation.

MSA350 GB

LANGUAGE: GB

EXAMP1

A1234567890Z

14:20

MNU MNU NXT 25/05/1999

Press RIGHT repeatedly until the desired language

appears. There is no need to press ENTER to confirm.

Operating Instructions 2157.70.28A 12. April 2000 17

MSA350 Operating Instructions

Configuration

Press UP or DOWN to switch to the configuration menu.

The current configuration is displayed.

MSA350 GB

CONFIGURATION

20/40/51/60

14:20

MNU MNU 25/05/1999

Date and Time

Z5, Z50, Z51

The date and time can be adjusted with the date barcode

(Z5).

Read in barcode Z5.

MSA350 GB

> 12:07

01-12-1998 EXAMP1

A1234567890Z

14:20

MNU MNU EDT ENT 25/05/1999

Press RIGHT to activate the editing function. The point at

which the cursor stands can now be edited. Press RIGHT

and LEFT to change the cursor position, press UP and

DOWN to select the desired figures. Press ENTER to

confirm.

Press DOWN to enter date.

Edit and enter the figures as described above.

To confirm, press ENTER.

18 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

To programme the unit to automatically switch over to

daylight saving time use the barcode Automatic Daylight

Saving Time (Z51). As the date of change is not

standardized in all countries, the unit may switch over

several days earlier or later.

The barcode Manual Daylight Savings Time (Z50)

allows the time change to be entered manually.

Operator

Identification

Z20, Z21

The MSA350 accepts all operator identification cards

which conform with the current ISO/TC138/SC4 WG12176

norm.

The barcodes Z20 Identification Voluntary and Z21

Identification Required can be used to set whether

identification is required for fusion. In the Identification

Required mode, the operator will be requested to enter

his operator identification barcode before fusion can begin.

In the Identification Voluntary mode, the operator can

enter his identification barcode if desired, but it this is not

necessarily required.

Enter Fusion

Data Manual Z30

ON/OFF

The barcode Enter Fusion Data Manually Z30 ON

activates the option to enter data by hand. Z30 OFF

deactivates this option.

Operating Instructions 2157.70.28A 12. April 2000 19

MSA350 Operating Instructions

Job Number

Z40 Z41

The barcodes Z40 Job Number Voluntary and Z41 Job

Number Required configure whether a job number is

required for fusion. This option functions in the same way

as the operator identification option.

Enter Job Num-

ber Manually

Z42 ON/OFF

The operator is able to enter the job number by hand with

the barcode setting Z42 ON, this option is blocked with

setting Z42 OFF.

Infotext

Z43 ON/OFF

The operator is able to enter the infotext by hand with the

barcode setting Z43 ON, this option is blocked with setting

Z43 OFF.

This function allows the operator to make an input of two

strings by keyboard before each start of a fusion. The two

text strings will be stored in the MSA 400 together with all

the other relevant fusion data.

The title, displayed during the entry of the text, is part of

the configuration barcode Z43. The configuration barcode

is generated by the program MSA WIN-WELD.

20 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Maintenance

Z6, Z60

The barcodes Z6 Maintenance Required and Z60

Maintenance Voluntary configerate the unit whether it

should remind the operator to perform a check-up after a

certain period of time.

If this reminder is switched off, the operator of the unit is

responsible for remembering to perform regular check-

ups.

Note When the tolerance time for a check-up is exceeded,

operation of the unit is blocked.

Fusion

Preparation

Z0 ON/OFF

A series of questions to assist in fusion preparation

appears when the function Confirm Scraped/Cleaned

Z0 is ON. When Z0 is OFF, this function is deactivated.

These details are stored in the fusion record memory.

Display Fusion

Time

Z10 ON/OFF

When the Count Time Upwards barcode is ON, the

fusion time will begin at zero. When Z10 is OFF, the fusion

time will start with the total time required and count down.

Enter Languages

The language card can be used to replace the operating

languages stored in the unit.

Operating Instructions 2157.70.28A 12. April 2000 21

MSA350 Operating Instructions

1. Insert language card.

2. Switch MSA350 on.

GB

LOAD LANGUAGES 1234/8900

PLEASE WAIT EXAMP1

A1234567890Z

14:20

25/05/1999

Note The MSA350 must be switched off when cables or

language card are inserted or removed.

The languages are entered after about five minutes.

GB

24 1234/8900

LANGUAGES LOADED EXAMP1

A1234567890Z

14:20

25/05/1999

Switch the MSA350 off and remove the language card.

22 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Protocol

General Use of

the Protocol

All fusion operations are stored in the back-up protocol

memory (SPS).

The SPS has enough memory to store up to 800 fusion

records. The oldest fusion record data will be overwritten

once the memory capacity is full.

Print Protocol

Connect the printer cable to the socket located underneath

the hinged lid on the right side of the MSA350.

Note The MSA350 must be switched off when cables or

language card are inserted or removed.

Switch the MSA350 on.

MSA350 GB

RS-232 MENU

14:20

MNU ENT 25/05/1999

Press DOWN to select the print function. It is possible to

print the contents of the back-up fusion record memory

(SPS) following the fusion numbers or job number.

Operating Instructions 2157.70.28A 12. April 2000 23

MSA350 Operating Instructions

Print Collective Protocols:

Press DOWN to select Collective Record. Press ENTER

to confirm.

MSA350 GB

PRINT

COLLECTIVE REC.

14:20

MNU MNU ENT 25/05/1999

Print Single Protocol:

Press DOWN to select Single Record. Press ENTER to

confirm.

MSA350 GB

PRINT

SINGLE RECORD

14:20

MNU MNU ENT 25/05/1999

Print by Fusion Number:

MSA350 GB

START 17/4383

STOP 1/4383

14:20

NXT ENT 25/05/1999

Press RIGHT to select the start position (last fusion

number). Press ENTER to confirm the start position.

The stop position (lowest fusion number) is selected in the

same way. Press ENTER to confirm and print out the

fusion records.

24 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Print by Job Number:

MSA350 GB

7/4383

JOB NUMBER

A123456789Z 14:20

NXT ENT 25/05/1999

Press RIGHT to select the desired job number and

ENTER to confirm. Press ENTER again to begin printing.

PC

Communication

A PC can be connected via the RS232 interface by means

of the appropriate interface cable. As an option, the MSA

WIN-WELD software is available, providing different useful

functions for data evaluation. Insert cable from the PC into

the socket located underneath the hinged lid.

Note The MSA350 must be switched off when cables or

language card are inserted or removed.

Switch MSA350 on.

Press DOWN to select the menu PC-Communication.

MSA350 GB

PC-COMMUNICATION

MNU ENT

Press ENTER to confirm.

Operating Instructions 2157.70.28A 12. April 2000 25

MSA350 Operating Instructions

Error Messages

Coded Messages

No Display Comments

2 MAINS VOLTAGE Check functioning of generator

TOO HIGH

5 AMBIENT TEMP.

TOO LOW

6 AMBIENT TEMP.

TOO HIGH

7 INTERNAL TEMP. Allow MSA350 to warm up in a heated room

TOO LOW

8 INTERNAL TEMP. Allow MSA350 to cool off

TOO HIGH

9 FITTING RESIS- Check fitting

TANCE TOO LOW

10 FITTING RESIS- Check fitting

TANCE TOO HIGH

11 FUSION VOLTAGE Check generator output/extension cord

TOO LOW

12 FUSION VOLTAGE If this occurs frequently, send MSA350 in for

TOO HIGH

servicing

13 FUSION CIRCUIT Check the fusion cord

INTERRUPTED

14 FUSION CURRENT If this occurs frequently, either the fitting is

TOO HIGH

defect or the MSA350 needs servicing

15 POWER SUPPLY Allow MSA350 to warm up in a heated room

TEMP. TOO LOW

26 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

No Display Comments

16 POWER SUPPLY Allow MSA350 to cool off

TEMP. TOO HIGH

21 OUTAGE DURING Check the last fusion operation

LAST FUSION

22 FUSION INTER- Check the last fusion operation

RUPTED WITH STOP

28 UNIT RANGE Use a fitting which can be joined with the

EXCEEDED

MSA350

71 SYS.-ER. MEASUR. Send MSA350 in for servicing

AMBIENT TEMP.

72 SHUTDOWN DUE TO Move MSA350 away from the generator

MAGN. INFLUENCE

74 FUSION POWER Check the generator output/extension cord

TOO LOW

75 FUSION POWER If this occurs frequently, send the MSA350 in

TOO HIGH

for servicing

78 POWERSUPPLY Send MSA350 in for servicing

ERROR

Operating Instructions 2157.70.28A 12. April 2000 27

MSA350 Operating Instructions

Uncoded Messages

Display Comments

MC BATTERY SOON Replace battery of the language card

EMPTY > REPLACE

MEMORY CARD Replace battery of the language card

BATTERY EMPTY

WRONG Use a language card with SRAM

MEMORY TYPE

BARCODE READER Switch off MSA350, connect barcode reader

NOT RECOGNISED

WRONG Enter barcode with the correct menu open

BARCODE TYPE

FUSION PROGRAM Use a barcode from the standard ISO/TR

INCORRECT

13950

UNKNOWN Use a MSA barcode

BARCODE

CONFIGURATION Send MSA350 in for servicing

ERROR

RESISTANCE MEAS- Disconnect MSA350 and fitting from the

UREMENT ERROR

generator, check the connection

SERVICE Send MSA350 in for servicing soon

NECESSARY

SERVICE NECESS. Send MSA350 in for servicing

UNIT BLOCKED

NO RECORDS Print later when the fusion operations have

EXISTING

been recorded

OPERATOR: Enter valid identification

INVALID FOR MSA

OPERATOR: Enter valid identification

EXPIRED

28 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Display Comments

IDENTITY WITHOUT Use identification which allows access to

MSA PERMISSION

MSA

PROCESSS CONTROL If this occurs frequently, send the MSA350 for

ERROR

servicing

ERROR OPERATOR Send MSA350 for servicing

CONFIGURATION

ERROR: INTERNAL Send MSA350 for servicing

MEMORY (SPS)

ERROR DURING Switch off MSA350, insert new language card

LOADING

VENTILATOR Check ventilator opening if unobstructed, send

ERROR

MSA350 for servicing

Operating Instructions 2157.70.28A 12. April 2000 29

MSA350 Operating Instructions

Product Information

Mains Voltage 180264 V AC

Nominal voltage: 230 V AC

Mains Frequency 4565 Hz

Nominal frequency: 50 Hz

Power Consumption max. 3500 W nominal output

Generator Output Performance 24 KVA Sinusoidal (unipolar operation)

depending on the fitting diameter

for ELGEF Plus up to d75 2KVA

Back-up Fuse 1015 AT

depending on the fitting size

Fusion Voltage 842 (48) V AC galvanically separated

Protection Type Protection class 1/IP 65

Operating Temperature 10 C to + 45 C

Operation Time 24%100% depending on the fitting size,

with electronic temperature monitoring of the unit

Dimensions Width: 285 mm

Depth: 200 mm

Height: 360 mm (measured with the carrying handle)

Weight 11,5 kg (with cables)

RS232 Interface 4800 baud, 7 data bit, 1 stop bit, even parity,

XON/XOFF-protocol

Secondary Cable Length 3 m

Primary Lead Length 3 m

Manufacturer Brtsch Elektronik AG

CH-8248 Uhwiesen

Switzerland

Tel. + 41 52 / 647 50 50

Fax +41 52 / 647 50 60

E-Mail brel@brel.ch

30 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Accesories Operating Instructions

2 adapters 4 mm

Configuration sheet

Operating Instructions 2157.70.28A 12. April 2000 31

MSA350 Operating Instructions

Maintenance

Cleaning

Clean the unit and the barcode reader regularly with a

slightly damp cloth. The front plate and other plates can be

cleaned with industrial alcohol if necessary (no solvents or

Trichlor products).

!

Under no circumstances should the unit be sprayed or

immersed in water nor cleaned with compressed air.

Warning

Function

Check-up

Regular functional check-ups and readjustments are

required and these must be carried out by a Georg Fischer

authorized service agent.

32 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Accident Prevention

Operating the

Unit

Do not let unauthorized or untrained personnel or children

use the unit. When the unit is not in operation, avoid

unauthorized use by keeping it in a dry, locked room.

Safe operation of the fusion unit can only be ensured when

the following criteria are fulfilled:

appropriate transport

appropriate storage

appropriate installation

operation for the correct purpose

careful handling and operation

periodic maintenance

!

The unit may only be used under surveillance.

Every person who is involved in the installation and

operation of the fusion unit must be properly qualified

Warning and should follow these Operating Instructions exactly.

Use of the unit can be dangerous, if the Operating

Instructions are not followed.

The unit may not be used in surroundings having a

high risk of explosion.

Operating Instructions 2157.70.28A 12. April 2000 33

MSA350 Operating Instructions

Check before

Operation

Before each operation, check the unit for damage and

whether it is able to function properly. All components

must be mounted correctly to ensure proper operation.

Protection of the

Unit

Keep the mains lead and secondary cables away from

sharp edges. Make sure damaged cables are immediately

replaced by an authorized service agent. Do not subject

the unit to heavy mechanical loads. The unit is water spray

resistant.

Defect Unit

Arrange that damaged housings or other parts are

replaced or repaired by an authorized service agent. If the

unit is not functioning properly it must be repaired by an

authorized service agent without delay.

!

Only authorized and properly qualified personnel are

allowed to make repairs on the unit. Such specialized

technicians must be fully aware of all the safety

Warning guidelines, maintenance measures and possible

dangers described in this manual!

34 12. April 2000 Operating Instructions 2157.70.28A

MSA350 Operating Instructions

Opening the Unit

The unit may only be opened by an authorized service

agent.

!

When the unit has been opened or the housing

removed, parts of the fusion unit are exposed which

may have a dangerous electrical charge!

Warning

Operating Instructions 2157.70.28A 12. April 2000 35

MSA350 Operating Instructions

The technical data given in this publication are for general

information purpose only.

They imply no warranty of whatever kind.

Please consult our General Conditions of Supply.

All rights reserved, in particular those pertaining to

reproduction, distribution and translation. No part of this

publication may be reproduced in any form (print,

photocopying, microfilm or data recording) without the

written permission of Georg Fischer Piping Systems Ltd.

36 12. April 2000 Operating Instructions 2157.70.28A

Das könnte Ihnen auch gefallen

- iSTAR Ultra G2 UM 8200 1995 01 B0 enDokument87 SeiteniSTAR Ultra G2 UM 8200 1995 01 B0 enSAYRI ENGINEERS S.A.C. SEGURIDAD ELECTRÓNICANoch keine Bewertungen

- Yarnmaster ZenitDokument83 SeitenYarnmaster ZenitFs FarhanNoch keine Bewertungen

- Arcomet Self Erecting Tower Crane T33ADokument4 SeitenArcomet Self Erecting Tower Crane T33AviksofNoch keine Bewertungen

- P Training For ResilienceDokument35 SeitenP Training For ResilienceLbrito01100% (1)

- Common Rail Injector Tester CR-C +S60H Multifunction Test MachineDokument3 SeitenCommon Rail Injector Tester CR-C +S60H Multifunction Test MachineAlen HuangNoch keine Bewertungen

- Final Report of BBSMDokument37 SeitenFinal Report of BBSMraazoo1967% (9)

- Good Data Won't Guarantee Good DecisionsDokument3 SeitenGood Data Won't Guarantee Good DecisionsAditya SharmaNoch keine Bewertungen

- .Agventur : Magpro Family User GuideDokument52 Seiten.Agventur : Magpro Family User GuideJiThiN vPNoch keine Bewertungen

- GUI m-etr132II-$2001 INDokument86 SeitenGUI m-etr132II-$2001 INRoberto linaresNoch keine Bewertungen

- PN UserGuideDokument52 SeitenPN UserGuidenicolás_lorréNoch keine Bewertungen

- Operating Instructions: ETS 132 Net Temperature Controller ModuleDokument90 SeitenOperating Instructions: ETS 132 Net Temperature Controller ModuleJuan Carlos HernandezNoch keine Bewertungen

- Instruction Manual: Tgr2050 SeriesDokument100 SeitenInstruction Manual: Tgr2050 SeriesClaire AragoncilloNoch keine Bewertungen

- DMA-EZCCM-001 Reference Manual PDFDokument50 SeitenDMA-EZCCM-001 Reference Manual PDFKarthikMeenakshiSundaramNoch keine Bewertungen

- Fischertechnik TXT Operating Manual - ENDokument32 SeitenFischertechnik TXT Operating Manual - ENZenilto Gonçalves de FreitasNoch keine Bewertungen

- Control ManualDokument44 SeitenControl ManualclimacomNoch keine Bewertungen

- VLT51 ProgrammingDokument77 SeitenVLT51 ProgrammingAnonymous GbfoQcCNoch keine Bewertungen

- Industrial PC Series C61xx From - 0060: Installation and Operating Instructions ForDokument23 SeitenIndustrial PC Series C61xx From - 0060: Installation and Operating Instructions ForFabio Roberto GambaNoch keine Bewertungen

- Q-See QS Security Network DVR ManualDokument28 SeitenQ-See QS Security Network DVR ManualFlorian IonNoch keine Bewertungen

- ARC4. Programmers ReferenceDokument206 SeitenARC4. Programmers ReferenceAmit KumarNoch keine Bewertungen

- 05 6568A01 PulseNET Enterprise User Guide 4.4.0Dokument41 Seiten05 6568A01 PulseNET Enterprise User Guide 4.4.0NayeliNoch keine Bewertungen

- TC System ManagerDokument297 SeitenTC System Managerarreosa0% (1)

- Murhead Controller PDFDokument28 SeitenMurhead Controller PDFFajar Burhanuddin RajagauNoch keine Bewertungen

- Instruction Manual: MSA 230 Polivalent Electrofusion UnitDokument36 SeitenInstruction Manual: MSA 230 Polivalent Electrofusion UnitOmar GuillenNoch keine Bewertungen

- Built-In Control Panel CP66xx: Installation and Operating Instructions ForDokument21 SeitenBuilt-In Control Panel CP66xx: Installation and Operating Instructions ForAntonio Carlos CardosoNoch keine Bewertungen

- Elektronikon ManualDokument40 SeitenElektronikon ManualMark CarterNoch keine Bewertungen

- Z.x.B.310 410 405-User Manual (English)Dokument52 SeitenZ.x.B.310 410 405-User Manual (English)Cosmin SpataruNoch keine Bewertungen

- PSXX Omv0004 FaDokument88 SeitenPSXX Omv0004 Fachamberlain2406Noch keine Bewertungen

- 42,0410,2124Dokument192 Seiten42,0410,2124Walter SorianoNoch keine Bewertungen

- PSXX OMV0004 DDokument88 SeitenPSXX OMV0004 Dchamberlain2406Noch keine Bewertungen

- 42,0410,2124Dokument188 Seiten42,0410,2124ELMOUSSAOUI TARIQNoch keine Bewertungen

- Man Bni PNT 50X 105 Z015 en L19 Dok 895082 09 000Dokument52 SeitenMan Bni PNT 50X 105 Z015 en L19 Dok 895082 09 000AdrianDawidJankowiczNoch keine Bewertungen

- NDC-4-A Full User Manual Issue 1.09Dokument44 SeitenNDC-4-A Full User Manual Issue 1.09Nazmi ZulkifliNoch keine Bewertungen

- 2CDC135004D0203Dokument104 Seiten2CDC135004D0203lucassilvapidNoch keine Bewertungen

- UNIFLAIR BCWC 320to1250 InstructionManualDokument40 SeitenUNIFLAIR BCWC 320to1250 InstructionManualPrieto RamiroNoch keine Bewertungen

- 42,0426,0021, enDokument248 Seiten42,0426,0021, enArtem IegorovNoch keine Bewertungen

- MFD 3 00 340 ECDIS UtilitesDokument98 SeitenMFD 3 00 340 ECDIS UtilitesAbrahamNoch keine Bewertungen

- Built-In Control Panel CP68xx: Installation and Operating Instructions ForDokument20 SeitenBuilt-In Control Panel CP68xx: Installation and Operating Instructions ForjoeNoch keine Bewertungen

- User Manual ZoneControl ESDokument54 SeitenUser Manual ZoneControl ESjose alexisNoch keine Bewertungen

- Indigovision 20 Channel EncoderDokument50 SeitenIndigovision 20 Channel EncoderScott KirklandNoch keine Bewertungen

- 16Dokument220 Seiten16indrajeetNoch keine Bewertungen

- User Manual DriveControl ENDokument60 SeitenUser Manual DriveControl ENFelipeNoch keine Bewertungen

- Citrex h5 Manual ENDokument61 SeitenCitrex h5 Manual ENkaeterNoch keine Bewertungen

- K32903UM (13) K-Systems G210 InviCell Long Term Incubator UM WEBDokument59 SeitenK32903UM (13) K-Systems G210 InviCell Long Term Incubator UM WEBdawitNoch keine Bewertungen

- Safety Regulation: MCO351 Positioning ControllerDokument49 SeitenSafety Regulation: MCO351 Positioning ControllerpaulNoch keine Bewertungen

- Installation and Operating Instructions ForDokument31 SeitenInstallation and Operating Instructions ForRachid MoussaouiNoch keine Bewertungen

- LtmanualDokument31 SeitenLtmanualZeshan Chan MNoch keine Bewertungen

- Dsp-Ohmni v2 ManualDokument44 SeitenDsp-Ohmni v2 ManualJNoch keine Bewertungen

- Vigilon: A F D A SDokument60 SeitenVigilon: A F D A SBisi AgomoNoch keine Bewertungen

- SG46 Atex-EnDokument32 SeitenSG46 Atex-EnRafael Pertile CarneiroNoch keine Bewertungen

- DSASW0044642Dokument45 SeitenDSASW0044642amin radNoch keine Bewertungen

- Escort Escort Escort Escort: Windows Windows Windows Windows User Manual User Manual User Manual User ManualDokument64 SeitenEscort Escort Escort Escort: Windows Windows Windows Windows User Manual User Manual User Manual User Manualfernando.fful8380Noch keine Bewertungen

- Manual Fronius PDFDokument176 SeitenManual Fronius PDFBrinza MariusNoch keine Bewertungen

- Ventilation Control: For Suprabox Comfort 800 To 5000Dokument51 SeitenVentilation Control: For Suprabox Comfort 800 To 5000Tempo BrasilNoch keine Bewertungen

- LM2 (HGC Software)Dokument39 SeitenLM2 (HGC Software)Vali PopescuNoch keine Bewertungen

- MSA330-340 UK - Eng - Rev03Dokument44 SeitenMSA330-340 UK - Eng - Rev03Samy Vargas Castillo0% (1)

- Office Hours Pro V15Dokument47 SeitenOffice Hours Pro V15John smithNoch keine Bewertungen

- BerkoffDokument27 SeitenBerkoffstanley AgbaforNoch keine Bewertungen

- Grundfosliterature 6226681Dokument46 SeitenGrundfosliterature 6226681Tomislav SandakNoch keine Bewertungen

- InteliVision 12touch and InteliVision 12touch OEM 1 4 0 Global GuideDokument65 SeitenInteliVision 12touch and InteliVision 12touch OEM 1 4 0 Global GuideMiguel Angel Garrido CardenasNoch keine Bewertungen

- SDX30 UM 10082280 enDokument209 SeitenSDX30 UM 10082280 enBerny777Noch keine Bewertungen

- Ranger Pro Wireless Gateway User Guide - 158M1430Dokument46 SeitenRanger Pro Wireless Gateway User Guide - 158M1430Matheus PhilippeNoch keine Bewertungen

- BNI IOL-104-S02-R012: IO-Link 1.1 Sensor Hub With Extension Port User's GuideDokument32 SeitenBNI IOL-104-S02-R012: IO-Link 1.1 Sensor Hub With Extension Port User's GuideJuan Luis Cuevas ResendizNoch keine Bewertungen

- Enforcer V10-Extended User Guide-ENDokument44 SeitenEnforcer V10-Extended User Guide-ENfsyzfrNoch keine Bewertungen

- Table Saw ZB400 User ManualDokument13 SeitenTable Saw ZB400 User ManualviksofNoch keine Bewertungen

- Zarges UK LTD Professional Ladder Frame Instruction ManualDokument7 SeitenZarges UK LTD Professional Ladder Frame Instruction ManualviksofNoch keine Bewertungen

- Zarges UK LTD Trademaster Instruction Manual PDFDokument16 SeitenZarges UK LTD Trademaster Instruction Manual PDFviksofNoch keine Bewertungen

- Zarges UK LTD Speedy 80 Instruction ManualDokument2 SeitenZarges UK LTD Speedy 80 Instruction ManualviksofNoch keine Bewertungen

- Zarges UK LTD Professional Ladder Frame Instruction ManualDokument7 SeitenZarges UK LTD Professional Ladder Frame Instruction ManualviksofNoch keine Bewertungen

- Euro Towers LTD Klick Double Width Instruction ManualDokument3 SeitenEuro Towers LTD Klick Double Width Instruction ManualviksofNoch keine Bewertungen

- Butt Fusion Machine GF 315Dokument40 SeitenButt Fusion Machine GF 315viksof100% (2)

- CIP Section 03Dokument26 SeitenCIP Section 03viksofNoch keine Bewertungen

- Potain MD 265 B1 J12Dokument4 SeitenPotain MD 265 B1 J12viksofNoch keine Bewertungen

- The Safe Operation of CranesDokument52 SeitenThe Safe Operation of Cranesviksof100% (1)

- Grove Mobile Crane GROVE RT750Dokument3 SeitenGrove Mobile Crane GROVE RT750viksof100% (1)

- CIP Section 02Dokument14 SeitenCIP Section 02viksofNoch keine Bewertungen

- CIP Section 0FDokument20 SeitenCIP Section 0FviksofNoch keine Bewertungen

- CIP Section 01Dokument50 SeitenCIP Section 01viksofNoch keine Bewertungen

- The Safe Operation of CranesDokument52 SeitenThe Safe Operation of Cranesviksof100% (1)

- OSHA 500 ScaffoldDokument68 SeitenOSHA 500 Scaffoldviksof100% (1)

- Cues Nursing Diagnosis Background Knowledge Goal and Objectives Nursing Interventions and Rationale Evaluation Subjective: Noc: NIC: Fluid ManagementDokument10 SeitenCues Nursing Diagnosis Background Knowledge Goal and Objectives Nursing Interventions and Rationale Evaluation Subjective: Noc: NIC: Fluid ManagementSkyla FiestaNoch keine Bewertungen

- HRIRDokument23 SeitenHRIRPhuong HoNoch keine Bewertungen

- Sponsor and Principal Investigator: Responsibilities of The SponsorDokument10 SeitenSponsor and Principal Investigator: Responsibilities of The SponsorNoriNoch keine Bewertungen

- Secondary Scheme of Work Form 2Dokument163 SeitenSecondary Scheme of Work Form 2Fariha RismanNoch keine Bewertungen

- Concordance C Index - 2 PDFDokument8 SeitenConcordance C Index - 2 PDFnuriyesanNoch keine Bewertungen

- Week 5 Teradata Practice ExerciseDokument14 SeitenWeek 5 Teradata Practice ExerciseWooyeon ChoNoch keine Bewertungen

- Lesson 2.4Dokument8 SeitenLesson 2.4Tobi TobiasNoch keine Bewertungen

- Practical Econometrics Data Collection Analysis and Application 1st Edition Hilmer Test BankDokument27 SeitenPractical Econometrics Data Collection Analysis and Application 1st Edition Hilmer Test Bankdavidhallwopkseimgc100% (28)

- SolBridge Application 2012Dokument14 SeitenSolBridge Application 2012Corissa WandmacherNoch keine Bewertungen

- Interdisciplinary Project 1Dokument11 SeitenInterdisciplinary Project 1api-424250570Noch keine Bewertungen

- Test Bank For Macroeconomics 8th Canadian Edition Andrew AbelDokument16 SeitenTest Bank For Macroeconomics 8th Canadian Edition Andrew AbelstebinrothNoch keine Bewertungen

- Cosmology Questions and Answers - SanfoundryDokument9 SeitenCosmology Questions and Answers - SanfoundryGopinathan MNoch keine Bewertungen

- Ga-Ta10 (LHH)Dokument181 SeitenGa-Ta10 (LHH)Linh T.Thảo NguyễnNoch keine Bewertungen

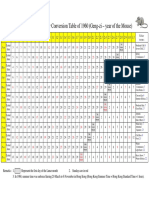

- Gregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Dokument1 SeiteGregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Anomali SahamNoch keine Bewertungen

- Data Sheet For T-8101.RevCDokument5 SeitenData Sheet For T-8101.RevCSuresh SjNoch keine Bewertungen

- WB-Mech 120 Ch05 ModalDokument16 SeitenWB-Mech 120 Ch05 ModalhebiyongNoch keine Bewertungen

- 1) About The Pandemic COVID-19Dokument2 Seiten1) About The Pandemic COVID-19محسين اشيكNoch keine Bewertungen

- Mechanical Energy Storage: Created by Nick StroudDokument24 SeitenMechanical Energy Storage: Created by Nick StroudAli ShazanNoch keine Bewertungen

- Plasterboard FyrchekDokument4 SeitenPlasterboard FyrchekAlex ZecevicNoch keine Bewertungen

- Tia Portal V16 OrderlistDokument7 SeitenTia Portal V16 OrderlistJahidul IslamNoch keine Bewertungen

- Omran WalidDokument196 SeitenOmran WalidDébora AmougouNoch keine Bewertungen

- HC-97G FactsheetDokument1 SeiteHC-97G FactsheettylerturpinNoch keine Bewertungen

- Certification Programs: Service As An ExpertiseDokument5 SeitenCertification Programs: Service As An ExpertiseMaria RobNoch keine Bewertungen

- 67 9268Dokument34 Seiten67 9268Salvador ReyesNoch keine Bewertungen

- MC-8002 Mixer 2Dokument1 SeiteMC-8002 Mixer 2JAIDEV KUMAR RANINoch keine Bewertungen

- Nexus 1500+ Power Quality Meter User Manual - E154713Dokument362 SeitenNexus 1500+ Power Quality Meter User Manual - E154713Antonio BocanegraNoch keine Bewertungen